Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-42-00-430-001 Diffuser And Combustion Group - Assemble The Diffuser And Combustion Group, Assembly-001

General

CAUTION

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-129 ANTI-SEIZE PASTE, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to SPM TASK 70-44-01-400-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1P16004 Handling bracket | 0AM53 | IAE 1P16004 | 2 | |

| IAE 1P16005 Build stand | 0AM53 | IAE 1P16005 | 1 | |

| IAE 1P16042 Test adapter | 0AM53 | IAE 1P16042 | 1 | |

| IAE 1P16044 Lift fixture | 0AM53 | IAE 1P16044 | 1 | |

| IAE 1P16068 Support fixture | 0AM53 | IAE 1P16068 | ||

| IAE 1P16070 Guide pin | 0AM53 | IAE 1P16070 | 2 | |

| IAE 1P16086 Air flow adapter | 0AM53 | IAE 1P16086 | 1 | |

| IAE 1P16089 Leak check cap | 0AM53 | IAE 1P16089 | 1 | |

| IAE 1P16090 Leak check fixture | 0AM53 | IAE 1P16090 | 1 | |

| IAE 1P16091 Leak check fixture | 0AM53 | IAE 1P16091 | 1 | |

| IAE 1P16092 Igniter immersion gage | 0AM53 | IAE 1P16092 | 1 | |

| IAE 1P16095 Leak check cap | 0AM53 | IAE 1P16095 | 1 | |

| IAE 1P16102 Lift sling | 0AM53 | IAE 1P16102 | 1 | |

| IAE 1P16103 Alignment fixture | 0AM53 | IAE 1P16103 | 1 | |

| IAE 1P16108 cover | 0AM53 | IAE 1P16108 | ||

| IAE 1P16139 Wrench | 0AM53 | IAE 1P16139 | 1 | |

| IAE 1P16173 Lift sling | 0AM53 | IAE 1P16173 | 1 | |

| IAE 1P16231 Alignment pin | 0AM53 | IAE 1P16231 | 2 | |

| IAE 1P17000 Protective cover | 0AM53 | IAE 1P17000 | 1 | |

| IAE 6F10029 Air flow test cart | 0AM53 | IAE 6F10029 | 1 | |

| IAE 6F10030 Vacuum test cart | 0AM53 | IAE 6F10030 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-223 WAX, REFINED PARAFFIN | X111X | CoMat 01-223 | ||

| CoMat 01-573 WAX BLEND, PARAFFIN | 24269 | CoMat 01-573 | ||

| CoMat 02-141 LOCKWIRE | LOCAL | CoMat 02-141 | ||

| CoMat 02-150 LOCKWIRE | LOCAL | CoMat 02-150 | ||

| CoMat 10-041 PETROLATUM, WHITE | LOCAL | CoMat 10-041 | ||

| CoMat 10-045 LEAK CHECK FLUID, BUBBLES-TYPE | 03530 | CoMat 10-045 | ||

| CoMat 10-050 ASSEMBLY FLUID | 0AM53 | CoMat 10-050 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 | ||

| CoMat 10-087 SEALING RING LUBRICANT | 56385 | CoMat 10-087 | ||

| CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL | K2147 | CoMat 10-094 | ||

| CoMat 10-109 HIGH TEMPERATURE ANTI-SEIZELUBRICANT | LOCAL | CoMat 10-109 | ||

| CoMat 10-129 ANTI-SEIZE PASTE | 34568 | CoMat 10-129 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Gasket - CSN to be provided | 77445 | Gasket | 1 | 01-040 |

| Gasket - CSN to be provided | 77445 | Gasket | 1 | 02-001 |

| Gasket - CSN to be provided | 77445 | Gasket | 2 | 02-160 |

| Gasket - CSN to be provided | 77445 | Gasket | 1 | 02-300 |

| Gasket - CSN to be provided | 77445 | Gasket | 1 | (V2500-A1 Pre SBE 72-0016) 03-020 |

| Gasket - CSN to be provided | 77445 | Gasket | 1 | (V2500-A1 SBE 72-0016 and A5) 03-030 |

| Gasket - CSN to be provided | 77445 | Gasket | 3 | 05-001 |

| Gasket - CSN to be provided | 77445 | Gasket | 3 | 05-160 |

| Gasket - CSN to be provided | 77445 | Gasket | 2 | 06-001 |

| Gasket - CSN to be provided | 77445 | Gasket | 20 | 01-010 |

| Packing - CSN to be provided | 77445 | Packing | 10 | (V2500-A1 Pre SBE 72-0119) 01-060 |

| Packing - CSN to be provided | 77445 | Packing | 24 | (V2500-A1 Pre SBE 72-0119) 03-001 |

| Gasket - CSN to be provided | 77445 | Gasket | 16 | (V2500-A1 SBE 72-0119 and A5) 03-001 |

| Gasket - CSN to be provided | 77445 | Gasket | 4 | (V2500-A1 Pre SBE 72-0119 and V2500 A1/A5 Pre SBE 73-0088) 03-040 |

| Gasket - CSN to be provided | 77445 | Gasket | 8 | (V2500-A1/A5 Pre SBE 73-0088) 03-050 |

| Packing - CSN to be provided | 77445 | Packing | 18 | (V2500-A1 Pre SBE 72-0119) 02-001 |

| Packing - CSN to be provided | 77445 | Packing | 12 | (V2500-A1 SBE 72-0119 and A5) 02-001 |

| Gasket - CSN to be provided | 77445 | Gasket | 3 | (V2500-A1 Pre SBE 72-0119 and V2500-A1/A5 Pre SBE 73-0088) 02-040 |

| Gasket - CSN to be provided | 77445 | Gasket | 6 | (V2500 A1/A5 Pre SBE 73-0088) 02-050 |

| Packing - CSN to be provided | 77445 | Packing | 18 | (V2500-A1 Pre SBE 72-0119) 01-010 |

| Packing - CSN to be provided | 77445 | Packing | 12 | (V2500-A1 SBE 72-0119 and A5) 01-010 |

| Gasket - CSN to be provided | 77445 | Gasket | 3 | (V2500-A1 Pre SBE 72-0119 and V2500 A1/A5 Pre SBE 73-0088) 01-040 |

| Gasket - CSN to be provided | 77445 | Gasket | 6 | (V2500-A1/A5 Pre SBE 73-0088) 01-050 |

Safety Requirements

NONEProcedure

Assemble the diffuser case assembly and the fitting. Refer to TASK 72-42-10-440-001 (ASSEMBLY).

SUBTASK 72-42-00-430-065 Assemble the Diffuser Case Assembly

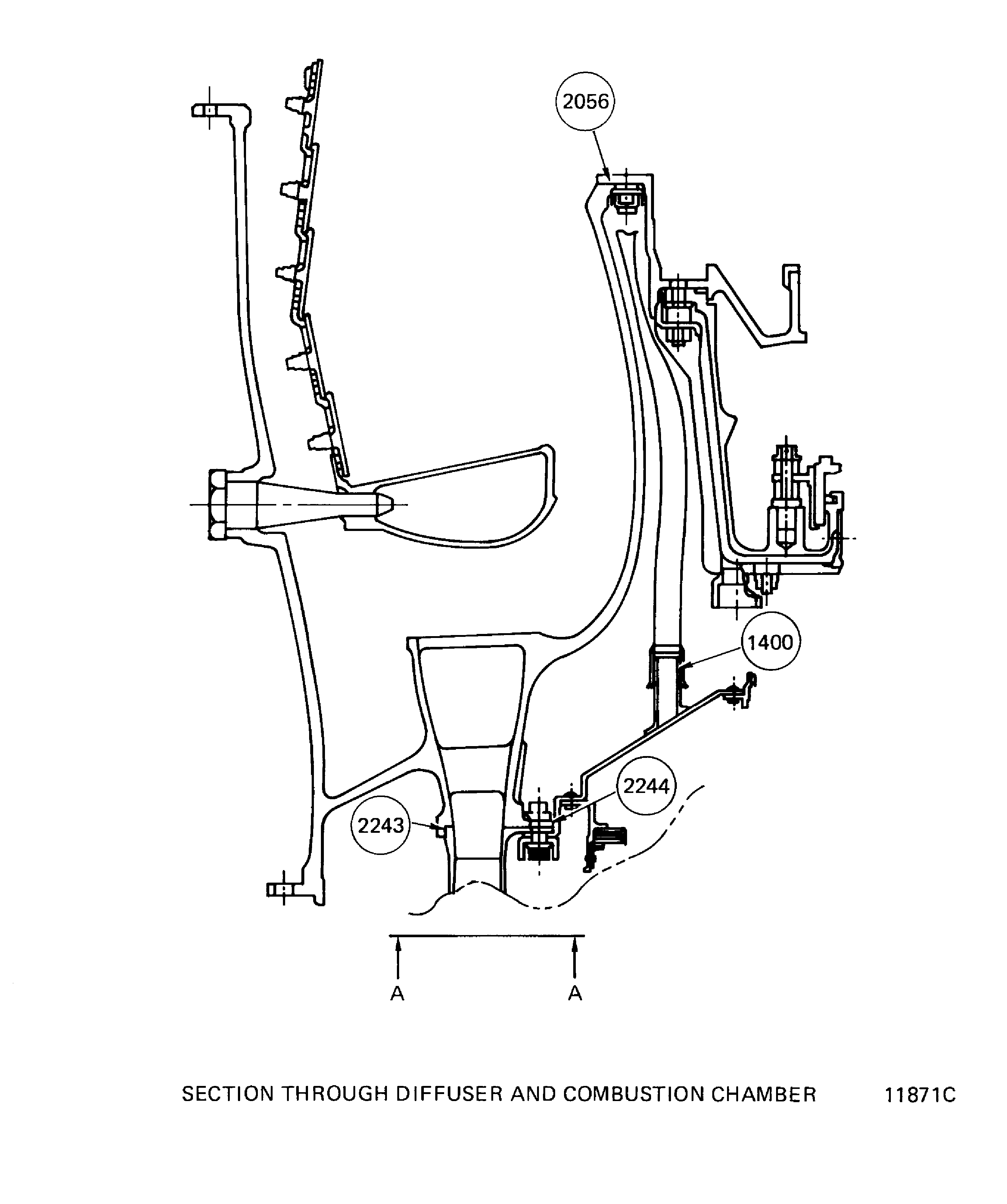

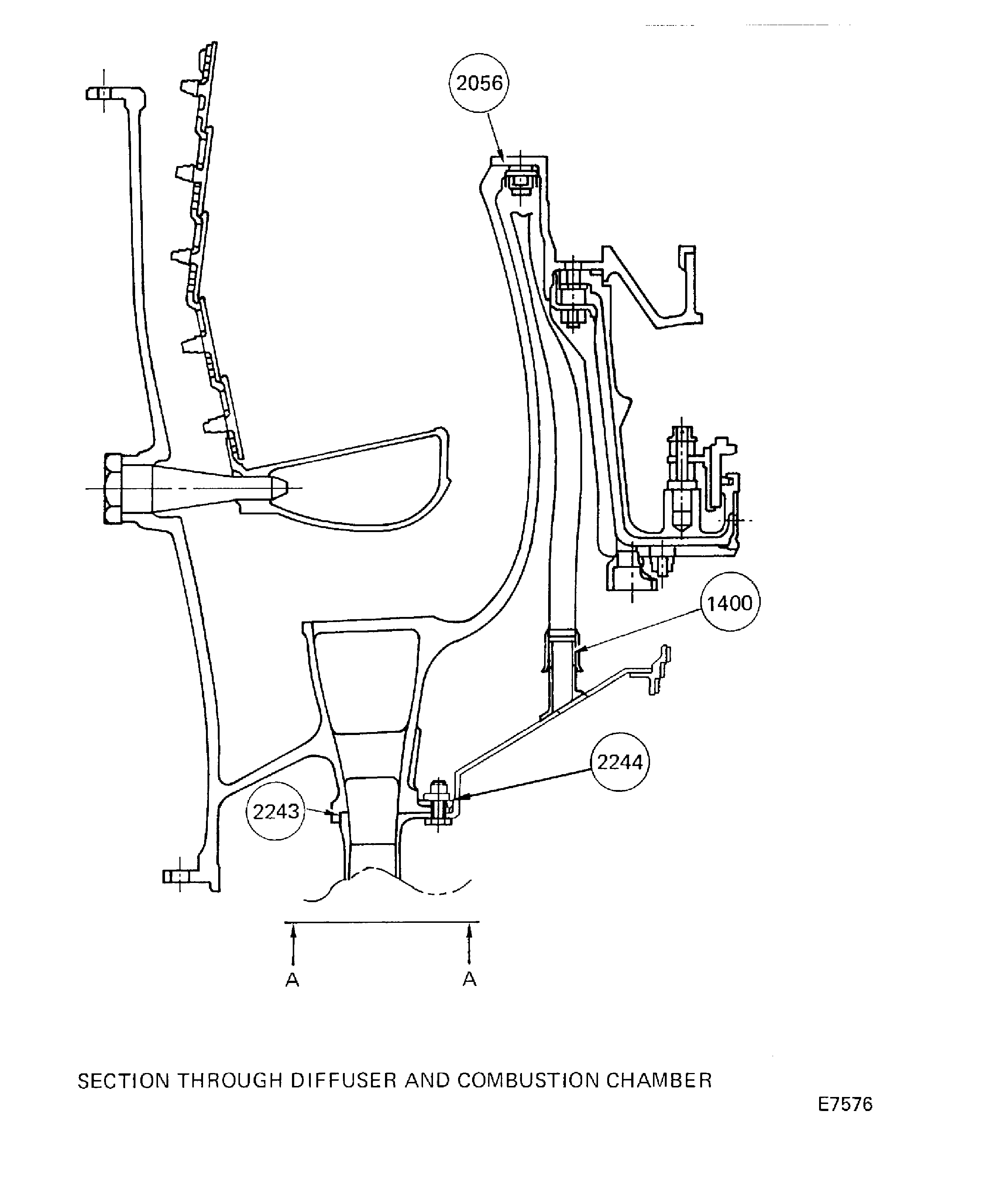

Refer to Figure

Reference the clearance at location 1400. If required, use the data written as a note in TASK 72-42-50-200-000 (INSPECTION/CHECK-000) and TASK 72-42-20-200-000 (INSPECTION/CHECK-000).

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 1400

Static seal assembly location

in thrust balance vent tube

Static seal assembly diameter

0.5010

Clear

0.5000

0.0035

Thrust balance vent tube bore

0.5065

0.0065

0.5045

Clear

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 1400

Static seal assembly location

in thrust balance vent tube

Static seal assembly diameter

12.7254

Clear

12.7000

0.089

Thrust balance vent tube bore

12.815

0.165

12.865

Clear

SUBTASK 72-42-00-220-066 Reference the Fits and Clearances of the Static Seal Assembly and the Thrust Balance Tubes at Location 1400

Refer to Figure

Reference the interference at location 2056. If required, use the data written as a note in TASK 72-42-11-200-000 (INSPECTION/CHECK-000) and TASK 72-42-31-200-000 (INSPECTION/CHECK-000).

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2056

Diffuser case assembly Diffuser Case (72-42-11,01-010), location diameter

No.4 bearing support assembly ENGINE-NO.4 BEARING SUPPORT ASSEMBLY (72-42-31,01-010), location diameter

Case location diameter

13.343

Intf

13.343

Intf

13.337

0.000

13.337

0.000

Support location diameter

13.349

0.012

13.350

0.012

13.343

Intf

13.338

Intf

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2056

Diffuser case assembly Diffuser Case (72-42-11,01-010), location diameter

No.4 bearing support assembly ENGINE-NO.4 BEARING SUPPORT ASSEMBLY (72-42-31,01-010), location diameter

Case location diameter

338.912

Intf

338.912

Intf

338.760

0.00

338.760

0.00

Support location diameter

339.065

0.30

339.790

0.30

338.912

Intf

338.090

Intf

SUBTASK 72-42-00-220-054 Reference the Fits and Clearances of the No. 4 Bearing Front Compartment at Location 2056

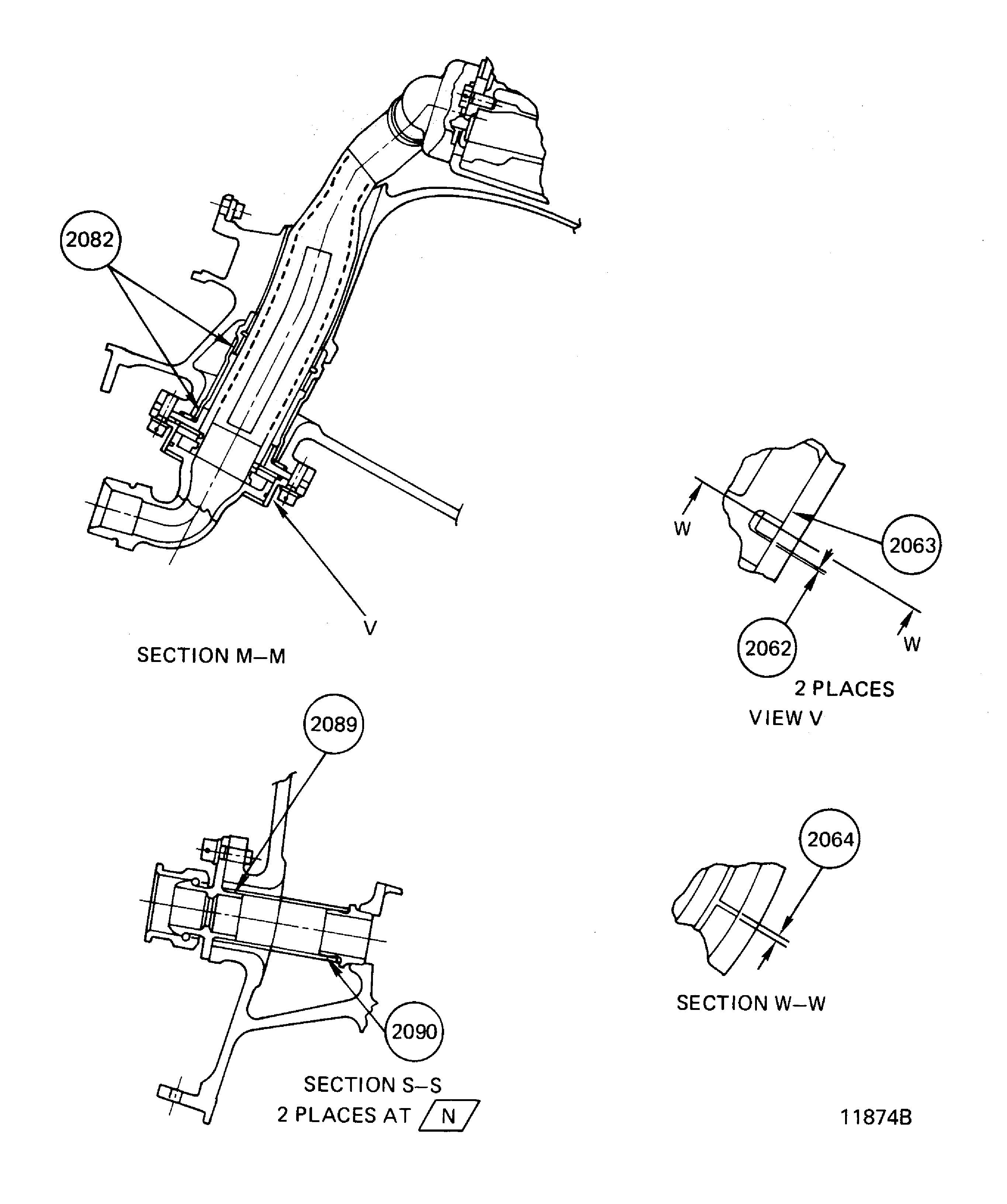

Refer to Figure

Reference the clearance at location 2062. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION/CHECK-000).

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2062

Side clearance No. 4 bearing seal ring No. 4 Bearing Compartment Tubes (72-42-20,02-320)

Scavenge tube elbow No. 4 Bearing Compartment Tubes (72-42-20,02-340)

Seal ring

0.077

Clear

0.078

0.002

Scavenge tube elbow

0.080

0.005

0.082

Clear

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2062

Side clearance No. 4 bearing seal ring No. 4 Bearing Compartment Tubes (72-42-20,02-320)

Scavenge tube elbow No. 4 Bearing Compartment Tubes (72-42-20,02-340)

Seal ring

1.956

Clear

1.981

0.051

Scavenge tube elbow

2.032

0.127

2.082

Clear

SUBTASK 72-42-00-220-055 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2062

Refer to Figure

Reference the clearance at location 2063. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION/CHECK-000).

Table 7. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2063

No.4 bearing scavenge tube elbow No. 4 Bearing Compartment Tubes (72-42-20,02-340), location diameter

Sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20,02-260), location diameter

Elbow location diameter

2.3475

Clear

2.3535

0.0005

Sleeve location diameter

2.354

0.0085

2.356

Clear

Table 8. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2063

No. 4 bearing scavenge tube elbow No. 4 Bearing Compartment Tubes (72-42-20,02-340), location diameter

Sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20,02-260), location diameter

Elbow location diameter

59.627

Clear

59.779

0.013

Sleeve location diameter

59.729

0.215

59.842

Clear

SUBTASK 72-42-00-220-056 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2063

Refer to Figure

Reference the clearance at location 2064. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION/CHECK-000).

Table 9. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2064

Gap No.4 bearing seal ring No. 4 Bearing Compartment Tubes (72-42-20,02-320), gap at 2.354 inches gage

Sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20,02-260), Inside diameter

Gap

0.005

Clear

0.015

0.005

Inside diameter

2.354

0.021

2.356

Clear

Table 10. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2064

Gap No.4 bearing seal ring No. 4 Bearing Compartment Tubes (72-42-20,02-320), gap at 59.792 millimeters gage

Sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20,02-260), Inside diameter

Gap

0.13

Clear

0.38

0.13

Inside diameter

59.792

0.53

59.842

Clear

SUBTASK 72-42-00-220-057-A00 V2500-A1: Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2064 (Pre SBE 72-0221)

Reference the clearance at location 2064. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION/CHECK-000).

Table 11. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2064

Gap No.4 bearing seal ring No. 4 Bearing Compartment Tubes (72-42-20,02-320), gap at 2.354 inches gage

Sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20,02-260) Inside diameter

Gap

0.005

Clear

0.020

0.005

Inside diameter

2.354

0.026

2.356

Clear

Table 12. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2064

Gap No.4 bearing seal ring No. 4 Bearing Compartment Tubes (72-42-20,02-320), gap at 59.792 millimeters gage

Sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20,02-260) Inside diameter

Gap

0.13

Clear

0.51

0.13

Inside diameter

59.792

0.66

59.842

Clear

SUBTASK 72-42-00-220-057-B00 V2500-A1: Reference the Fits and Clearances of the Diffuser Case Rear Assembly at Location 2064 (SBE 72-0221)

Refer to Figure

Reference the clearance at location 2064. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION/CHECK-000).

Table 13. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2064

Gap No. 4 bearing seal ring No. 4 Bearing Compartment Tubes (72-42-20,02-320), gap at 2.354 inches gage

Sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20,02-260) Inside diameter

Gap

0.005

Clear

0.020

0.005

Inside diameter

2.354

0.026

2.356

Clear

Table 14. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2064

Gap No. 4 bearing seal ring No. 4 Bearing Compartment Tubes (72-42-20,02-320), gap at 59.792 millimeters gage

Sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20,02-260) Inside diameter

Gap

0.13

Clear

0.51

0.13

Inside diameter

59.792

0.66

59.842

Clear

SUBTASK 72-42-00-220-057-C00 V2500-A5: Reference the Fits and Clearances of the Diffuser Case Rear Assembly at Location 2064

Refer to Figure

Reference the interference at location 2082. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION/CHECK-000).

Table 15. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2082

Heatshield No. 4 Bearing Compartment Tubes (72-42-20,02-140), location diameter

Sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20,02-180), location diameter

Heatshield diameter

1.9485

Intf

1.9445

0.0005

Sealing sleeve diameter

1.951

0.0065

1.949

Intf

Table 16. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2082

Heatshield No. 4 Bearing Compartment Tubes (72-42-20,02-140), location diameter

Sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20,02-180), location diameter

Heatshield diameter

49.491

Intf

49.391

0.013

Sealing sleeve diameter

49.555

0.165

49.505

Intf

SUBTASK 72-42-00-220-058 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2082

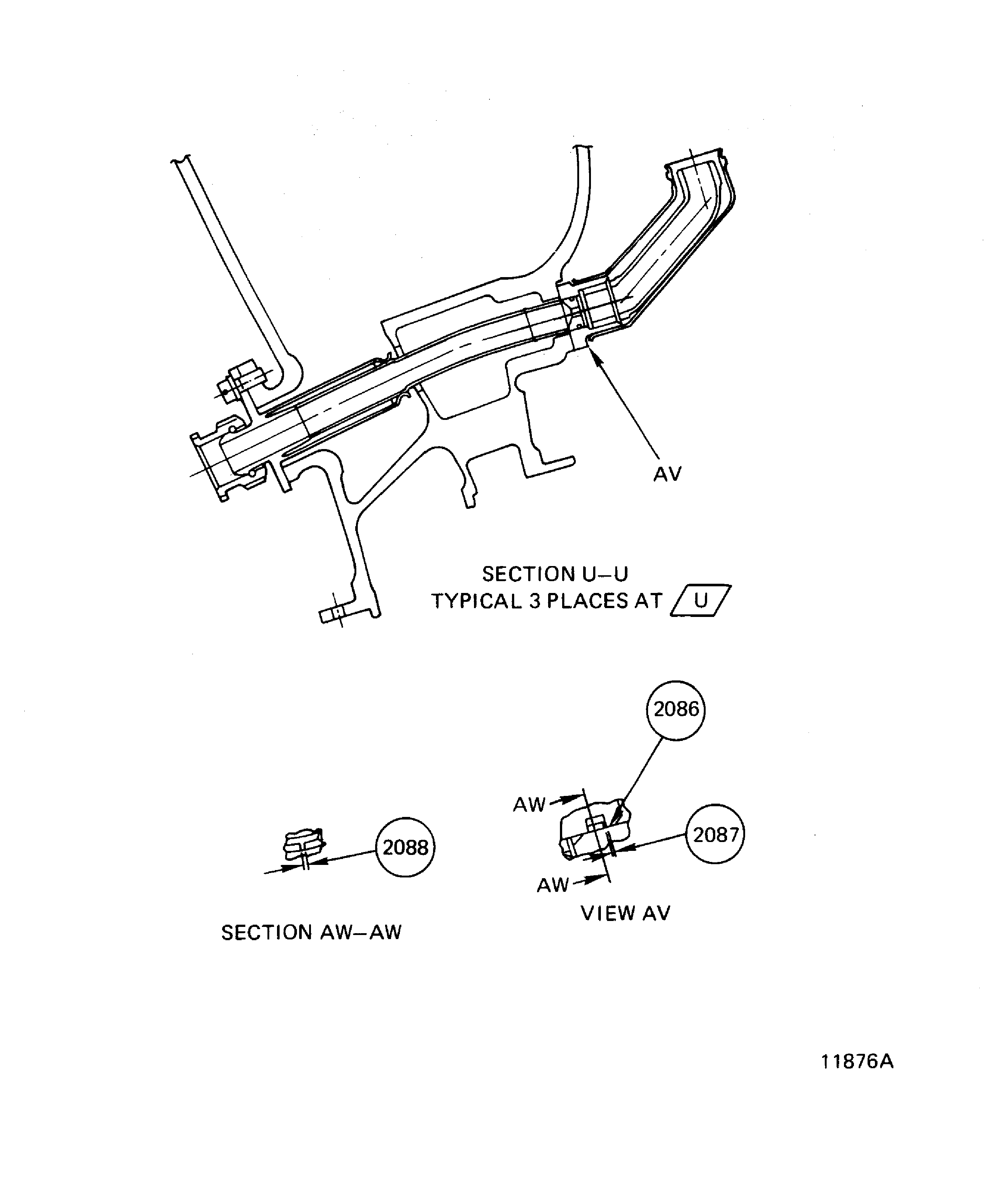

Refer to Figure

Reference the clearance at location 2086. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION/CHECK-000).

Table 17. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2086

No. 4 bearing cooling tube assembly No. 4 Bearing Compartment Tubes (72-42-20,05-020), location diameter

Sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20,05-180), location diameter

Tube location diameter

0.556

Clear

0.560

0.002

Sleeve location diameter

0.562

0.010

0.566

Clear

Table 18. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2086

No. 4 bearing cooling tube assembly No. 4 Bearing Compartment Tubes (72-42-20,05-020), location diameter

Sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20,05-180), location diameter

Tube location diameter

14.123

Clear

14.224

0.051

Sleeve location diameter

14.275

0.254

14.376

Clear

SUBTASK 72-42-00-220-059 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2086

Refer to Figure

Reference the clearance at location 2087. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION/CHECK-000).

Table 19. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2087

Side clearance Seal ring No. 4 Bearing Compartment Tubes (72-42-20,05-140), thickness

No. bearing cooling tube assembly No. 4 Bearing Compartment Tubes (72-42-20,05-020), groove width

Seal ring thickness

0.0615

Clear

0.0625

0.002

Groove width

0.0645

0.005

0.0665

Clear

Table 20. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2087

Side clearance Seal ring No. 4 Bearing Compartment Tubes (72-42-20,05-140), thickness

No. 4 bearing cooling tube assembly No. 4 Bearing Compartment Tubes (72-42-20,05-020), groove width

Seal ring thickness

1.563

Clear

1.587

0.051

Groove width

1.639

0.127

1.689

Clear

SUBTASK 72-42-00-220-060 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2087

Refer to Figure

Reference the clearance at location 2088. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION/CHECK-000).

Table 21. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2088

Gap No. 4 bearing seal ring No. 4 Bearing Compartment Tubes (72-42-20,05-140), gap at 0.562 inches gage

Sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20,05-180), inside diameter

Gap

0.005

Clear

0.015

0.005

Sleeve inside diameter

0.562

0.028

0.566

Clear

Table 22. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2088

Gap No. 4 bearing seal ring No. 4 Bearing Compartment Tubes (72-42-20,05-140), gap at 14.275 millimeters gage

Sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20,05-180), inside diameter

Gap

0.13

Clear

0.38

0.13

Sleeve inside diameter

14.275

0.71

14.376

Clear

SUBTASK 72-42-00-220-061 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2088

Refer to Figure

Reference the interference at location 2089. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION/CHECK-000).

Table 23. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2089

Transfer tube No. 4 Bearing Compartment Tubes (72-42-20,06-220), location diameter

Adapter tube No. 4 Bearing Compartment Tubes (72-42-20,06-240), location diameter

Transfer tube diameter

0.8285

Intf

0.8255

0.0005

Adapter tube diameter

0.831

0.0055

0.829

Intf

Table 24. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2089

Transfer tube No. 4 Bearing Compartment Tubes (72-42-20,06-220), location diameter

Adapter tube No. 4 Bearing Compartment Tubes (72-42-20,06-240), location diameter

Transfer tube diameter

21.043

Intf

20.968

0.013

Adapter tube diameter

21.107

0.139

21.057

Intf

SUBTASK 72-42-00-220-062 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2089

Refer to Figure

NOTE

Adapter tube and transfer tube must be assembled in sets prior to inserting into Diffuser Case. Gap between adapter tube flange and transfer tube should not be greater than 0.045 in. (1.143 mm) after assembly.Reference the interference at location 2089. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION/CHECK-000).

Table 25. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2089

Transfer tube

No. 4 Bearing Compartment Tubes (72-42-20,06-220),

location diameter

Adapter tube

No. 4 Bearing Compartment Tubes (72-42-20,06-240),

location diameter

Transfer tube diameter

0.832

0.831

0.000 TIGHT

Adapter tube diameter

0.834

0.832

0.003

Table 26. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2089

Transfer tube

No. 4 Bearing Compartment Tubes (72-42-20,06-220),

location diameter

Adapter tube

No. 4 Bearing Compartment Tubes (72-42-20,06-240),

location diameter

Transfer tube diameter

21.133

21.107

0.0 TIGHT

Adapter tube diameter

21.184

21.133

0.076

SUBTASK 72-42-00-220-069 P/N 2A3464, P/N 2A3465 and P/N 2A3466 Only: Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2089

Reference the interference at location 2090. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION/CHECK-000) and TASK 72-42-11-200-000 (INSPECTION/CHECK-000).

Table 27. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2090

Transfer tube

No. 4 Bearing Compartment Tubes (72-42-20,06-220),

location diameter

Diffuser case assembly

Diffuser Case (72-42-11,01-010),

sealing sleeve location diameter

Tube diameter

0.832

0.831

0.000 LOOSE

Sealing sleeve diameter

0.831

0.829

0.003

Table 28. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2090

Transfer tube

No. 4 Bearing Compartment Tubes (72-42-20,06-220),

location diameter

Diffuser case assembly

Diffuser Case (72-42-11,01-010),

sealing sleeve location diameter

Tube diameter

21.133

21.107

0.0 LOOSE

Sealing sleeve diameter

21.107

21.057

0.076

SUBTASK 72-42-00-220-070 P/N 2A3466 Transfer Tube Only: Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2090

Refer to Figure

Reference the interference at location 2090. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION/CHECK-000) and TASK 72-42-11-200-000 (INSPECTION/CHECK-000).

Table 29. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2090

Transfer tube No. 4 Bearing Compartment Tubes (72-42-20,06-220), location diameter

Diffuser case assembly Diffuser Case (72-42-11,01-010), sealing sleeve location diameter

Tube diameter

0.8285

Intf

0.8255

0.0005

Sealing sleeve diameter

0.831

0.0055

0.829

Intf

Table 30. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2090

Transfer tube No. 4 Bearing Compartment Tubes (72-42-20,06-220), location diameter

Diffuser case assembly Diffuser Case (72-42-11,01-010), sealing sleeve location diameter

Tube diameter

21.043

Intf

20.968

0.013

Sealing sleeve diameter

21.107

0.139

21.057

Intf

SUBTASK 72-42-00-220-063 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2090

Refer to Figure

Reference the interference at location 2243. If required, use the data written as a note in TASK 72-42-11-200-000 (INSPECTION/CHECK-000) and TASK 72-42-40-200-000 (INSPECTION/CHECK-000).

