Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-42-10-440-001 Diffuser Case Assembly And Fittings - Assemble The Diffuser Case Assembly, Assembly-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to the SPM TASK 70-44-01-400-501.

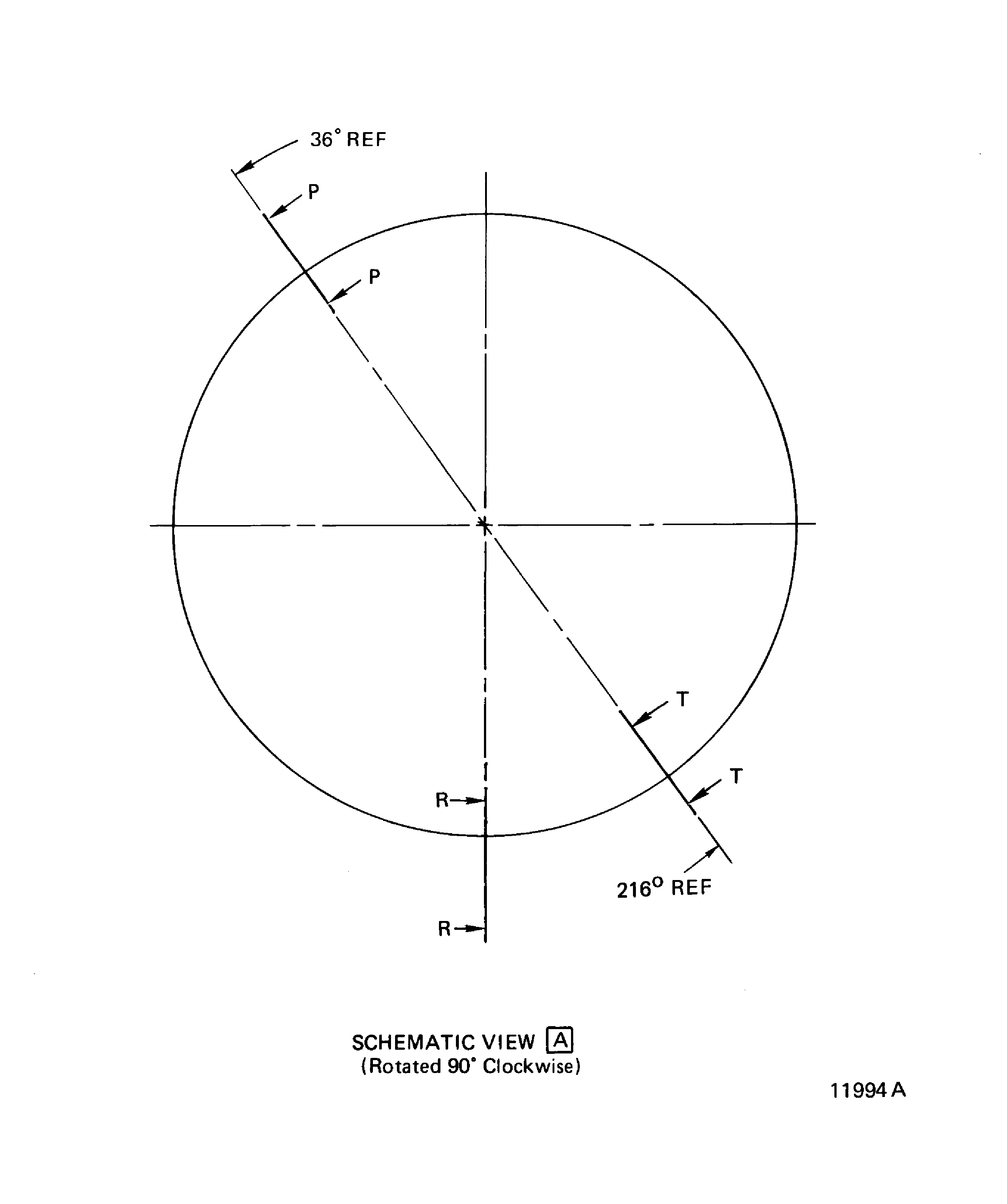

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

For lockwire data and procedures, refer to TASK 70-42-05-400-501.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1P16004 Handling bracket | 0AM53 | IAE 1P16004 | 2 | |

| IAE 1P16005 Build stand | 0AM53 | IAE 1P16005 | 1 | |

| IAE 1P16173 Lift sling | 0AM53 | IAE 1P16173 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-141 LOCKWIRE | LOCAL | CoMat 02-141 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Ring seal | 1 | |||

| Gasket | 1 | |||

| Thrust wire | 1 | |||

| Ring seal | 2 | |||

| Gasket | 1 | |||

| Gasket | 1 | |||

| Thrust wire | 1 | |||

| Gasket | 1 | |||

| Ring seal | 2 | |||

| Ring seal | 2 | |||

| Gasket | 1 | |||

| Thrust wire | 1 |

Safety Requirements

NONEProcedure

Refer to Figure.

Reference the clearance at location 2065. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION-000).

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2065

Side Clearance No. 4 Bearing Seal Ring ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-010), Thickness

No. 4 Bearing Pressure Tube Assembly ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-060), Groove Width

Seal Ring Thickness

0.0615

Clear

0.0625

0.0015

Groove Width

0.064

0.0045

0.066

Clear

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2065

Side Clearance No. 4 Bearing Seal Ring ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-010), Thickness

No. 4 Bearing Pressure Tube Assembly ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-060), Groove Width

Seal Ring Thickness

1.563

Clear

1.587

0.039

Groove Width

1.626

0.114

1.676

Clear

SUBTASK 72-42-10-220-055 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2065

