Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-50-220-001 LPT Module - Examine The LPT Module Front Face At Interface D-50/10, Inspection-001

Effectivity

FIG/ITEM | PART NO. |

01-001 | 4W5192 |

01-001 | 4W5222 |

01-001 | 4W5224 |

01-001 | 4W5225 |

01-001 | 4W5227 |

01-001 | 4W6013 |

01-001 | 4W6423 |

01-001 | 4W6243 |

General

The word 'reject' is used after an interface inspection statement to show that a higher level inspection and possible repair to the damaged part is necessary. Do the higher level inspection procedure as found in the applicable Chapter/Section/Subject of this manual on the damaged part(s). It is not necessary to do the higher level inspection on parts that are serviceable to the interface inspection standard.

Refer to TASK 72-00-00-200-000 (INSPECTION-000) before you do this TASK.

The policy that is necessary for inspection is given in SPM TASK 70-20-01-200-501.

All parts must be visually examined for damage, corrosion, and wear. Any defects that are not identified in the procedure must be referred to IAE.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| 10x illuminated magnifier | LOCAL | 10x illuminated magnifier |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Before inspection, clean the interface parts. Refer to TASK 72-00-50-100-001 (CLEANING-001).

SUBTASK 72-00-50-220-131 General Instructions for the Inspection of the LP Turbine at Interface

Disassemble the LP turbine module. Refer to TASK 72-50-00-030-000 (DISASSEMBLY-000).

Do not clean the parts without prior agreement of IAE Technical Services.

Visually inspect all parts for unusual signs of overheating, melting, discoloration, soot, and deposits.

Do the hardness test on disk stage 3

Do the overtemperature inspection on blade stage 3. If stage 3 blades show signs of melting, reject complete set of stage 3 blades and vanes and examine stage 4 blades for overheating.

Take photos from all damaged parts.

Tell IAE Technical Services.

Oil fire/Titanium fire

SUBTASK 72-00-50-280-001 Visually Examine the LP Turbine Module for Unusual Running Conditions

Repair, VRS4343 TASK 72-50-21-300-031 (REPAIR-031)