Table 31. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2243

Diffuser case assembly Diffuser Case (72-42-11,01-010), bore

HP compressor outlet guide vane ENGINE-HP COMPRESSOR EXIT STATOR (72-42-40,01-200), location diameter

Case bore

20.672

Intf

20.672

Intf

20.668

0.002

20.661

0.002

Outlet guide vane location

20.678

0.010

20.678

0.010

diameter

20.674

Intf

20.674

Intf

Table 32. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2243

Diffuser case assembly Diffuser Case (72-42-11,01-010), bore

HP compressor outlet guide vane ENGINE-HP COMPRESSOR EXIT STATOR (72-42-40,01-200), location diameter

Case bore

525.068

Intf

525.070

Intf

524.968

0.052

524.790

0.052

Outlet guide vane location

525.120

0.253

525.120

0.253

diameter

525.221

Intf

525.221

Intf

SUBTASK 72-42-00-220-064 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2243

Refer to Figure.

Reference the interference at location 2244. If required, use the data written as a note in TASK 72-42-11-200-000 (INSPECTION/CHECK-000) and TASK 72-42-50-200-000 (INSPECTION/CHECK-000).

Table 33. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2244

Diffuser case assembly Diffuser Case (72-42-11,01-010), bore

Seal assembly ENGINE-STATIC SEAL (72-42-50,01-100), location diameter

Case diameter

16.901

Intf

16.901

Intf

16.899

0.0041

16.894

0.004

Vane location diameter

16.9074

0.0084

16.9074

0.0084

16.9050

Intf

16.9050

Intf

Table 34. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2244

Diffuser case assembly Diffuser Case (72-42-11,01-010), bore

Seal assembly ENGINE-STATIC SEAL (72-42-50,01-100), location diameter

Case diameter

429.285

Intf

429.285

Intf

429.235

0.102

429.108

0.102

Vane location diameter

429.449

0.214

429.449

0.214

429.387

Intf

429.387

Intf

SUBTASK 72-42-00-220-065 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2244

Refer to Figure

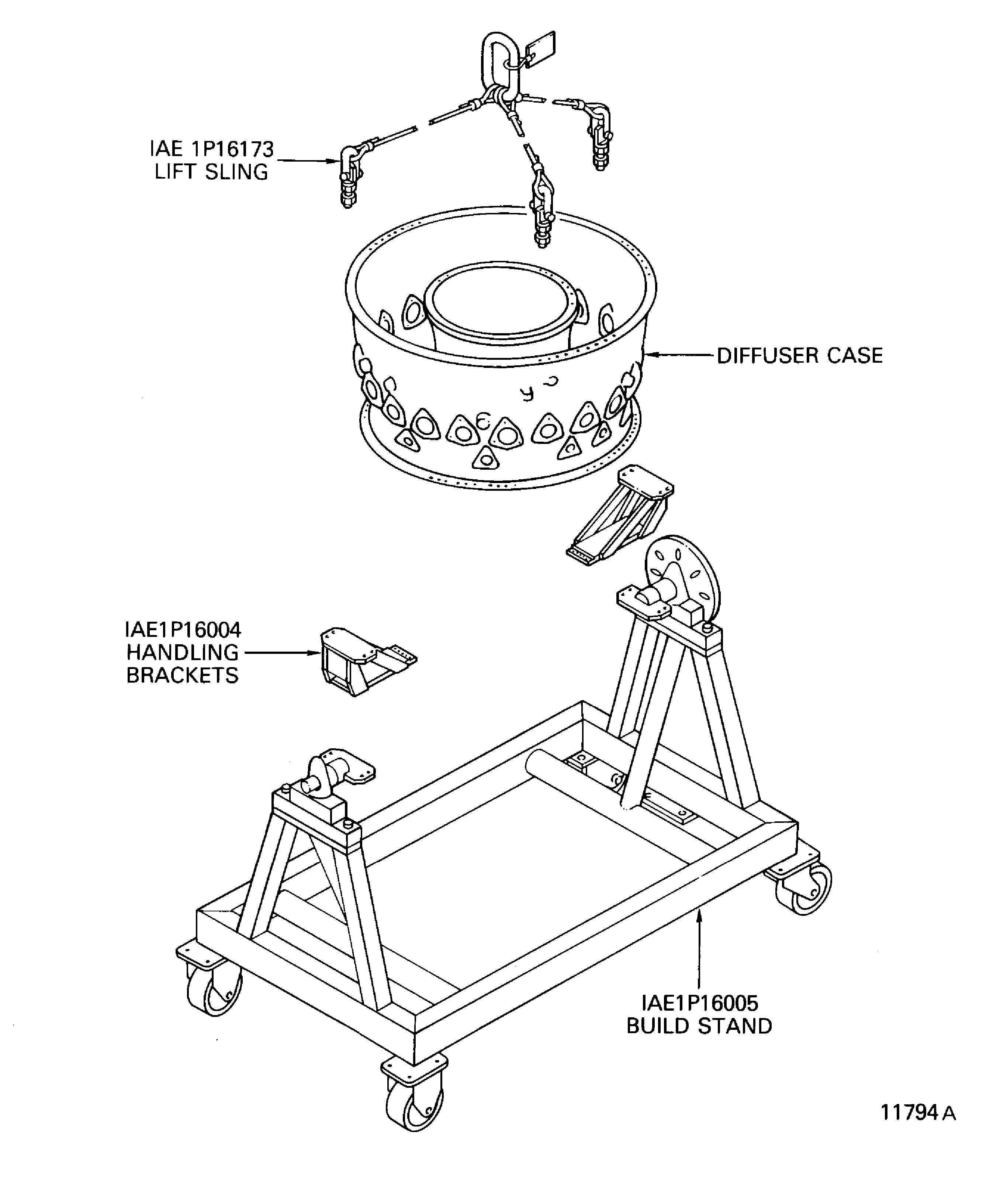

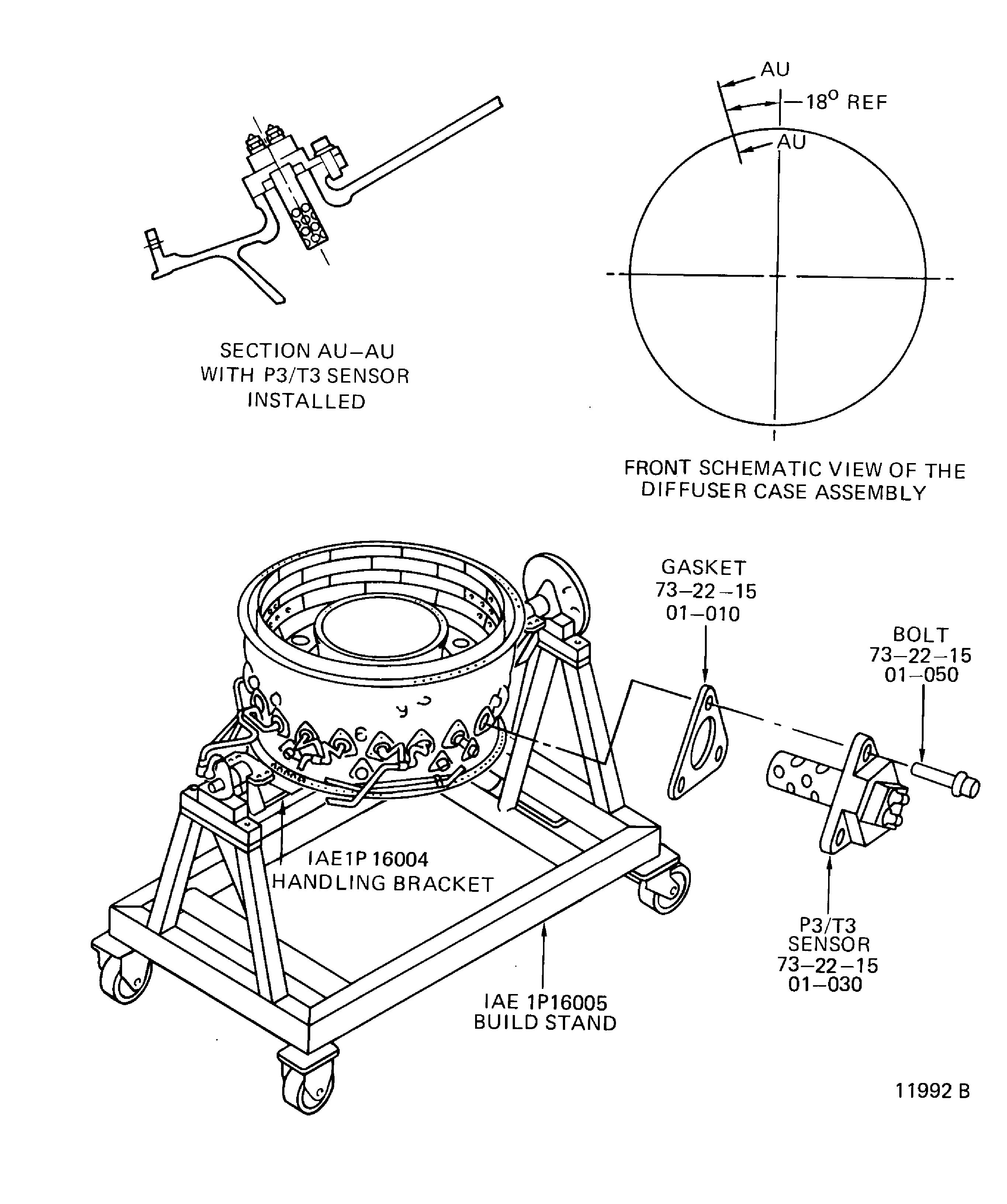

Attach a hoist to the IAE 1P16173 Lift sling 1 off.

Attach the IAE 1P16004 Handling bracket 2 off to the front flange of the diffuser case assembly 180 degrees apart with the five screws from the rear of the diffuser case front flange.

Position the diffuser case assembly in the IAE 1P16005 Build stand 1 off.

SUBTASK 72-42-00-430-066 Put the Diffuser Case Assembly in to the Build Stand

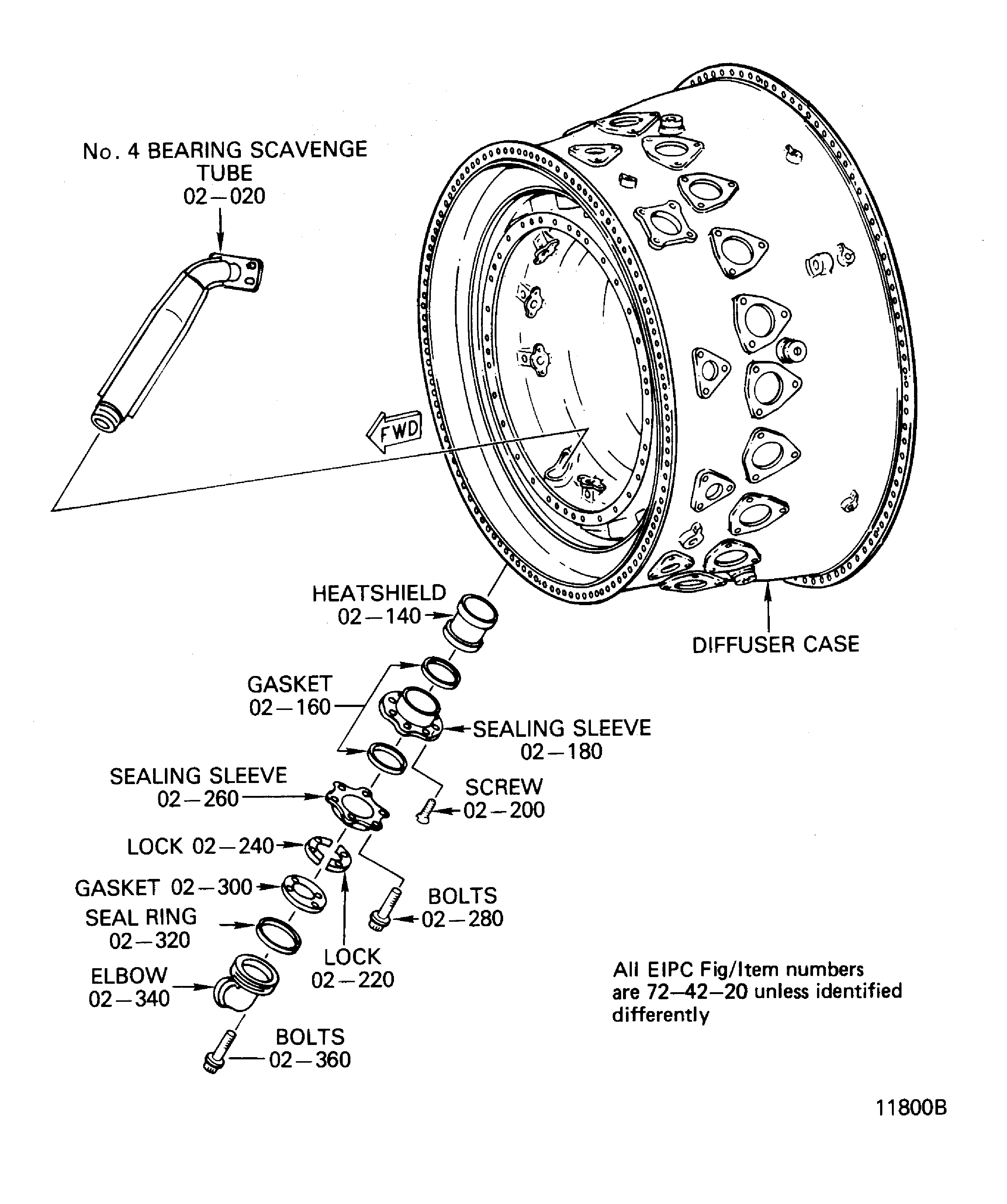

Install the gasket No. 4 Bearing Compartment Tubes (72-42-20,02-160) 1 off into recess on the diffuser case boss and hold in position with CoMat 10-041 PETROLATUM, WHITE.

Install the heatshield No. 4 Bearing Compartment Tubes (72-42-20,02-140) into the diffuser case boss.

Install the sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20,02-180) over the installed gasket No. 4 Bearing Compartment Tubes (72-42-20,02-160) in to the inner diameter of the diffuser case boss.

Secure the sealing sleeve with the two lubed screws No. 4 Bearing Compartment Tubes (72-42-20,02-200). Torque the two screws to the diffuser case assembly to 65 lbfin to 85 lbfin (7.344 Nm to 9.604 Nm).

Install the metal seal ring No. 4 Bearing Compartment Tubes (72-42-20,02-320) into the groove on elbow No. 4 Bearing Compartment Tubes (72-42-20,02-340).

Insall the No. 4 bearing scavenge tube No. 4 Bearing Compartment Tubes (72-42-20,02-020) from the inside of the diffuser case.

Install the upper and lower locks No. 4 Bearing Compartment Tubes (72-42-20,02-220) and No. 4 Bearing Compartment Tubes (72-42-20,02-240) with flat face inward into the groove at the end of installed No. 4 bearing scvange which is out through the center of eight hole pad.

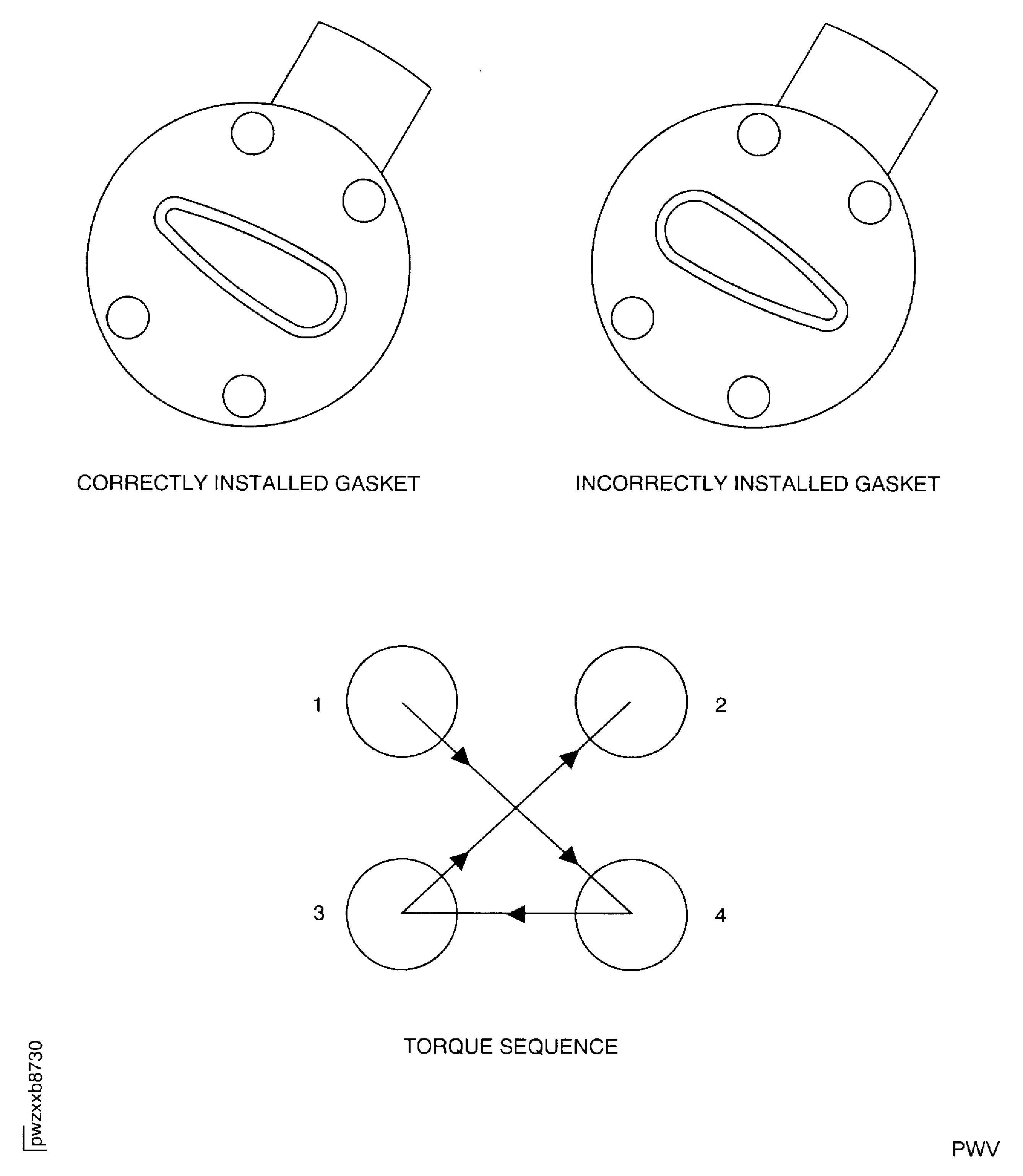

While you hold the locks in position, install the gasket No. 4 Bearing Compartment Tubes (72-42-20,02-300) and elbow No. 4 Bearing Compartment Tubes (72-42-20,02-340) over the locks. Refer to Figure.

Attach the elbow No. 4 Bearing Compartment Tubes (72-42-20,02-340) with four lubed bolts No. 4 Bearing Compartment Tubes (72-42-20,02-360), finger tight only. Do not tighten and torque the bolts at this time.

Put the sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20,02-260) on the bench with smaller O.D facing down. Install the gasket No. 4 Bearing Compartment Tubes (72-42-20,02-160) 1 off into recess on the sealing sleeve. Use CoMat 01-573 WAX BLEND, PARAFFIN to hold the gasket in the sleeve.

Install the sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20,02-260) with the larger O.D towards diffuser and gasket No. 4 Bearing Compartment Tubes (72-42-20,02-160) over the elbow to seat on the eight hole pad.

Attach the sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20,02-260) with six lubed bolts No. 4 Bearing Compartment Tubes (72-42-20,02-280), finger tight only. Do not tighten and torque the bolts at this time.

SUBTASK 72-42-00-430-067 Install the No. 4 Bearing Scavenge Tube

Refer to: Figure

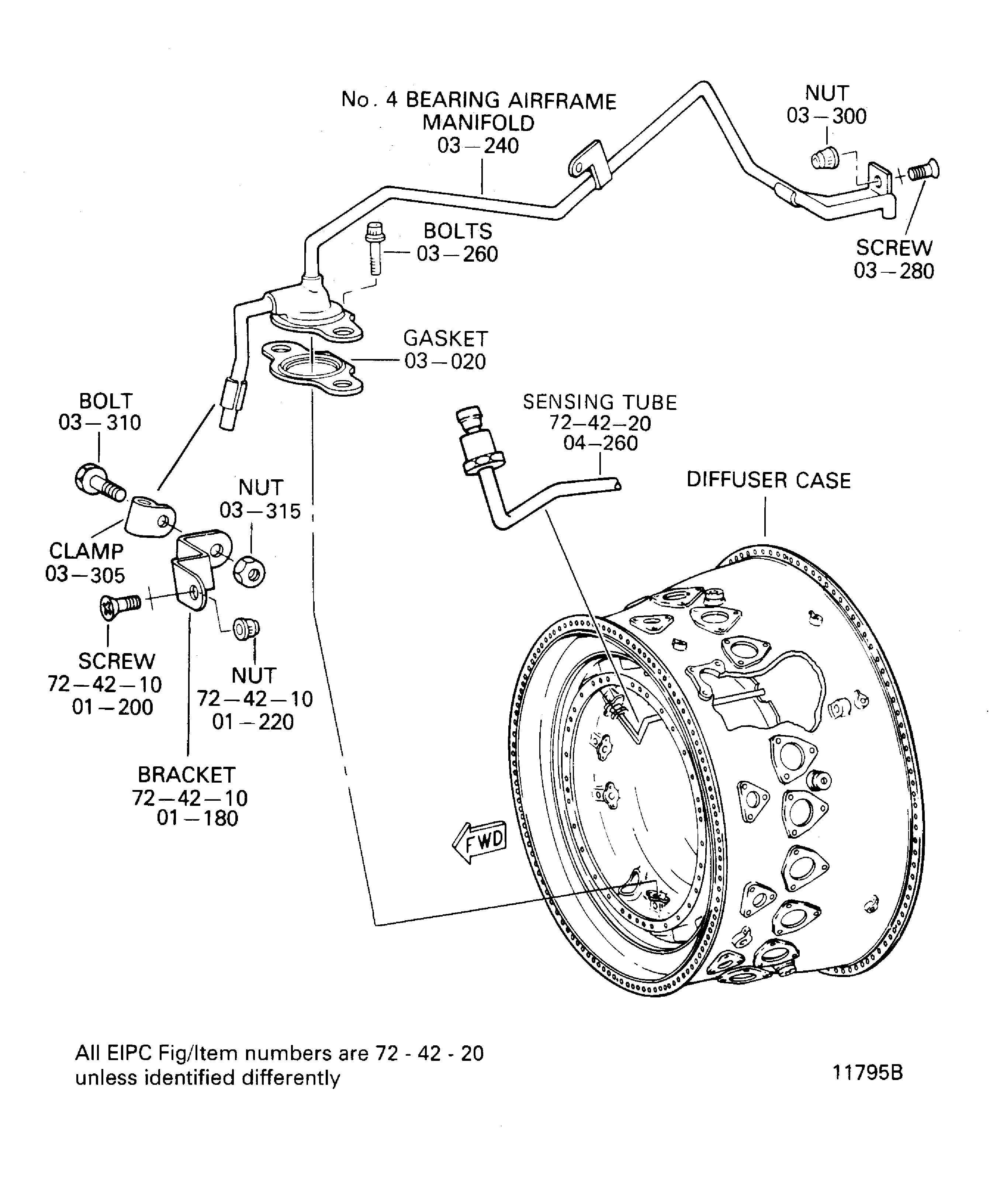

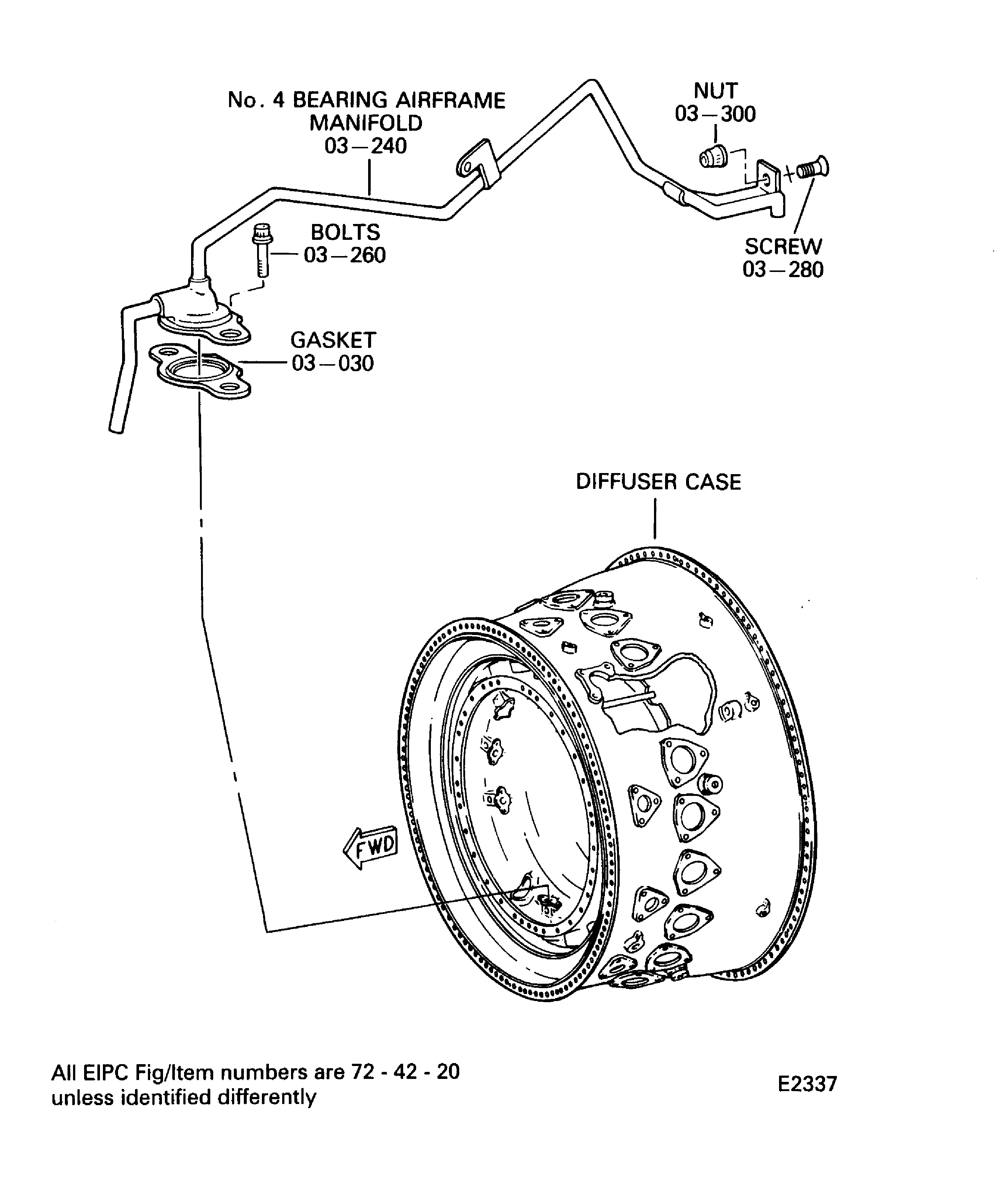

Put No. 4 Bearing Compartment Tubes (72-42-20,03-020) gasket 1 off on the outer airframe tube in the diffuser case.

Put the No. 4 bearing airframe manifold No. 4 Bearing Compartment Tubes (72-42-20,03-240) in place and attach with the two bolts No. 4 Bearing Compartment Tubes (72-42-20,03-260). Do not torque the bolts.

Install the bracket, Diffuser Case Assembly And Fittings (72-42-10,01-180) to the diffuser case assembly and attach with the screw Diffuser Case Assembly And Fittings (72-42-10,01-200) and the nut Diffuser Case Assembly And Fittings (72-42-10,01-220), to hold the airframe manifold. Torque the nut to 32 lbfin to 36 lbfin (3.616 Nm to 4.067 Nm).

Install the loop clamp No. 4 Bearing Compartment Tubes (72-42-20,03-305) on the airframe manifold.

Attach the bracket to the airframe manifold with the loop clamp No. 4 Bearing Compartment Tubes (72-42-20,03-305), the bolt No. 4 Bearing Compartment Tubes (72-42-20,03-310) and the nut No. 4 Bearing Compartment Tubes (72-42-20,03-315).

Attach the bracket on the airframe manifold to the rear inner flange of the diffuser case with the screw No. 4 Bearing Compartment Tubes (72-42-20,03-280) and the nut No. 4 Bearing Compartment Tubes (72-42-20,03-300). Torque the nut to 32 lbfin to 36 lbfin (3.616 Nm to 4.067 Nm).

SUBTASK 72-42-00-430-068-A00 V2500-A1: Install the No. 4 Bearing Airframe Manifold (72-42-20,03-240) (Pre SBE 72-0016, Pre SBE 72-0166 and Pre SBE 72-0221)

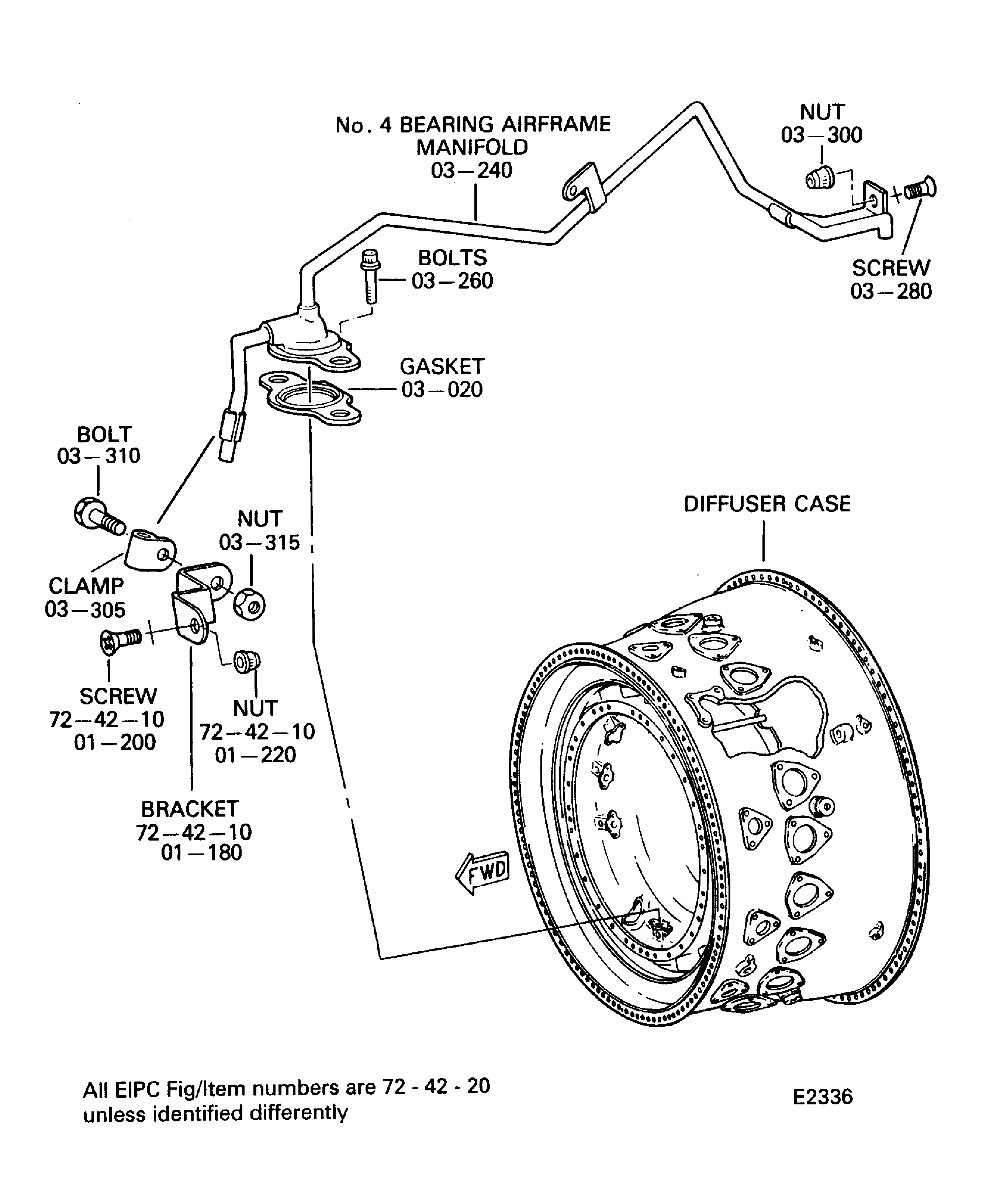

Put No. 4 Bearing Compartment Tubes (72-42-20,03-020) gasket 1 off on the outer airframe tube in the diffuser case.

Put the No. 4 bearing airframe manifold No. 4 Bearing Compartment Tubes (72-42-20,03-240) in place and attach with the two bolts No. 4 Bearing Compartment Tubes (72-42-20,03-260). Do not torque the bolts.

Install the bracket Diffuser Case Assembly And Fittings (72-42-10,01-180) to the diffuser case assembly and attach with the screw Diffuser Case Assembly And Fittings (72-42-10,01-200) and the nut Diffuser Case Assembly And Fittings (72-42-10,01-220) to hold the airframe manifold. Torque the nut to 32 lbfin to 36 lbfin (3.616 Nm to 4.067 Nm).

Install the loop clamp No. 4 Bearing Compartment Tubes (72-42-20,03-305) on the airframe manifold.

Attach the bracket to the airframe manifold with the loop clamp No. 4 Bearing Compartment Tubes (72-42-20,03-305), the bolt No. 4 Bearing Compartment Tubes (72-42-20,03-310) and the nut No. 4 Bearing Compartment Tubes (72-42-20,03-315).

Attach the bracket on the airframe manifold to the rear inner flange of the diffuser case with the screw No. 4 Bearing Compartment Tubes (72-42-20,03-280) and the nut No. 4 Bearing Compartment Tubes (72-42-20,03-300). Torque the nut to 32 lbfin to 36 lbfin (3.616 Nm to 4.067 Nm).