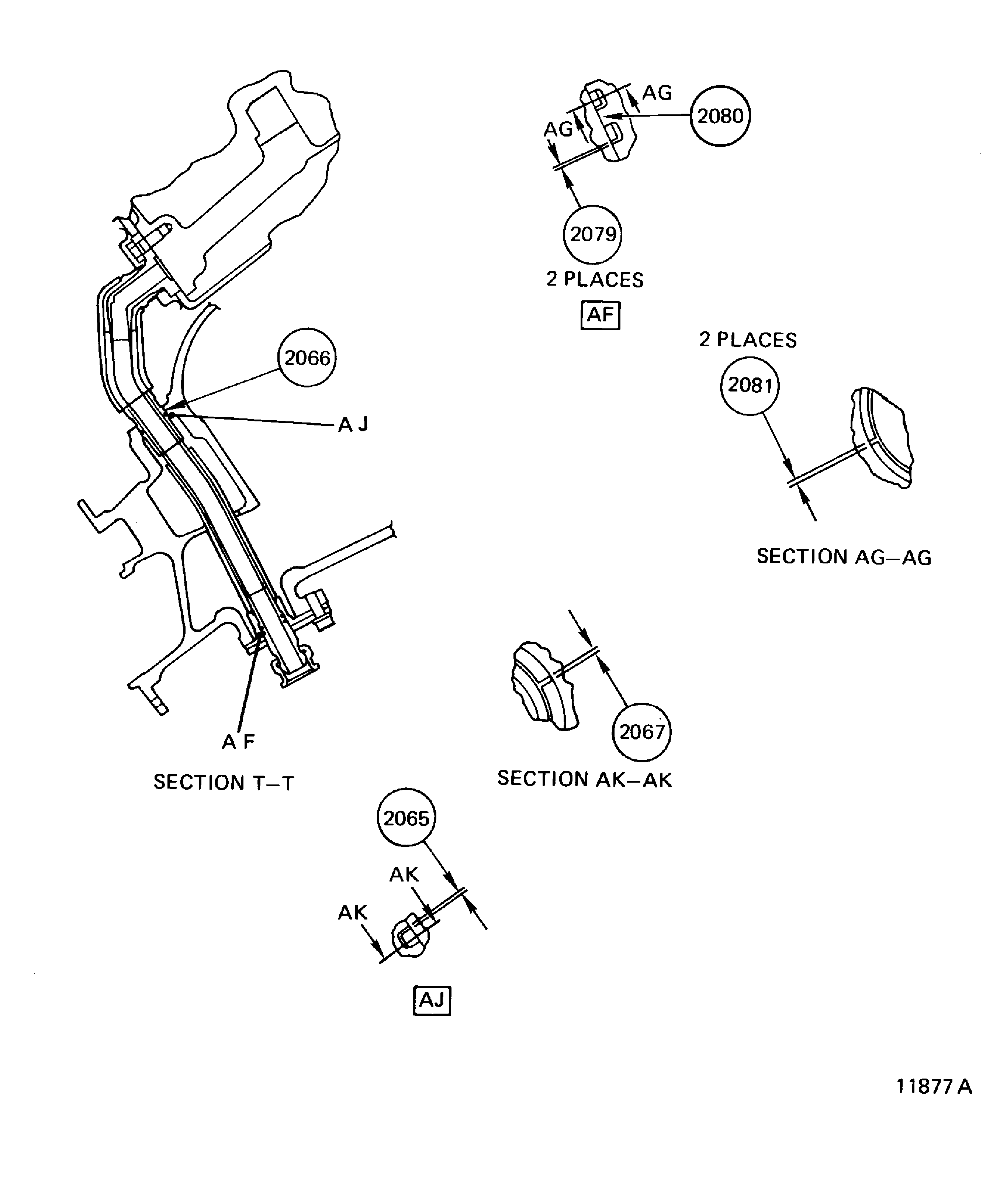

Refer to Figure

Reference the clearance at location 2066. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION-000) and V2500-D5-72-42-1100-00A-307A-C (INSPECTION-000).

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2066

No. 4 Bearing Pressure Tube Assembly ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-060), Location Diameter

Diffuser Case Assembly Diffuser Case (72-42-11, 01-010), Location Diameter

Seal Ring Holder Diameter

0.7415

Clear

0.7455

0.0005

Diffuser Case Diameter

0.746

0.0085

0.750

Clear

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2066

No. 4 Bearing Pressure Tube Assembly ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-060) Location Diameter

Diffuser Case Assembly Diffuser Case (72-42-11, 01-010), Location Diameter

Seal Ring Holder Diameter

18.835

Clear

18.935

0.013

Diffuser Case Diameter

18.949

0.216

19.050

Clear

SUBTASK 72-42-10-220-056 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2066

Refer to Figure.

Reference the clearance at location 2067. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION-000) and V2500-D5-72-42-1100-00A-307A-C (INSPECTION-000).

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2067

Gap No. 4 Bearing Metal Seal Ring ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-010), Gap At 0.746 Inch Gage

Diffuser Case Assembly Diffuser Case (72-42-11, 01-010), Location Diameter

Gap

0.005

Clear

0.015

0.005

Case Location Diameter

0.746

0.028

0.750

Clear

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2067

Gap No. 4 Bearing Metal Seal Ring ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-010), Gap At 18.949 Millimeters Gage

Diffuser Case Assembly Diffuser Case (72-42-11, 01-010), Location Diameter

Gap

0.13

Clear

0.38

0.13

Case Location Diameter

18.949

0.71

19.050

Clear

SUBTASK 72-42-10-220-057 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2067

Refer to Figure

Reference the clearance at location 2070. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION-000).

Table 7. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2070

Side Clearance No. 4 Bearing Seal Ring No. 4 Bearing Compartment Tubes (72-42-20, 04-001),

No. 4 Bearing Cooling Duct Sensing Tube Assembly No. 4 Bearing Compartment Tubes (72-42-20, 04-040), Groove Width

Ring Thickness

0.0615

Clear

0.0625

0.002

Groove Width

0.0645

0.005

0.0665

Clear

Table 8. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2070

Side Clearance No. 4 Bearing Seal Ring No. 4 Bearing Compartment Tubes (72-42-20, 04-001),

No. 4 Bearing Cooling Duct Sensing Tube Assembly No. 4 Bearing Compartment Tubes (72-42-20, 04-040), Groove Width