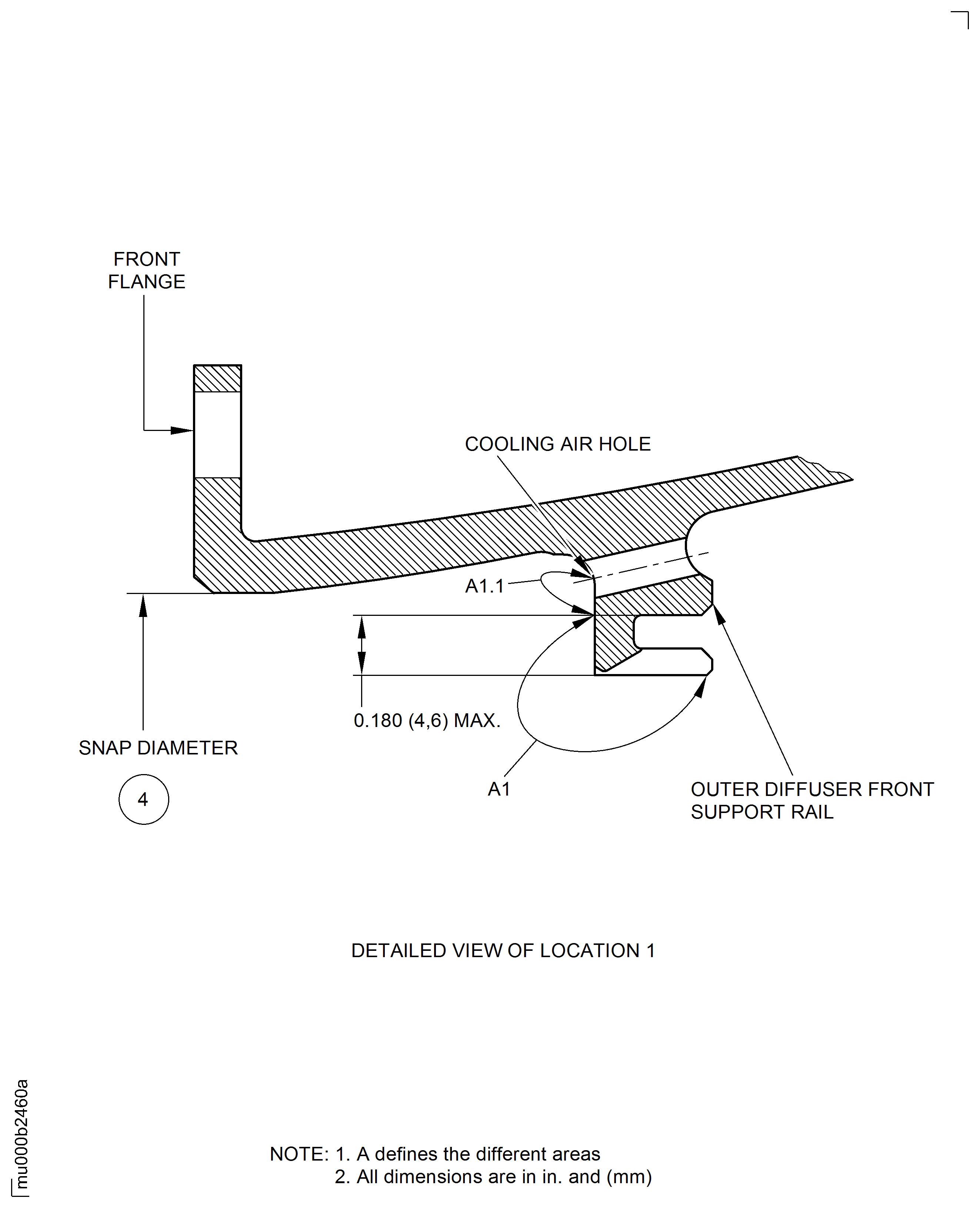

Examine the outer duct support hook for open stop holes which are 0.085 to 0.095 in. (2.16 to 2.41 mm) diameter.

Repair, VRS4343 TASK 72-50-21-300-031 (REPAIR-031)

Cracked in area A1, going across into area A1.1

NOTE

A total of ten air cooling holes that are 0.114 to 0.125 in. (2.90 to 3.20 mm) diameter must be open.Cracked

More than in Step

Nicked, dented

SUBTASK 72-00-50-220-070 Visually Examine the LP Turbine Case

Refer to Figure.

More than in Step

Coating loss or damage (only applicable when the duct was originally aluminide coated)

Repair, VRS4375 TASK 72-50-00-300-008 (REPAIR-008)

Uncoated segment

More than in Step

Nicked, dented

More than in Step

Seal strip deterioration

Refer to Step.

Deposits not caused with normal engine running

Deposits

SUBTASK 72-00-50-220-073 Visually Examine the Outer Diffuser Segment at Location 6

More than in Step

Pull the segment forward in axial direction as far as possible. Subsequently turn the rear end of the segment most inward and the front end most outward and inverse. Measure the deviation between the inner and outer end positions at the rear end of the segment at each location 12 and 13.

Measure the radial looseness.

More than in Step

Pull the segment forward in axial direction as far as possible. Measure the gap at dimension D8.

Measure the axial looseness.