SUBTASK 72-42-00-430-068-B00 V2500-A1: Install the No. 4 Bearing Airframe Manifold (72-42-20,03-240) (Pre SBE 72-0016, SBE 72-0166 and Pre SBE 72-0221)

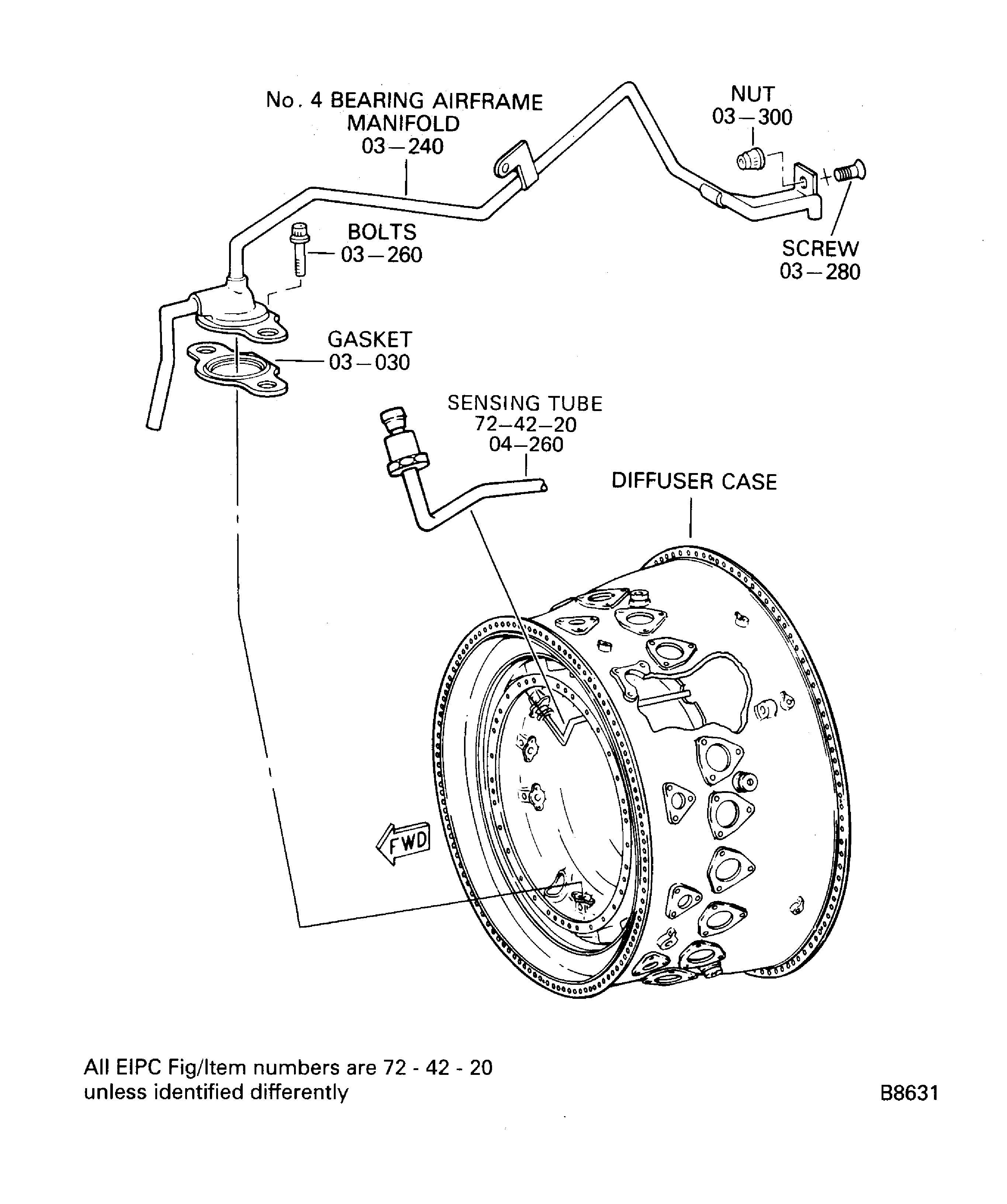

Put the No. 4 Bearing Compartment Tubes (72-42-20,03-030) gasket 1 off on the outer airframe tube in the diffuser case.

Put the No. 4 bearing airframe manifold No. 4 Bearing Compartment Tubes (72-42-20,03-240) in place and attach it with the two bolts No. 4 Bearing Compartment Tubes (72-42-20,03-260). Do not torque the bolts.

Attach the bracket on the airframe manifold to the rear inner flange of the diffuser case with the screw No. 4 Bearing Compartment Tubes (72-42-20,03-280) and the nut No. 4 Bearing Compartment Tubes (72-42-20,03-300). Torque the nut to 32 lbfin to 36 lbfin (3.616 Nm to 4.067 Nm).

SUBTASK 72-42-00-430-068-C00 V2500-A1: Install the No. 4 Bearing Airframe Manifold (SBE 72-0016, Pre SBE 72-0166 and Pre SBE 72-0221)

Refer to Figure

SBE 72-0016: New No. 4 bearing and airframe manifold assembly

SBE 72-0166: Remove the Stage 1 HP turbine cooling air tubes

SBE 72-0221: Introduce a new diffuser case

Put the No. 4 Bearing Compartment Tubes (72-42-20,03-030) gasket 1 off on the outer airframe tube in the diffuser case.

Put the No. 4 bearing airframe manifold No. 4 Bearing Compartment Tubes (72-42-20,03-240) in place and attach it with the two bolts No. 4 Bearing Compartment Tubes (72-42-20,03-260). Do not torque the bolts.

Attach the bracket on the airframe manifold to the rear inner flange of the diffuser case with the screw No. 4 Bearing Compartment Tubes (72-42-20,03-280) and the nut No. 4 Bearing Compartment Tubes (72-42-20,03-300). Torque the nut to 32 lbfin to 36 lbfin (3.616 Nm to 4.067 Nm).

SUBTASK 72-42-00-430-068-D00 V2500-A1: Install the No. 4 Bearing Airframe Manifold (SBE 72-0016, SBE 72-0166 and SBE 72-0221)

Refer to Figure

Put the No. 4 Bearing Compartment Tubes (72-42-20,03-030) gasket 1 off on the outer airframe tube in the diffuser case.

Put the No. 4 bearing airframe manifold No. 4 Bearing Compartment Tubes (72-42-20,03-240) in place and attach it with the two bolts No. 4 Bearing Compartment Tubes (72-42-20,03-260). Do not torque the bolts.

Attach the bracket on the airframe manifold to the rear inner flange of the diffuser case with the screw No. 4 Bearing Compartment Tubes (72-42-20,03-280) and the nut No. 4 Bearing Compartment Tubes (72-42-20,03-300). Torque the nut to 32 lbfin to 36 lbfin (3.616 Nm to 4.067 Nm).

SUBTASK 72-42-00-430-068-E00 V2500-A5: Install the No. 4 Bearing Airframe Manifold (Pre SBE 72-0166)

Put the No. 4 Bearing Compartment Tubes (72-42-20,03-030) gasket 1 off on the outer airframe tube in the diffuser case.

Put the No. 4 bearing airframe manifold No. 4 Bearing Compartment Tubes (72-42-20,03-240) in place and attach it with the two bolts No. 4 Bearing Compartment Tubes (72-42-20,03-260). Do not torque the bolts.

Attach the bracket on the airframe manifold to the rear inner flange of the diffuser case with the screw No. 4 Bearing Compartment Tubes (72-42-20,03-280) and the nut No. 4 Bearing Compartment Tubes (72-42-20,03-300). Torque the nut to 32 lbfin to 36 lbfin (3.616 Nm to 4.067 Nm).

SUBTASK 72-42-00-430-068-F00 V2500-A5: Install the No. 4 Bearing Airframe Manifold (SBE 72-0166)

Refer to Figure

Install the inner sensing tube No. 4 Bearing Compartment Tubes (72-42-20,04-260) to the outer sensing tube with the open end through the hole in the inner front flange of the diffuser case.

SUBTASK 72-42-00-430-069-A00 V2500-A1: Install the Turbine Cooling Air Duct Sensing Tube (Pre SBE 72-0016, Pre SBE 72-0166 and Pre SBE 72-0221)

Install the inner sensing tube No. 4 Bearing Compartment Tubes (72-42-20,04-260) to the outer sensing tube with the open end through the hole in the inner front flange of the diffuser case.

SUBTASK 72-42-00-430-069-B00 V2500-A1: Install the Turbine Cooling Air Duct Sensing Tube (SBE 72-0016 and Pre SBE 72-0166)

Refer to Figure

Install the inner sensing tube No. 4 Bearing Compartment Tubes (72-42-20,04-260) to the outer sensing tube with the open end through the hole in the inner front flange of the diffuser case.

SUBTASK 72-42-00-430-069-C00 V2500-A5: Install the Turbine Cooling Air Duct Sensing Tube (Pre SBE 72-0166)

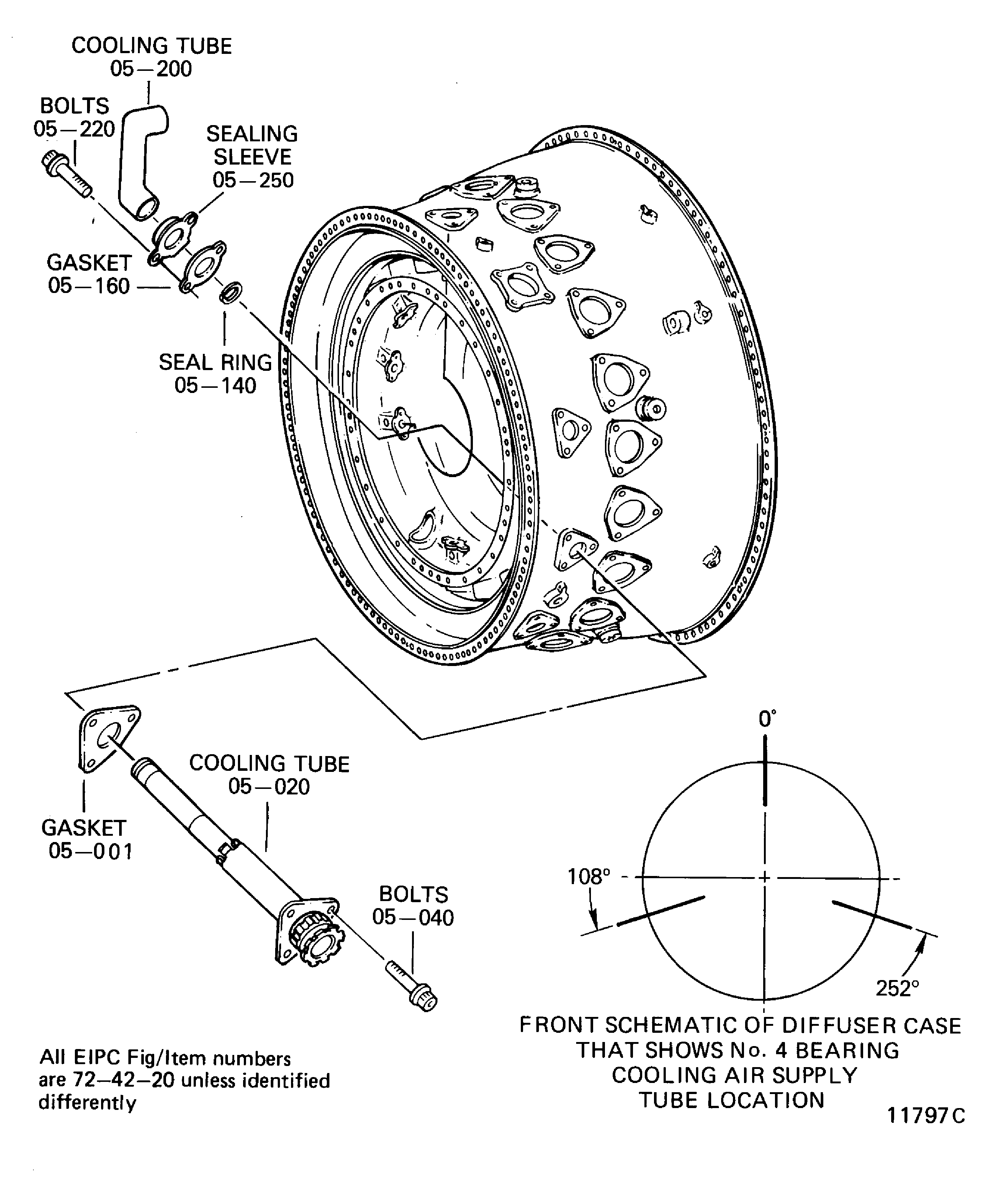

Refer to Figure.

Install No. 4 Bearing Compartment Tubes (72-42-20,05-160) gaskets 3 off on the mounting pads on the ID of the diffuser case.

Attach the three sealing sleeves No. 4 Bearing Compartment Tubes (72-42-20,05-250) with the six bolts No. 4 Bearing Compartment Tubes (72-42-20,05-220) to the diffuser case. Do not torque the bolts.

Install the three No. 4 bearing inner cooling tubes No. 4 Bearing Compartment Tubes (72-42-20,05-200).

SUBTASK 72-42-00-430-070 Install the No. 4 Bearing Inner Cooling Tube and the Sealing Sleeves

Refer to Figure.

Install the three seal rings No. 4 Bearing Compartment Tubes (72-42-20,05-140) to the three No. 4 bearing outer cooling tubes No. 4 Bearing Compartment Tubes (72-42-20,05-020).

Put No. 4 Bearing Compartment Tubes (72-42-20,05-001) gaskets 3 off on the diffuser case mounting pads.

Install the three No. 4 bearing outer cooling tubes No. 4 Bearing Compartment Tubes (72-42-20,05-020).

Attach the three cooling tubes to the diffuser case with the nine bolts No. 4 Bearing Compartment Tubes (72-42-20,05-040).

SUBTASK 72-42-00-430-071 Install the No. 4 Bearing Outer Cooling Tube

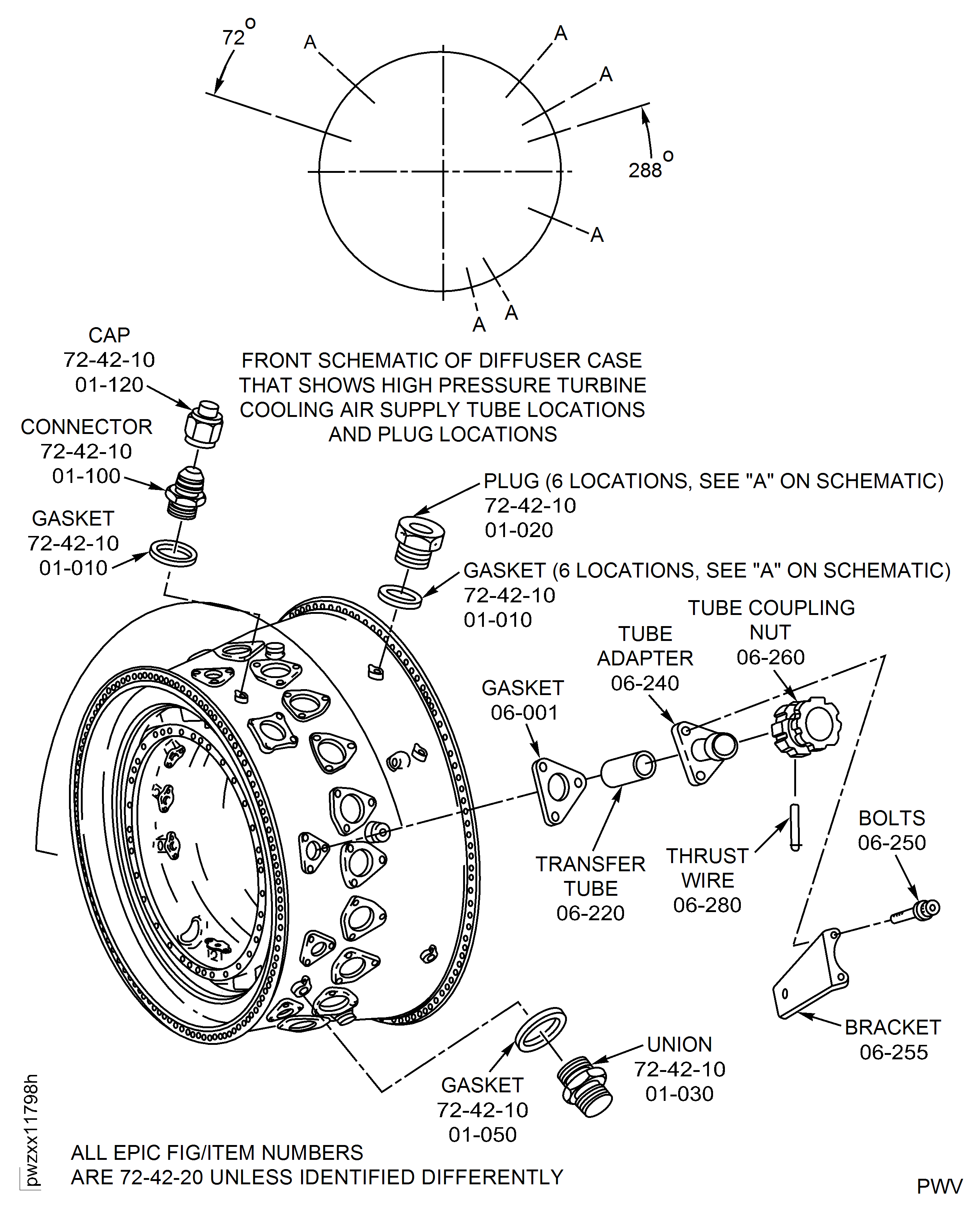

Refer to Figure

Put No. 4 Bearing Compartment Tubes (72-42-20,06-001) gaskets 2 off on the tube adapter mounting pads.

Install the two transfer tubes No. 4 Bearing Compartment Tubes (72-42-20,06-220).

Install the two tube adapters No. 4 Bearing Compartment Tubes (72-42-20,06-240).

Install the bracket No. 4 Bearing Compartment Tubes (72-42-20,06-255).

Attach the tube adapters and the bracket to the diffuser case with the six bolts No. 4 Bearing Compartment Tubes (72-42-20,06-250). Torque the bolts to 65 lbfin to 85 lbfin (7.344 Nm to 9.604 Nm).

Safety the bolts with CoMat 02-141 LOCKWIRE.

Install tube coupling nut to adapter No. 4 Bearing Compartment Tubes (72-42-20, 06-260).

Position the thrust wire in the hole of the tube coupling nut No. 4 Bearing Compartment Tubes (72-42-20, 06-280).

Use the mallet to move the thrust wire into position.

SUBTASK 72-42-00-430-072-A00 V2500-A1: Install the Transfer Tube and the Adapter in the Diffuser Case (Pre SBE 72-0221)

Put the No. 4 Bearing Compartment Tubes (72-42-20,06-001) gaskets 2 off on the tube adapter mounting pads.

Install the two transfer tube No. 4 Bearing Compartment Tubes (72-42-20,06-220).

Install the two tube adapters No. 4 Bearing Compartment Tubes (72-42-20,06-240).

Install the bracket No. 4 Bearing Compartment Tubes (72-42-20,06-255).

Attach the tube adapters and the bracket to the diffuser case with the six bolts No. 4 Bearing Compartment Tubes (72-42-20,06-250). Torque the bolts to 65 lbfin to 85 lbfin (7.344 Nm to 9.604 Nm).

Safety the bolts with CoMat 02-141 LOCKWIRE.

Install tube coupling nut to adapter No. 4 Bearing Compartment Tubes (72-42-20, 06-260).

Position the thrust wire in the hole of the tube coupling nut No. 4 Bearing Compartment Tubes (72-42-20, 06-280).

Use the mallet to move the thrust wire into position.

SUBTASK 72-42-00-430-072-B00 V2500-A1: Install the Transfer Tube and the Adapter in the Diffuser Case (SBE 72-0221)

Refer to Figure

Put the No. 4 Bearing Compartment Tubes (72-42-20,06-001) gaskets 2 off on the tube adapter mounting pads.

Install the two transfer tubes No. 4 Bearing Compartment Tubes (72-42-20,06-220).

Install the two tube adapters No. 4 Bearing Compartment Tubes (72-42-20,06-240).

Install the bracket No. 4 Bearing Compartment Tubes (72-42-20,06-255).

Attach the tube adapters and the bracket to the diffuser case with the six bolts No. 4 Bearing Compartment Tubes (72-42-20,06-250). Torque the bolts to 65 lbfin to 85 lbfin (7.344 Nm to 9.604 Nm).

Safety the bolts with CoMat 02-141 LOCKWIRE.

Install tube coupling nut to adapter No. 4 Bearing Compartment Tubes (72-42-20, 06-260).

Position the thrust wire in the hole of the tube coupling nut No. 4 Bearing Compartment Tubes (72-42-20, 06-280).

Use the mallet to move the thrust wire into position.

SUBTASK 72-42-00-430-072-C00 V2500-A5: Install the Transfer Tube and the Adapter in the Diffuser Case

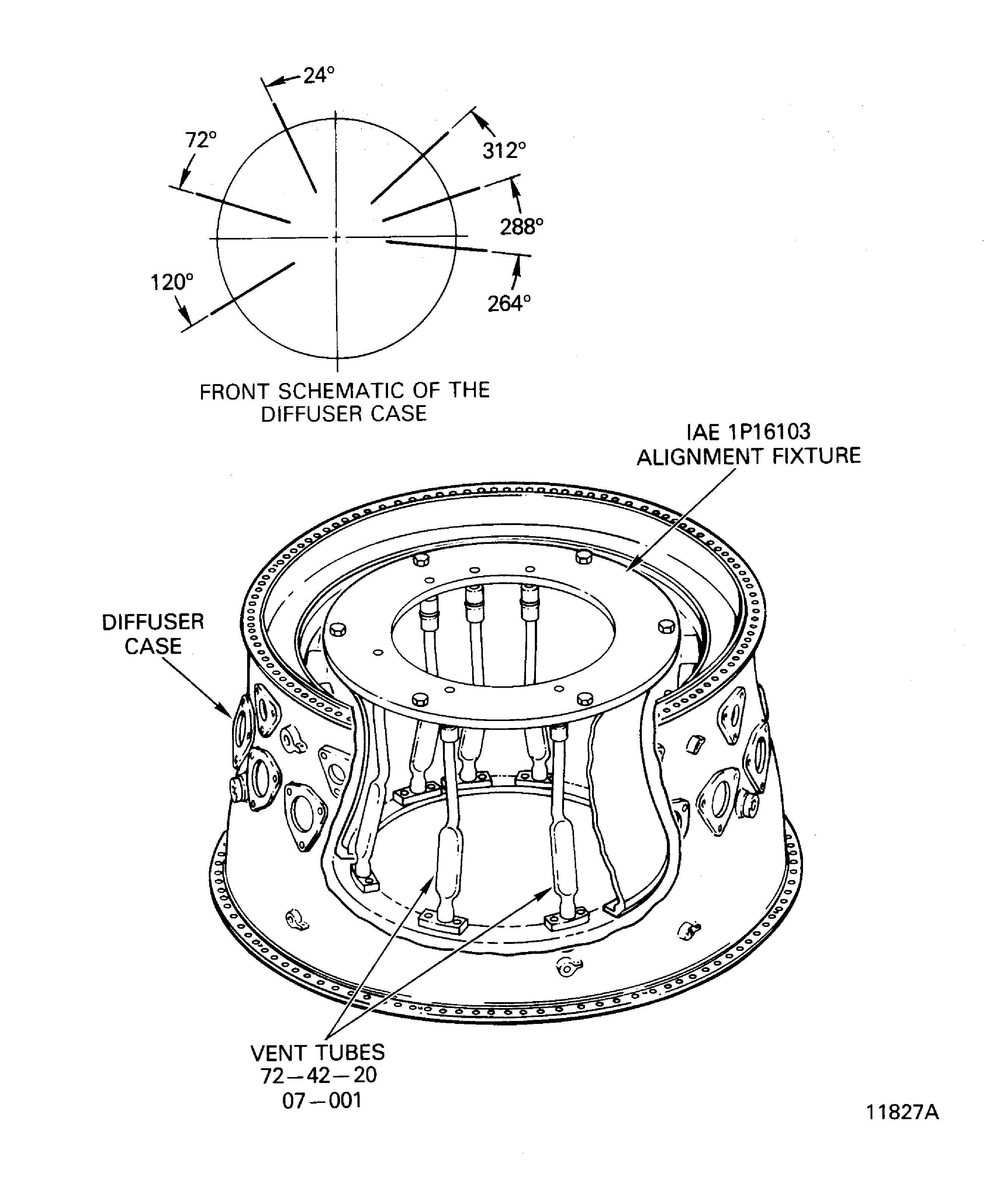

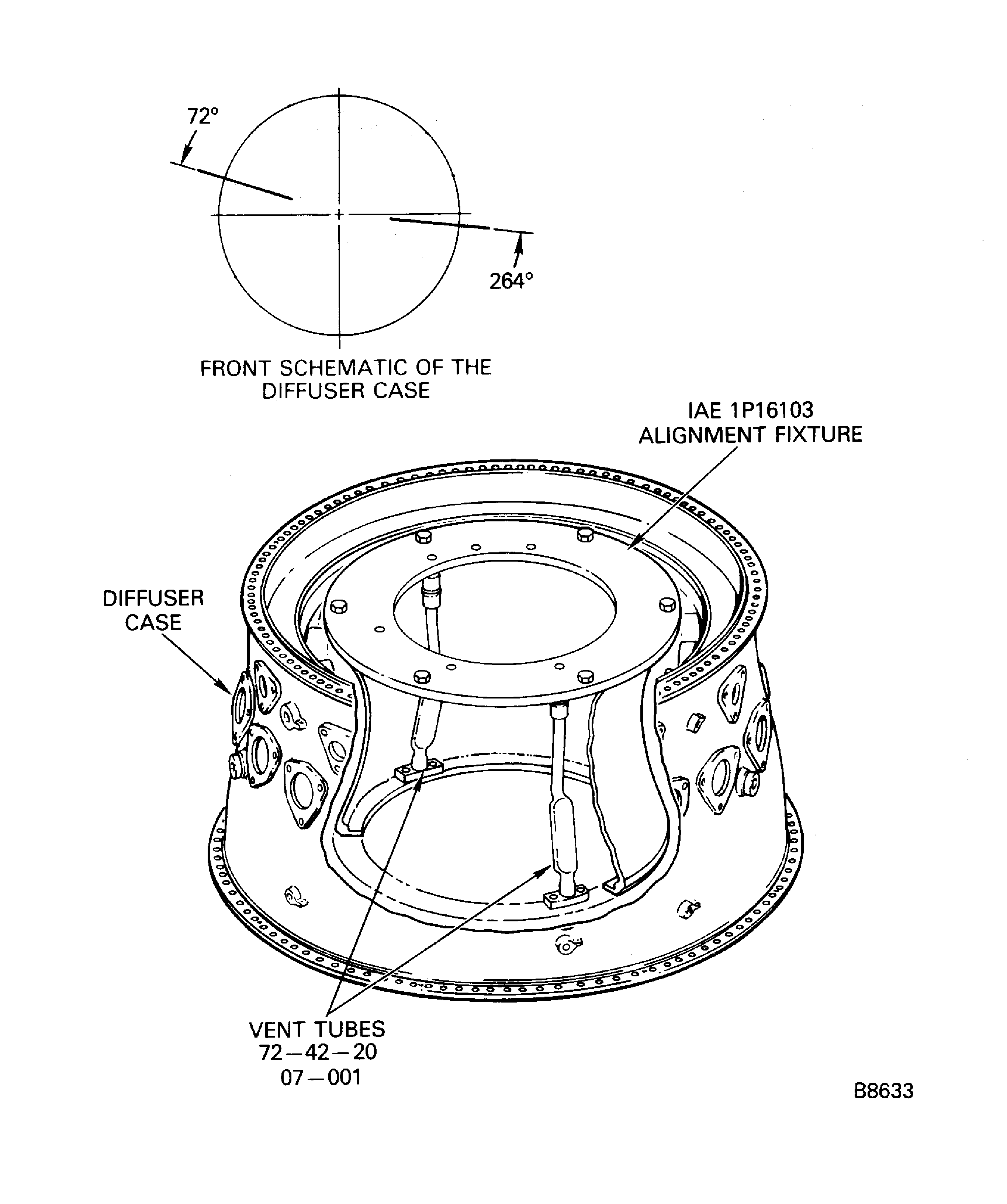

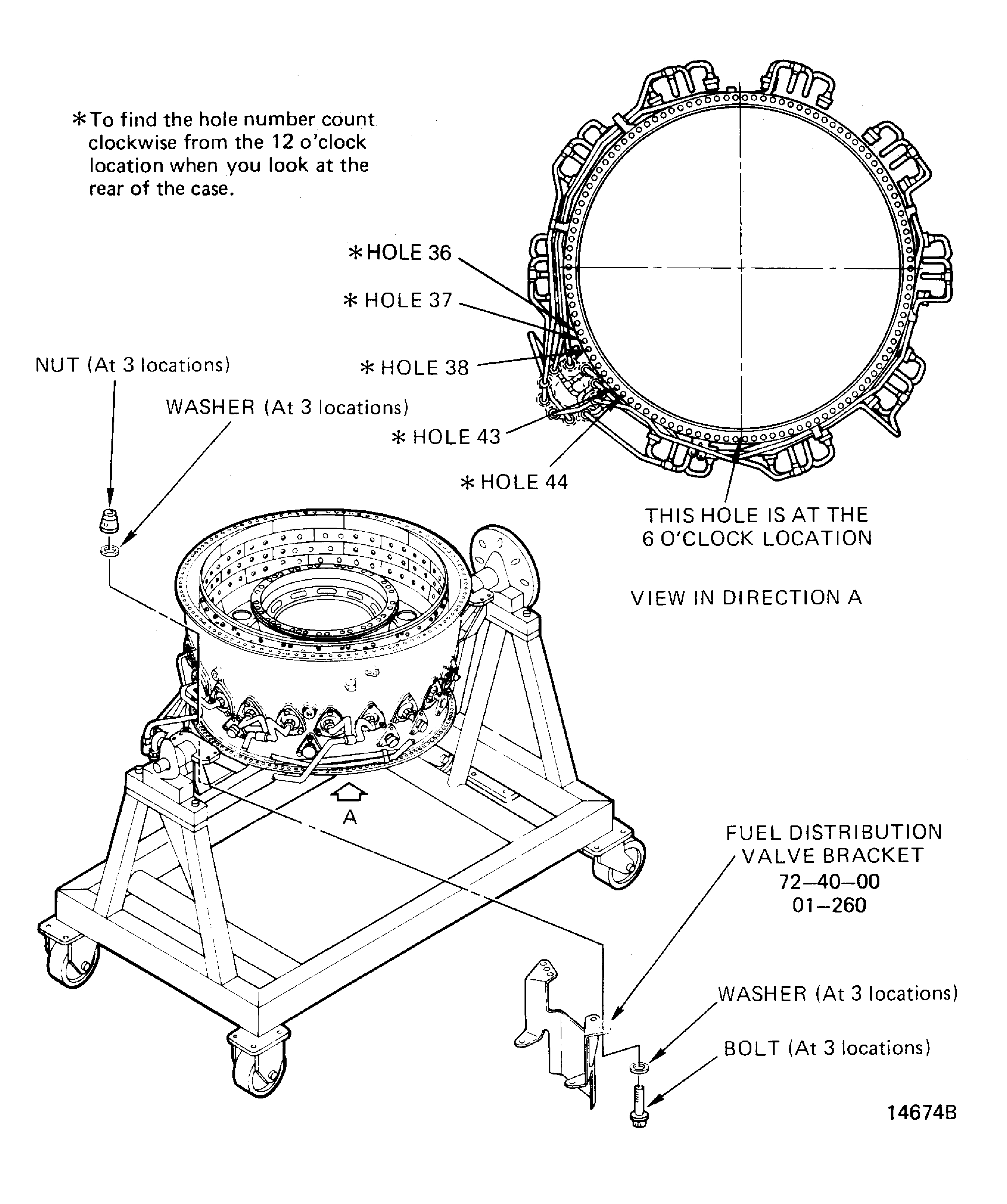

Refer to Figure

Turn the positioning rods of the IAE 1P16103 Alignment fixture 1 off in to the fixture plate.

Attach the IAE 1P16103 Alignment fixture 1 off to the front inner flange of the diffuser case. Align the fixture with the offset hole in the front inner flange of the diffuser case. Secure the fixture with the six bolts.

Install the six thrust balance vent tubes ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20,07-001) in to the diffuser case. Turn the positioning rods of the alignment fixture to hold the tubes in position.

SUBTASK 72-42-00-430-057-A00 V2500-A1: Install the Thrust Balance Vent Tubes in the Diffuser Case (Pre SBE 72-0221)

Turn the positioning rods of the IAE 1P16103 Alignment fixture 1 off into the fixture plate.

Attach the IAE 1P16103 Alignment fixture 1 off to the front inner flange of the diffuser case. Align the fixture with the offset hole in the front inner flange of the diffuser case. Secure the fixture with the six bolts.

Install the two thrust balance vent tubes ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20,07-001) into the diffuser case. Turn the positioning rods of the alignment fixture to hold the tubes in position.

SUBTASK 72-42-00-430-057-B00 V2500-A1: Install the Thrust Balance Vent Tubes in the Diffuser Case (SBE 72-0221)

Refer to Figure

Turn the positioning rods of the IAE 1P16103 Alignment fixture 1 off into the fixture plate.

Attach the IAE 1P16103 Alignment fixture 1 off to the front inner flange of the diffuser case. Align the fixture with the offset hole in the front inner flange of the diffuser case. Secure the fixture with the six bolts.

Install the two thrust balance vent tubes ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20,07-001) into the diffuser case. Turn the positioning rods of the alignment fixture to hold the tubes in position.