Ring Thickness

1.563

Clear

1.587

0.051

Groove Width

1.639

0.127

1.689

Clear

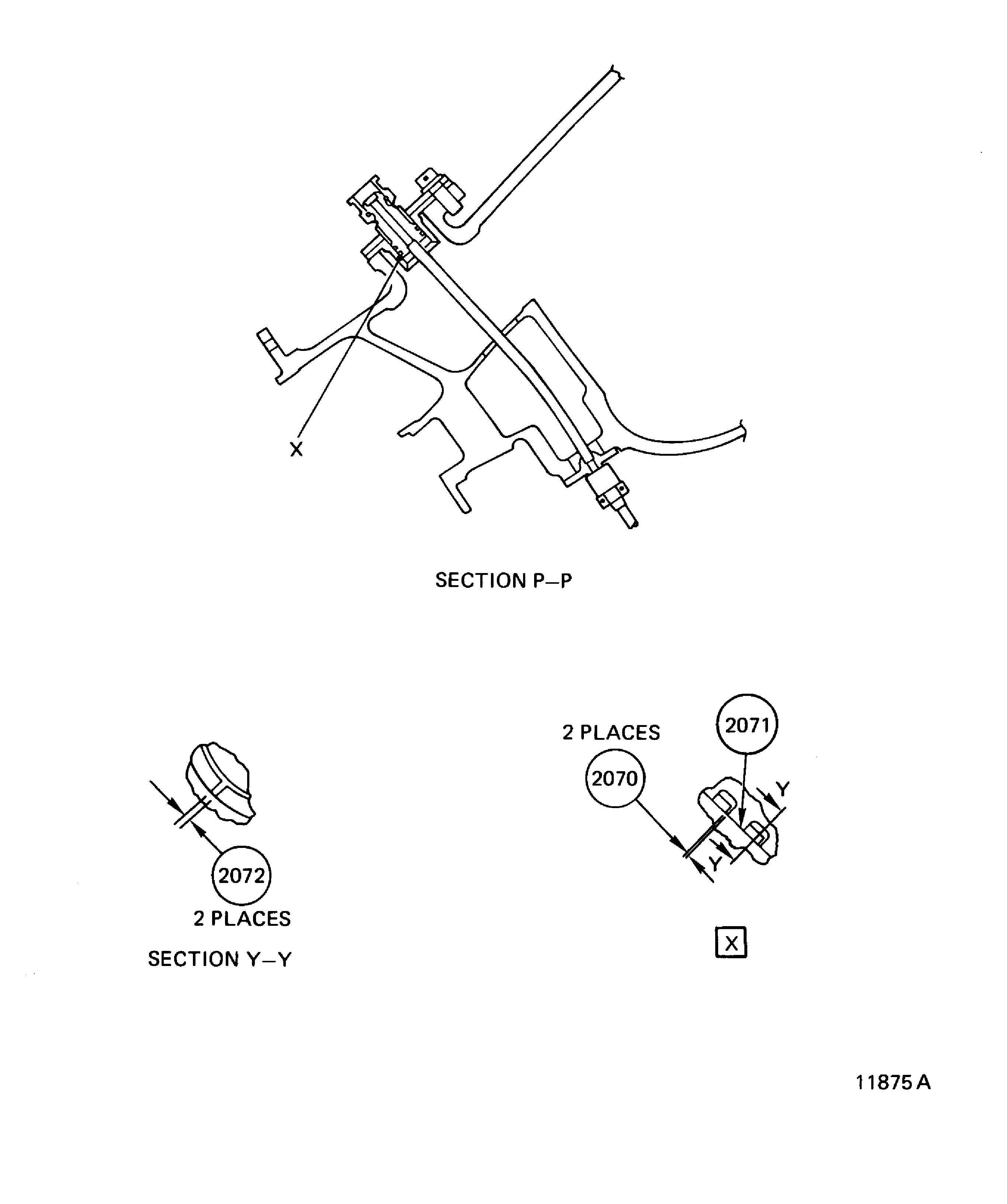

SUBTASK 72-42-10-220-058 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2070 (Pre SBE 72-0166)

Refer to Figure.

Reference the clearance at location 2071. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION-000).

Table 9. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2071

No. 4 Bearing Cooling Duct Sensing Tube Assembly No. 4 Bearing Compartment Tubes (72-42-20, 04-040), Location Diameter

Sealing Sleeve No. 4 Bearing Compartment Tubes (72-42-20, 04-160), Location Diameter

Tube Location Diameter

0.6190

Clear

0.6225

0.0225

Sleeve Location Diameter

0.645

0.030

0.649

Clear

Table 10. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2071

No. 4 Bearing Cooling Duct Sensing Tube Assembly No. 4 Bearing Compartment Tubes (72-42-20, 04-040), Location Diameter

Sealing Sleeve No. 4 Bearing Compartment Tubes (72-42-20, 04-160), Location Diameter

Tube Location Diameter

15.723

Clear

15.811

0.572

Sleeve Location Diameter

16.383

0.762

16.484

Clear

SUBTASK 72-42-10-220-059 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2071 (Pre SBE 72-0166)

Refer to Figure.

Reference the clearance at location 2072. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION-000).

Table 11. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2072

Gap No. 4 Bearing Seal Ring No. 4 Bearing Compartment Tubes (72-42-20, 04-001), Gap At 0.645 Inch Gage

Sealing Sleeve No. 4 Bearing Compartment Tubes (72-42-20, 04-160), Inner Diameter

Gap

0.005

Clear

0.015

0.005

Sleeve Inner Diameter

0.645

0.028

0.649

Clear

Table 12. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2072

Gap No. 4 Bearing Seal Ring No. 4 Bearing Compartment Tubes (72-42-20, 04-001), Gap At 16.383 Millimeters Gage

Sealing Sleeve No. 4 Bearing Compartment Tubes (72-42-20, 04-160), Inner Diameter

Gap

0.13

Clear

0.38

0.13

Sleeve Inner Diameter

16.383

0.71

16.484

Clear

SUBTASK 72-42-10-220-060 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2072 (Pre SBE 72-0166)

Refer to Figure.

Reference the clearance at location 2073. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION-000).

Table 13. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2073

Side Clearance No. 4 Bearing Seal Ring No. 4 Bearing Compartment Tubes (72-42-20, 03-001), Thickness

No. 4 Bearing Weep Tube Assembly No. 4 Bearing Compartment Tubes (72-42-20, 03-040), Groove Width

Ring Thickness

0.0615

Clear

0.0625

0.002

Groove Width

0.0645

0.005

0.0665

Clear

Table 14. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2073

Side Clearance No. 4 Bearing Seal Ring No. 4 Bearing Compartment Tubes (72-42-20, 03-001), Thickness

No. 4 Bearing Airframe Tube Assembly No. 4 Bearing Compartment Tubes (72-42-20, 03-040), Groove Width

Ring Thickness

1.563

Clear

1.587

0.051

Groove Width

1.639

0.127

1.689

Clear

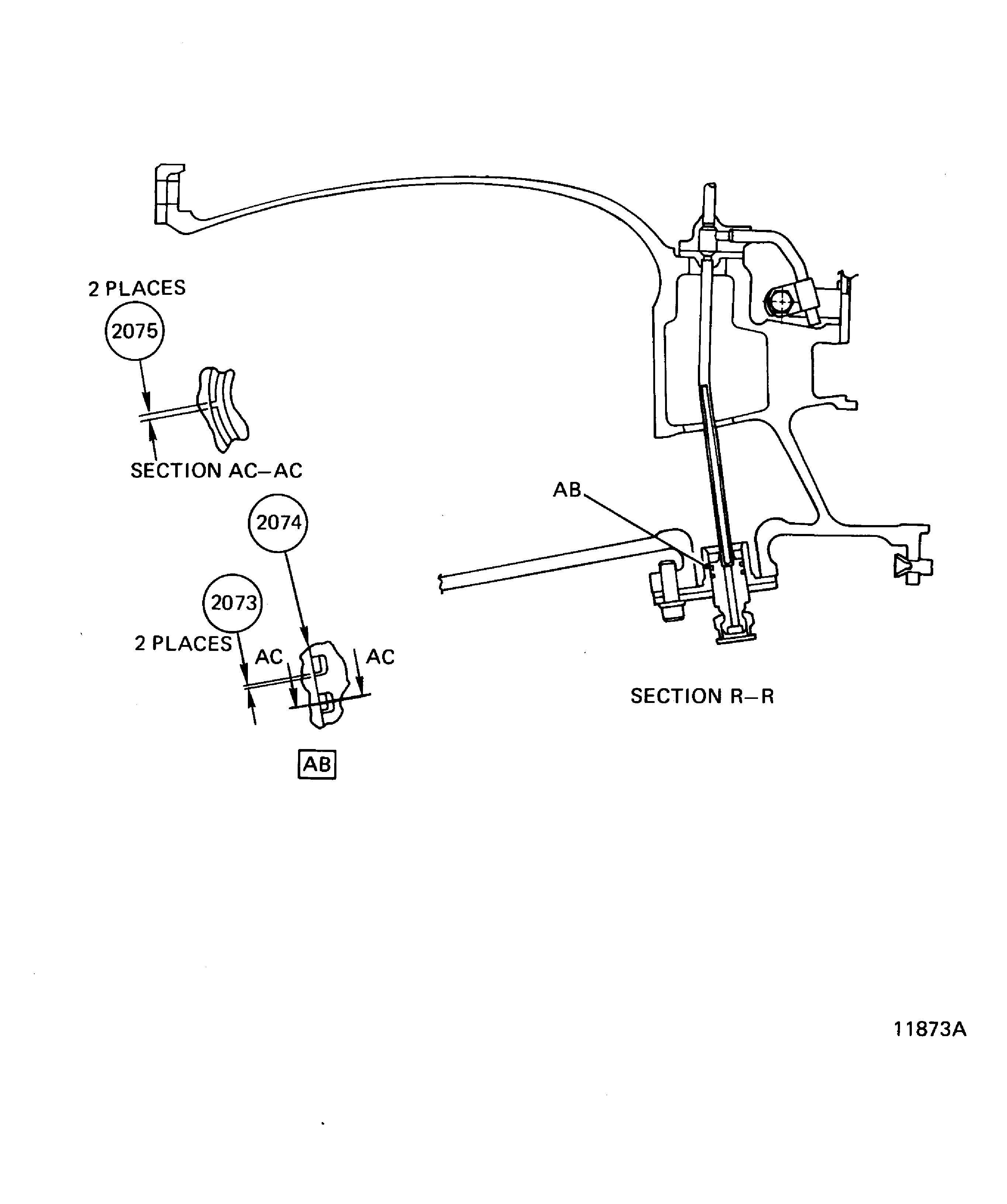

SUBTASK 72-42-10-220-061 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2073

Refer to Figure.