More than in Step

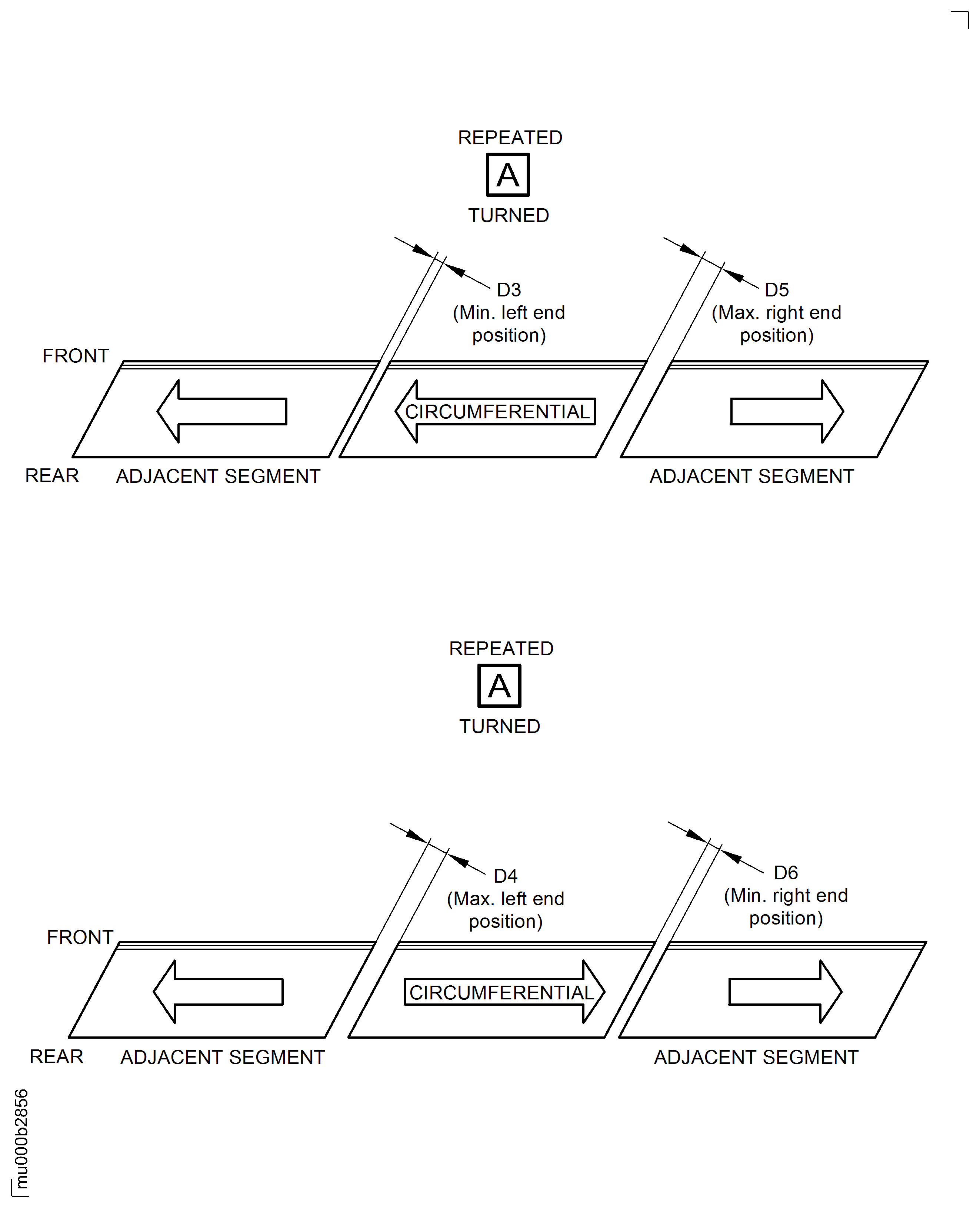

Pull the segment forward in axial direction as far as possible. Subsequently turn the rear end of the segment most outward and the front end most inward. The adjacent segments must be pushed away in circumferential direction as far as possible. Measure the deviation between dimensions D3 and D4 or between dimensions D5 and D6.

Measure the circumferential looseness.

More than in Step

Seal strip deterioration

Refer to Step.

Deposits not caused with normal engine running

Deposits

SUBTASK 72-00-50-220-074-A00 Visually Examine the Inner Duct Segment at Location 7 (Pre SBE 72-0359)

More than in Step

Pull the segment forward in axial direction as far as possible. Subsequently turn the rear end of the segment most inward and the front end most outward and inverse. Measure the deviation between the inner and outer end positions at the rear end of the segment at each location 12 and 13.

Measure the radial looseness.

More than in Step

Pull the segment forward in axial direction as far as possible. Measure the gap at dimension D8.

Measure the axial looseness.

More than in Step but total maximum one gap not more than 0.386 in. (9.80 mm) maximum gap if axial and radial looseness are within limits and if not more than three seal strips are missing or cracked.

More than in Step

Pull the segment forward in axial direction as far as possible. Subsequently turn the rear end of the segment most outward and the front end most inward. The adjacent segments must be pushed away in circumferential direction as far as possible. Measure the gap at dimension D7.

Measure the circumferential looseness.

More than in Step

Seal strip deterioration

Refer to Step.

Deposits not caused with normal engine running

Deposits

SUBTASK 72-00-50-220-074-B00 Visually Examine the Inner Duct Segment at Location 7 (SBE 72-0359)

Examine the fillet radius in area A2.2 for cracks. Use 10x illuminated magnifier.

Repair, VRS4375 TASK 72-50-00-300-008 (REPAIR-008)

More than in Step

Nicked, dented, pitted

Examine the surface in area A2.1.

Repair, VRS4375 TASK 72-50-00-300-008 (REPAIR-008)

Nicked, dented, pitted in area A2.3.1

Repair, VRS4375 TASK 72-50-00-300-008 (REPAIR-008)

Nicked, dented, pitted in area A2.3.2

Examine the surface in area A2.3.

Repair, VRS4375 TASK 72-50-00-300-008 (REPAIR-008)

Nicked, dented, pitted in area A2.4.1

Repair, VRS4375 TASK 72-50-00-300-008 (REPAIR-008)

Nicked, dented, pitted in area A2.4.2

Examine the surface in area A2.4.

Repair, VRS4375 TASK 72-50-00-300-008 (REPAIR-008)

More than in Step

Nicked, dented, pitted

Examine the surface in area A2.5.

Repair, VRS4375 TASK 72-50-00-300-008 (REPAIR-008)

More than in Step

Nicked, dented, pitted

Examine the surface in area A2.6.

Repair, VRS4375 TASK 72-50-00-300-008 (REPAIR-008)

More than in Step

Nicked, dented, pitted

Examine the surface in area A2.8.

Repair, VRS4375 TASK 72-50-00-300-008 (REPAIR-008)

Cracked or chipped coating at nick or dent

Coating loss or damage

Refer to Step

Deposits not caused with normal engine running

Deposits

SUBTASK 72-00-50-220-079 Visually Examine the Stage 3 Turbine Vanes at Location 2

Accept with inspection each 2000 cycles or 3500 hours whichever occurs first

Sulphidation originating from the side face not reaching the fillet radius

Accept with inspection each 600 cycles or 1000 hours whichever occurs first

Sulphidation originating from the side face reaching the fillet radius but not extending into the radius

Reject

Other than in Step

Examine the side face and outer shroud platform for sulphidation.

SUBTASK 72-00-50-220-007 Visually Examine the Stage 3 Turbine Vanes at Outer Shroud Side Faces for Sulphidation/Corrosion at Location 2

Repair, VRS4375 TASK 72-50-00-300-008 (REPAIR-008)