SUBTASK 72-42-00-430-057-C00 V2500-A5: Install the Thrust Balance Vent Tubes in the Diffuser Case

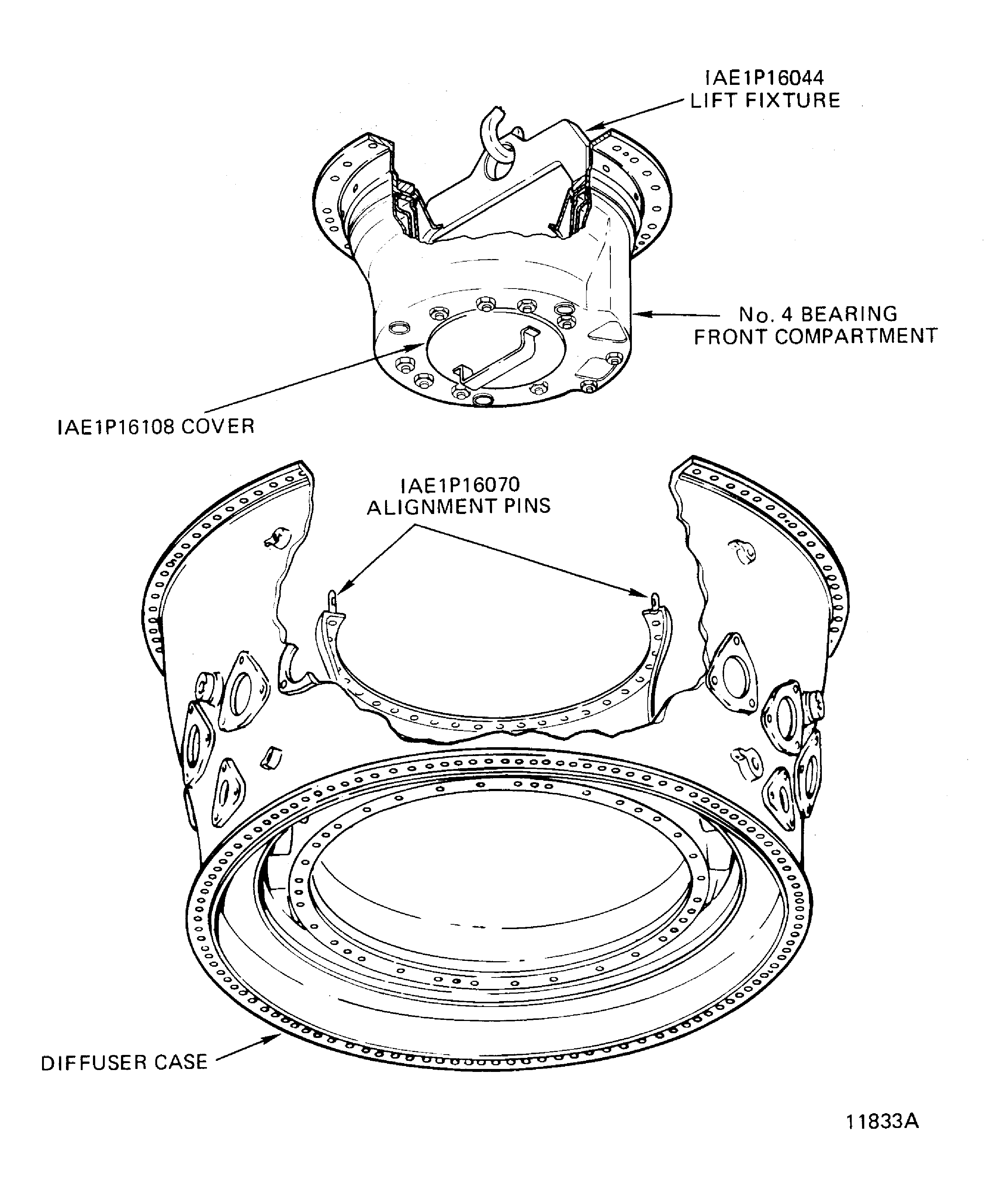

Refer to Figure.

Install the IAE 1P16070 Guide pin 2 off in the rear inner flange of the diffuser case assembly 180 degrees apart.

Remove the work bolts which attach the No. 4 bearing front compartment to the IAE 1P16068 Support fixture.

Install the IAE 1P17000 Protective cover 1 off onto the No. 4 bearing face seal.

Attach a hoist to the IAE 1P16044 Lift fixture 1 off.

SUBTASK 72-42-00-430-051 Install the No. 4 Bearing Front Compartment to the Diffuser Case Assembly

CAUTION

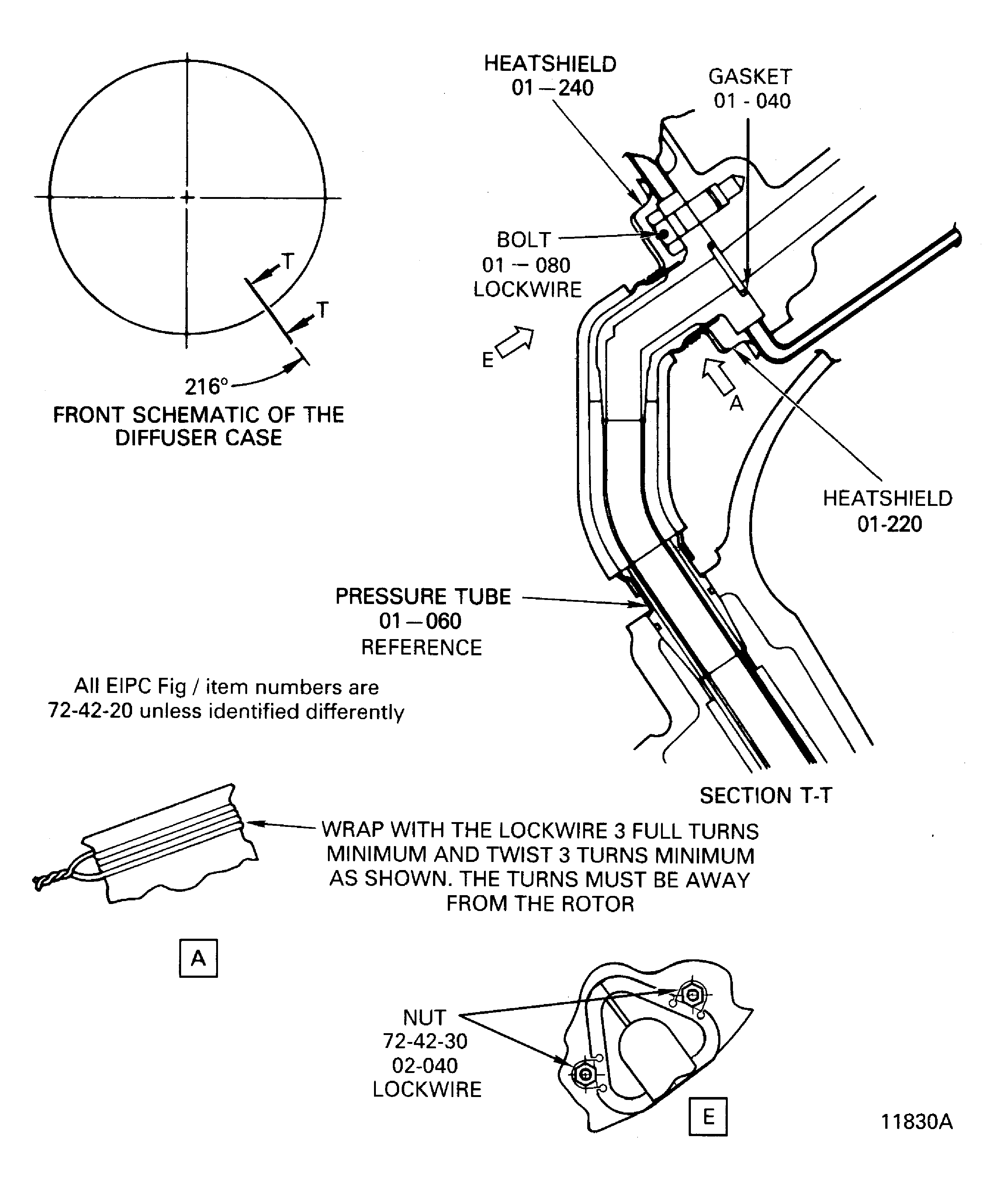

TWO PERSONS ARE REQUIRED TO TURN THE DIFFUSER CASE ASSEMBLY IN THE BUILD STAND.Install ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20,01-040) gasket 1 off in the recess of the pressure tube adjacent to the bearing compartment.

Lubricate the threads on the three bolts ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20,01-080) with CoMat 10-129 ANTI-SEIZE PASTE.

Attach the pressure tube to the front bearing compartment with the three bolts ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20,01-080).

Torque the bolts which attach the pressure tube to the No. 4 bearing compartment to 45 lbfin to 60 lbfin (5.084 Nm to 6.779 Nm). Safety with CoMat 02-141 LOCKWIRE.

Torque the bolts which attach the pressure tube to the diffuser case assembly to 65 lbfin to 85 lbfin (7.3 Nm to 9.6 Nm). Safety with CoMat 02-141 LOCKWIRE.

Attach the No. 4 bearing oil pressure tube.

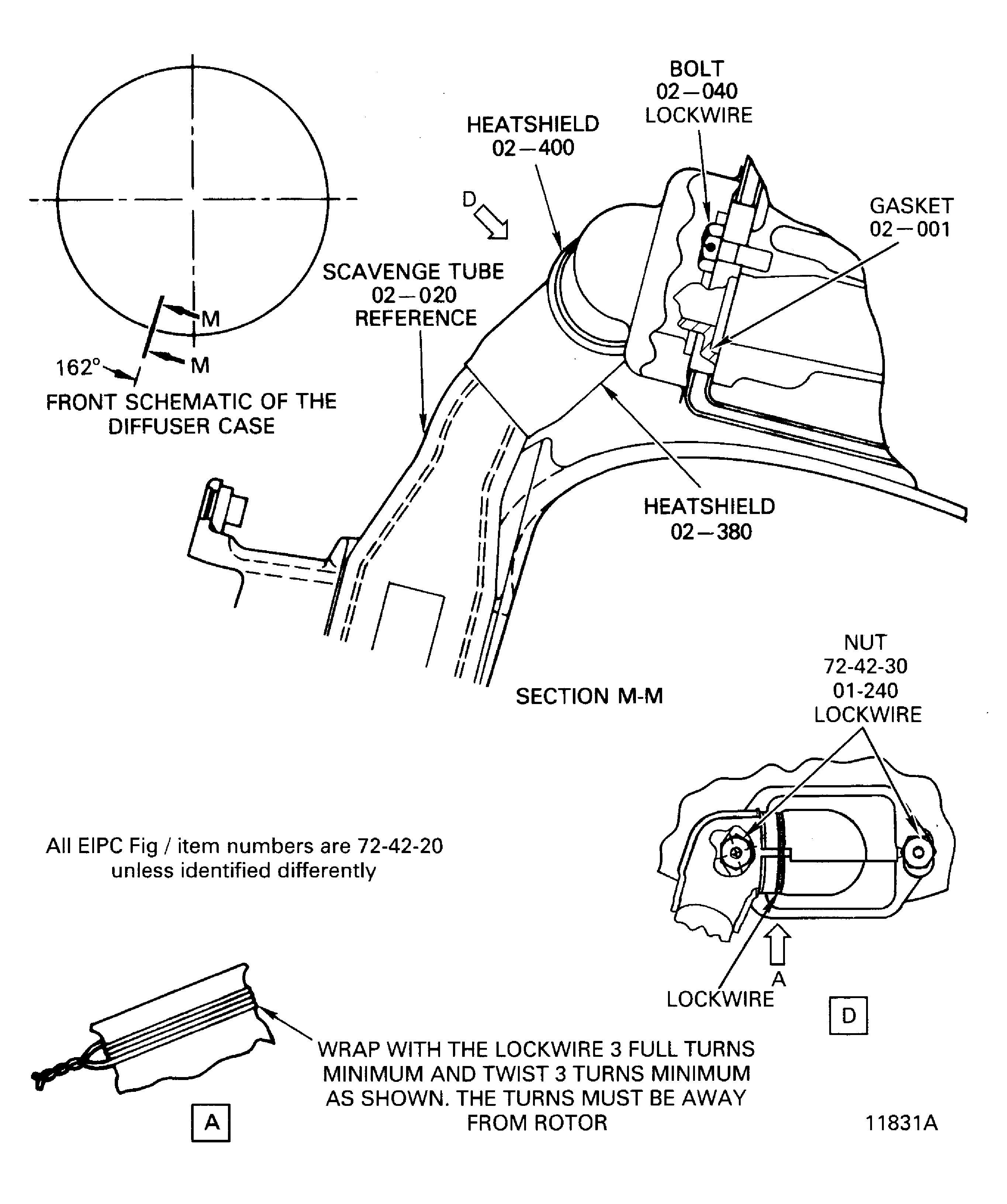

Install No. 4 Bearing Compartment Tubes (72-42-20,02-001) gasket 1 off in the recess of the scavenge tube adjacent to the No. 4 bearing compartment.

Lubricate the threads on the four bolts No. 4 Bearing Compartment Tubes (72-42-20,02-040) with CoMat 10-129 ANTI-SEIZE PASTE.

Attach the scavenge tube to the bearing compartment with the four bolts No. 4 Bearing Compartment Tubes (72-42-20,02-040).

Torque the bolts which attach the scavenge tube to the bearing compartment to 45 lbfin to 60 lbfin (5.084 Nm to 6.779 Nm). Safety with CoMat 02-141 LOCKWIRE.

Torque the six bolts which attach the sealing sleeve to the diffuser case assembly to 75 lbfin to 85 lbfin (8.474 Nm to 9.604 Nm). Safety with CoMat 02-141 LOCKWIRE.

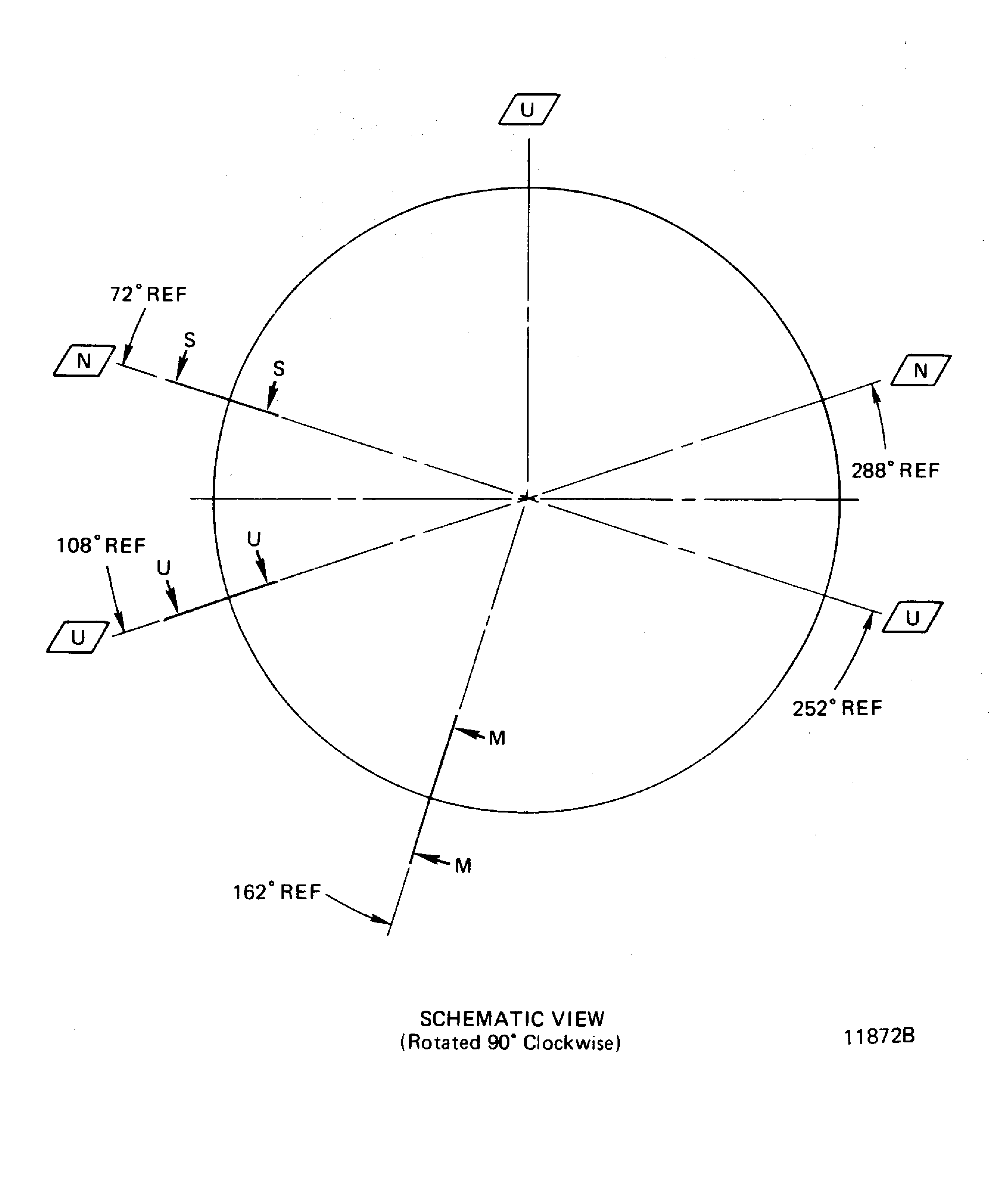

Use the 180 degree alternative torque pattern to torque the four bolts which attach the elbow to the scavenge tube to 25 lbfin to 30 lbfin (2.825 Nm to 3.390 Nm). Use the same 180 degree alternative torque pattern and apply final torque of 75 lbfin to 85 lbfin (8.474 Nm to 9.604 Nm). Refer to Figure for torque pattern. Safety with CoMat 02-141 LOCKWIRE.

CAUTION

USE ONLY CoMat 10-050 ASSEMBLY FLUID TO HOLD GASKET IN PLACE. DO NOT USE WAX.Attach the No. 4 bearing scavenge tube.

Torque the nine bolts No. 4 Bearing Compartment Tubes (72-42-20,05-040) which attach the three cooling air tubes No. 4 Bearing Compartment Tubes (72-42-20,05-020) to the outer side of the diffuser case assembly to 65 lbfin to 85 lbfin (7.3 Nm to 9.6 Nm). Safety with CoMat 02-141 LOCKWIRE.

Torque the six bolts No. 4 Bearing Compartment Tubes (72-42-20,05-220) which attach the three cooling air sleeves No. 4 Bearing Compartment Tubes (72-42-20,05-250) to the inner side of the diffuser case assembly to 65 lbfin to 85 lbfin (7.344 Nm to 9.604 Nm). Safety with CoMat 02-141 LOCKWIRE.

Remove the IAE 1P16108 cover from the front of the No. 4 bearing front compartment.

Make sure the cooling air tubes engage the cooling air duct.

SUBTASK 72-42-00-430-052 Attach the Tubes to the No. 4 Bearing Front Compartment

CAUTION

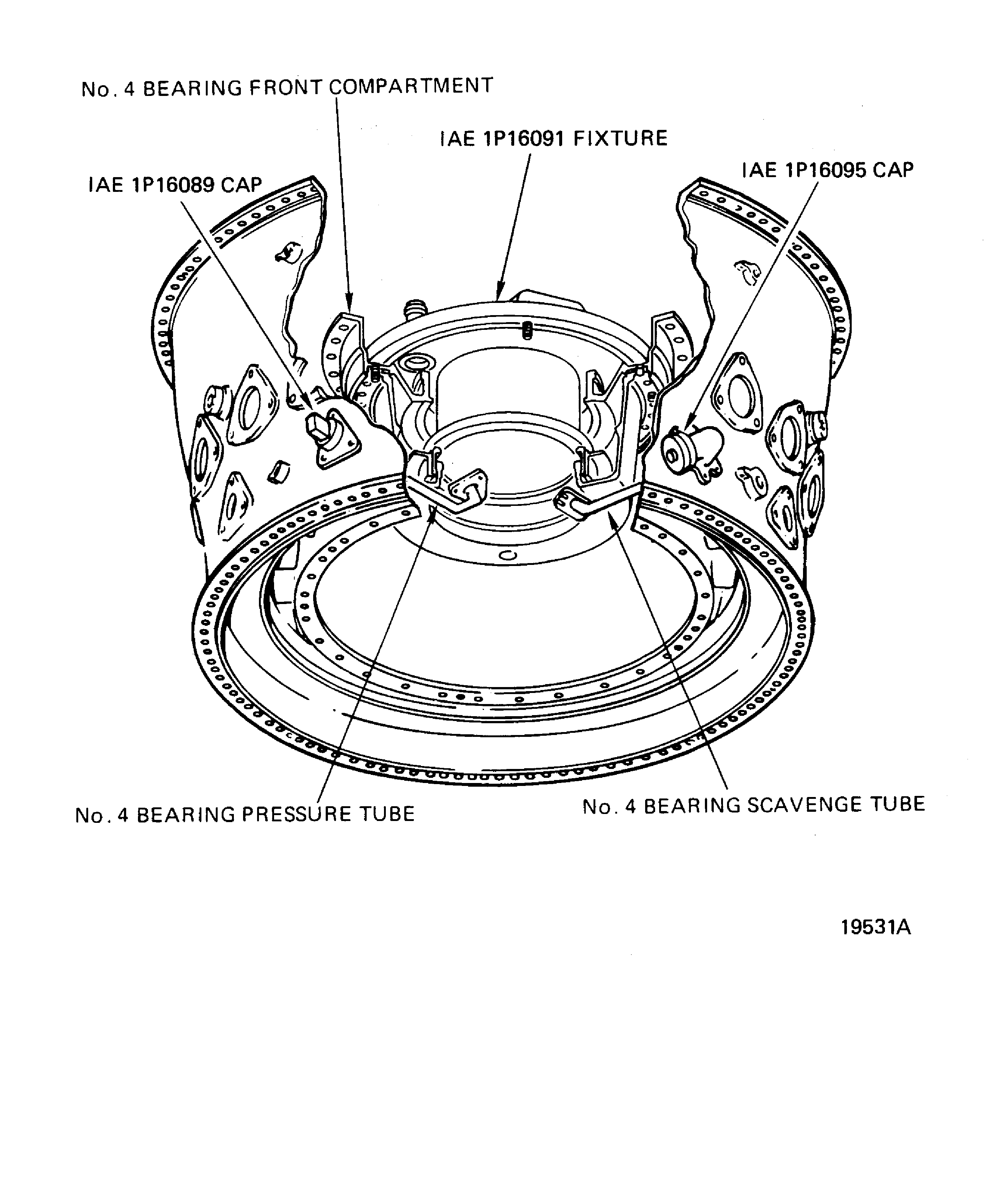

USE ONLY CoMat 10-050 ASSEMBLY FLUID TO HOLD GASKET IN PLACE. DO NOT USE WAX.Refer to Figure

Install the IAE 1P16089 Leak check cap 1 off in the coupling nut of the pressure tube.

Install the IAE 1P16095 Leak check cap 1 off in to the elbow on the end of the scavenge tube.

Install the three locating pins of the IAE 1P16090 Leak check fixture 1 off at the three equally spaced locations on the rear flange of the diffuser case assembly.

Connect the IAE 6F10029 Air flow test cart 1 off to the fixture.

SUBTASK 72-42-00-790-051 Do a Check of the No. 4 Bearing Oil Scavenge and Oil Pressure Tubes for Leaks

Refer to Figure

Install the IAE IAE 1P16089 Leak check cap 1 off in the coupling nut of the pressure tube.

Install the IAE IAE 1P16095 Leak check cap 1 off in the elbow on the end of the scavenge tube.

NOTE

Make sure the detail tool packing is installed in the groove on the fixture.Coat the five detail cap screw threads located on the IAE IAE 1P16091 Leak check fixture 1 off with CoMat 10-129 ANTI-SEIZE PASTE. Wipe off excess paste.

Connect the IAE IAE 6F10030 Vacuum test cart 1 off to the fixture.

Adjust the vacuum on the cart to 20 Hg and evacuate the bearing compartment. Based on the ambient pressure, refer to the table below for the vacuum pressure in psia.

Ambient Pressure of the Day (psia)

Vacuum Pressure (psia)

14.7

4.9

14.5

4.7

14.3

4.5

14.1

4.3

13.9

4.1

13.7

3.9

13.5

3.7

13.3

3.5

13.1

3.3

Vacuum pressure (psia) = Ambient pressure of the day (psia) - 9.8 psia

Remove the IAE 1P17000 Protective cover from the No. 4 bearing face seal.

SUBTASK 72-42-00-720-053 Do a Check of the No. 4 Front Carbon Seal Bearing Compartment for Leaks

Install the IAE IAE 1P16086 Air flow adapter 1 off to the No. 4 bearing oil pressure tube.

Attach the hose on the IAE IAE 6F10029 Air flow test cart 1 off to the adapter on the oil pressure tube.

SUBTASK 72-42-00-720-054 Air Flow Check the No. 4 Bearing Compartment Oiling System

Torque the three bolts No. 4 Bearing Compartment Tubes (72-42-20,04-200) which attach the TOBI duct sensing tube to the outer side of the diffuser case to 65 lbfin to 85 lbfin (7.344 Nm to 9.604 Nm) and safety the bolts with CoMat 02-141 LOCKWIRE.

Torque the two bolts No. 4 Bearing Compartment Tubes (72-42-20,04-060) which attach the TOBI duct sensing tube to the inner side of the diffuser case to 65 lbfin to 85 lbfin (7.344 Nm to 9.604 Nm).

Torque the coupling nut of the inner TOBI duct sensing tube No. 4 Bearing Compartment Tubes (72-42-20,04-260) to 50 lbfin to 60 lbfin (5.649 Nm to 6.779 Nm).

SUBTASK 72-42-00-430-053 Safety the Turbine Cooling Air Duct (TOBI Duct) Sensing Tube (Pre SBE 72-0166)

CAUTION

TWO PERSONS ARE REQUIRED TO TURN THE DIFFUSER CASE.Attach the bracket on the No. 4 bearing airframe manifold (forward end) to the No. 4 bearing front heatshield bracket with bolt No. 4 Bearing Compartment Tubes (72-42-20, 03-310) and nut No. 4 Bearing Compartment Tubes (72-42-20, 03-315). Torque the nut to 24 lbfin to 36 lbfin (2.712 Nm to 4.067 Nm).

Torque the two bolts No. 4 Bearing Compartment Tubes (72-42-20, 03-260) which attach the airframe tube and manifold to the inner side of the diffuser case to 65 lbfin to 85 lbfin (7.344 Nm to 9.604 Nm). Safety with CoMat 02-141 LOCKWIRE.

Torque the three bolts No. 4 Bearing Compartment Tubes (72-42-20, 03-180) which attach the airframe tube to the outer side of the diffuser case to 65 lbfin to 85 lbfin (7.344 Nm to 9.604 Nm). Safety with CoMat 02-141 LOCKWIRE.

Attach the bracket on the No. 4 bearing airframe manifold (aft end) to inner side of diffuser case with screw No. 4 Bearing Compartment Tubes (72-42-20, 03-280) and nut No. 4 Bearing Compartment Tubes (72-42-20, 03-300). Torque the nut to 24 lbfin to 36 lbfin (2.712 Nm to 4.067 Nm).

SUBTASK 72-42-00-430-054 Safety the No. 4 Bearing Airframe Tube and Manifold

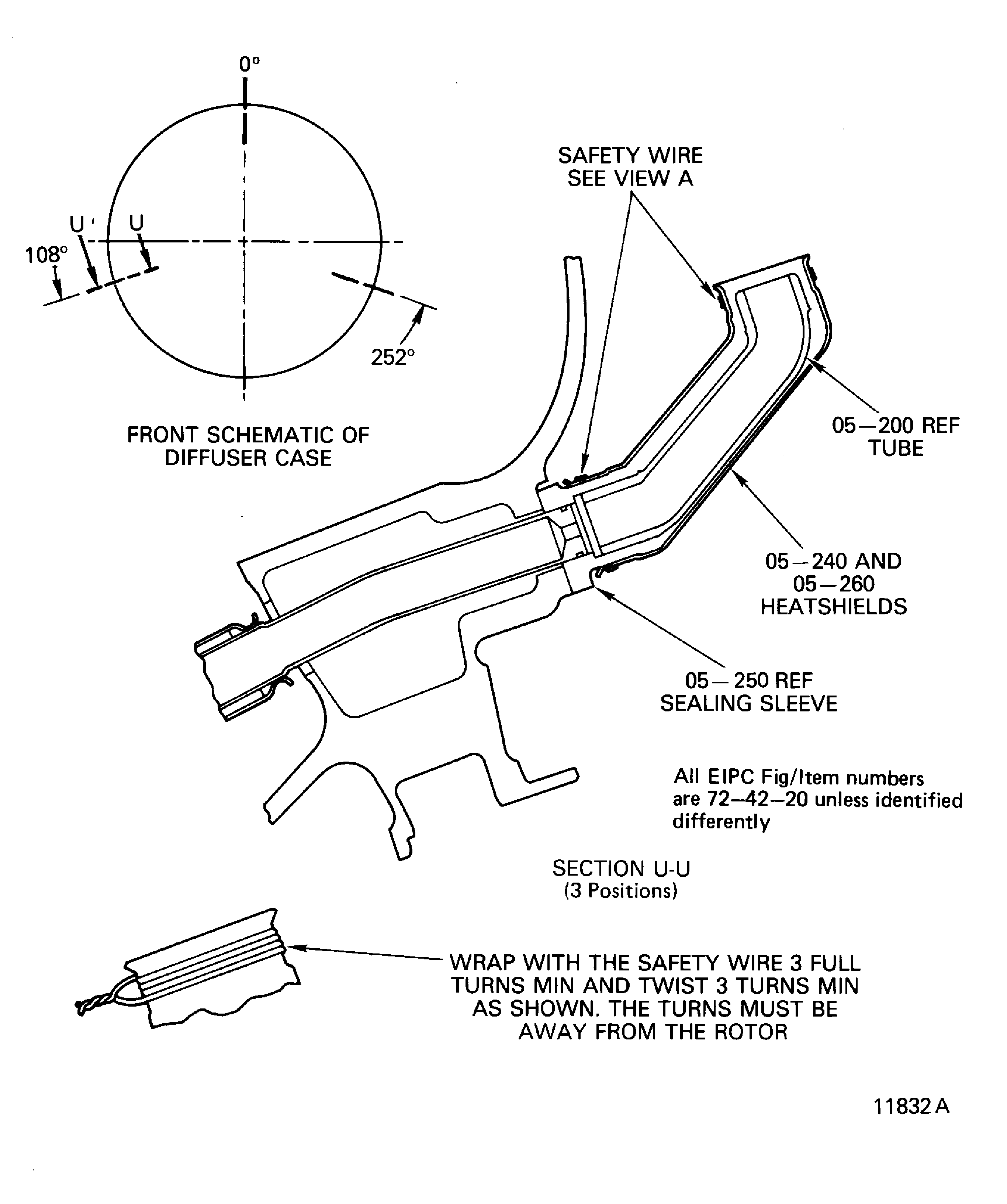

Install the heatshields ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-340 and ENGINE-NO.4 BEARING COMPARTMENT TUBES 01-360) over the inner end of the No. 4 bearing pressure tube with the holes over the spacer studs, refer to Figure. Install the nuts No. 4 Bearing Front Compartment Assembly (72-42-30,01-240). Torque the nuts to 24 lbfin to 36 lbfin (2.712 Nm to 4.067 Nm). Safety the nuts with CoMat 02-141 LOCKWIRE. Safety the small ends of the heatshields with three full turns minimum of CoMat 02-150 LOCKWIRE. Twist the lockwire a minimum of three times away from the rotor.

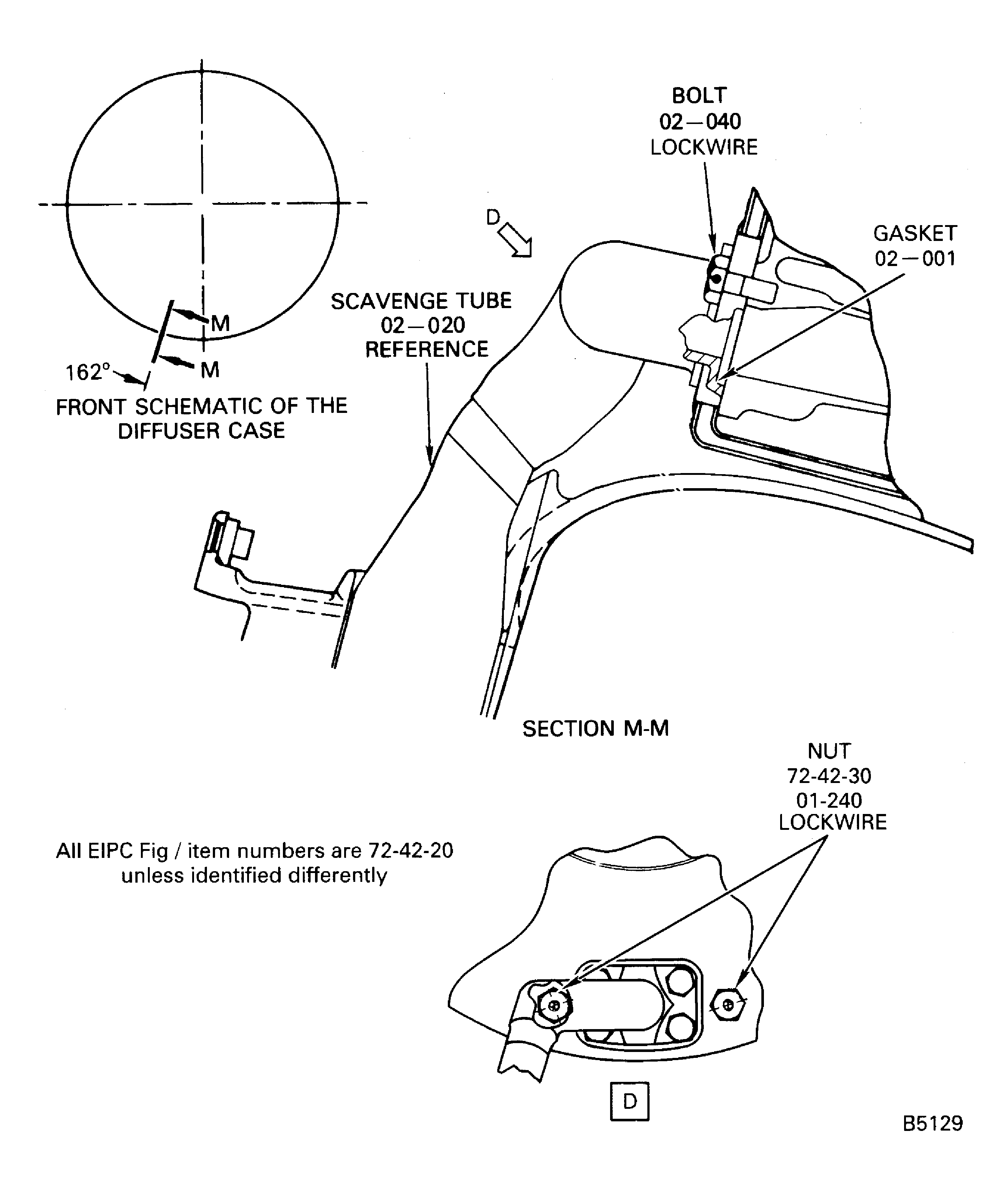

Install the heatshields No. 4 Bearing Compartment Tubes (72-42-20, 02-380 and No. 4 Bearing Compartment Tubes 02-400) over the inner end of the No. 4 bearing scavenge tube (outer first and inner second) with the holes over the spacer studs, refer to Figure. Install the nuts No. 4 Bearing Front Compartment Assembly (72-42-30,01-240). Torque the nuts to 24 lbfin to 36 lbfin (2.712 Nm to 4.067 Nm). Safety the nuts with CoMat 02-141 LOCKWIRE. Safety the small ends of the heatshields with three full turns minimum of CoMat 02-141 LOCKWIRE. Twist the lockwire a minimum of three times away from the rotor.