Reference the clearance at location 2074. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION-000).

Table 15. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2074

No. 4 Bearing Weep Tube Assembly No. 4 Bearing Compartment Tubes (72-42-20, 03-040), Location Diameter

Sealing Sleeve No. 4 Bearing Compartment Tubes (72-42-20, 03-140), Location Diameter

Tube Diameter

0.6190

Clear

0.6225

0.0225

Sleeve Diameter

0.645

0.030

0.649

Clear

Table 16. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2074

No. 4 Bearing Weep Tube Assembly No. 4 Bearing Compartment Tubes (72-42-20, 03-040), Location Diameter

Sealing Sleeve No. 4 Bearing Compartment Tubes (72-42-20, 03-140), Location Diameter

Tube Diameter

15.723

Clear

15.811

0.572

Sleeve Diameter

16.383

0.762

16.484

Clear

SUBTASK 72-42-10-220-062 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2074

Pre SB 72-0168

Refer to Figure.

Reference the clearance at location 2074. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION-000).

Table 17. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2074

No. 4 Bearing Weep Tube Assembly No. 4 Bearing Compartment Tubes (72-42-20, 03-040), Location Diameter

Sealing Sleeve No. 4 Bearing Compartment Tubes (72-42-20, 03-140), Location Diameter

Tube Diameter

0.639

Clear

0.641

0.004

Sleeve Diameter

0.645

0.010

0.649

Clear

Table 18. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2074

No. 4 Bearing Weep Tube Assembly No. 4 Bearing Compartment Tubes (72-42-20, 03-040), Location Diameter

Sealing Sleeve No. 4 Bearing Compartment Tubes (72-42-20, 03-140), Location Diameter

Tube Diameter

16.231

Clear

16.281

0.102

Sleeve Diameter

16.383

0.254

16.485

Clear

SUBTASK 72-42-10-220-067 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2074

SB 72-0168

Refer to Figure.

Reference the clearance at location 2075. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION-000).

Table 19. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2075

Gap No. 4 Bearing Seal Ring No. 4 Bearing Compartment Tubes (72-42-20, 03-001), Gap At 0.645 Inch Gage

Sealing Sleeve No. 4 Bearing Compartment Tubes (72-42-20, 03-140), Inside Diameter

Gap

0.005

Clear

0.015

0.005

Sleeve Inside Diameter

0.645

0.028

0.649

Clear

Table 20. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2075

Gap No. 4 Bearing Seal Ring No. 4 Bearing Compartment Tubes (72-42-20, 03-001), Gap At 16.383 Millimeters Gage

Sealing Sleeve No. 4 Bearing Compartment Tubes (72-42-20, 03-140), Inside Diameter

Gap

0.13

Clear

0.38

0.13

Sleeve Inside Diameter

16.383

0.71

16.484

Clear

SUBTASK 72-42-10-220-063 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2075

Refer to Figure.

Reference the clearance at location 2079. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION-000).

Table 21. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2079

Side Clearance No. 4 Bearing Seal Ring ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-020), Thickness

Oil Pressure Tube Connector ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-120), Groove Width

Seal Ring Thickness

0.0615

Clear

0.0625

0.002

Groove Width

0.0645

0.005

0.0665

Clear

Table 22. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2079

Side Clearance No. 4 Bearing Seal Ring ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-020), Thickness

Oil Pressure Tube Connector ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-120), Groove Width

Seal Ring Thickness

1.563

Clear

1.587

0.051

Groove Width

1.639

0.127

1.689

Clear

SUBTASK 72-42-10-220-064 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2079

Refer to Figure

Reference the clearance at location 2080. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION-000).

Table 23. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2080

No. 4 Bearing Oil Pressure Tube Assembly ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-060), Connector Location Diameter

Sealing Sleeve ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-280), Location Diameter

Connector Location Diameter

0.639

Clear

0.641

0.004

Sleeve Location Diameter

0.645

0.010

0.649

Clear

Table 24. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2080

No. 4 Bearing Oil Pressure Tube Assembly ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-060), Connector Location Diameter

Sealing SleeveENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-280), Location Diameter

Connector Location Diameter

16.231

Clear

16.281

0.102

Sleeve Location Diameter

16.383

0.254

16.484

Clear

SUBTASK 72-42-10-220-065 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2080

Refer to Figure.

Reference the clearance at location 2081. If required, use the data written as a note in TASK 72-42-20-200-000 (INSPECTION-000).

Table 25. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2081

Gap No. 4 Bearing Seal Ring ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-020), Gap At 0.645 Inch Gage

Sleeve ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-280), Inside Diameter

Gap

0.005

Clear

0.015

0.005

Sleeve Inside Diameter

0.645

0.028

0.649

Clear

Table 26. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2081

Gap No. 4 Bearing Seal Ring ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-020), Gap At 16.383 Millimeters Gage

Sleeve ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-280), Inside Diameter

Gap

0.13

Clear

0.38

0.13

Sleeve Inside Diameter

16.383

0.71

16.484

Clear

SUBTASK 72-42-10-220-066 Reference the Fits and Clearances of the Diffuser Case Assembly at Location 2081