More than in Step

Nicked, dented, pitted

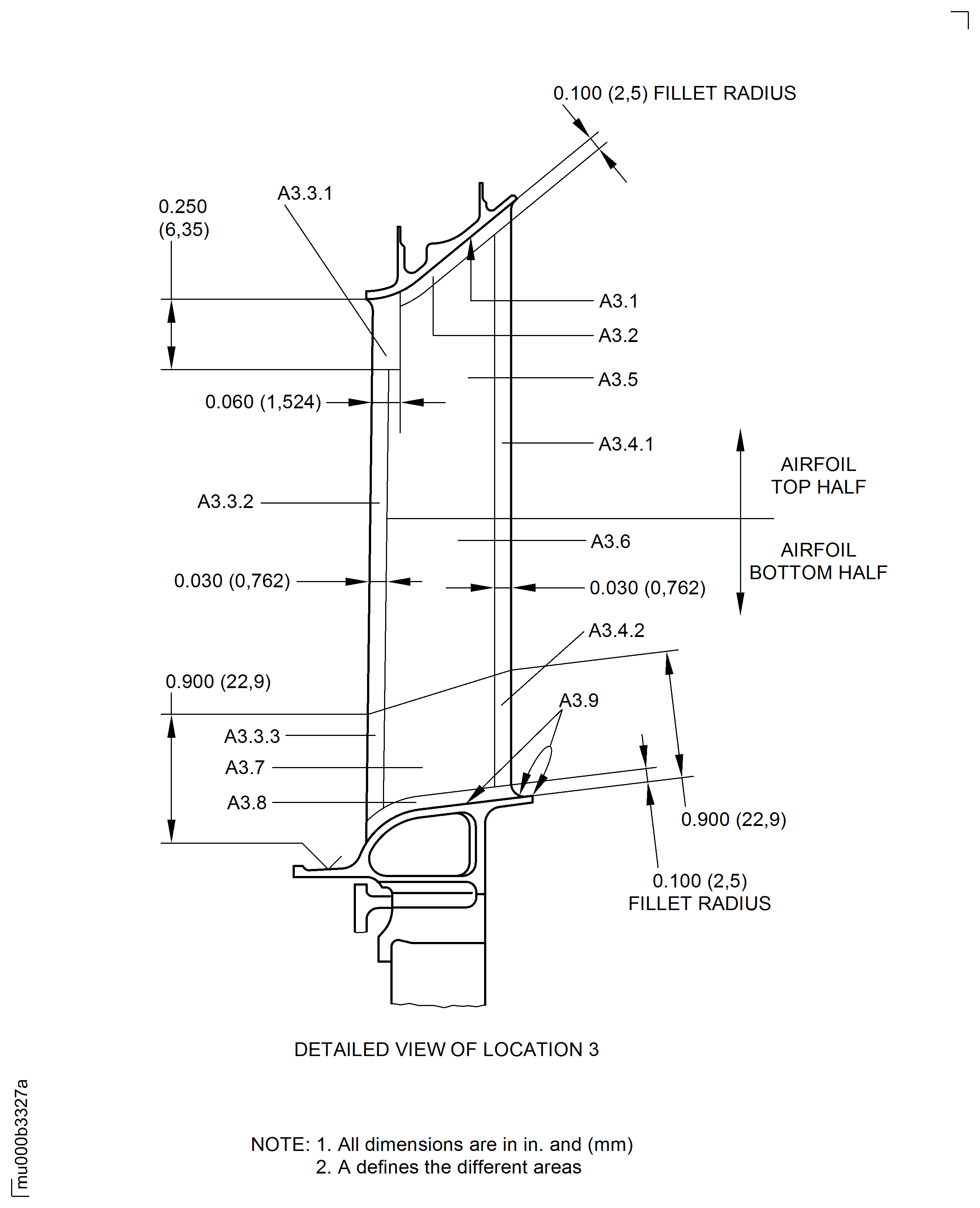

Examine the surface in area A3.1.

Repair, VRS4375 TASK 72-50-00-300-008 (REPAIR-008)

Examine the surface in area A3.3.

Repair, VRS4375 TASK 72-50-00-300-008 (REPAIR-008)

Examine the surface in area A3.4.

Repair, VRS4375 TASK 72-50-00-300-008 (REPAIR-008)

Other than in Step

Nicked, dented, pitted

Examine the surface in area A3.5.

Repair, VRS4375 TASK 72-50-00-300-008 (REPAIR-008)

Other than in Step

Nicked, dented, pitted

Examine the surface in area A3.6.

Repair, VRS4375 TASK 72-50-00-300-008 (REPAIR-008)

More than in Step

Nicked, dented, pitted

Examine the surface in area A3.7.

Refer to Step.