Install the heatshields No. 4 Bearing Compartment Tubes (72-42-20, 05-240 and No. 4 Bearing Compartment Tubes 05-260) over the inner end of the No. 4 bearing cooling air tubes, refer to Figure. Safety both ends of the three heatshields with three full turns minimum of CoMat 02-150 LOCKWIRE. Twist the lockwire a minimum of three times away from the rotor.

SUBTASK 72-42-00-430-056-A00 Install the Heatshields for the Tubes in the No. 4 Bearing Compartment (Pre SBE 72-0004, SBE 72-0087 and Pre SBE 72-012)

SBE 72-0004: No. 4 bearing scavenge tube without heatshields

SBE 72-0120: New No. 4 bearing scavenge tube and gasket

Install the heatshields ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-340 and ENGINE-NO.4 BEARING COMPARTMENT TUBES 01-360) over the inner end of the No. 4 bearing pressure tube with the holes over the spacer studs, refer to Figure. Install the nuts No. 4 Bearing Front Compartment Assembly (72-42-30,01-240). Torque the nuts to 24 lbfin to 36 lbfin (2.712 Nm to 4.067 Nm). Safety the nuts with CoMat 02-141 LOCKWIRE. Safety the small ends of the heatshields with three full turns minimum of CoMat 02-150 LOCKWIRE. Twist the lockwire a minimum of three times away from the rotor.

Install two nuts No. 4 Bearing Front Compartment Assembly (72-42-30,01-240) onto the two spacers No. 4 Bearing Front Compartment Assembly (72-42-30,01-200) adjacent to the No. 4 bearing scavenge tube, refer to Figure. Torque the nuts to 24 lbfin to 36 lbfin (2.712 Nm to 4.067 Nm). Safety the nuts with CoMat 02-141 LOCKWIRE.

Install the heatshields No. 4 Bearing Compartment Tubes (72-42-20, 05-240 and No. 4 Bearing Compartment Tubes 05-260) over the inner end of the No. 4 bearing cooling air tubes, refer to Figure. Safety both ends of the three heatshields with three full turns minimum of CoMat 02-150 LOCKWIRE. Twist the lockwire a minimum of three times away from the rotor.

SUBTASK 72-42-00-430-056-B00 V2500-A1: Install the Heatshields for the Tubes in the No. 4 Bearing Compartment (SBE 72-0004 and SBE 72-0120)

Install the heatshields ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20,01-340) and ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20,01-360) over the inner end of the No. 4 bearing pressure tube with the holes over the spacer studs. Install the nuts No. 4 Bearing Front Compartment Assembly (72-42-30,01-240). Torque the nuts to 24 lbfin to 36 lbfin (2.7 Nm to 4.1 Nm). Safety the nuts with CoMat 02-141 LOCKWIRE. Safety the small ends of the heatshields with three full turns minimum of CoMat 02-150 LOCKWIRE. Twist the lockwire a minimum of three times away from the rotor.

Install two nuts No. 4 Bearing Front Compartment Assembly (72-42-30,01-240) onto the two spacers No. 4 Bearing Front Compartment Assembly (72-42-30,01-200) adjacent to the No. 4 bearing scavenge tube. Torque the nuts to 24 lbfin to 36 lbfin (2.7 Nm to 4.1 Nm). Safety the nuts with CoMat 02-141 LOCKWIRE.

Install the heatshields No. 4 Bearing Compartment Tubes (72-42-20,05-240) and No. 4 Bearing Compartment Tubes (72-42-20,05-260) over the inner end of the No. 4 bearing cooling air tubes. Safety both ends of the three heatshields with three full turns minimum of CoMat 02-150 LOCKWIRE. Twist the lockwire a minimum of three times away from the rotor.

SUBTASK 72-42-00-430-056-C00 V2500-A5: Install the Heatshields for the Tubes in the No. 4 Bearing Compartment

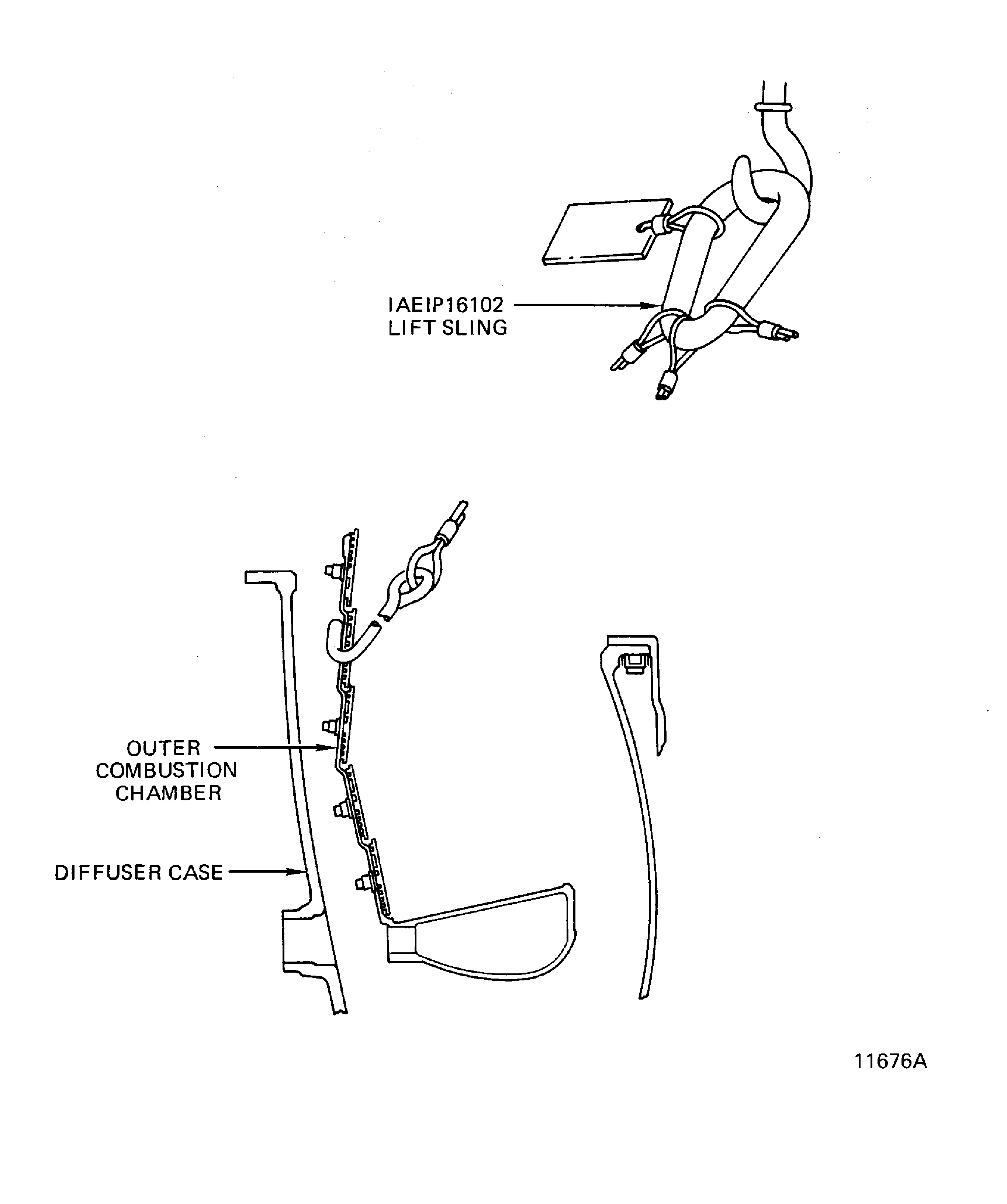

Put the IAE 1P16102 Lift sling 1 off on a hoist. Lower the hoist to the outer combustion chamber Outer Combustion Chamber Assembly (72-42-61,01-501).

SUBTASK 72-42-00-430-058 Install the Outer Combustion Chamber

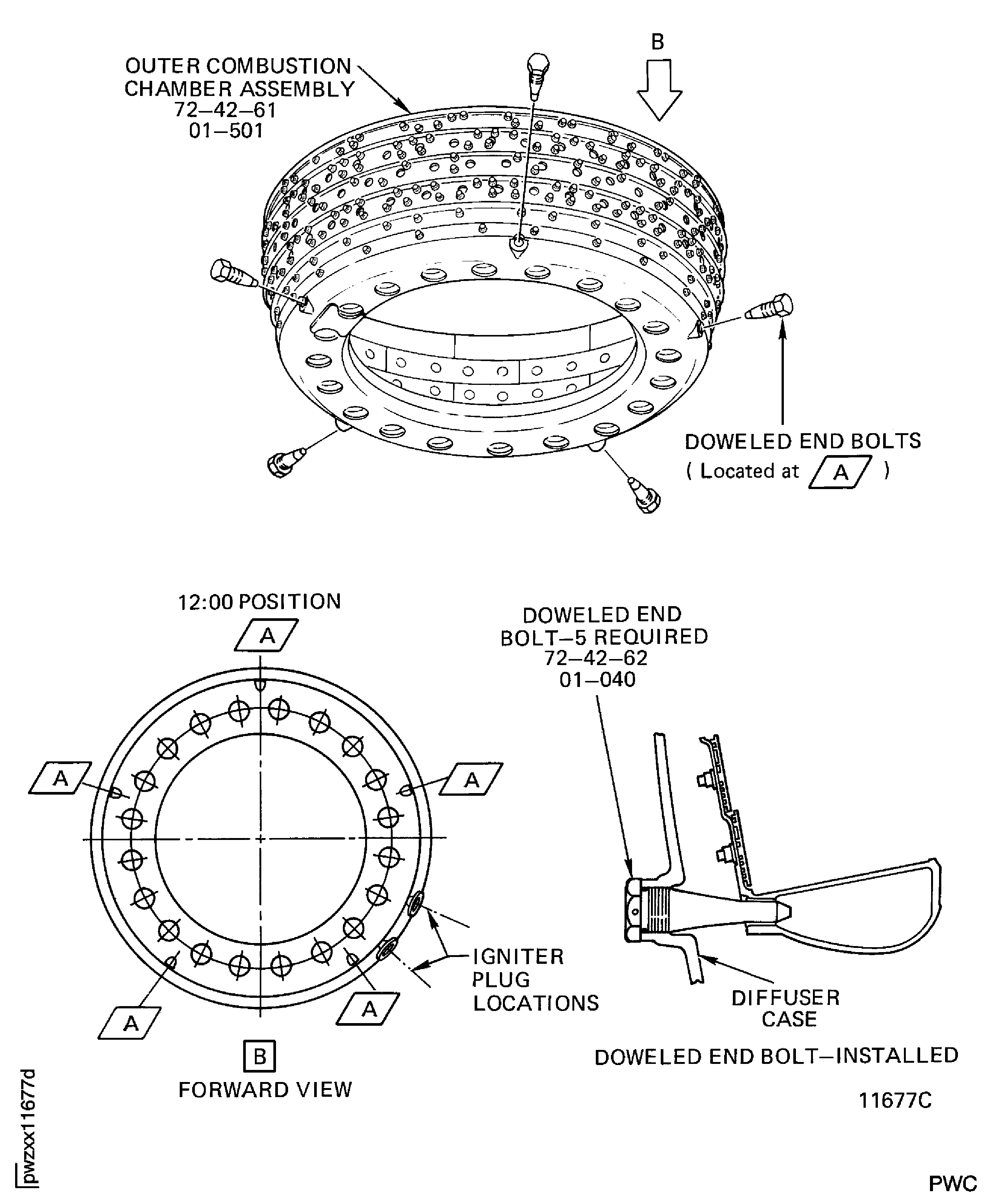

Refer to Figure.

Install the two IAE 1P16231 Alignment pin, equally spaced, to the bosses on the outer diameter of the diffuser case and retract the inner portion of the pins.

Install three doweled end bolts ENGINE-COMBUSTION CHAMBER RETAINING BOLTS (72-42-62,01-040) to attach the outer combustion chamber to the diffuser case and torque the bolts to 550 lbfin to 650 lbfin (62.1 Nm to 73.4 Nm).

SUBTASK 72-42-00-430-059 Install the Five Doweled End Bolts to Attach the Combustion Chamber to the Diffuser Case

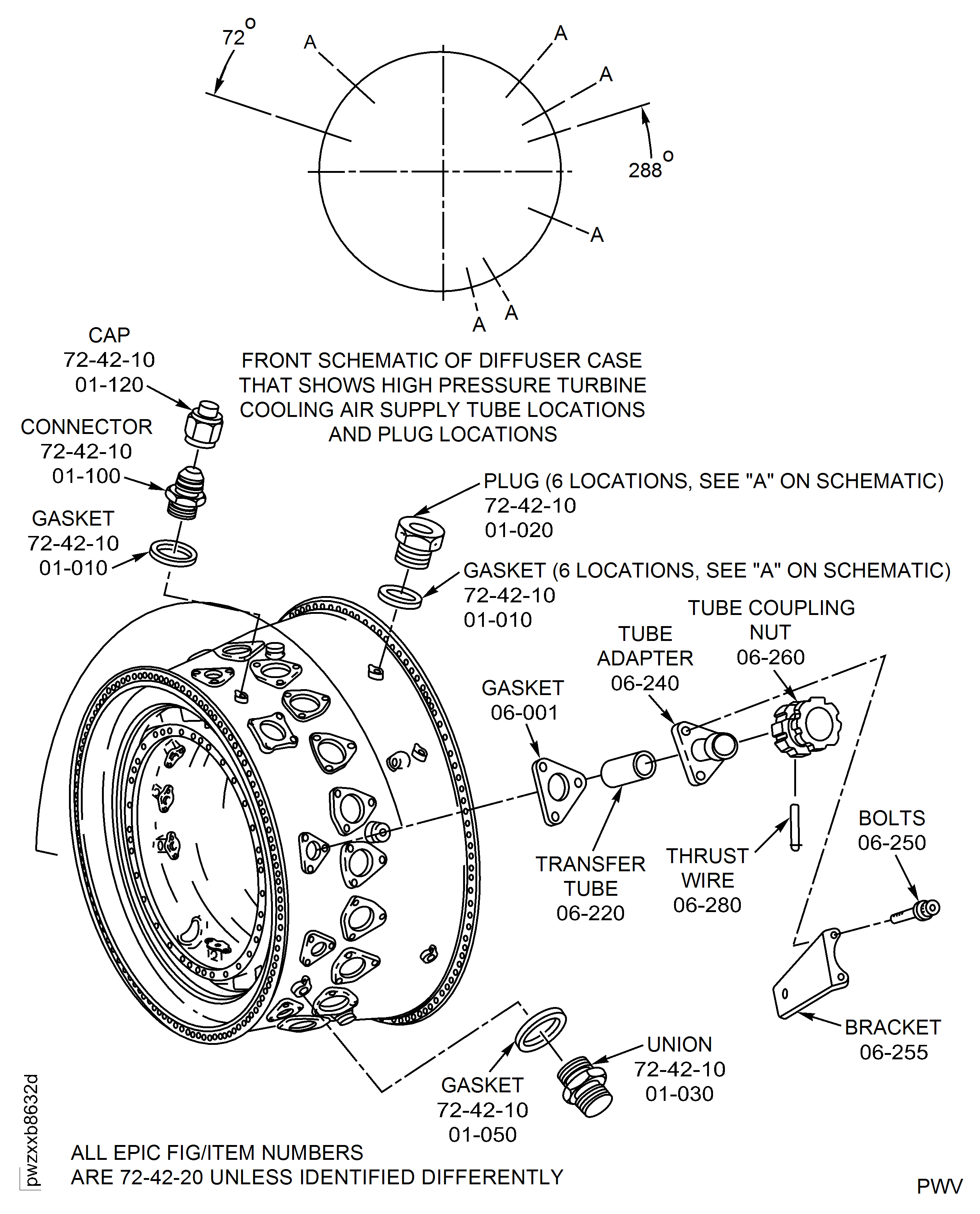

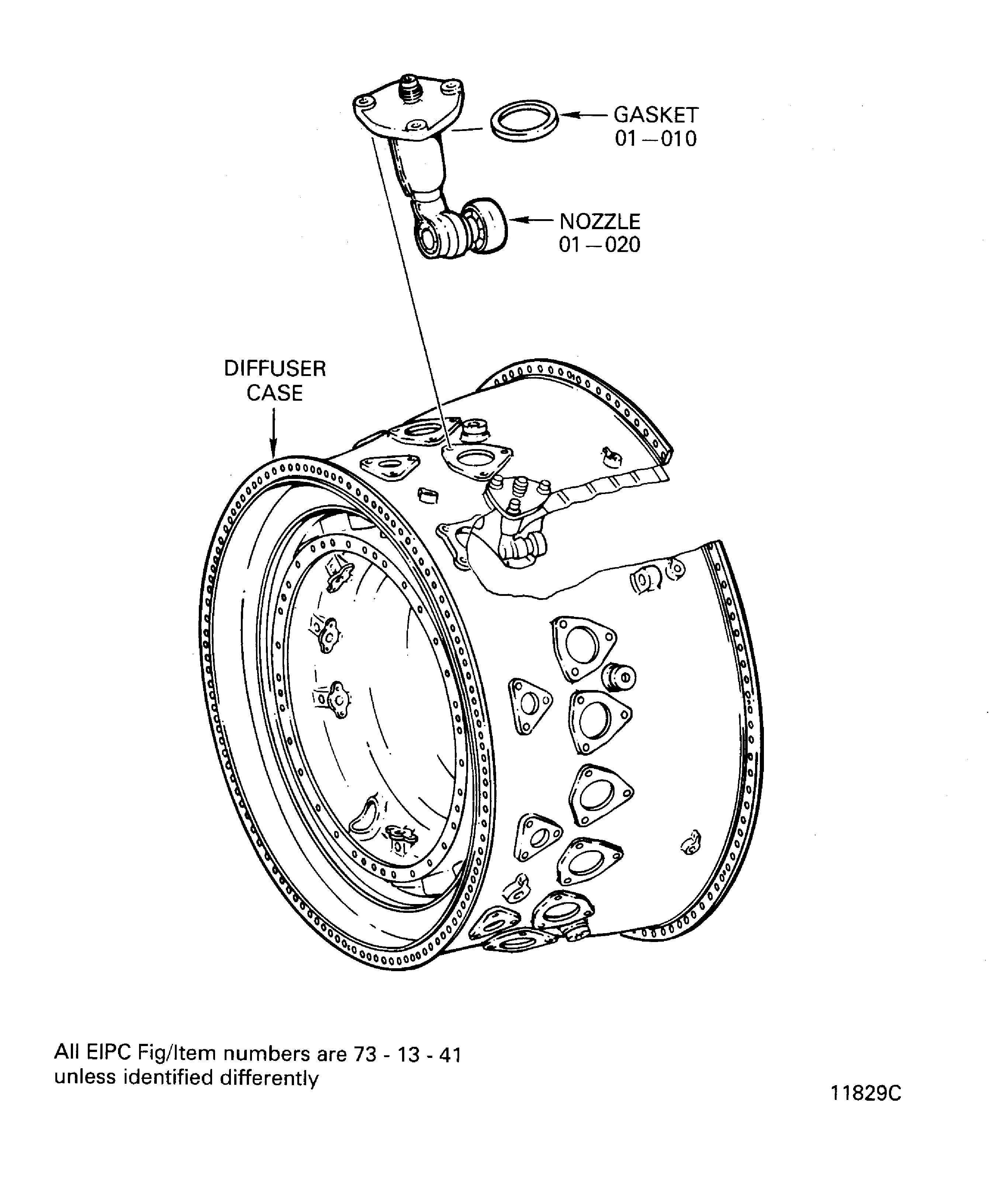

Lubricate the plug Diffuser Case Assembly And Fittings (72-42-10,01-020) threads with CoMat 10-129 ANTI-SEIZE PASTE or CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL.

Install the plugs and the gaskets Diffuser Case Assembly And Fittings (72-42-10,01-010). Wipe off excess paste.

Safety the plugs with CoMat 02-141 LOCKWIRE.

SUBTASK 72-42-00-430-073-A00 V2500-A1: Install the Five Plugs (72-42-10,01-020) and Gaskets (72-42-10,01-010) (Pre SBE 72-0221)

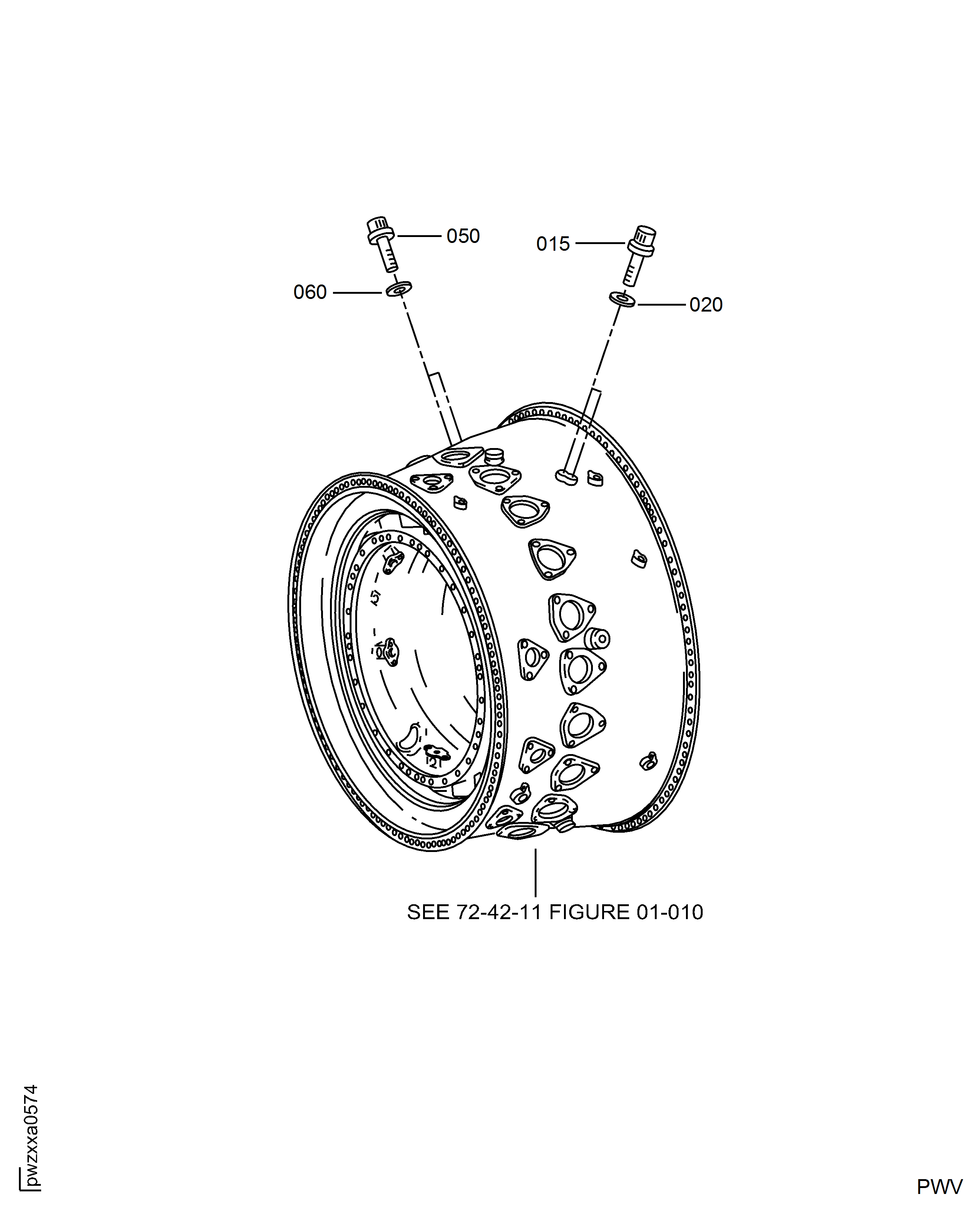

Refer to Figure.

Lubricate the plug Diffuser Case Assembly And Fittings (72-42-10,01-020) threads with CoMat 10-129 ANTI-SEIZE PASTE or CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL.

Install the plugs and the gaskets Diffuser Case Assembly And Fittings (72-42-10,01-010). Wipe off excess paste.

Safety the plugs with CoMat 02-141 LOCKWIRE.

SUBTASK 72-42-00-430-073-B00 V2500-A1: Install the Six Plugs and Gaskets (SBE 72-0221)

Refer to Figure

Lubricate the plug Diffuser Case Assembly And Fittings (72-42-10,01-020) threads with CoMat 10-129 ANTI-SEIZE PASTE or CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL.

Install the plugs and the gaskets Diffuser Case Assembly And Fittings (72-42-10,01-010). Wipe off excess paste.

Safety the plugs with CoMat 02-141 LOCKWIRE.

SUBTASK 72-42-00-430-073-C00 V2500-A5: Install the Six Plugs and Gaskets

Refer to Figure.

Lubricate the bolt ENGINE-ATTACH PARTS & FITTINGS-HP SYSTEM (72-40-00, 06-015/050) threads with CoMat 10-077 APPROVED ENGINE OILS.

Install the bolts and the washers into the Diffuser Case Assembly.

Torque the bolts to 65 lbfin to 85 lbfin (7.344 Nm to 9.603 Nm).

Safety the bolts with CoMat 02-141 LOCKWIRE.

SUBTASK 72-42-00-430-002 Install the Four Bolts (72-40-00, 06-015/050) and Washers (72-40-00, 06-020/060)

Refer to Figure

Install the gasket Diffuser Case Assembly And Fittings (72-42-10,01-010) in the diffuser case boss.

Put the connector Diffuser Case Assembly And Fittings (72-42-10,01-100) in to the boss and tighten it by hand.

Install the cap Diffuser Case Assembly And Fittings (72-42-10, 01-120) on to the connector.

Safety the connector to the boss with CoMat 02-141 LOCKWIRE.

SUBTASK 72-42-00-430-074-A00 V2500-A1: Install the Connector (72-42-10,01-100) and the Cap (72-42-10,01-120) in the Diffuser Case (Pre SBE 72-0221)

Install the gasket Diffuser Case Assembly And Fittings (72-42-10,01-010) in the diffuser case boss.

Put the connector Diffuser Case Assembly And Fittings (72-42-10,01-100) into the boss and tighten it by hand.

Install the cap Diffuser Case Assembly And Fittings (72-42-10,01-120) onto the connector.

Safety the connector to the boss with CoMat 02-141 LOCKWIRE.

SUBTASK 72-42-00-430-074-B00 V2500-A1: Install the Connector and the Cap in the Diffuser Case (SBE 72-0221)

Refer to Figure

Install the gasket Diffuser Case Assembly And Fittings (72-42-10,01-010) in the diffuser case boss.

Put the connector Diffuser Case Assembly And Fittings (72-42-10,01-100) into the boss and tighten it by hand.

Install the cap Diffuser Case Assembly And Fittings (72-42-10,01-120) onto the connector.

Safety the connector to the boss with CoMat 02-141 LOCKWIRE.

SUBTASK 72-42-00-430-074-C00 V2500-A5: Install the Connector and the Cap in the Diffuser Case

Refer to Figure

Install the gasket Diffuser Case Assembly And Fittings (72-42-10,01-050) to the union Diffuser Case Assembly And Fittings (72-42-10,01-030) and install to the boss on the diffuser case.

CAUTION

WHEN YOU USE AN EXTENSION ON A TORQUE WRENCH, THE ACTUAL TORQUE READING WILL BE LESS THAN THE TORQUE GIVEN BELOW. REFER TO THE SPM TASK 70-41-01-400-501.Torque the union to 478 lbfin to 522 lbfin (54 Nm to 59 Nm).

SUBTASK 72-42-00-430-080-A00 V2500-A1: Install the Union and Gasket (Pre SBE 72-0221)

Install the gasket Diffuser Case Assembly And Fittings (72-42-10,01-050) to the union Diffuser Case Assembly And Fittings (72-42-10,01-030) and install to the boss on the diffuser case.

CAUTION

WHEN YOU USE AN EXTENSION ON A TORQUE WRENCH, THE ACTUAL TORQUE WRENCH READING WILL BE LESS THAN THE TORQUE GIVEN BELOW. REFER TO TASK 70-41-01-400-501.Torque the union to 478 lbfin to 522 lbfin (54 Nm to 59 Nm).

SUBTASK 72-42-00-430-080-B00 V2500-A1: Install the Union and the Gasket (SBE 72-0221)

Refer to Figure

Install the gasket Diffuser Case Assembly And Fittings (72-42-10,01-050) to the union Diffuser Case Assembly And Fittings (72-42-10,01-030) and install to the boss on the diffuser case.

CAUTION

WHEN YOU USE AN EXTENSION ON A TORQUE WRENCH, THE ACTUAL TORQUE WRENCH READING WILL BE LESS THAN THE TORQUE GIVEN BELOW. REFER TO TASK 70-41-01-400-501.Torque the union to 478 lbfin to 522 lbfin (54 Nm to 59 Nm).

SUBTASK 72-42-00-430-080-C00 V2500-A5: Install the Union and Gasket

Refer to Figure.

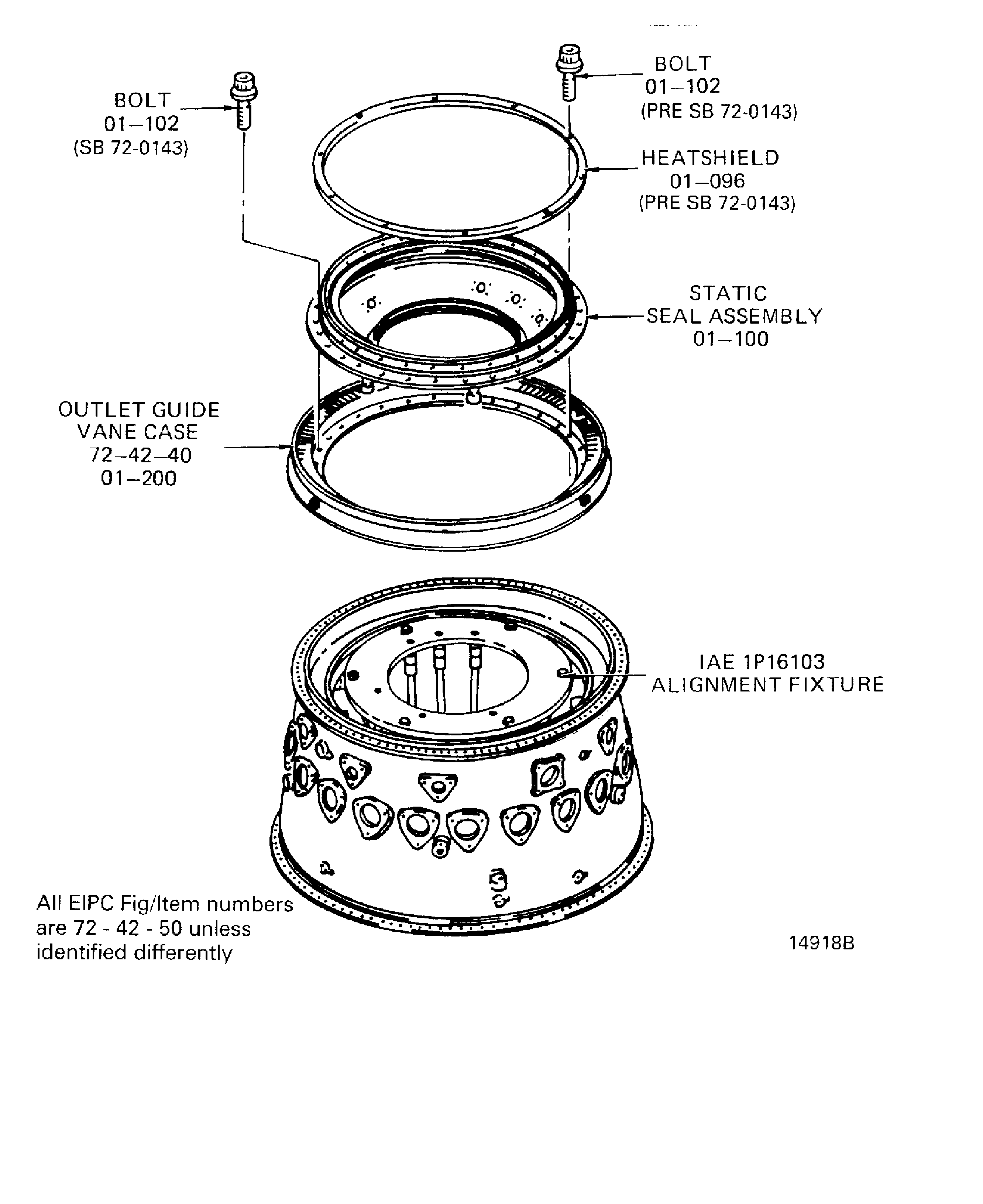

Locate the inner diameter of bolthole flange inside the diffuser case. It will have 30, silver plated, self locking, clinch nuts attached below the flange.

Locate the offset hole in the inner diameter of bolthole flange, which is 185 degrees clockwise from the dowel pin on the outer diameter front flange of the diffuser case.

Mark the offset hole location on the diffuser case, rear seal assembly and outlet guide vane case.