Refer to Figure

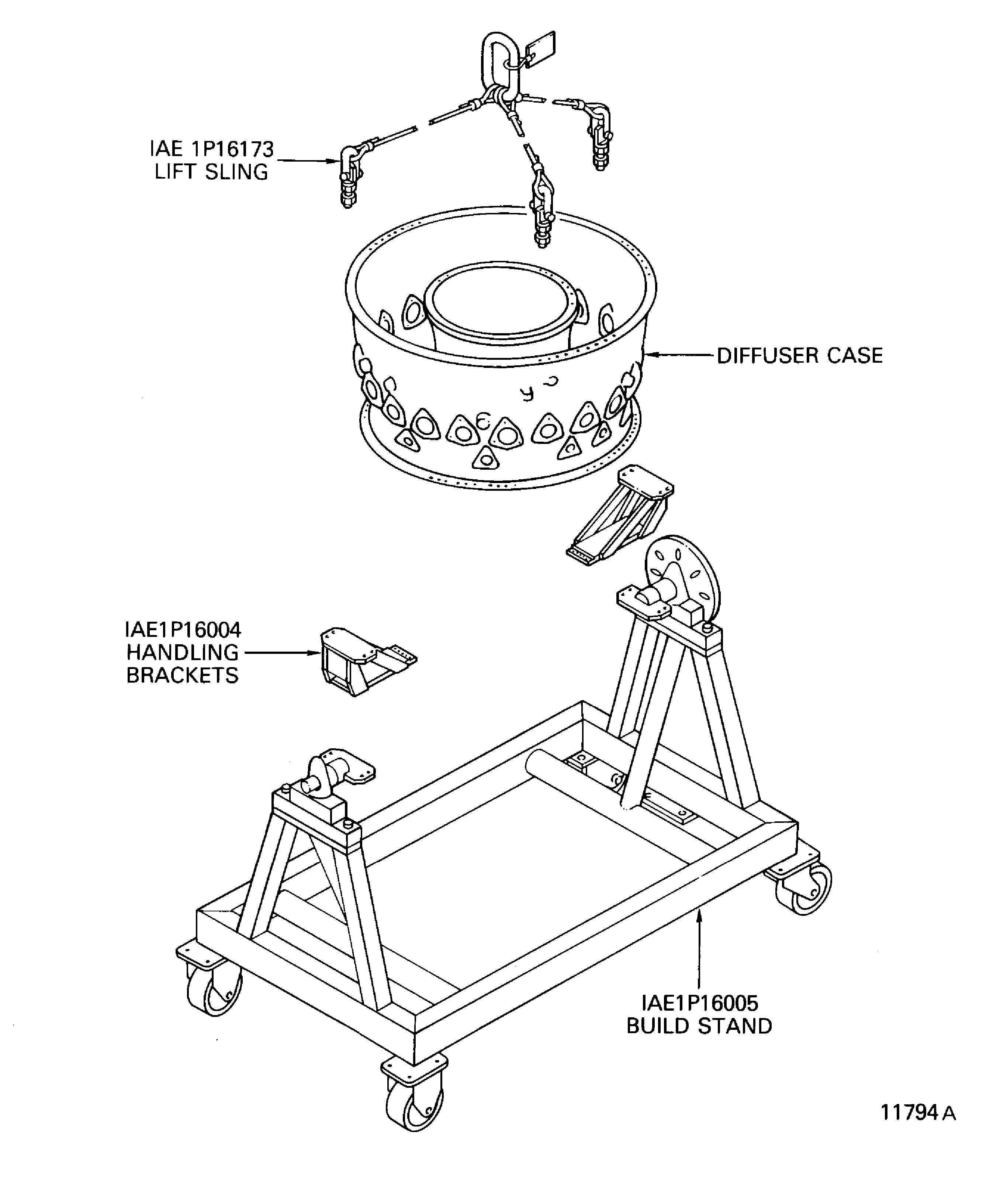

Attach a hoist to the IAE 1P16173 Lift sling 1 off.

Attach the IAE 1P16004 Handling bracket 2 off to the front flange of the diffuser case assembly 180 degrees apart with the five screws from the rear of the diffuser case front flange.

Position the diffuser case assembly in the IAE 1P16005 Build stand 1 off.

SUBTASK 72-42-10-440-051 Put the Diffuser Case Assembly in to the Build Stand

Refer to Figure.

Install two new seal rings No. 4 Bearing Compartment Tubes (72-42-20, 03-001) in to the outer end of the No. 4 bearing weep tube No. 4 Bearing Compartment Tubes (72-42-20, 03-040).

Install No. 4 Bearing Compartment Tubes (72-42-20, 03-020) gasket 1 off on the pad in the ID of the diffuser case for the No. 4 bearing outer airframe tube.

Install the No. 4 bearing weep tube No. 4 Bearing Compartment Tubes (72-42-20, 03-040) from the ID of the diffuser case.

NOTE

Gasket can be installed with the compressor feature in any direction.Install No. 4 Bearing Compartment Tubes (72-42-20, 03-120) gasket 1 off to the pad on the outer surface of the diffuser case over the outer weep tube.

Install the sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20, 03-140) over the tube and against the gasket.

Install the retaining plate No. 4 Bearing Compartment Tubes (72-42-20, 03-160) over the tube and against the sealing sleeve.

Install the three bolts No. 4 Bearing Compartment Tubes (72-42-20, 03-180) to hold the gasket, the sleeve and the plate in position. Do not torque the bolts.

Install the coupling nut No. 4 Bearing Compartment Tubes (72-42-20, 03-200) to the outer end of the weep tube and lock in place with No. 4 Bearing Compartment Tubes (72-42-20, 03-220) thrust wire 1 off.

SUBTASK 72-42-10-440-052 Install the No. 4 Bearing Weep Tube Seal Rings

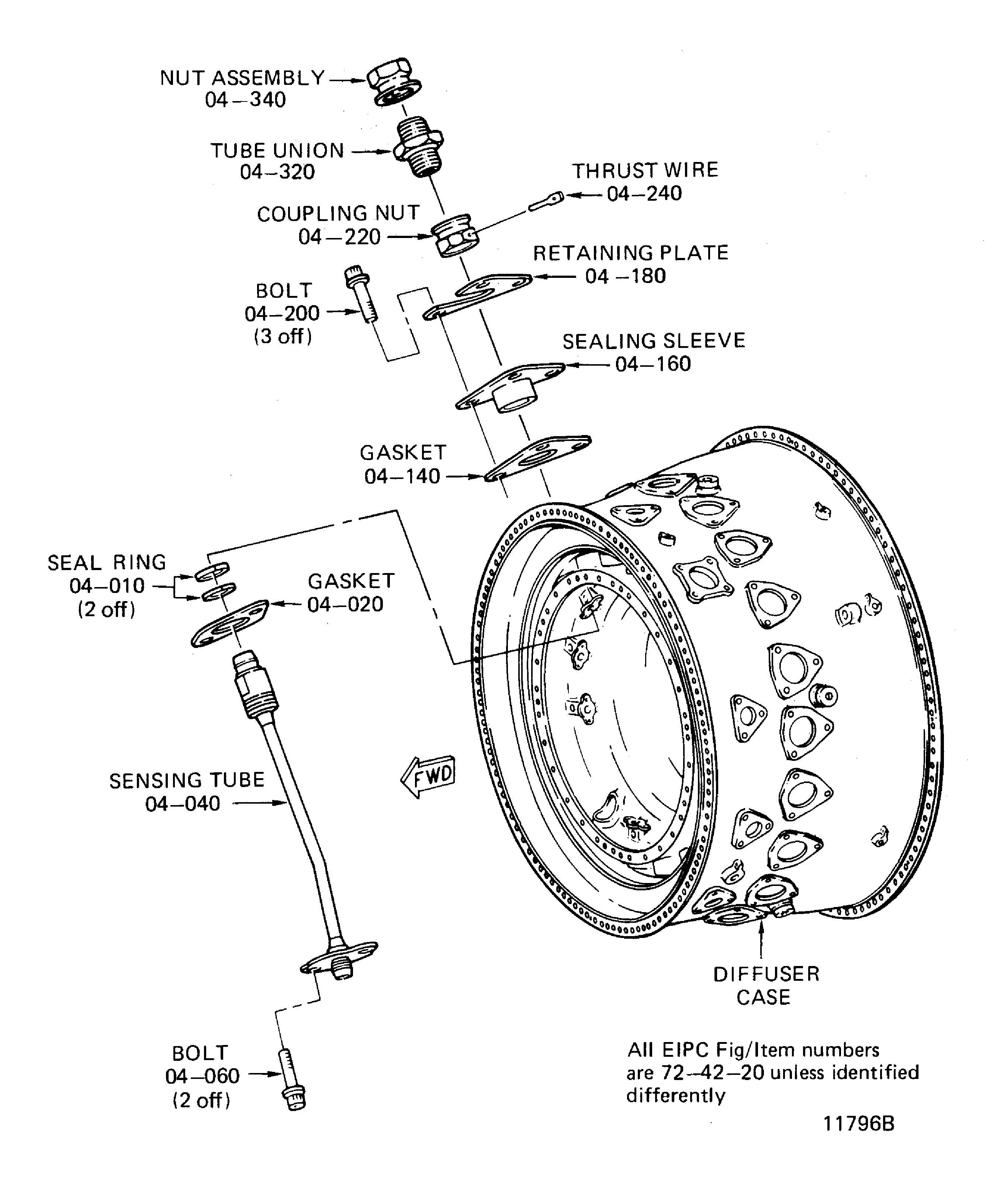

Refer to Figure

Install two new seal rings No. 4 Bearing Compartment Tubes (72-42-20, 04-001) in to the outer end of the turbine cooling air duct sensing tube No. 4 Bearing Compartment Tubes (72-42-20, 04-040).