Deposits not caused with normal engine running

Deposits

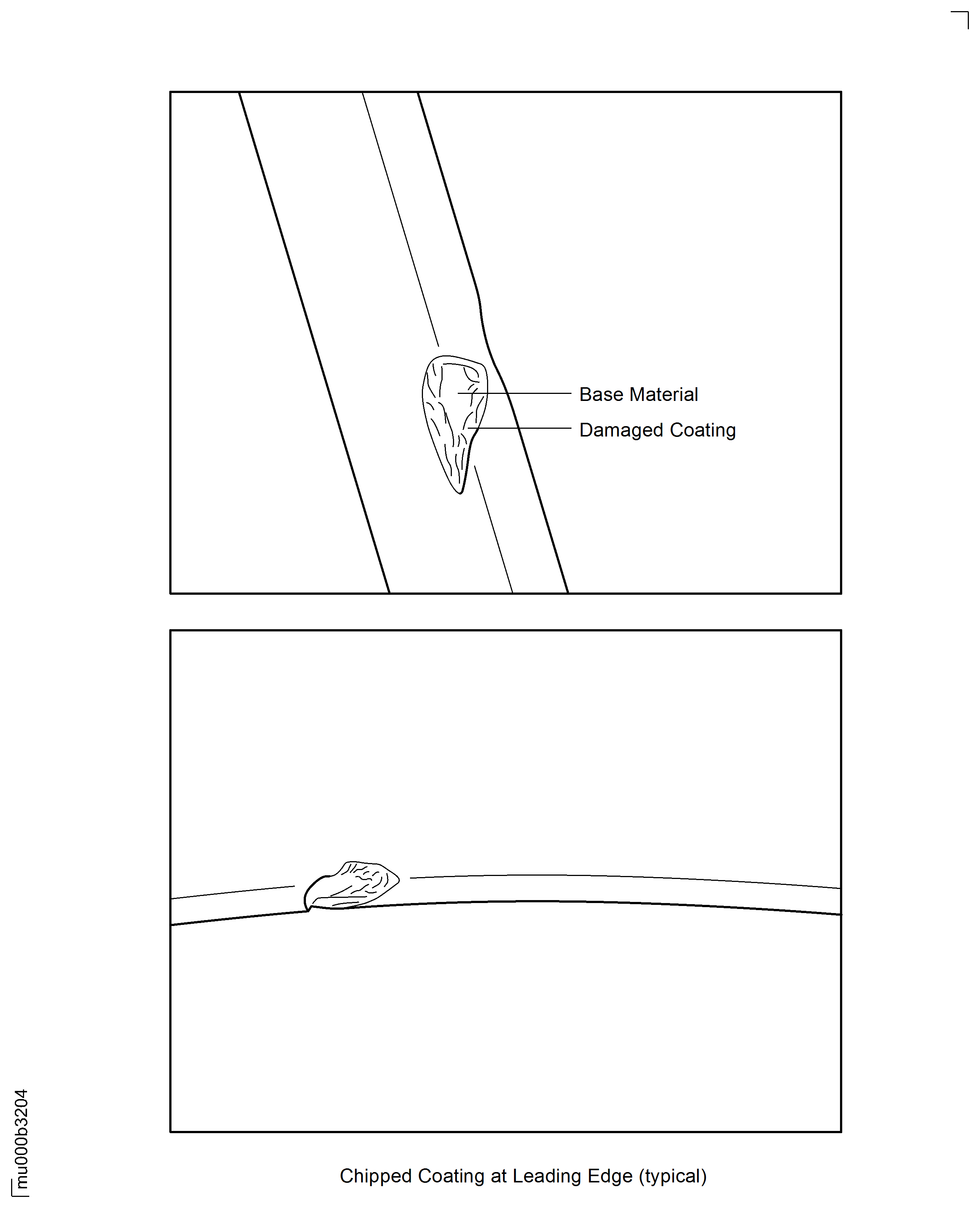

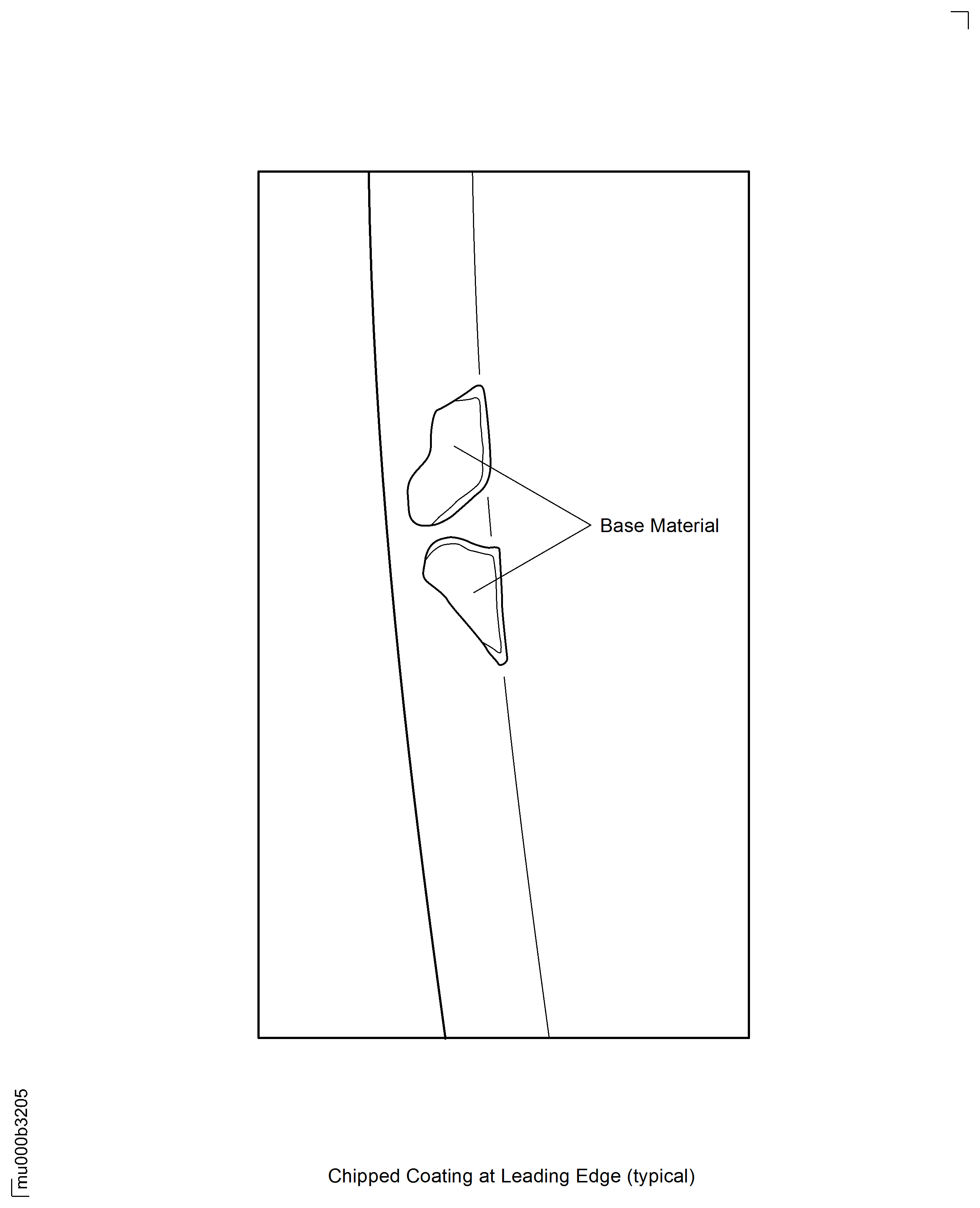

SUBTASK 72-00-50-220-077 Visually Examine