Chill outlet guide vane case in dry ice for 25 minutes or more to sufficiently assemble the outlet guide vane to the exit stator.

If repair, VRS6233 TASK 72-42-40-300-004 (REPAIR-004) was done, visually examine the coat surface.

Visually examine the diffuser and combustion group internally and externally for safety of details, no damage and no foreign material with particular attention to the mating surfaces.

CAUTION

DO NOT ROTATE STAND FULLY AROUND BECAUSE THE DIFFUSER WILL HIT THE FLOOR.Position diffuser case by rotating IAE 1P16005 Build stand 1 off as necessary to place case with larger outer diameter flange down towards the floor, but without hitting the floor.

Install IAE 1P16231 Alignment pin 2 off in the diffuser case 180 degrees apart.

Remove outlet guide vane case from dry ice.

Install six of the bolts ENGINE-STATIC SEAL (72-42-50,01-102) at equal distances around the Outlet Guide Vane (OGV) case.

Do Step again until the Outlet Guide Vane (OGV) case is fully installed.

Turn each bolt one turn in sequence to pull the Outlet Guide Vane (OGV) case down equally.

Install the outlet guide vane case ENGINE-HP COMPRESSOR EXIT STATOR (72-42-40,01-200).

Remove all of the offset markings that are there before.

Install six of the bolts ENGINE-STATIC SEAL (72-42-50,01-102) at equal distances around the static seal assembly.

Do Step again until the static seal assembly is fully installed.

Remove the alignment pins.

Install the static seal assembly ENGINE-STATIC SEAL (72-42-50,01-100).

Install 20 of the remaining 24 bolts ENGINE-STATIC SEAL (72-42-50,01-102) through the seal assembly and outlet guide vane case, in to the diffuser case. Install the 20 bolts by hand and start with the off-set hole. Do not install every third bolt after the off-set hole. Torque the bolts to 85 lbfin to 105 lbfin (10.0 Nm to 12.0 Nm).

Install the heatshield ENGINE-STATIC SEAL (72-42-50,01-096).

SUBTASK 72-42-00-430-060-A00 V2500-A1: Install the Outlet Guide Vane (OGV) Case, the Static Seal Assembly and the Heatshield (Pre SBE 72-0143 and Pre SBE 72-0221)

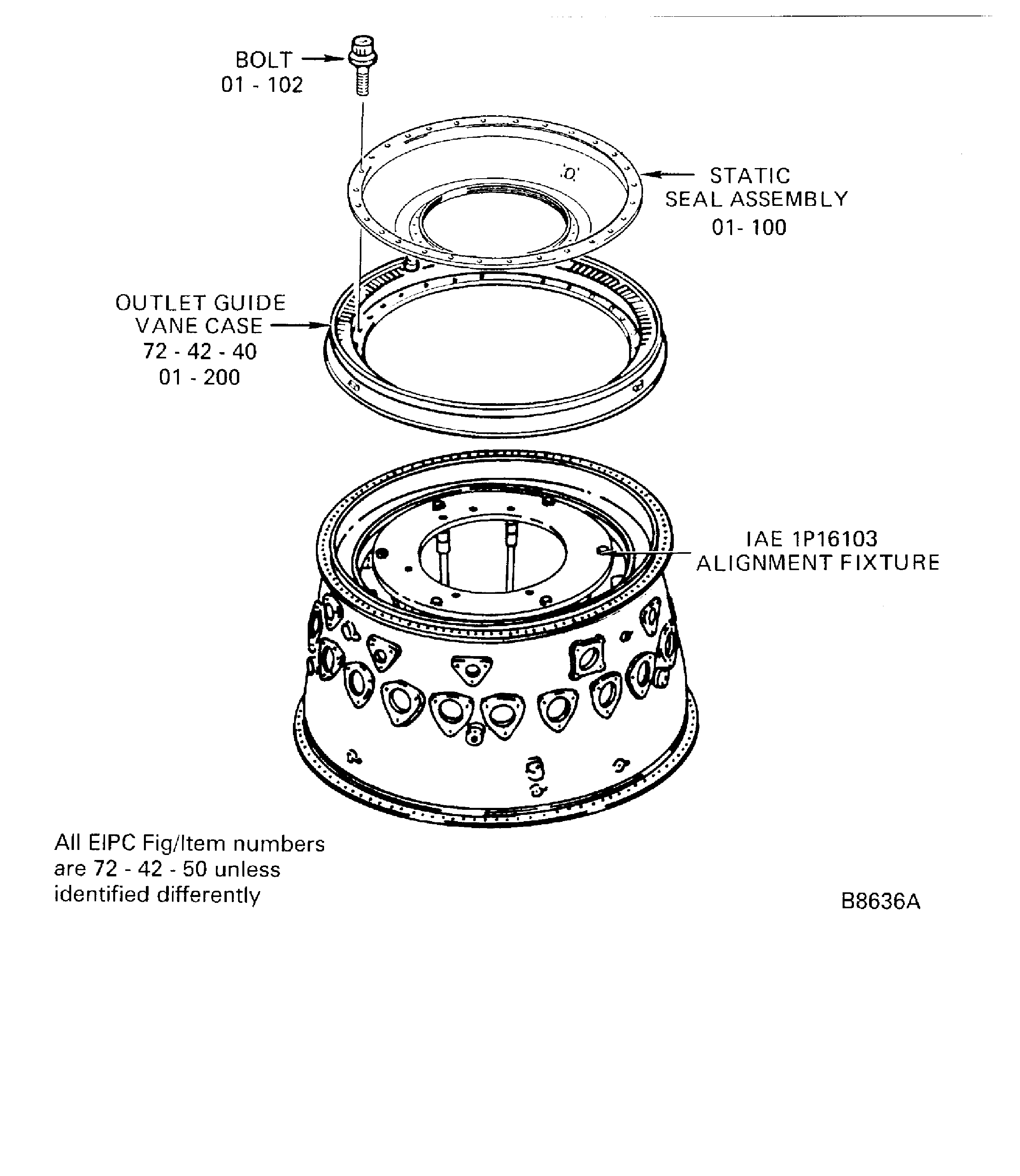

Locate the inner diameter of bolthole flange inside the diffuser case. It will have 30, silver plated, self locking, clinch nuts on it's below side.

Locate the offset hole in the inner diameter of bolthole flange, which is 185 degrees clockwise from the dowel pin on the outer diameter front flange of the diffuser case.

Mark the offset hole location on the diffuser case, rear seal assembly and outlet guide vane case.

Chill outlet guide vane case in dry ice for 25 minutes or more to sufficiently assemble the outlet guide vane to the exit stator.

If repair, VRS6233 TASK 72-42-40-300-004 (REPAIR-004) was done, visually examine the coat surface.

Visually examine the diffuser and combustion group internally and externally for safety of details, no damage and no foreign material with particular attention to the mating surfaces.

CAUTION

DO NOT ROTATE STAND FULLY AROUND BECAUSE THE DIFFUSER WILL HIT THE FLOOR.Position diffuser case by rotating IAE 1P16005 Build stand 1 off as necessary to place case with larger outer diameter flange down towards the floor, but without hitting the floor.

Install IAE 1P16231 Alignment pin 2 off in the diffuser case 180 degrees apart.

Remove outlet guide vane case from dry ice.

Install six of the bolts ENGINE-STATIC SEAL (72-42-50,01-102) at equal distances around the outlet guide vane case.

Do Step again until the outlet guide vane case is fully installed.

Turn each bolt one turn in sequence to pull the outlet guide vane case down equally.

Install the outlet guide vane case ENGINE-HP COMPRESSOR EXIT STATOR (72-42-40,01-200).

Remove all of the offset markings that are there before.

Install six of the bolts ENGINE-STATIC SEAL (72-42-50,01-102) at equal distances around the static seal assembly.

Do Step again until the static seal assembly is fully installed.

Remove the alignment pins.

Install the static seal assembly ENGINE-STATIC SEAL (72-42-50,01-100).

Install the remaining 24 bolts ENGINE-STATIC SEAL (72-42-50,01-102) through the seal assembly and outlet guide vane case and into the diffuser case. Torque the bolts to 85 lbfin to 105 lbfin (10.0 Nm to 12.0 Nm).

SUBTASK 72-42-00-430-060-B00 V2500-A1: Install the Outlet Guide Vane (OGV) Case and the Static Seal Assembly (SBE 72-0143 and SBE 72-0221)

Refer to Figure.

Locate the inner diameter of bolthole flange inside the diffuser case. It will have 30, silver plated, self locking, clinch nuts on it's below side.

Locate the offset hole in the inner diameter of bolthole flange, which is 185 degrees clockwise from the dowel pin on the outer diameter front flange of the diffuser case.

Mark the offset hole location on the diffuser case, rear seal assembly and outlet guide vane case.

Chill outlet guide vane case in dry ice for 25 minutes or more to sufficiently assemble the outlet guide vane to the exit stator.

If repair, VRS6233 TASK 72-42-40-300-004 (REPAIR-004) was done, visually examine the coat surface.

Visually examine the diffuser and combustion group internally and externally for safety of details, no damage and no foreign material with particular attention to the mating surfaces.

CAUTION

DO NOT ROTATE STAND FULLY AROUND BECAUSE THE DIFFUSER WILL HIT THE FLOOR.Position diffuser case by rotating IAE 1P16005 Build stand as necessary to place case with larger outer diameter flange down towards the floor, but without hitting the floor.

Install IAE 1P16231 Alignment pin in the diffuser case 180 degrees apart.

Remove outlet guide vane case from dry ice.

Install six of the bolts ENGINE-STATIC SEAL (72-42-50,01-102) at equal distances around the outlet guide vane case.

Do Step again until the outlet guide vane case is fully installed.

Turn each bolt one turn in sequence to pull the outlet guide vane case down equally.

Install the outlet guide vane case ENGINE-HP COMPRESSOR EXIT STATOR (72-42-40,01-200).

Remove all of the offset markings that are there before.

Install six of the bolts ENGINE-STATIC SEAL (72-42-50,01-102) at equal distances around the static seal assembly.

Do Step again until the static seal assembly is fully installed.

Remove the alignment pins.

Install the static seal assembly ENGINE-STATIC SEAL (72-42-50,01-100).

Install the remaining 24 bolts ENGINE-STATIC SEAL (72-42-50,01-102) through the seal assembly and outlet guide vane case and into the diffuser case. Torque the bolts 85 lbfin to 105 lbfin (10.0 Nm to 12.0 Nm).

SUBTASK 72-42-00-430-060-C00 V2500-A5: Install the Outlet Guide Vane (OGV) Case and the Static Seal Assembly

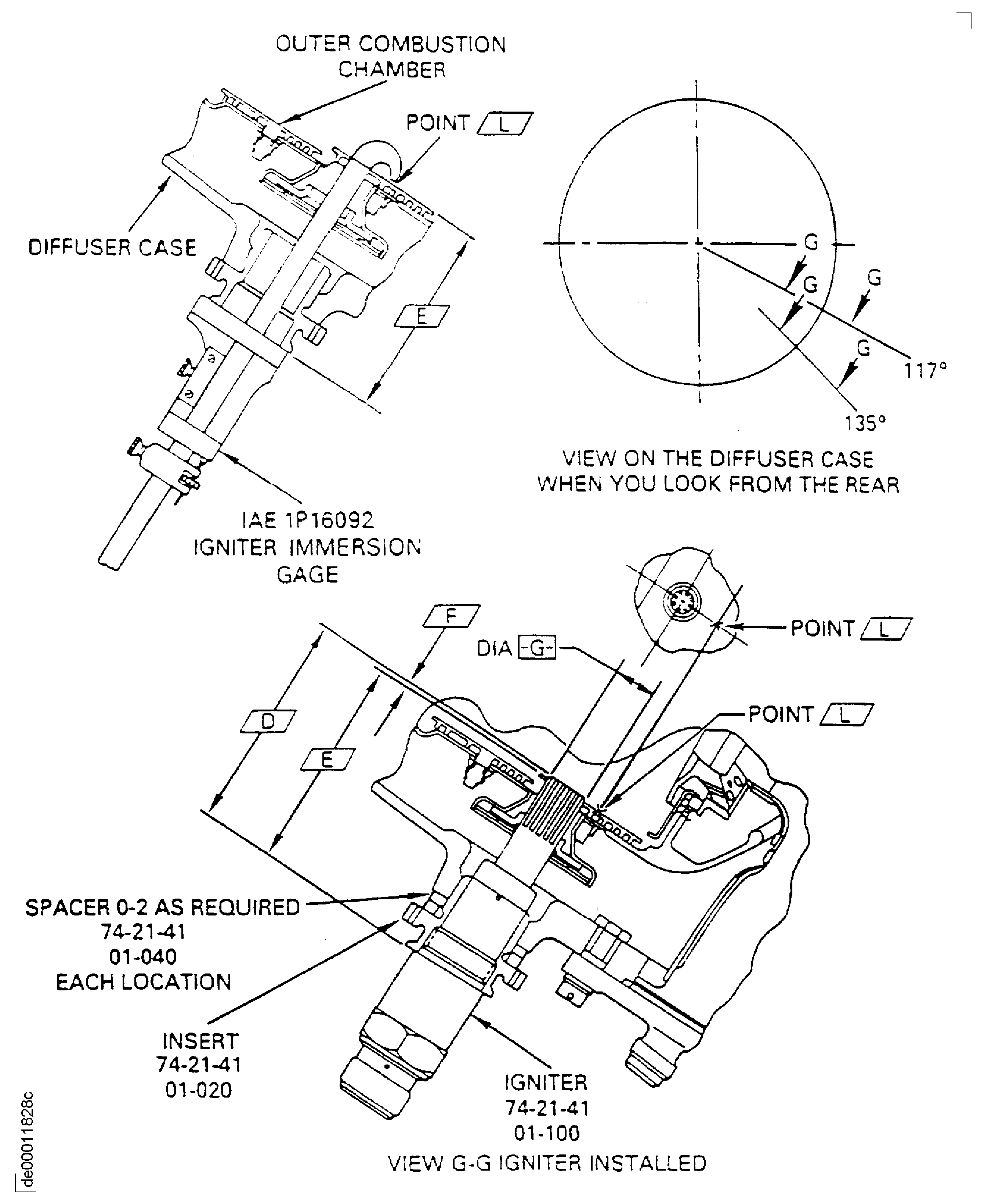

Refer to Figure.

CAUTION

APPLY ANTI-SEIZE PASTE OR ANTI-SEIZE LUBRICANT MODERATELY TO THE IGNITER THREAD. DO NOT APPLY TOO MUCH ANTI-SEIZE PASTE OR LUBRICANT, AS IT CAN GO INTO THE ENGINE.Apply CoMat 10-129 ANTI-SEIZE PASTE or CoMat 10-109 HIGH TEMPERATURE ANTI-SEIZELUBRICANT to the igniter threaded insert. Remove all unwanted compound.

Install the threaded inserts Igniter Plug (74-21-41,01-020) in the diffuser case until the bottom of the flange of the threaded inserts touches the diffuser case.

Measure the distance E from the top of the inserts to the point L on the outer combustion chamber nearest the fuel nozzle. Use the IAE 1P16092 Igniter immersion gage 1 off.

Use initial immersion depth F and (if required) one or two classified spacers Igniter Plug (74-21-41, 01-040) to get an immersion depth of 0.040 to 0.080 in. (1.02 to 2.03 mm). A maximum of two spacers may be used at each igniter location. Total thickness of the two spacers must not be more than 0.300 in. (7.62 mm).

CAUTION

APPLY ANTI-SEIZE PASTE OR ANTI-SEIZE LUBRICANT MODERATELY TO THE PLUG THREAD. YOU MUST NOT APPLY TOO MUCH PASTE OR ANTI-SEIZE LUBRICANT, AS IT CAN GO IN TO THE ENGINE.Apply CoMat 10-109 HIGH TEMPERATURE ANTI-SEIZELUBRICANT or CoMat 10-129 ANTI-SEIZE PASTE to the plug thread.

SUBTASK 72-42-00-430-061 Install the Igniter Plugs

NOTE

For the location of the igniter plugs on the diffuser case see view G-G (two places on Figure.).Refer to Figure.