NOTE

Gasket can be installed with the compression feature in either direction.Install No. 4 Bearing Compartment Tubes (72-42-20, 04-020) gasket 1 off on to the diffuser case ID mounting pad.

Install the outer sensing tube No. 4 Bearing Compartment Tubes (72-42-20, 04-040) from the inside of the diffuser case.

Attach the outer sensing tube to the diffuser case inner boss with the two bolts No. 4 Bearing Compartment Tubes (72-42-20, 04-060). Do not torque the bolts.

Install No. 4 Bearing Compartment Tubes (72-42-20, 04-140) gasket 1 off to the pad on the outer surface of the diffuser case over the outer sensing tube.

Install the sealing sleeve No. 4 Bearing Compartment Tubes (72-42-20, 04-160) over the tube and against the gasket.

Install the retaining plate No. 4 Bearing Compartment Tubes (72-42-20, 04-180) over the tube and against the sealing sleeve.

Install the three bolts No. 4 Bearing Compartment Tubes (72-42-20, 04-200) to hold the gasket, the sleeve and the plate in position. Do not torque the bolts.

Install the coupling nut No. 4 Bearing Compartment Tubes (72-42-20, 04-220) to the outer end of the sensing tube and lock in place with No. 4 Bearing Compartment Tubes (72-42-20, 04-240) thrust wire 1 off.

Install the tube union No. 4 Bearing Compartment Tubes (72-42-20, 04-320) to the coupling nut.

Install the nut assembly No. 4 Bearing Compartment Tubes (72-42-20, 04-340) to the tube union.

Safety the nut assembly with CoMat 02-141 LOCKWIRE.

SUBTASK 72-42-10-440-053-A00 Install the Turbine Cooling Air Duct Sensing Tube (Pre SBE 72-0166)

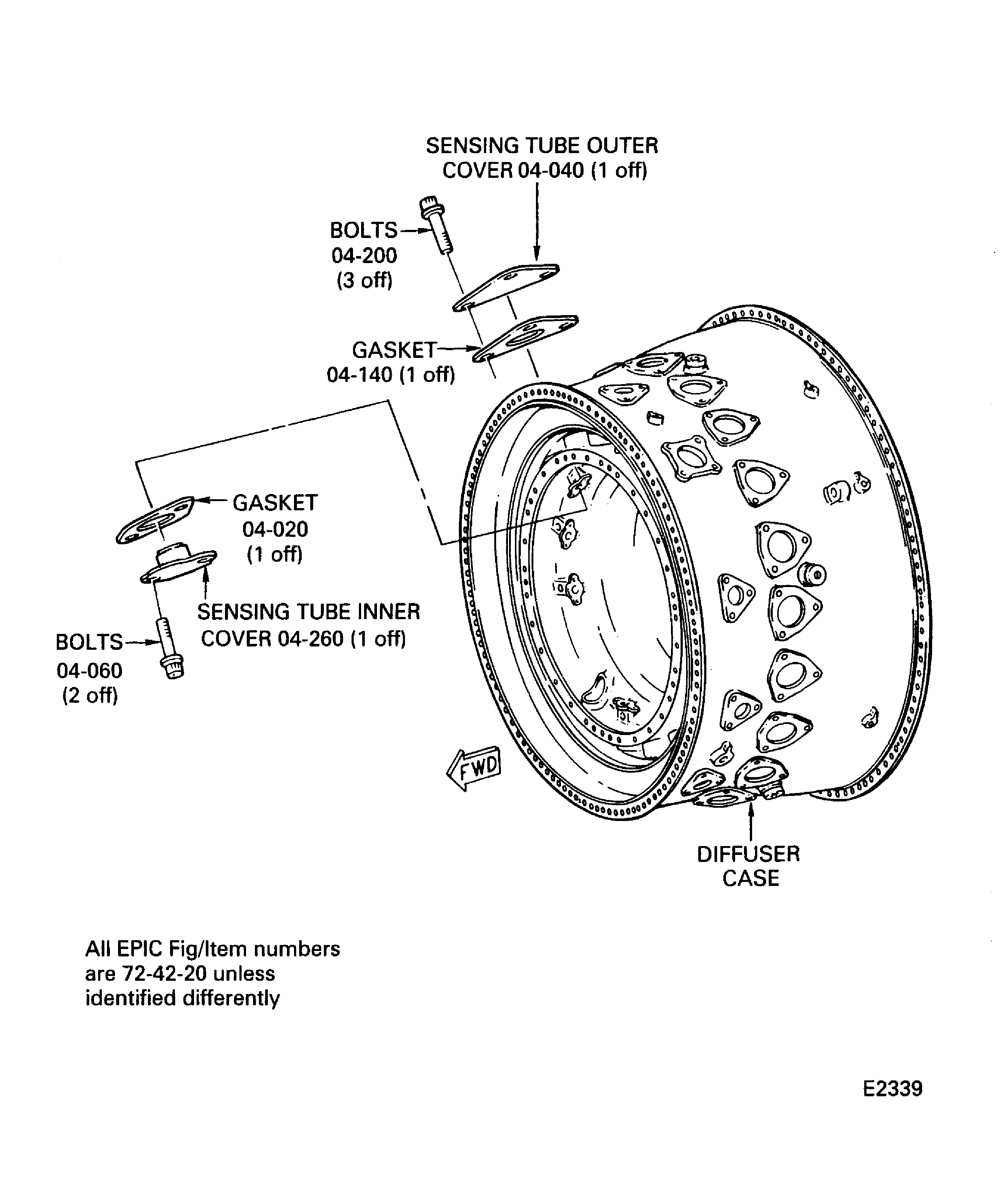

Refer to Figure.

SBE 72-0166: (Part 1) Remove the turbine cooling air duct sensing tubes.

Apply CoMat 10-077 APPROVED ENGINE OILS to the threads of the bolts No. 4 Bearing Compartment Tubes (72-42-20, 04-060) and No. 4 Bearing Compartment Tubes (72-42-20, 04-200).

NOTE

The gasket can be installed with the compression feature in either direction.Install the No. 4 Bearing Compartment Tubes (72-42-20, 04-020) gasket 1 off on the boss in the diffuser case inner diameter.

Install the No. 4 Bearing Compartment Tubes (72-42-20, 04-260) inner cover 1 off onto the diffuser case boss.

Attach the inner cover No. 4 Bearing Compartment Tubes (72-42-20, 04-260) to the diffuser case inner boss with the two bolts No. 4 Bearing Compartment Tubes (72-42-20, 04-060).