the Stage 3 Turbine Blades at Location 3

More than Step

Single pits in base material or raised pustules

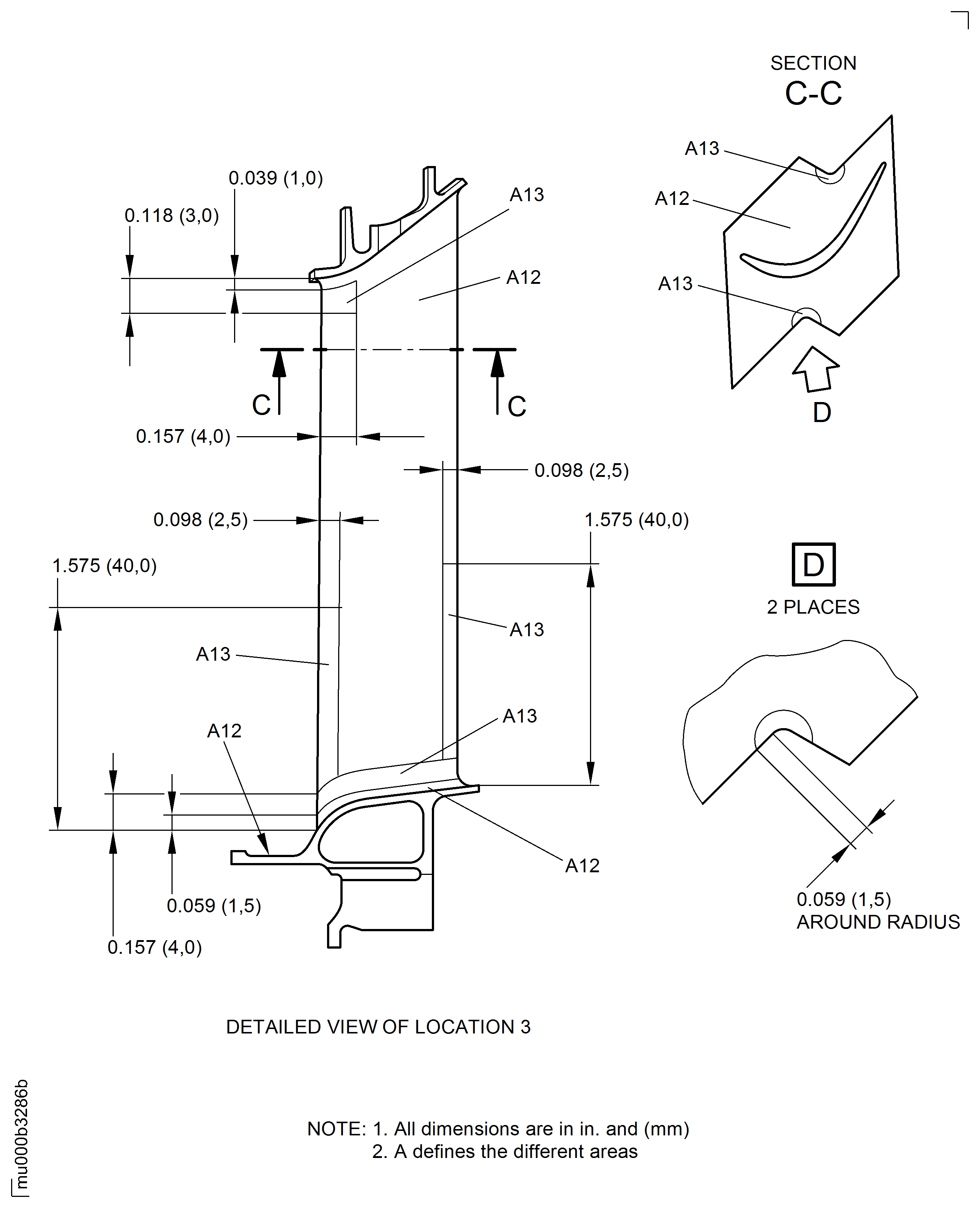

Examine the surface in area A12.