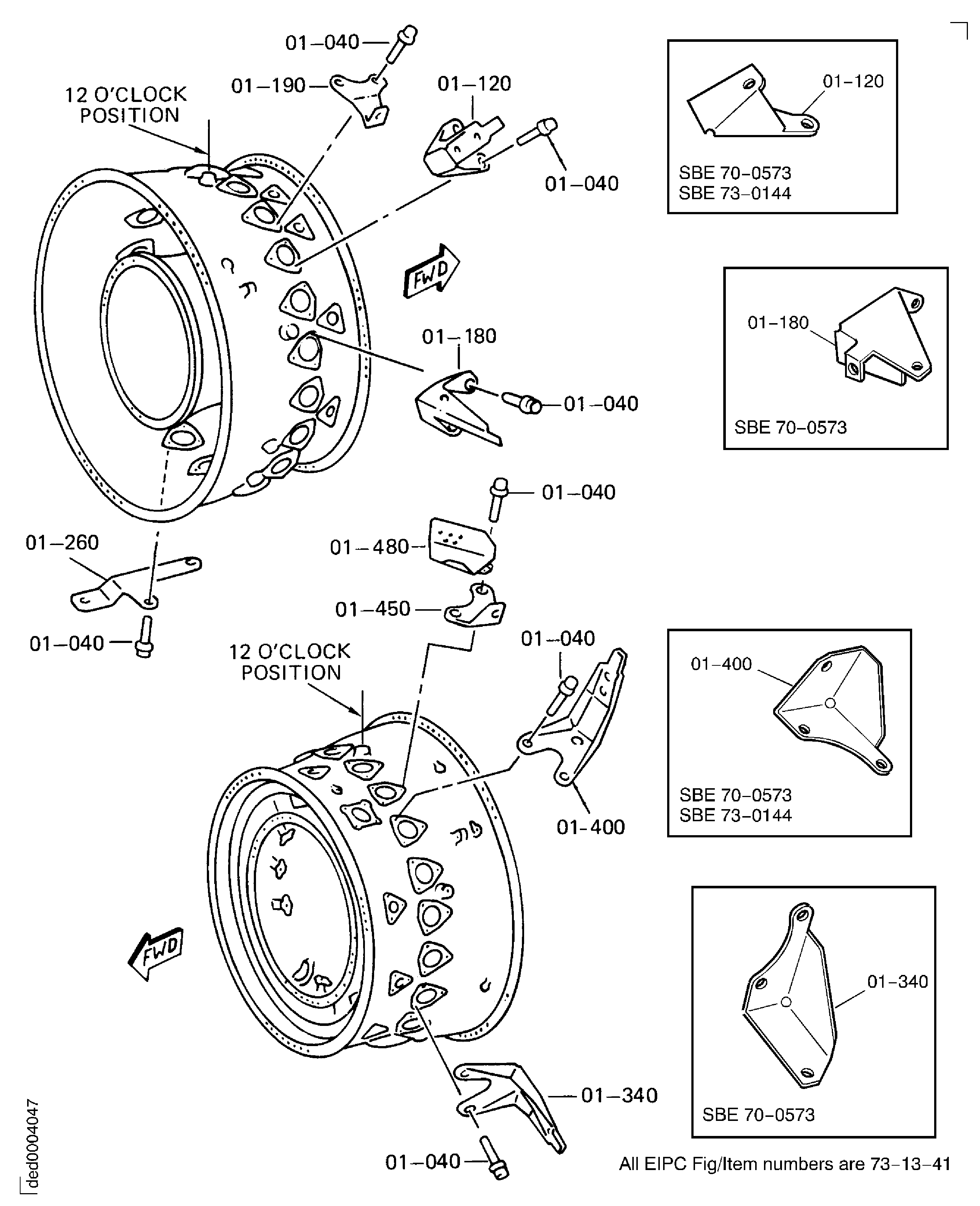

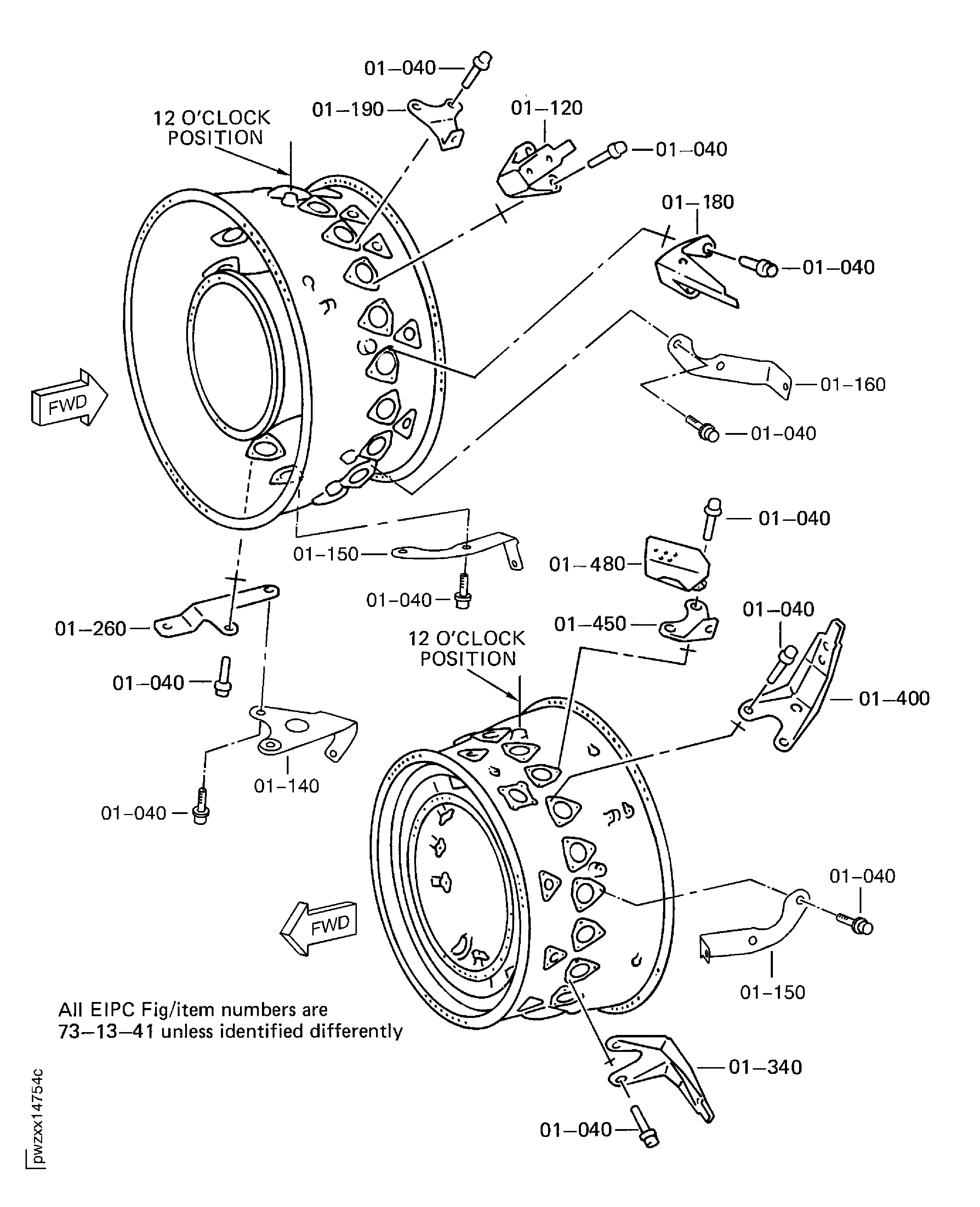

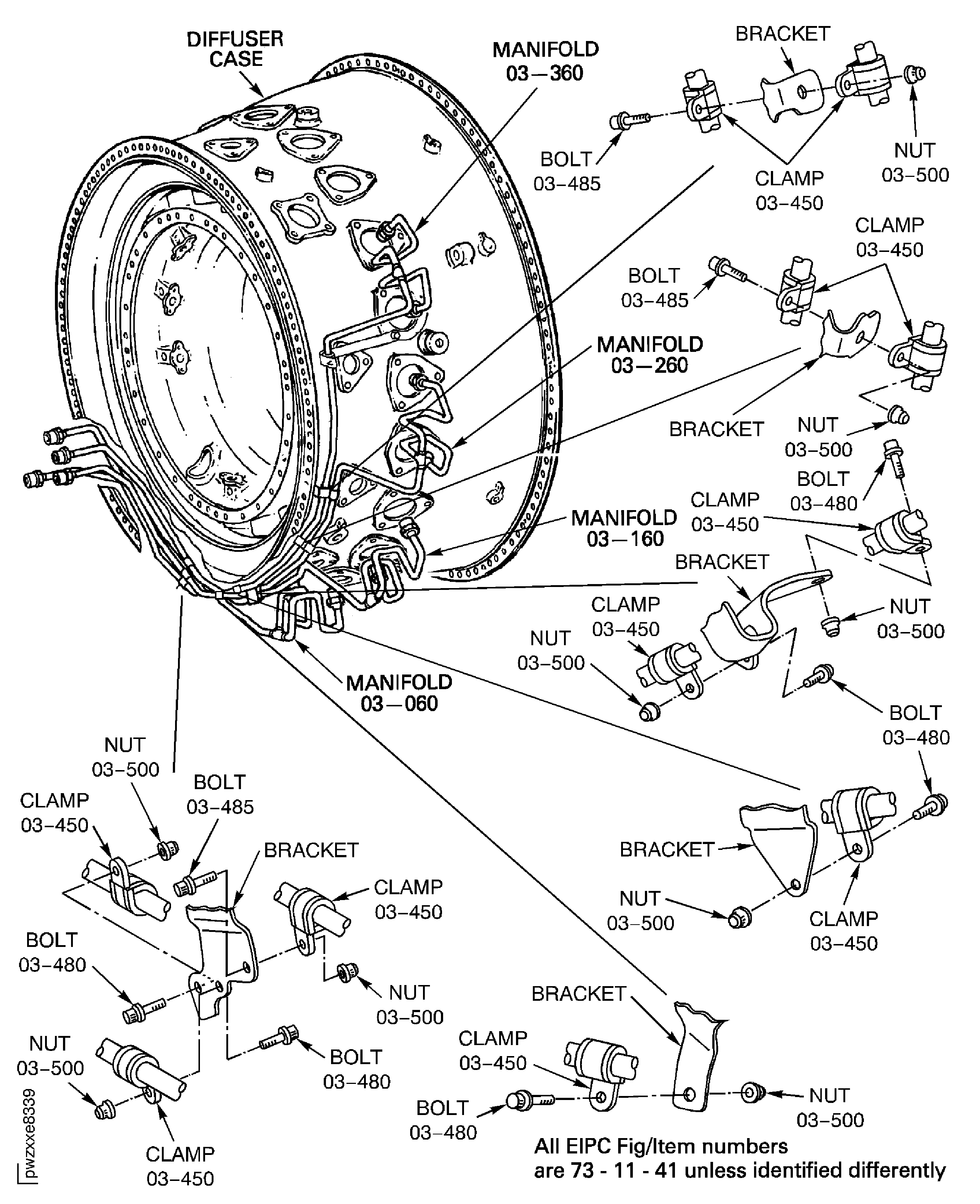

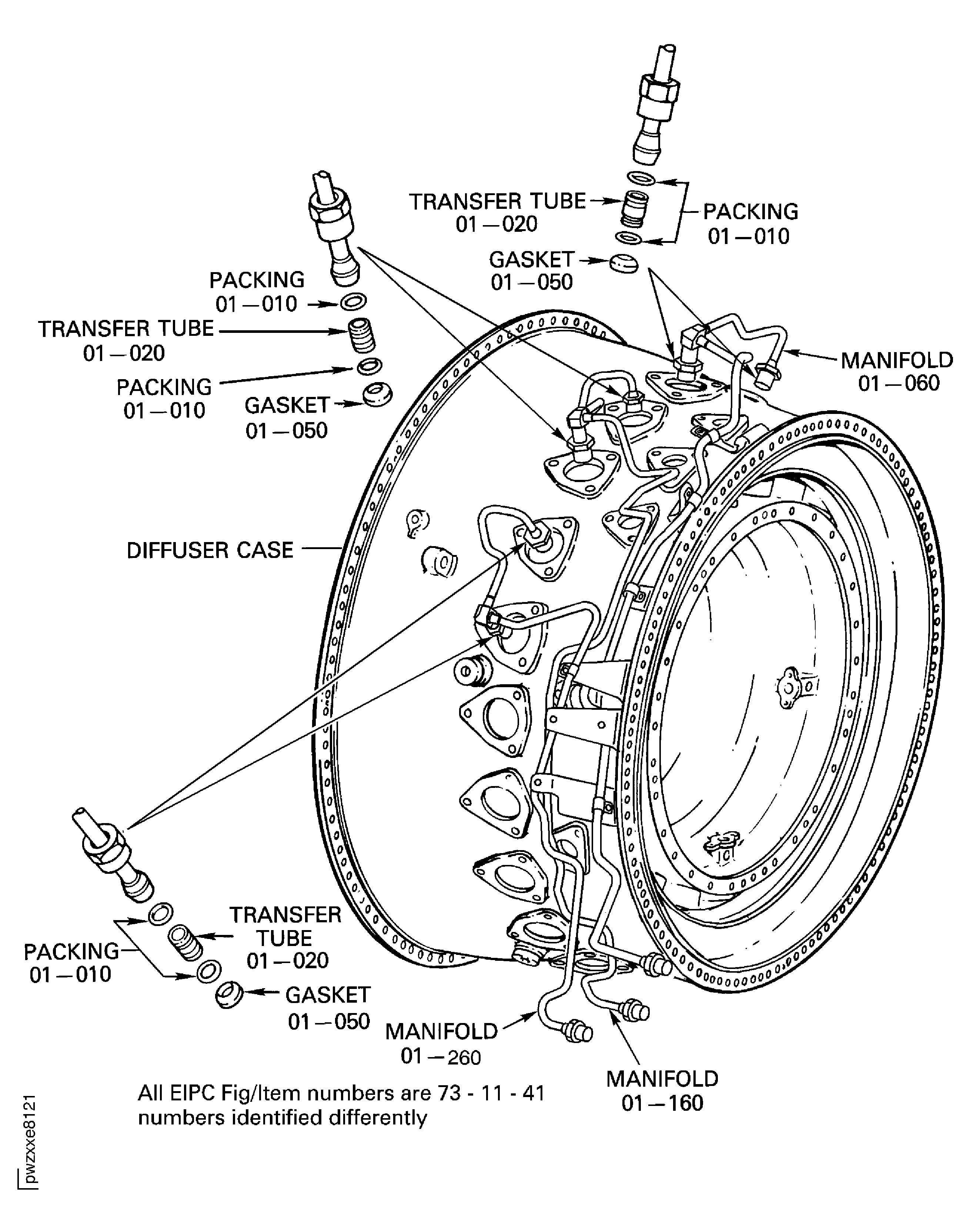

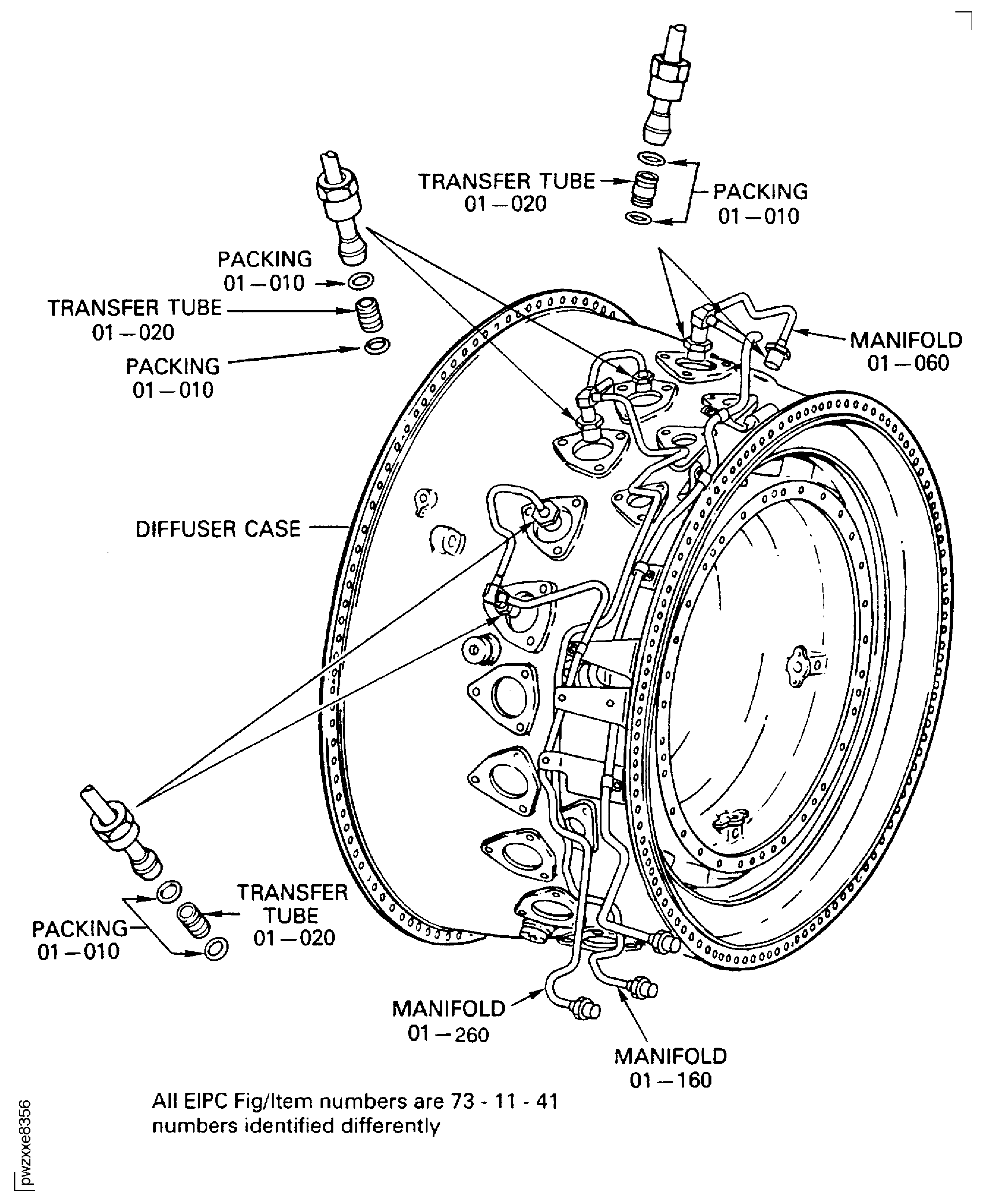

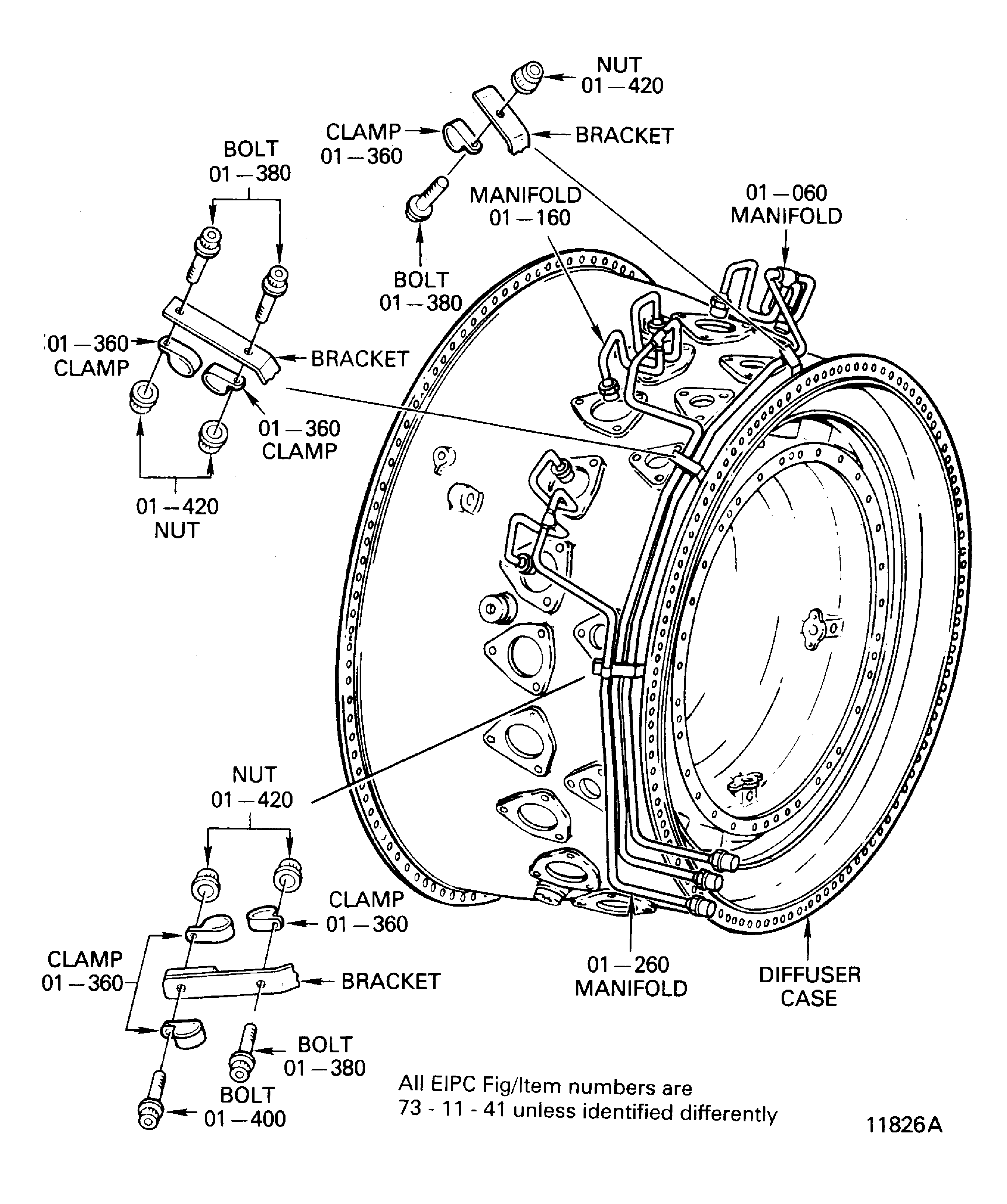

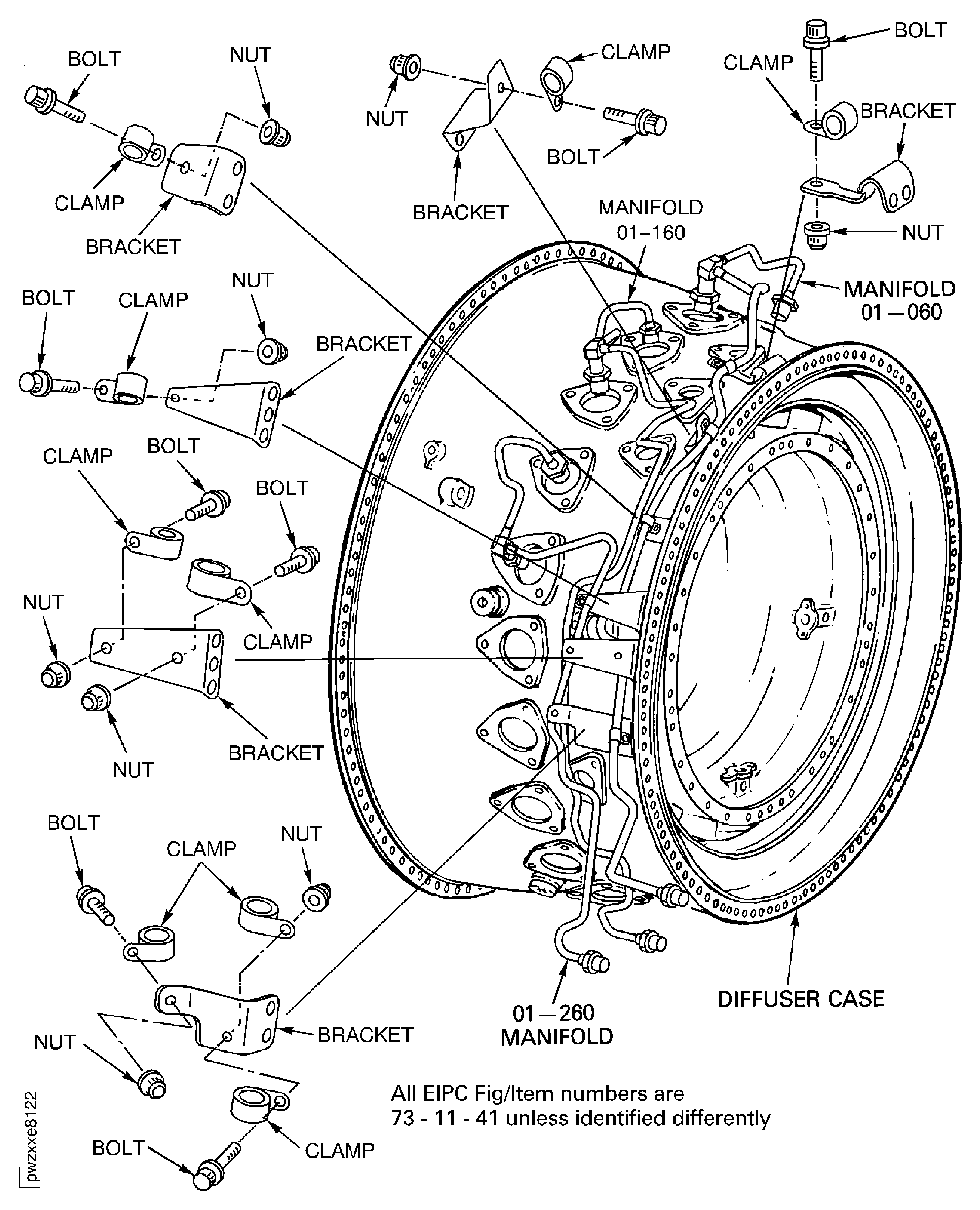

Install Fuel Nozzle And Support Assembly (73-13-41,01-010) gaskets 20 off in to the recesses on the diffuser case. Use CoMat 01-573 WAX BLEND, PARAFFIN to hold the gaskets in place.

Install the 20 fuel nozzles Fuel Nozzle And Support Assembly (73-13-41,01-020).

Install the brackets Fuel Nozzle And Support Assembly (73-13-41,01-120), Fuel Nozzle And Support Assembly (73-13-41,01-180), Fuel Nozzle And Support Assembly (73-13-41,01-190), Fuel Nozzle And Support Assembly (73-13-41,01-260), Fuel Nozzle And Support Assembly (73-13-41,01-340), Fuel Nozzle And Support Assembly (73-13-41,01-400), Fuel Nozzle And Support Assembly (73-13-41,01-450) and Fuel Nozzle And Support Assembly (73-13-41,01-480) on the fuel nozzles. Attach the fuel nozzles and the fuel nozzles and brackets with the 60 bolts Fuel Nozzle And Support Assembly (73-13-41,01-040).

Torque the bolts to 65 lbfin to 85 lbfin (7.3 Nm to 9.6 Nm). Safety the bolts with CoMat 02-141 LOCKWIRE. Safety the fuel nozzles to the doweled end bolts with CoMat 02-141 LOCKWIRE. Safety the igniter plug threaded inserts to bolt on adjacent fuel nozzles with the lockwire.

SUBTASK 72-42-00-430-062-A00 Install the 20 Fuel Nozzles (Pre SBE 73-0147)

Install Fuel Nozzle And Support Assembly (73-13-41,01-010) gaskets 20 off in to the recesses on the diffuser case. Use CoMat 01-573 WAX BLEND, PARAFFIN to hold the gaskets in place.

Install the 20 fuel nozzles Fuel Nozzle And Support Assembly (73-13-41,01-020).

Install the brackets Fuel Nozzle And Support Assembly (73-13-41,01-120), Fuel Nozzle And Support Assembly (73-13-41,01-140), Fuel Nozzle And Support Assembly (73-13-41,01-150), Fuel Nozzle And Support Assembly (73-13-41,01-160), Fuel Nozzle And Support Assembly (73-13-41,01-180), Fuel Nozzle And Support Assembly (73-13-41,01-190), Fuel Nozzle And Support Assembly (73-13-41,01-260), Fuel Nozzle And Support Assembly (73-13-41,01-340), Fuel Nozzle And Support Assembly (73-13-41,01-400), Fuel Nozzle And Support Assembly (73-13-41,01-450), Fuel Nozzle And Support Assembly (73-13-41,01-480) and Fuel Nozzle Supply Fuel Manifolds (73-11-41,01-165) on the fuel nozzles. Attach the fuel nozzles and the fuel nozzles and brackets with the 60 bolts Fuel Nozzle And Support Assembly (73-13-41,01-040).

Torque the bolts to 65 lbfin to 85 lbfin (7.3 Nm to 9.6 Nm). Safety the bolts with CoMat 02-141 LOCKWIRE. Safety the fuel nozzles to the doweled end bolts with CoMat 02-141 LOCKWIRE. Safety the igniter plug threaded inserts to bolt on adjacent fuel nozzles with the lockwire.

SUBTASK 72-42-00-430-062-B00 Install the 20 Fuel Nozzles (SBE 73-0147)