Safety the bolts with CoMat 02-141 LOCKWIRE.

NOTE

The gasket can be installed with the compression feature in either direction.Install the No. 4 Bearing Compartment Tubes (72-42-20, 04-140) gasket 1 off on the boss in the diffuser case outer diameter.

Install the No. 4 Bearing Compartment Tubes (72-42-20, 04-040) outer cover 1 off onto the diffuser case boss.

Attach the outer cover No. 4 Bearing Compartment Tubes (72-42-20, 04-040) to the diffuser case outer boss with the three bolts No. 4 Bearing Compartment Tubes (72-42-20, 04-200).

Safety the bolts with CoMat 02-141 LOCKWIRE.

SUBTASK 72-42-10-440-053-B00 Install the Sensing Tube Covers (SBE 72-0166)

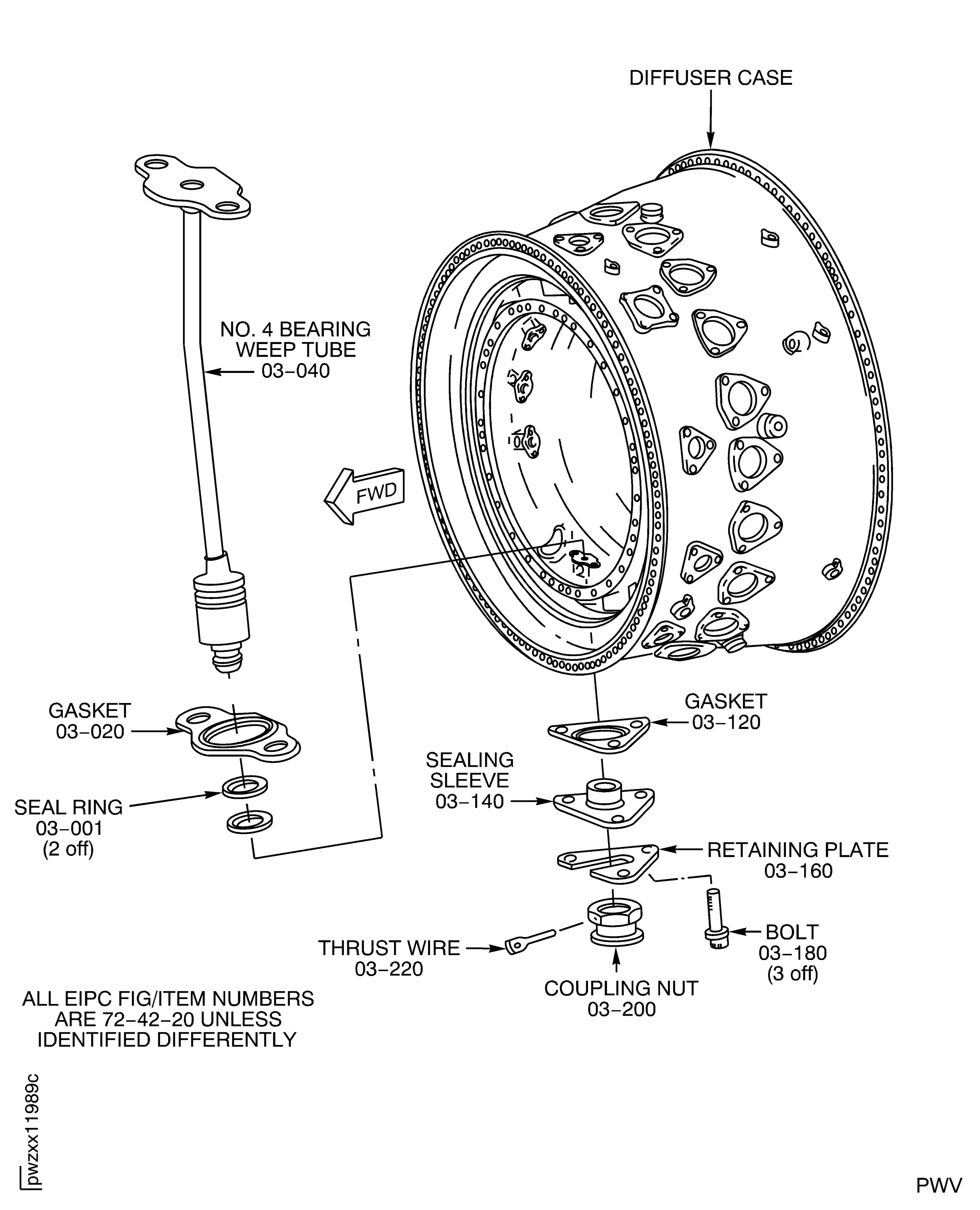

Refer to Figure.

