Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-00-300-008 LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit - Blend Repair, Repair-008 (VRS4375)

Effectivity

FIG/ITEM | PART NO. | |

|---|---|---|

01-001 | 4W5192 | |

01-001 | 4W6013 | |

01-001 | 4W6243 | |

01-001 | 4W6423 | |

01-001 | 4W5222 | |

01-001 | 4W5224 | |

01-001 | 4W5225 | |

01-001 | 4W5227 |

General

VRS 4375 TASK 72-50-00-300-008 (REPAIR-008) gives a blend repair for surface damage in specified areas of the outer diffuser segment, the stage 3 turbine vane and stage 3 turbine blade for a LP Turbine Module, which is not disassembled.

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Action swivel vise | LOCAL | Action swivel vise | ||

| Radius gage set | LOCAL | Radius gage set | ||

| Illuminated comparator magnifier | LOCAL | Illuminated comparator magnifier | ||

| Dial caliper | LOCAL | Dial caliper | ||

| External dial caliper | LOCAL | External dial caliper |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

The blend repair can be done only when the access for blend repair is good enough to allow the complete removal of the damage to get the required quality of the repair.

Be careful that no particles or dirt get into or stay in the assembled LP turbine module.

Unless specified differently, do not blend repair dents.

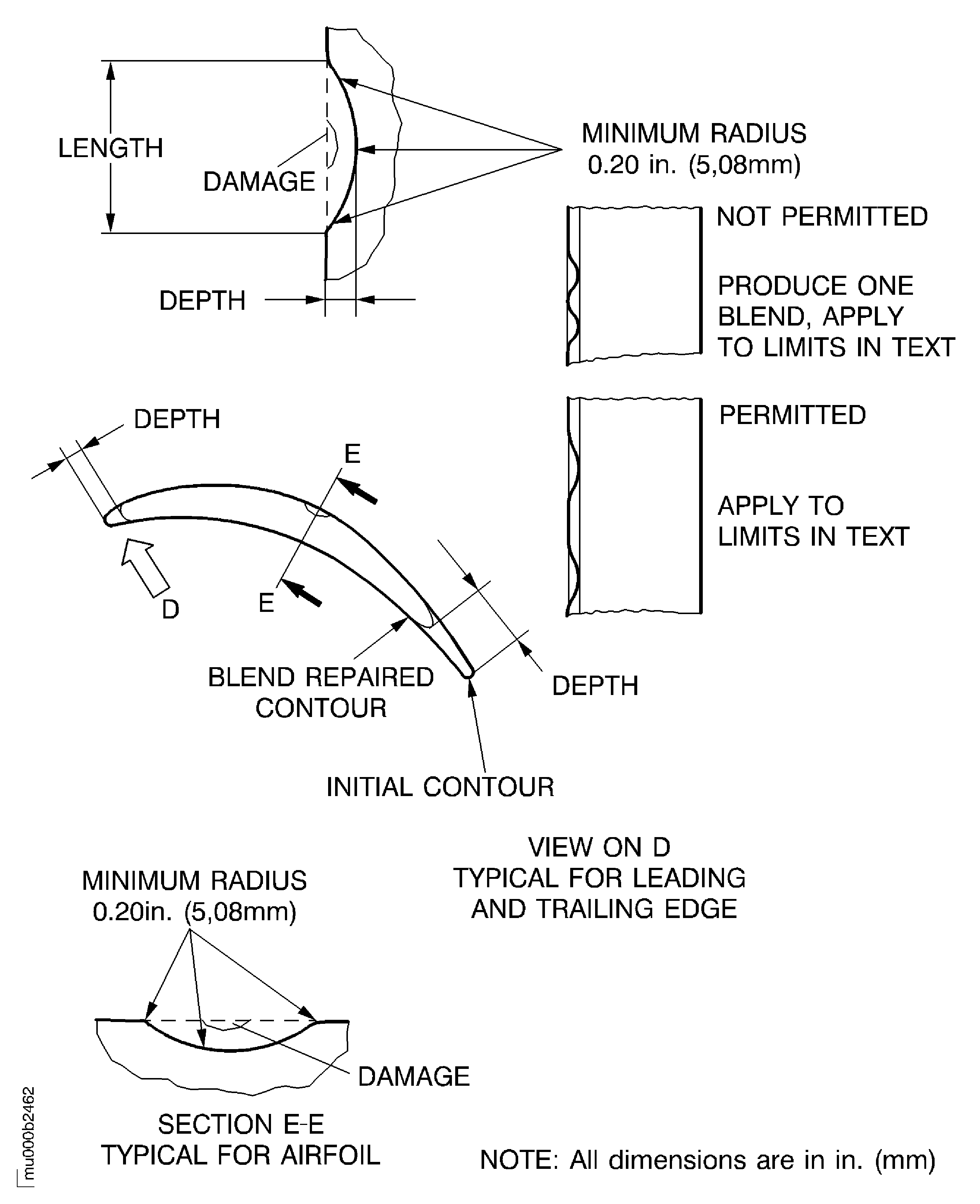

Unless specified differently, the blend ratio, length to depth, must be a minimum of 5:1. For correct shape of the blend refer to Figure.

Unless specified differently, there is no limit for the number of blends. If there is a number of damage marks together, blend the whole area to the specified depth.