More than in Step

Single pits in base material

Examine the surface in area A13.

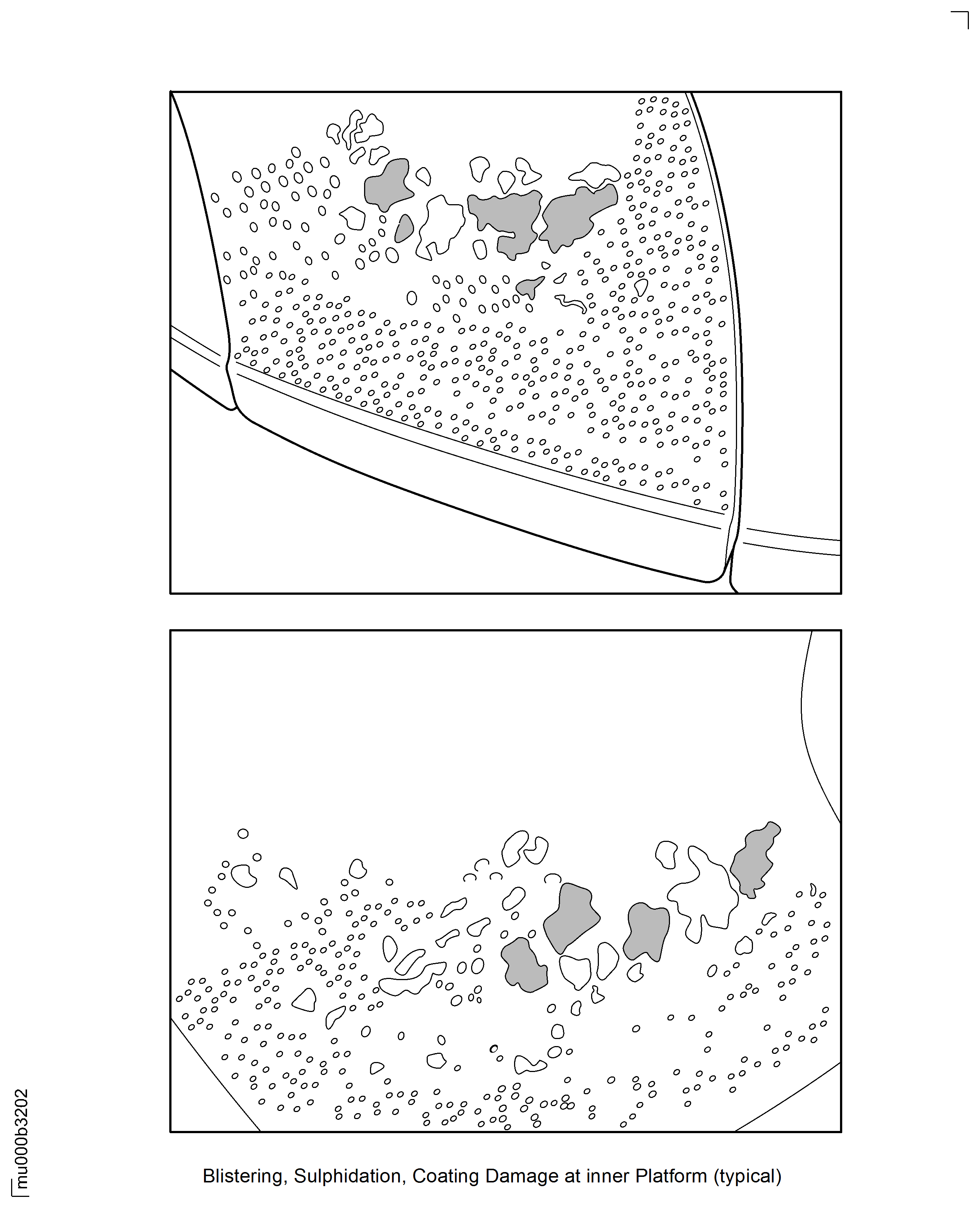

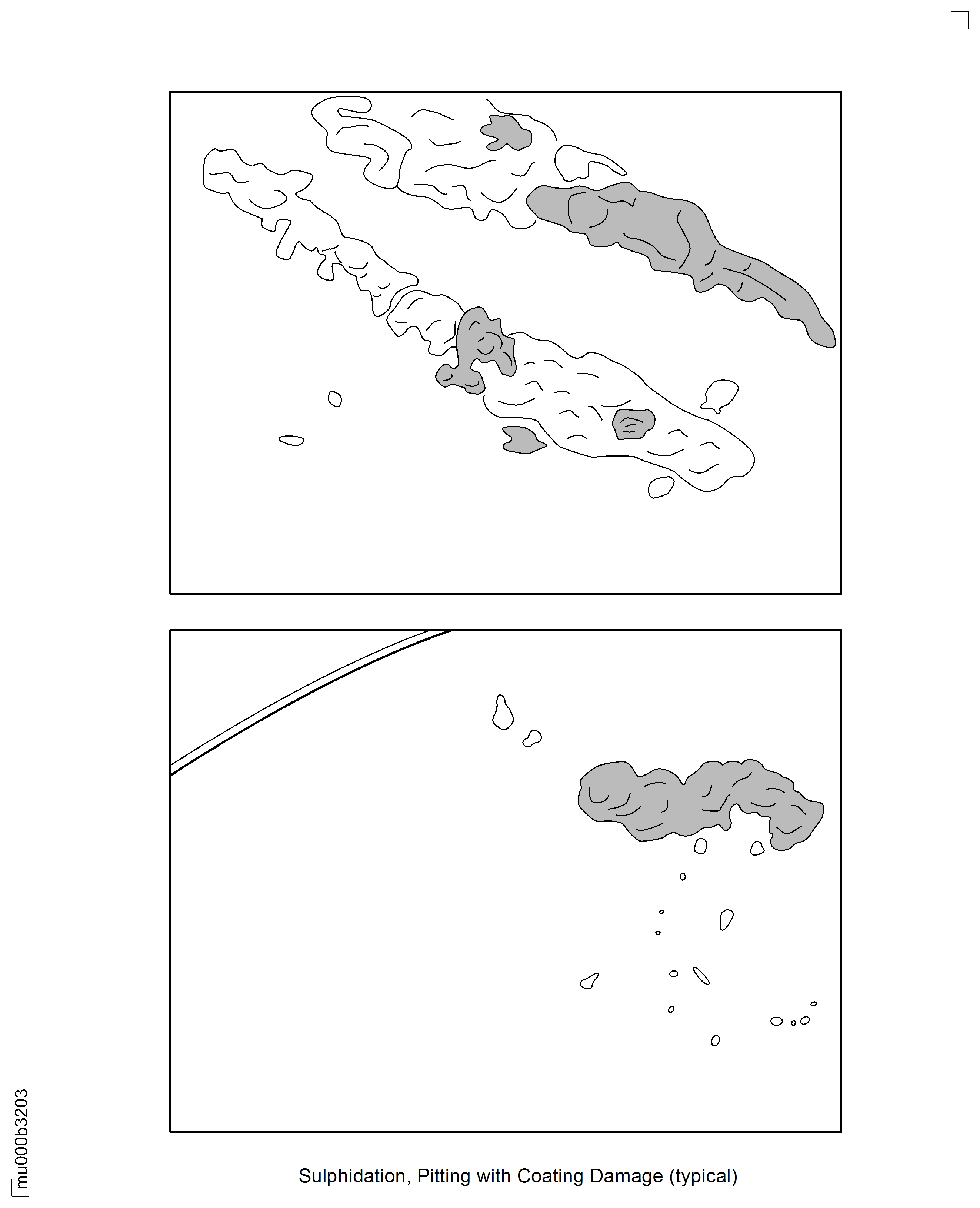

SUBTASK 72-00-50-220-250 Visually Examine the Stage 3 Turbine Blades for Sulphidation/Corrosion/Blistering/Coating Damage at Location 3

Refer to Figure.

SUBTASK 72-00-50-220-081 Visually Examine the Stage 3 Air Seal Ring at Location 9

Refer to Figure.

NOTE

Blades are in unlatched condition if the outer shroud interlock between two blades is lost.

SUBTASK 72-00-50-220-249 Visually Examine the Stage 3 Blades for Unlatching

Refer to Figure.

Reject

Shingled

Examine all blades for signs of shingling.

SUBTASK 72-00-50-220-008 Visually Examine the Stage 3 Blades for Shingling

Figure: Locations at Interface D-50/10

Locations at Interface D-50/10

Figure: Locations at Interface D-50/10

Locations at Interface D-50/10

Figure: Locations at Interface D-50/10

Locations at Interface D-50/10

Figure: Locations at Interface D-50/10

Locations at Interface D-50/10

Figure: Locations at Interface D-50/10

Locations at Interface D-50/10

Figure: Locations at Interface D-50/10