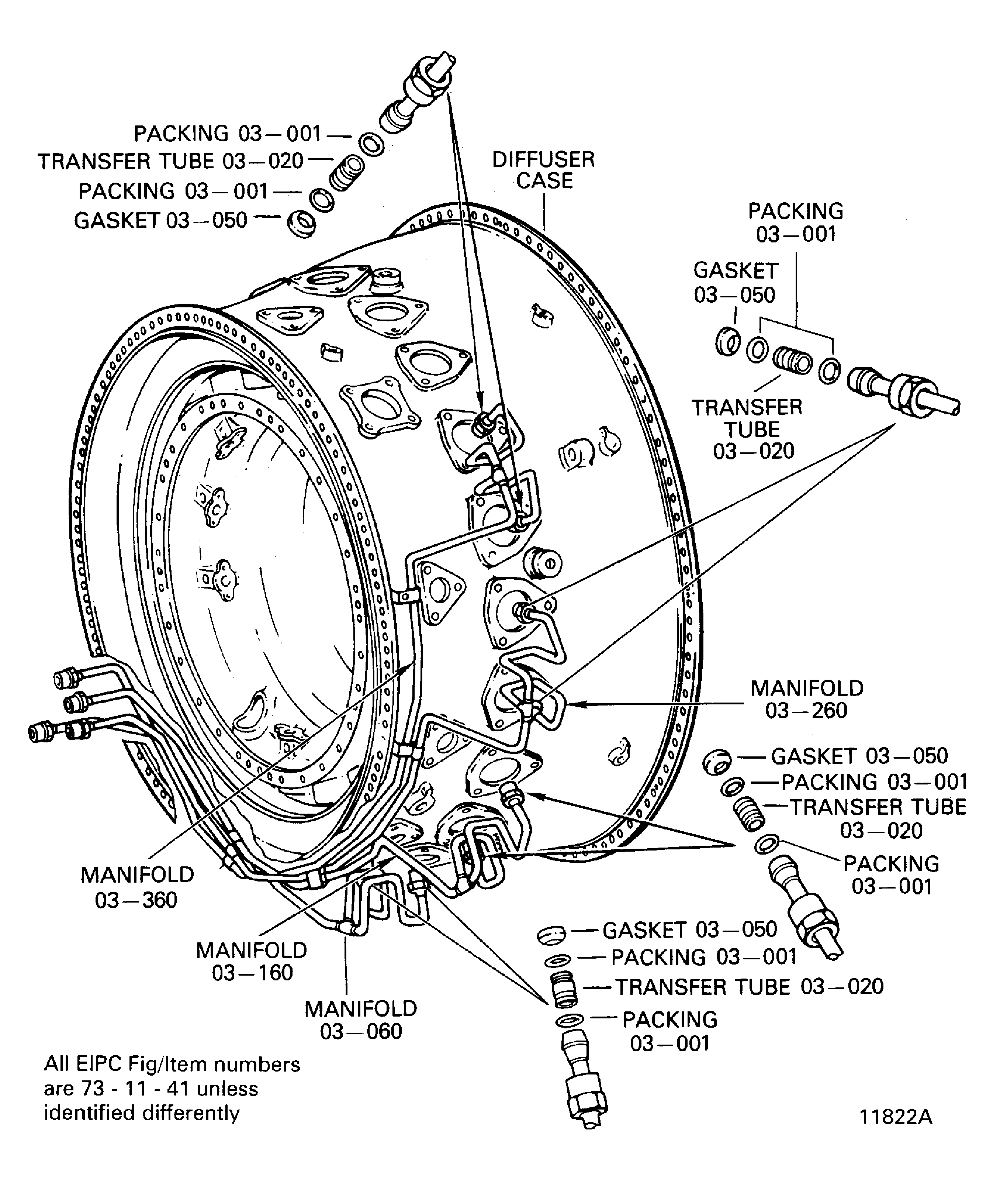

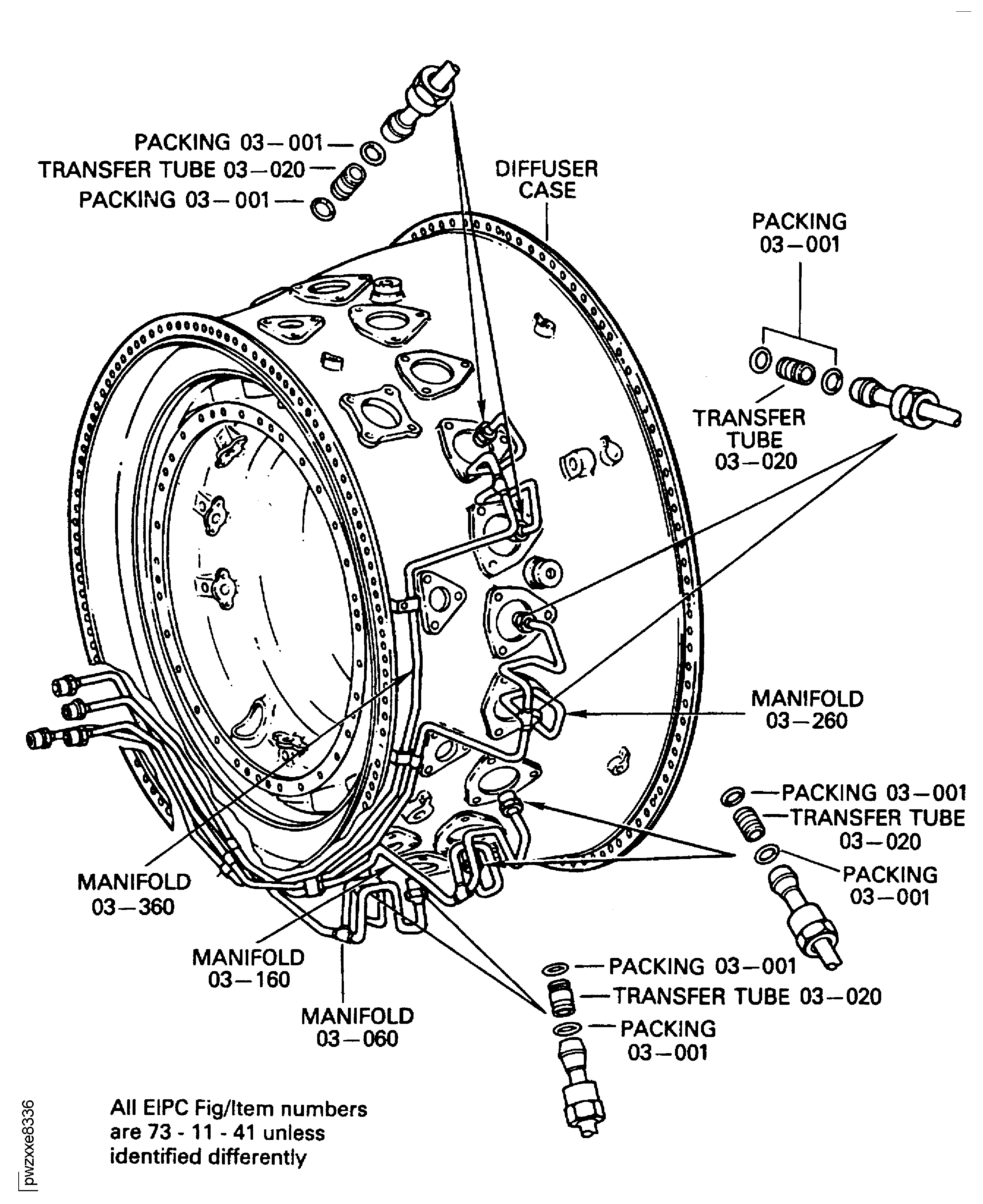

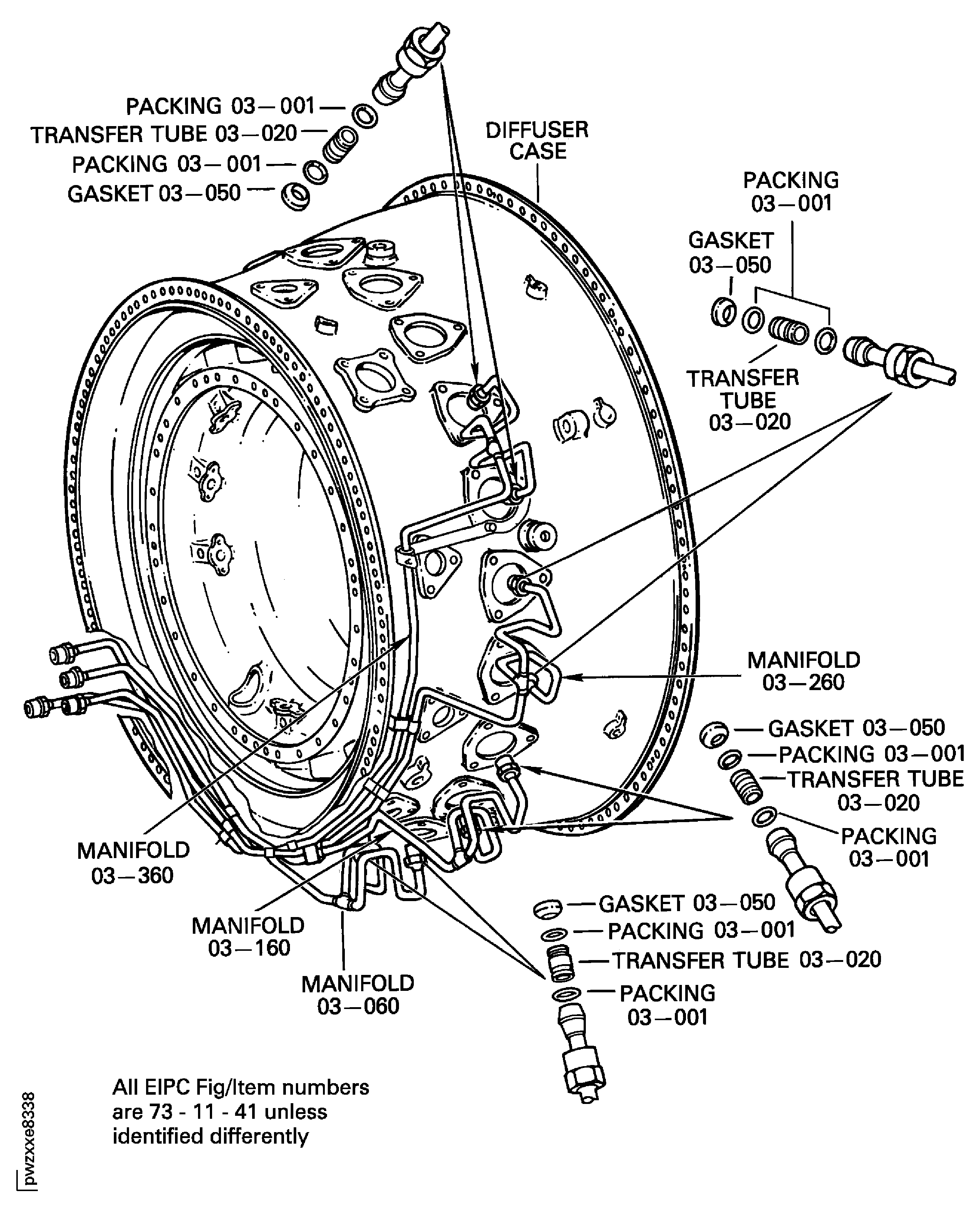

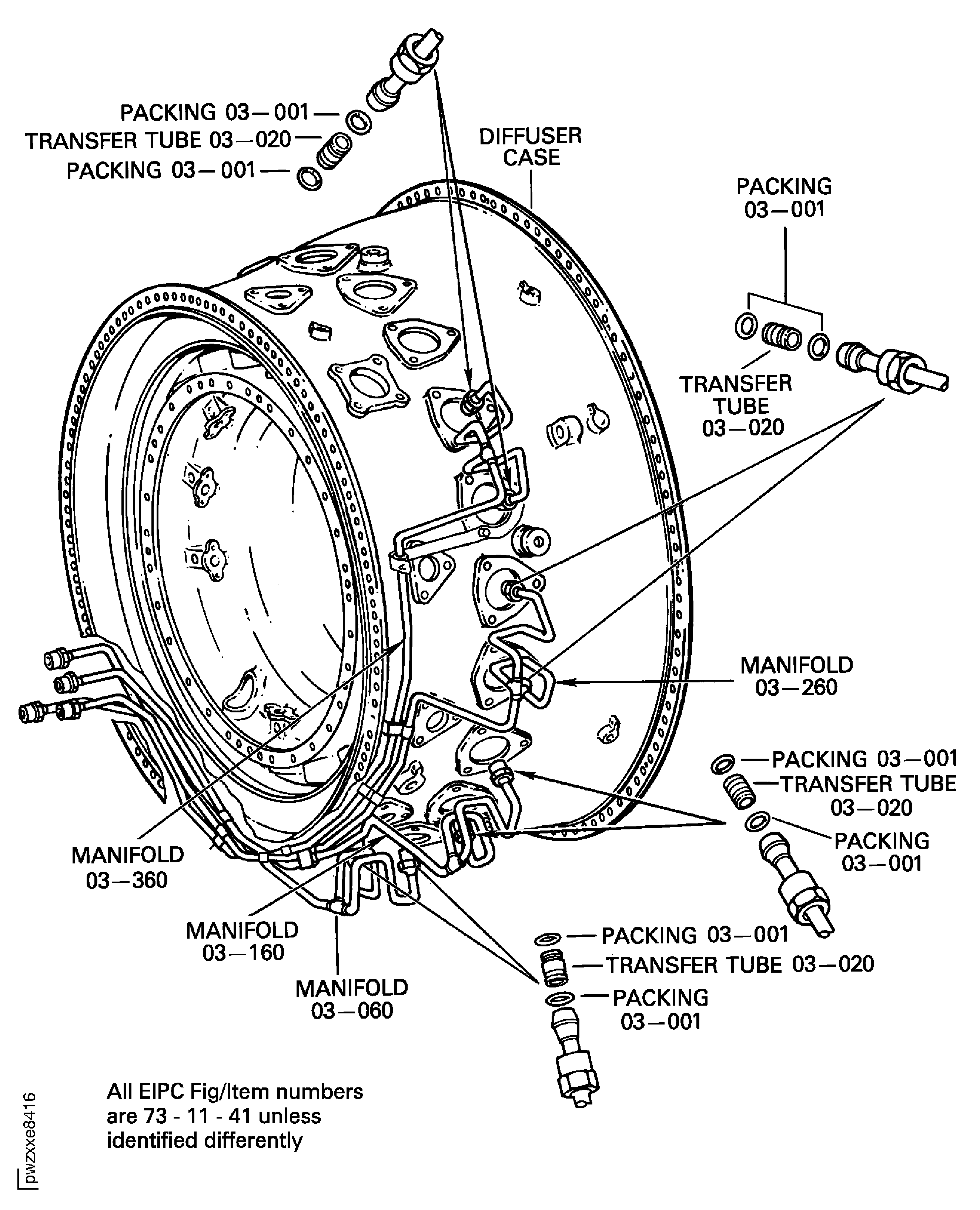

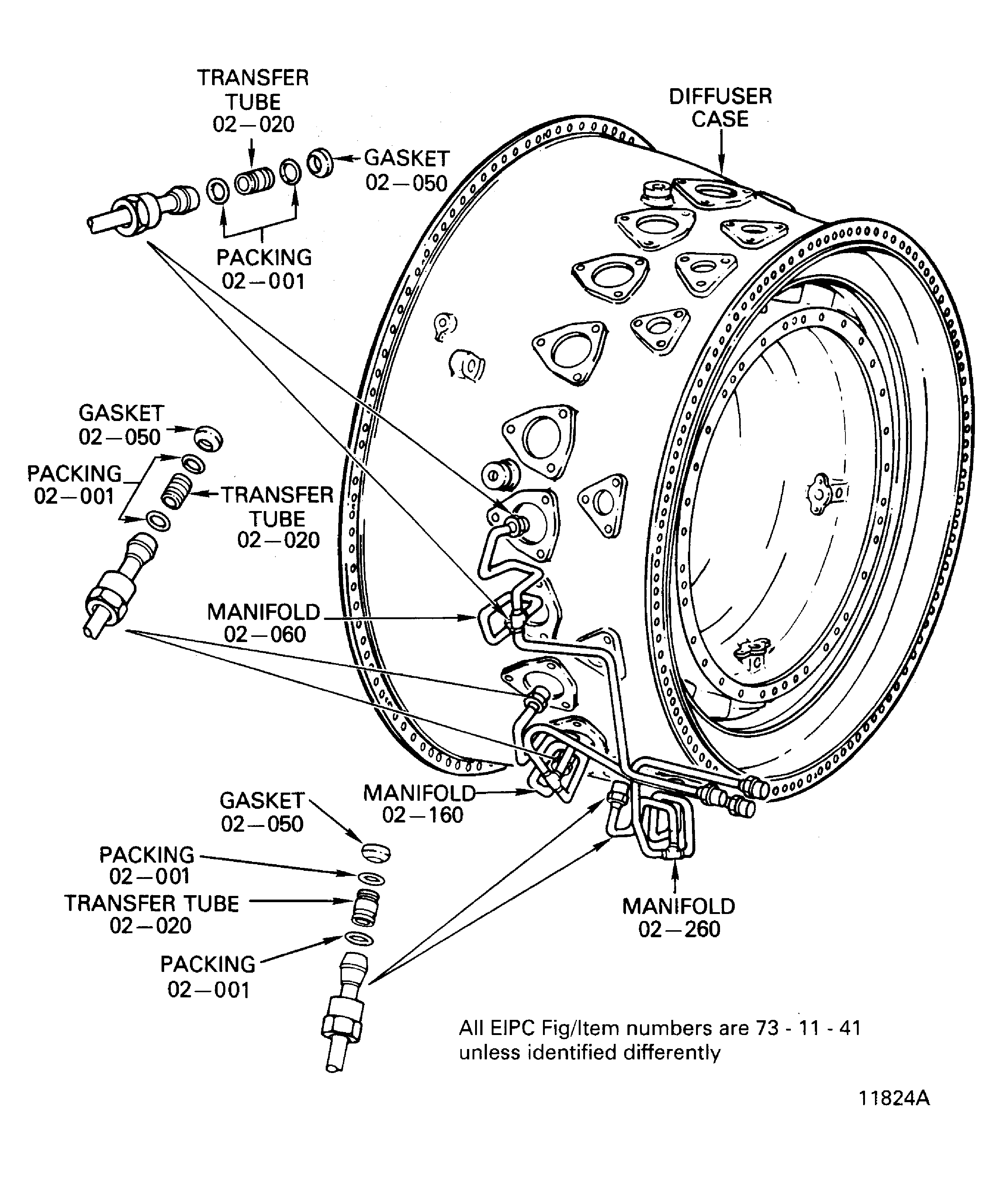

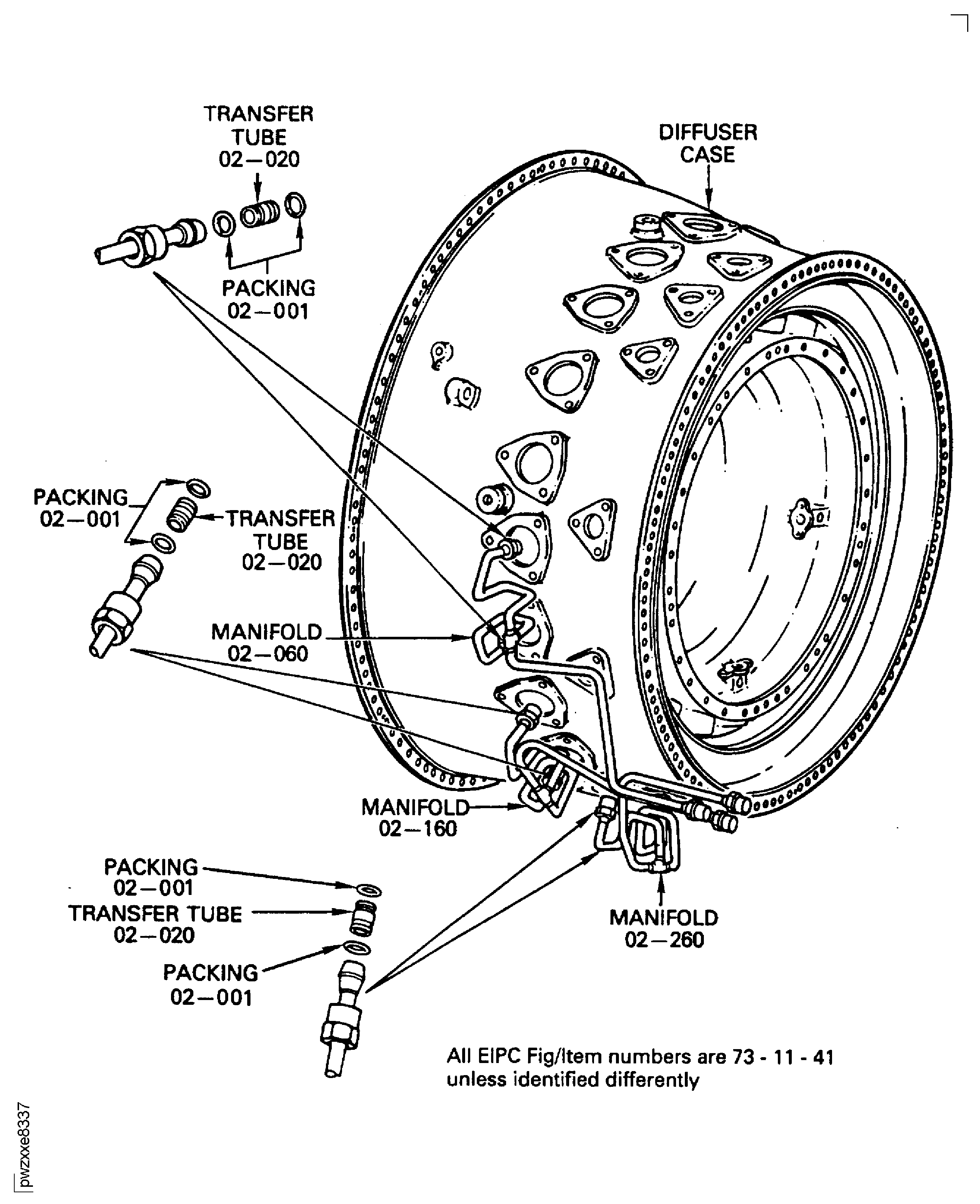

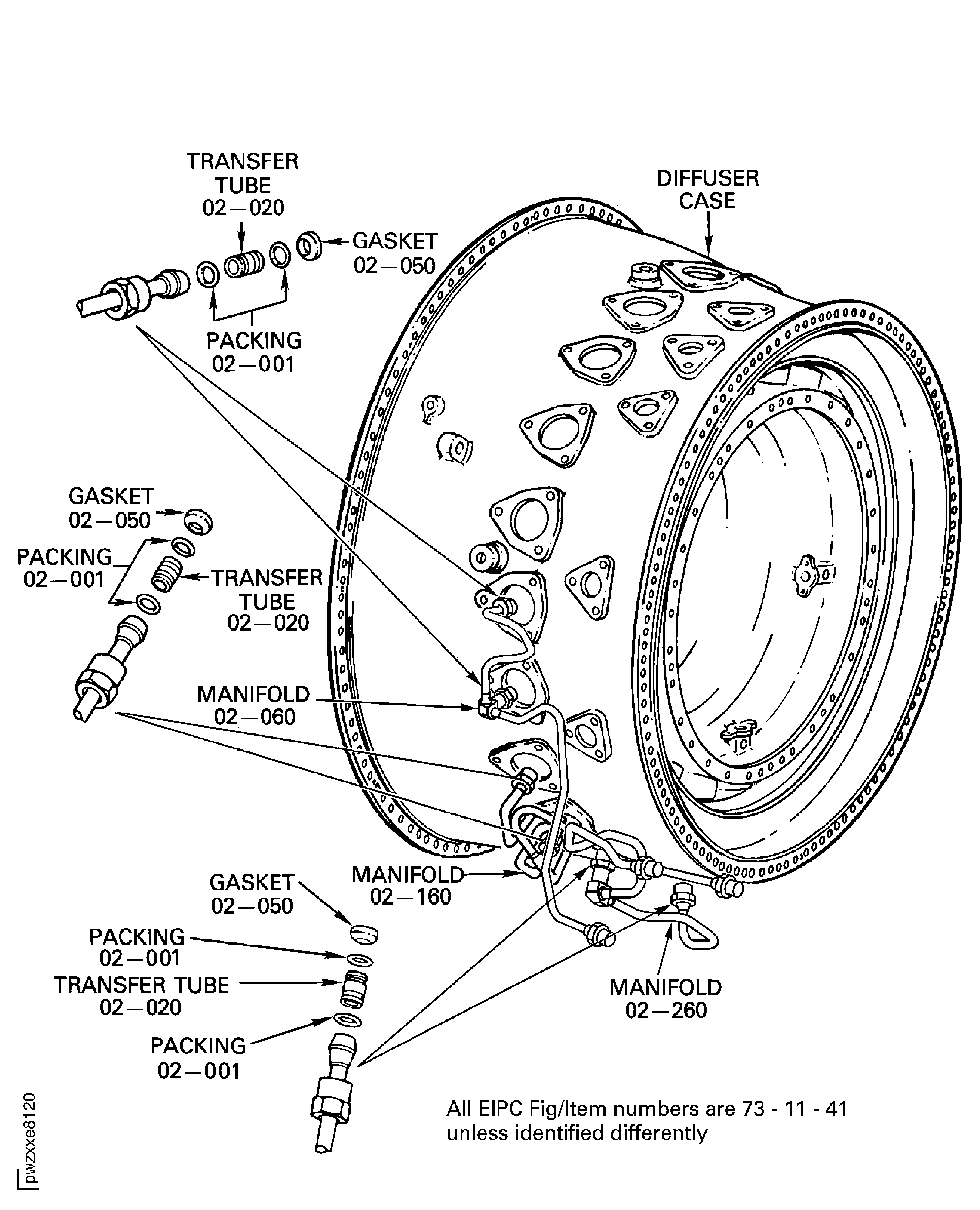

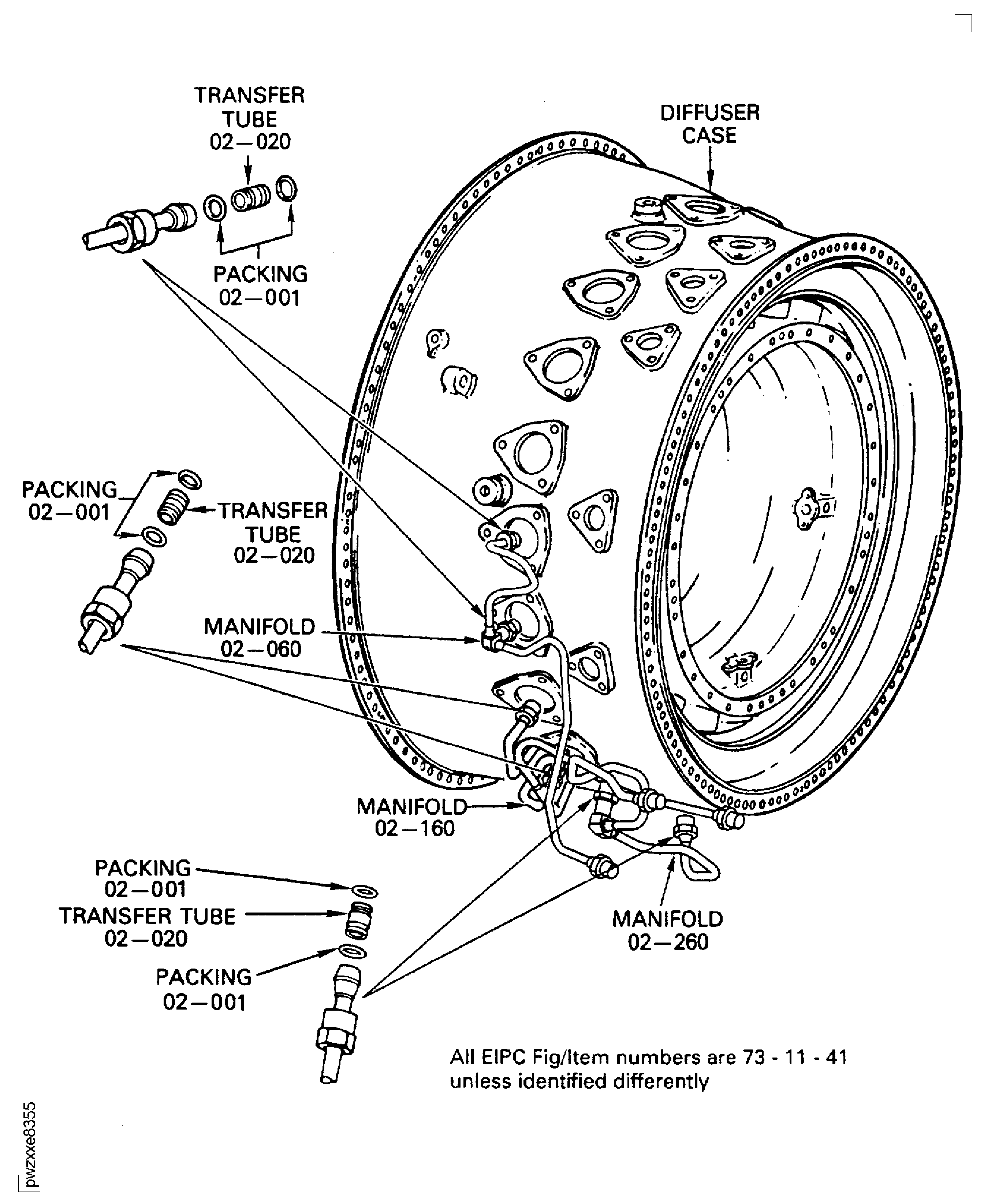

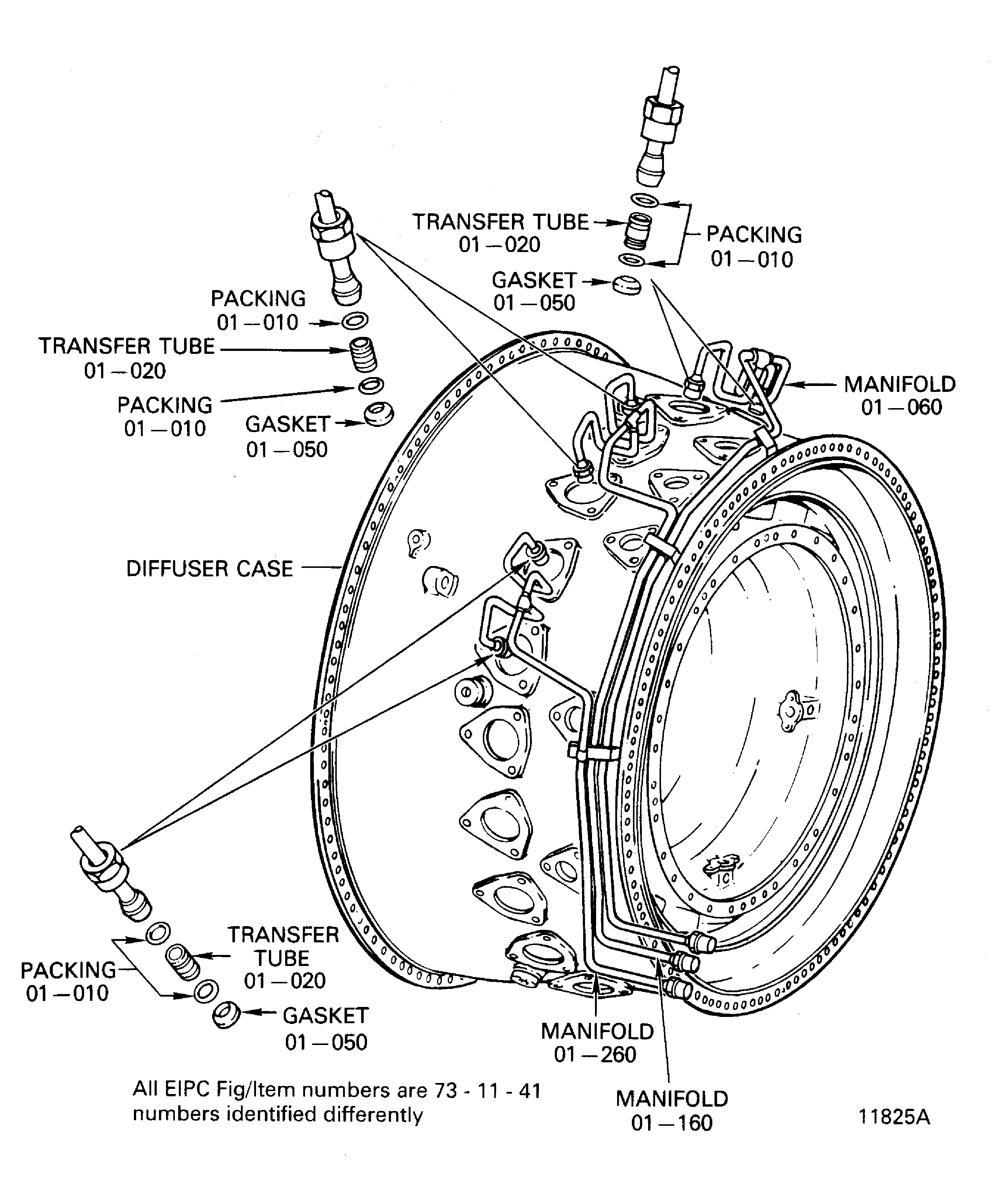

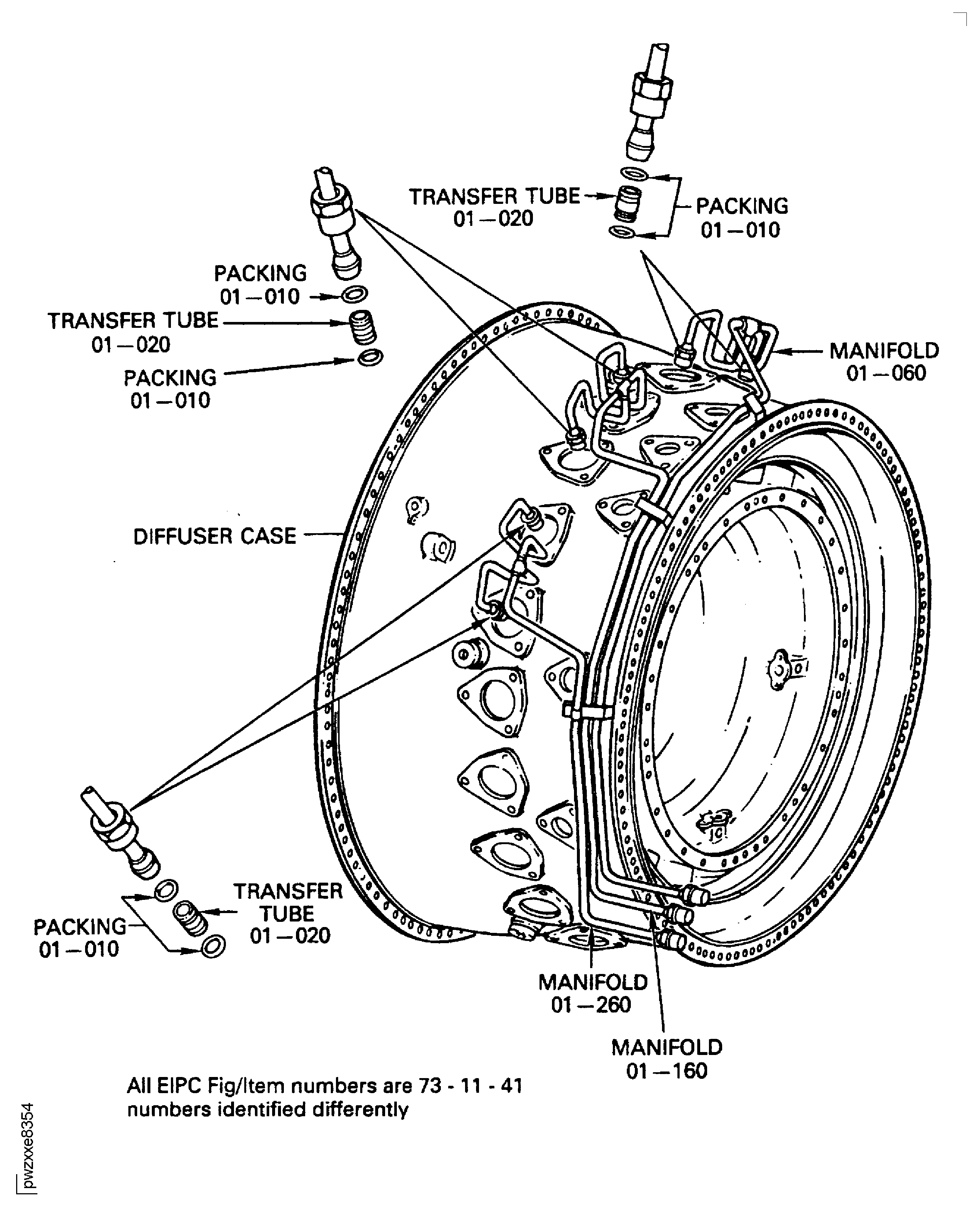

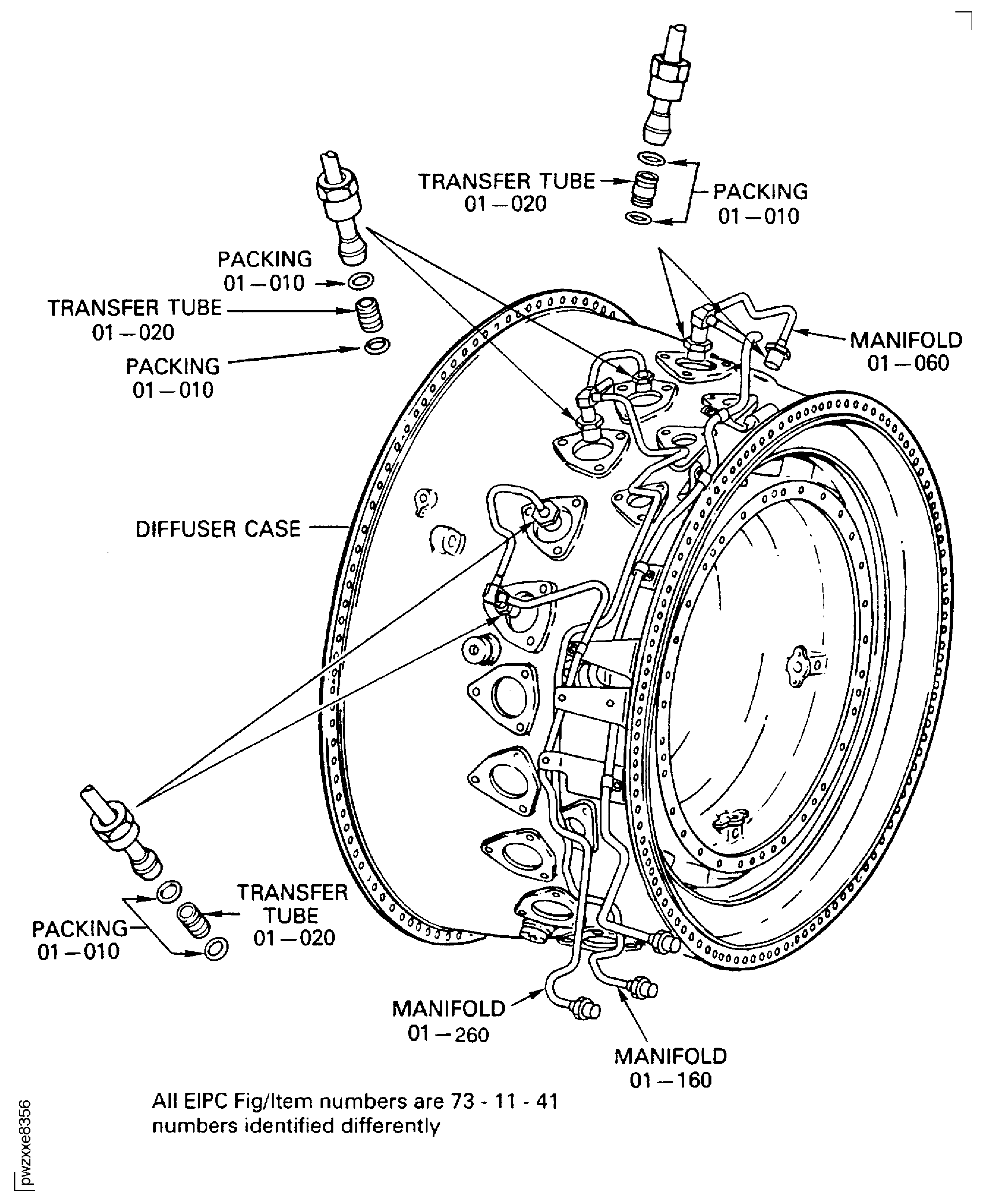

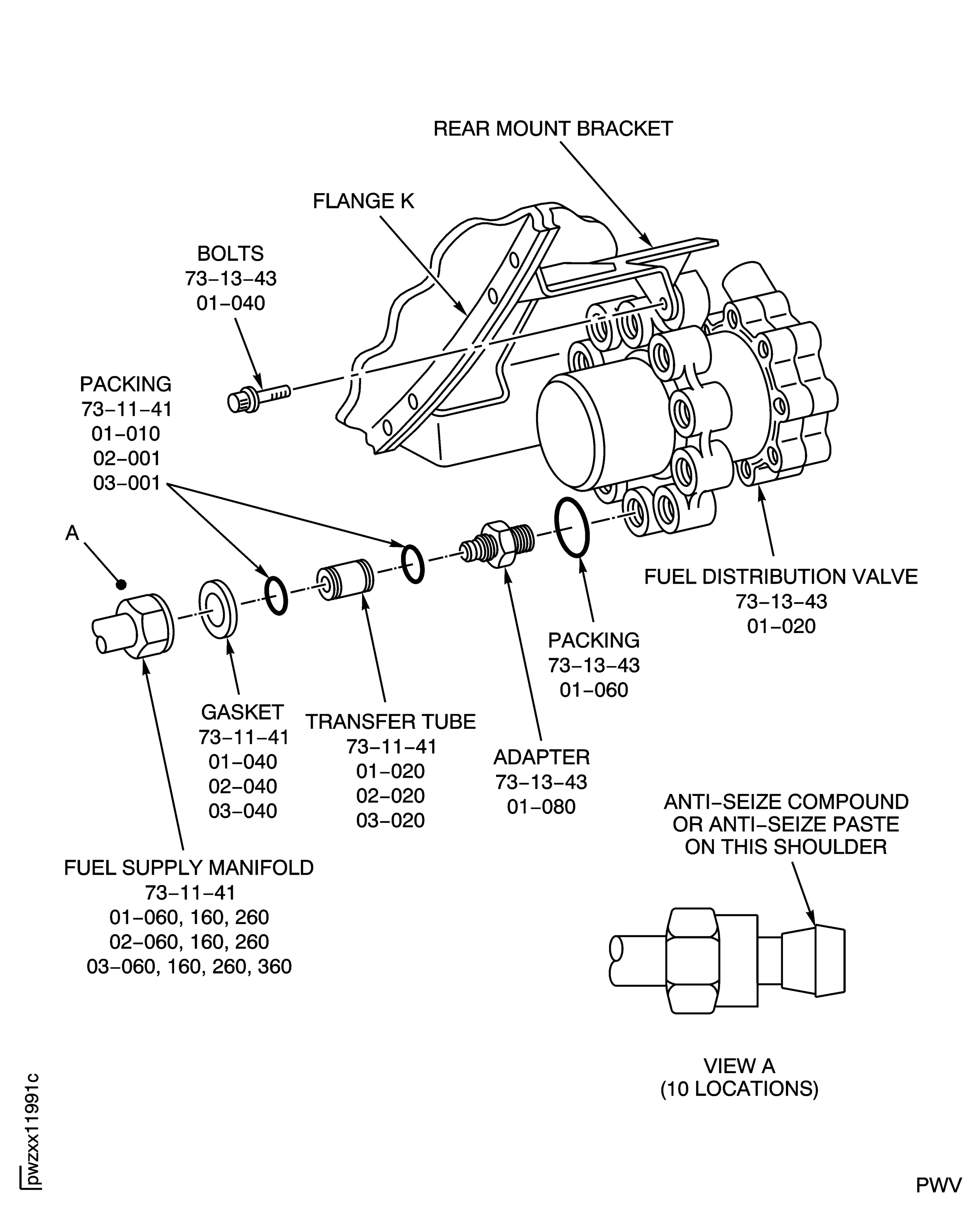

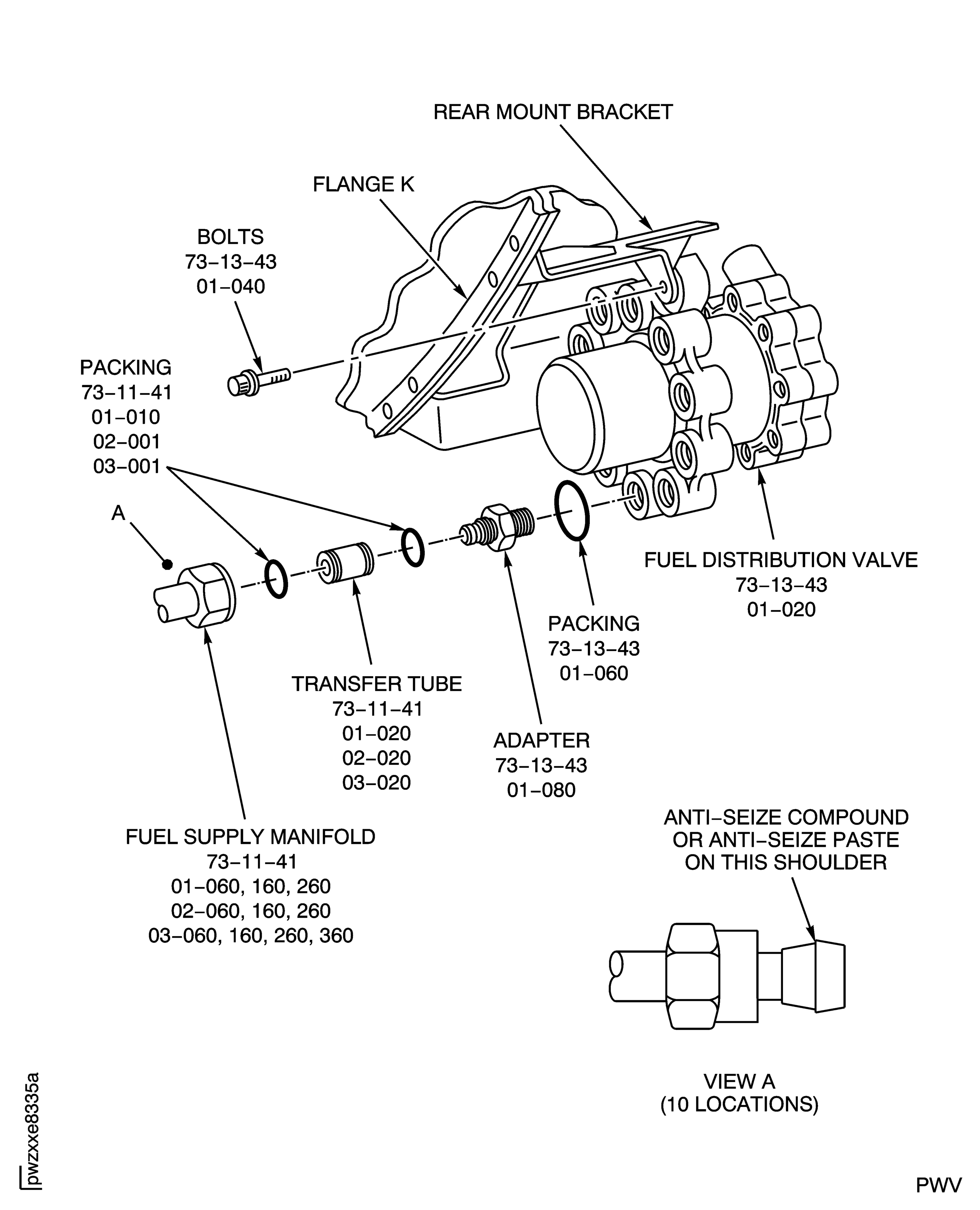

Apply CoMat 10-077 APPROVED ENGINE OILS or CoMat 10-087 SEALING RING LUBRICANT to Fuel Nozzle Supply Fuel Manifolds (73-11-41, 03-001) packings 16 off.

Install the packings on the eight transfer tubes Fuel Nozzle Supply Fuel Manifolds (73-11-41,03-020) and install the transfer tubes on to the fuel nozzles.

Install Fuel Nozzle Supply Fuel Manifolds (73-11-41,03-050) gaskets 8 off on to the fuel nozzles.

NOTE

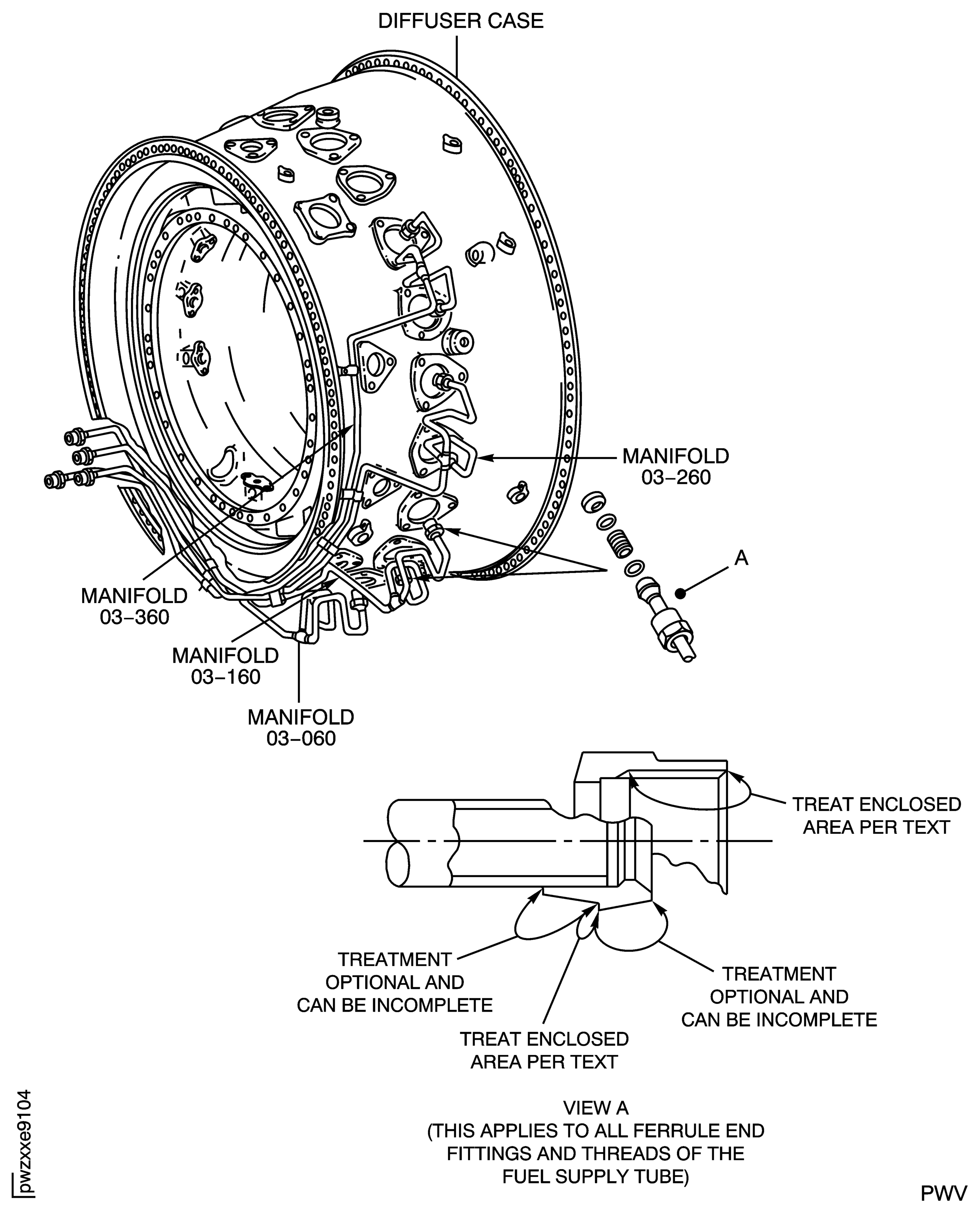

If the fuel supply tubes were replaced with new tubes, then do not apply CoMat 10-129 ANTI-SEIZE PASTE to the shoulders. The new fuel supply tubes have dry anti-gallant at production.Apply CoMat 10-129 ANTI-SEIZE PASTE to the shoulders of the end fittings and also on the nut threads of the fuel supply tubes Fuel Nozzle Supply Fuel Manifolds (73-11-41,03-360), Fuel Nozzle Supply Fuel Manifolds (73-11-41,03-260), Fuel Nozzle Supply Fuel Manifolds (73-11-41,03-160) and Fuel Nozzle Supply Fuel Manifolds (73-11-41,03-060) that attach to the fuel nozzle. Refer to the SPM TASK 70-38-38-380-501. Refer to Figure.

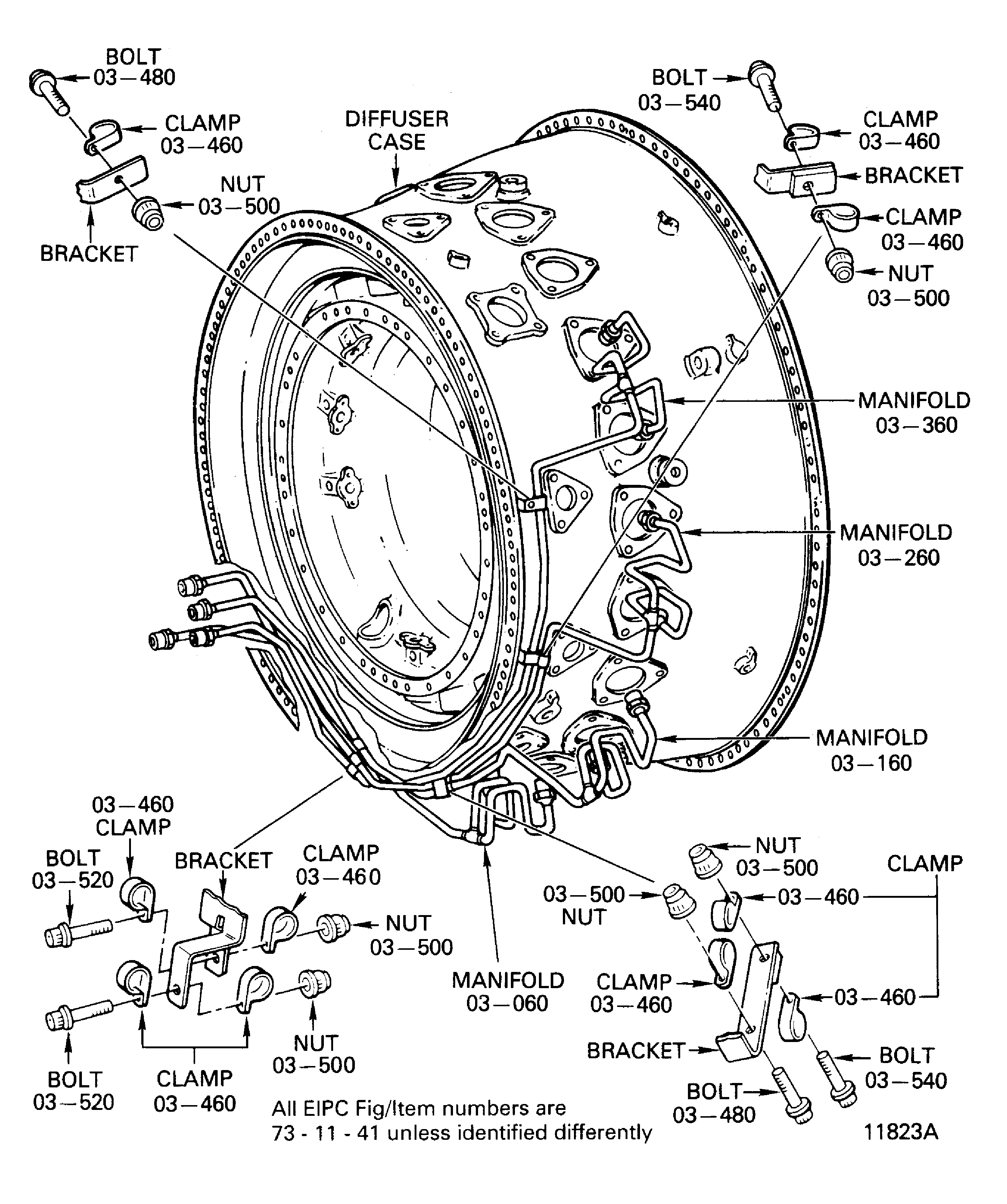

Attach the four fuel manifolds Fuel Nozzle Supply Fuel Manifolds (73-11-41, 03-360, Fuel Nozzle Supply Fuel Manifolds 03-260, Fuel Nozzle Supply Fuel Manifolds 03-160 and Fuel Nozzle Supply Fuel Manifolds 03-060) in the sequence written.