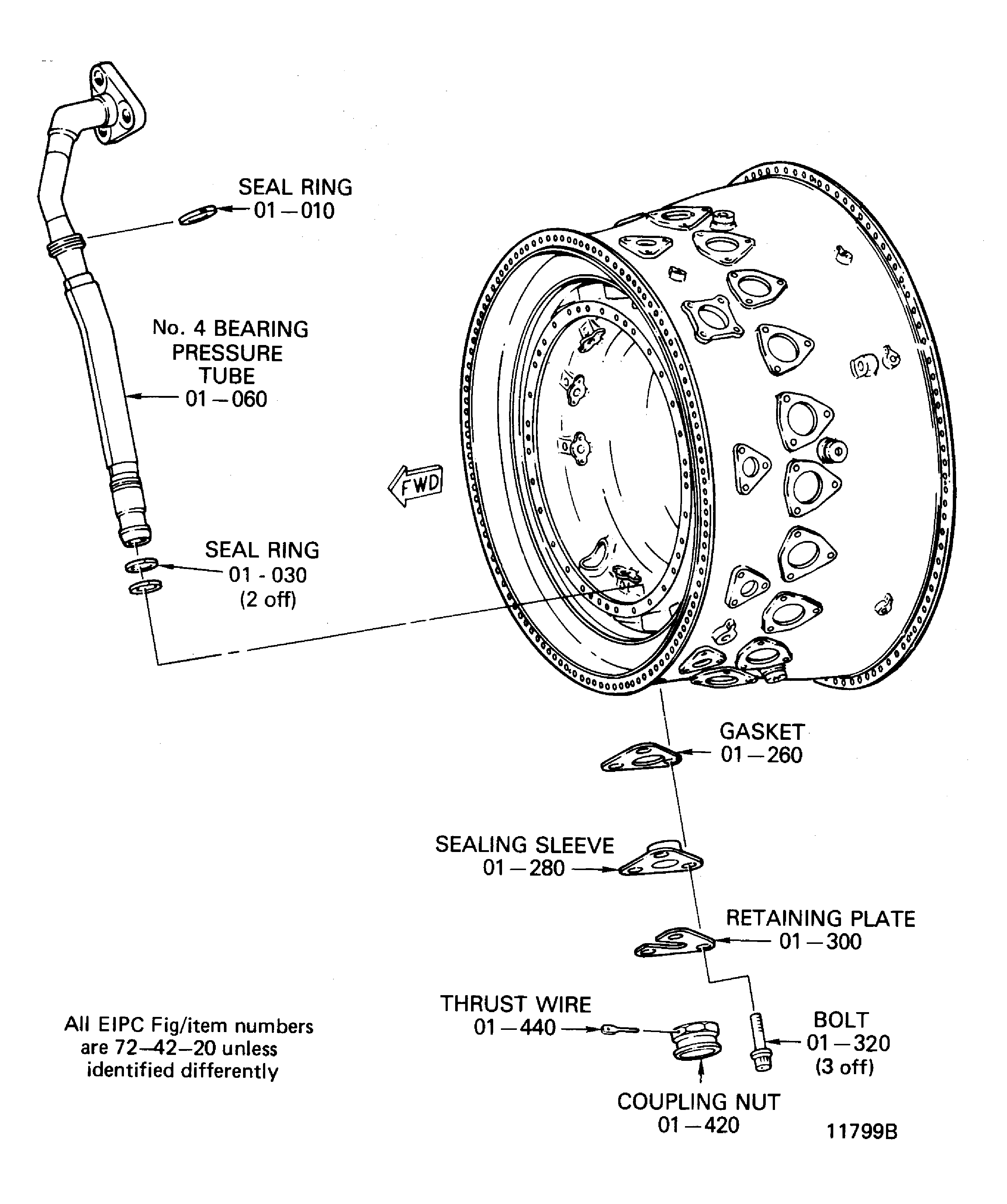

Install the new seal ring ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-010) to the No. 4 bearing pressure tube ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-060).

Install the two seal rings ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-030) to the outer end of the No. 4 bearing pressure tube.

Install the No. 4 bearing pressure tube ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-060) from the inside of the diffuser case.

NOTE

Gasket can be installed with the compression feature in either direction.Install ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-260) gasket 1 off to the pad on the outer surface of the diffuser case over the No. 4 bearing pressure tube.

Install the sealing sleeve ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-280) over the tube and against the gasket.

Install the retaining plate ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-300) over the tube and against the sealing sleeve.

Install the three bolts ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-320) to hold the gasket, the sleeve and the plate in position. Do not torque the bolts.

Install the coupling nut ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-420) to the outer end of the pressure tube and lock in place with ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 01-440) thrust wire 1 off.

SUBTASK 72-42-10-440-061 Install the No. 4 Bearing Pressure Tube

Refer to Figure.

Attach a hoist to the IAE 1P16173 Lift sling 1 off.

Remove the 10 bolts that attach the IAE 1P16004 Handling bracket 2 off to the diffuser case assembly.

SUBTASK 72-42-10-440-063 Remove the Diffuser Case Assembly from the Build Stand

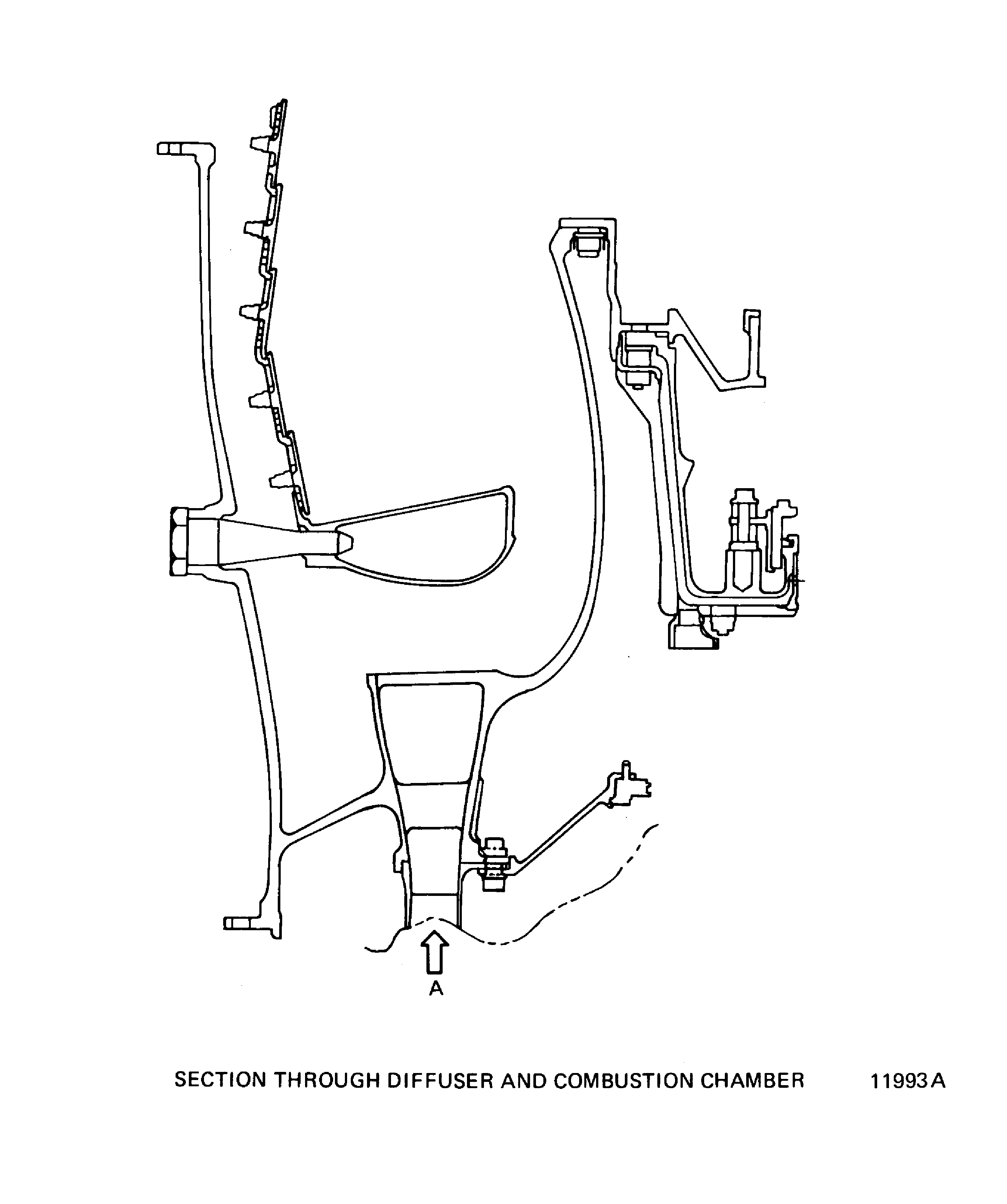

Figure: Diffuser Case Assembly - Fits and Clearances

Sheet 1

Figure: Diffuser Case Assembly - Fits and Clearances

Sheet 2

Figure: Diffuser Case Assembly - Fits and Clearances

Sheet 3

Figure: Pre SBE 72-0166: Diffuser Case Assembly - Fits and Clearances

Sheet 4

Figure: Diffuser Case Assembly - Fits and Clearances

Sheet 5

Figure: Install/Remove the Diffuser Case Assembly to/from the Build Stand

Install/Remove the Diffuser Case Assembly to/from the Build Stand

Figure: Install the No. 4 Bearing Weep Tube

Install the No. 4 Bearing Weep Tube

Figure: Pre SBE 72-0166: Install the Turbine Cooling Air Duct Sensing Tube

Pre SBE 72-0166: Install the Turbine Cooling Air Duct Sensing Tube

Figure: SBE 72-0166 Part 1: Install the Sensing Tube Covers

SBE 72-0166 Part 1: Install the Sensing Tube Covers

Figure: Install the No. 4 Baring Pressure Tube

Install the No. 4 Baring Pressure Tube