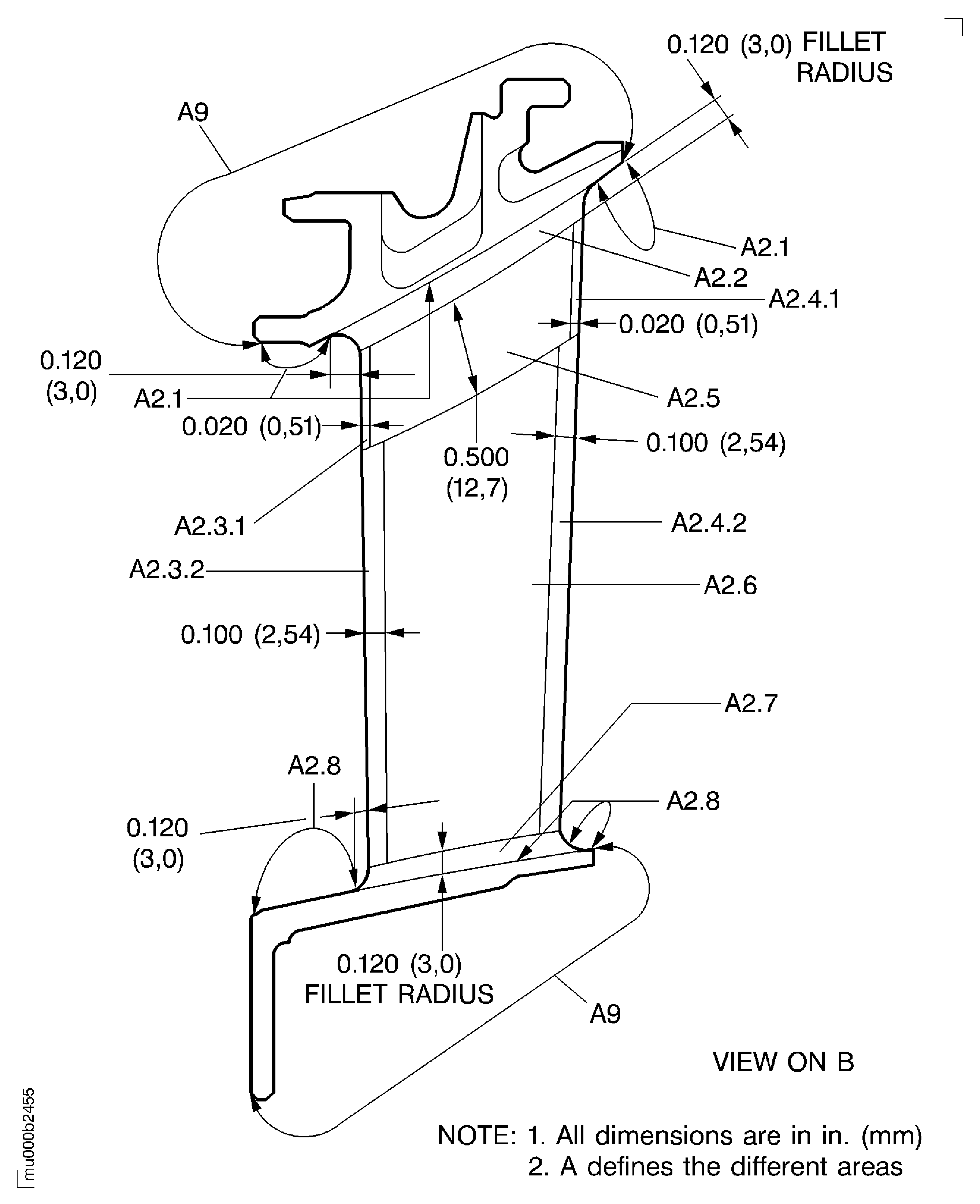

The minimum distance between the blends is 0.500in. (12.7 mm) for the outer diffuser segment and the stage 3 turbine vanes leading edge and trailing edge. For the stage 3 turbine blades the minimum distance between the blends is 0.200in. (5.0 mm).

Keep the material removal to the minimum necessary to remove damage.

The surface texture of all repaired surfaces must have the same or better quality to that of the adjacent not damaged area.

After blending in coated areas of vanes and blades, touch-up of the coating is not necessary.

Nicks, within acceptable limits do not require blend repair. If there is raised material, remove it only.

Repeated blending in one place is acceptable to the specified maximum depth, measured from the initial unblended surface.

SUBTASK 72-50-00-350-062 General Instructions for the Blend Repair of the Stage 3 Turbine Blade

NOTE

Refer to SUBTASK 72-50-00-350-062 before you do the blend repairs.

This blend repair is only applicable to uncoated outer diffuser segments P/N 3A1791 (coated outer diffuser segments, P/N 3A0090 and 3A0958 will be replaced).

Refer to: Figure

SUBTASK 72-50-00-350-063 Blend Repair the Uncoated Outer Diffuser Segments

NOTE

Refer to SUBTASK 72-50-00-350-062 before you do the blend repairs.

The extent of blend repair is limited. The total area of coatings loss (blended off and worn or damaged coating) is limited to max. 1.000 sqin. (645 sqmm) per vane cluster (shrouds and airfoil together).

Area definition is identical with area definition at visual inspection.

Refer to: Figure

SUBTASK 72-50-00-350-064 Blend Repair the Stage 3 Turbine Vanes

NOTE

Refer to SUBTASK 72-50-00-350-001 before you do the blend repairs.

The extent of blend repair is limited. The total area of coatings loss (blended off and worn or damaged coating) is limited to max. 1.000sqin. (645 sqmm) per blade (shrouds and airfoil together).

Area definition is identical with the area definition at visual inspection.

Polish the airfoils in spanwise direction only.

