Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

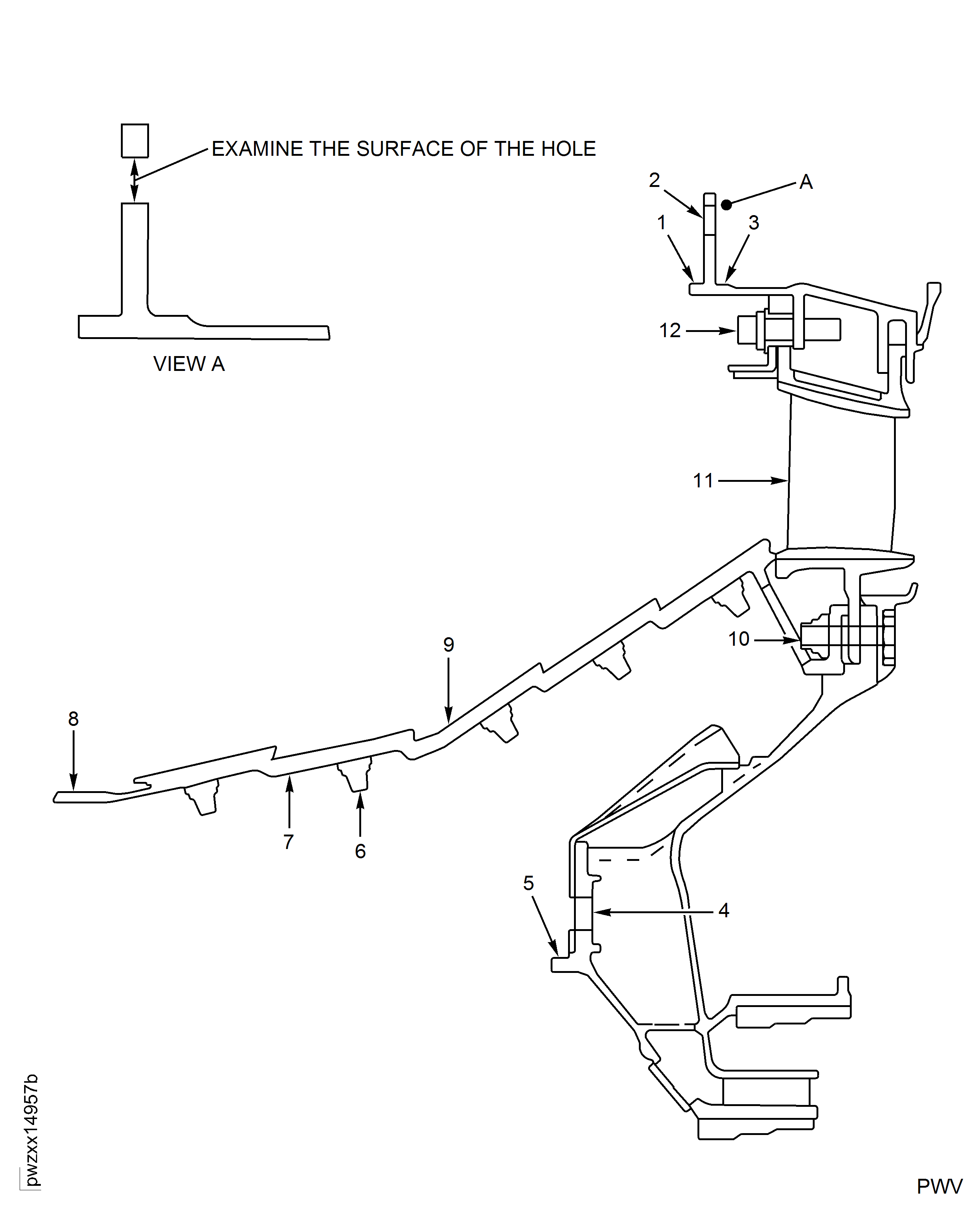

TASK 72-00-44-220-001 Stage 1 Turbine Nozzle Assembly - Examine The Stage 1 Turbine Nozzle Assembly Front Face At Interface L-44, Inspection-001

General

The word "Reject" after an interface inspection statement requires that further detailed inspection or repair as applicable, of the affected area be accomplished using data in the applicable ATA section of the part in question. Contact IAE for FAA approved data if the referenced TASK is not in the manual.

Refer to TASK 72-00-00-200-001 (examine the modular/non-modular interfaces) before you do this TASK.

The policy that is necessary for inspection is given in the SPM TASK 70-20-01-200-501.

You can do the inspections that follow if the stage 1 turbine nozzle assembly is removed (Refer to TASK 72-00-44-020-001-001).

Installation of modules that are near the maximum interface limits can result in decreased module run times.

Use a bright light and a 3X magnifying glass to find surface cracks.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure.

SUBTASK 72-00-44-220-056 Visually Examine the Support Assembly Outer Flange Bolt Holes at Location 2

Refer to Figure.

Clean the bolt holes per SPM TASK 70-11-26-300-503 (PW equivalent SPOP 208).

Perform local FPI per SPM TASK 70-23-05-230-501 (high sensitivity) (or equivalent PW SPOP 70).

Examine the flange bolt holes carefully.

Reject.

If you find any indication.

SUBTASK 72-00-44-220-083 Examine the Support Assembly Outer Flange at Location 2

Refer to Figure.

SUBTASK 72-00-44-220-059 Visually Examine the Duct Assembly Bolt Holes at Location 4

Refer to Figure.

SUBTASK 72-00-44-220-060 Visually Examine the Inner Combustion Chamber at Location 6

Refer to Figure.

SUBTASK 72-00-44-220-061 Visually Examine the Shell of the Inner Combustion Chamber Assembly at Location 7

Refer to Figure.

SUBTASK 72-00-44-220-062 Visually Examine the Front Seal of the Inner Combustion Chamber Assembly at Location 8

Refer to Figure.

SUBTASK 72-00-44-220-063 Visually Examine the Liner Segments at Location 9

Refer to Figure.

SUBTASK 72-00-44-220-078 Examine the Combustion Chamber Inner Liner Nut Channel at Location 10

Refer to Figure.

Concave or convex side axial cracks not more than 1.500 in. (38.10 mm) long and/or concave or convex side radial cracks not more than 1.500 in. (38.10 mm) long. All cracks must be less than 0.050 in. (1.27 mm) wide and must not have connected loop cracks more than 0.400 in. (10.16 mm) long or look like this will occur

SUBTASK 72-00-44-220-064 Visually Examine the Stage 1 Vanes at Location 11

Refer to Figure.

SUBTASK 72-00-44-220-066 Visually Examine the Turbine Vane Retaining Bolts at Location 12

Figure: Locations at Interface L-44

Locations at Interface L-44