Locations at Interface D-50/10

Figure: Locations at Interface D-50/10

Locations at Interface D-50/10

Figure: Locations at Interface D-50/10

Locations at Interface D-50/10

Figure: Unlatched Blades at Interface D-50/10

Unlatched Blades at Interface D-50/10

Figure: Locations at Interface D-50/10

Locations at Interface D-50/10

Locations at Interface D-50/10

Locations at Interface D-50/10

Locations at Interface D-50/10

Locations at Interface D-50/10

Locations at Interface D-50/10

Locations at Interface D-50/10

Locations at Interface D-50/10

Locations at Interface D-50/10

Figure: Damaged Blades at Interface D-50/10

Damaged Blades at Interface D-50/10

Figure: Sulphidated Vanes Outer Shroud Side Faces at Interface D-50/10

Sulphidated Vanes Outer Shroud Side Faces at Interface D-50/10

Figure: Sulphidated Vanes Outer Shroud Side Faces at Interface D-50/10

Sulphidated Vanes Outer Shroud Side Faces at Interface D-50/10

Figure: Sulphidated Vanes Outer Shroud Side Faces at Interface D-50/10

Sulphidated Vanes Outer Shroud Side Faces at Interface D-50/10

Figure: Shingled Blades at Interface D-50/10

Shingled Blades at Interface D-50/10