Refer to: Figure

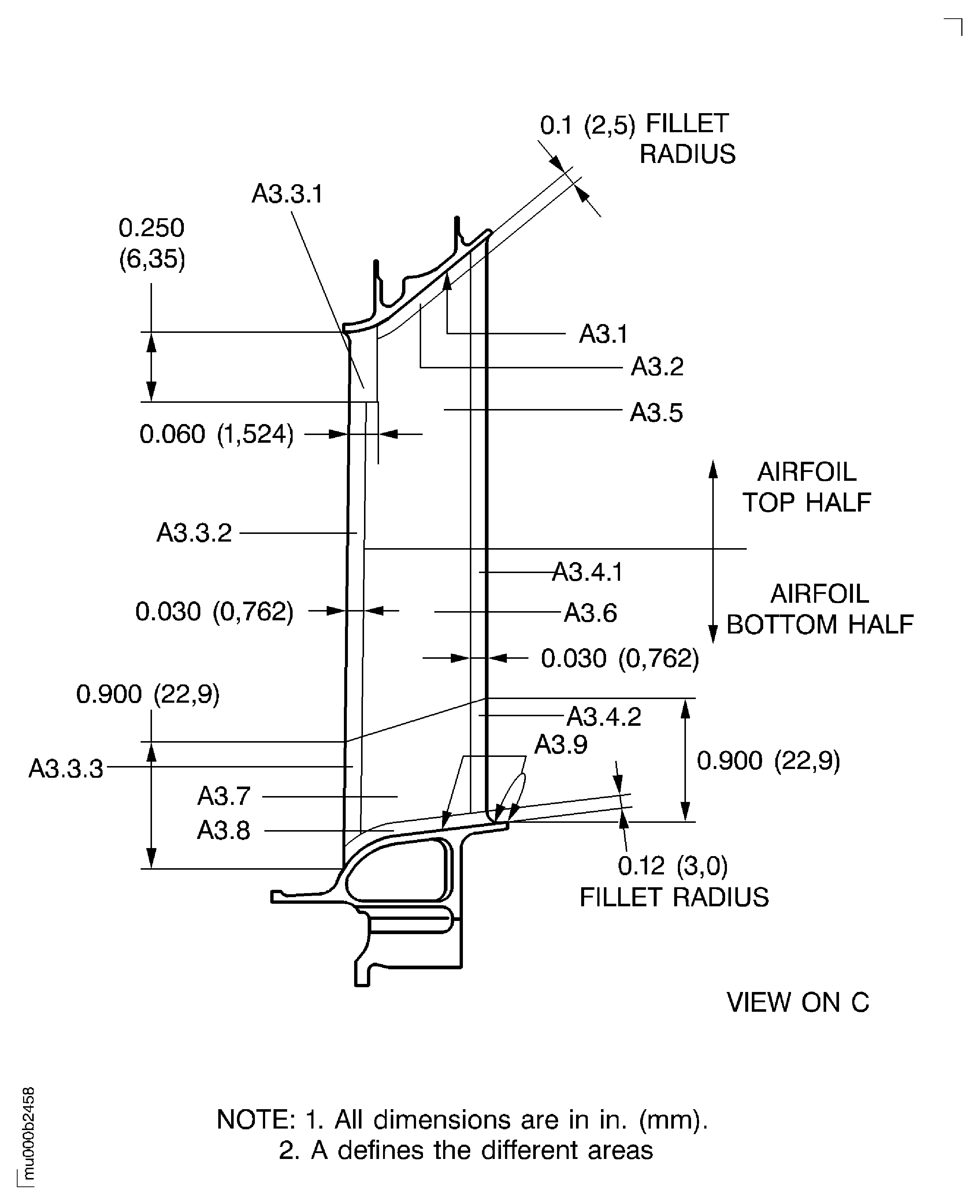

Blend depth from initial surface 0.060 in. (1.524 mm).

The maximum permitted total depth of opposite blends on leading and trailing edge is 0.060 in. (1.524 mm).

The total length of all blends on leading edge must not be more than 10 percent of the span.

The minimum transition radius to the outer shroud is 0.08 in. (2.0 mm).

Blend the surface in area A3.3.1.

Blend depth from initial surface 0.030 in. (0.762 mm).

The maximum permitted total depth of opposite blends on leading and trailing edge is 0.060 in. (1.524 mm).

The total length of all blends on leading edge must not be more than 10 percent of the span.

The blend ratio, length to depth, must be a minimum of 6:1.

Blend the surface in area A3.3.2.

Blend depth from initial surface 0.030 in. (0.762 mm).

The maximum permitted total depth of opposite blends on leading and trailing edge is 0.060 in. (1.524 mm).

The total length of all blends on each leading and trailing edge must not be more than 10 percent of the span.

The blend ratio, length to depth, must be a minimum of 6:1.

Blend the surface in area A3.3.3.

SUBTASK 72-50-00-350-065 Blend Repair the Stage 3 Turbine Blades

NOTE

Refer to the SPM TASK 70-11-26-300-503.

Clean the repaired areas.

SUBTASK 72-50-00-110-058 Cleaning

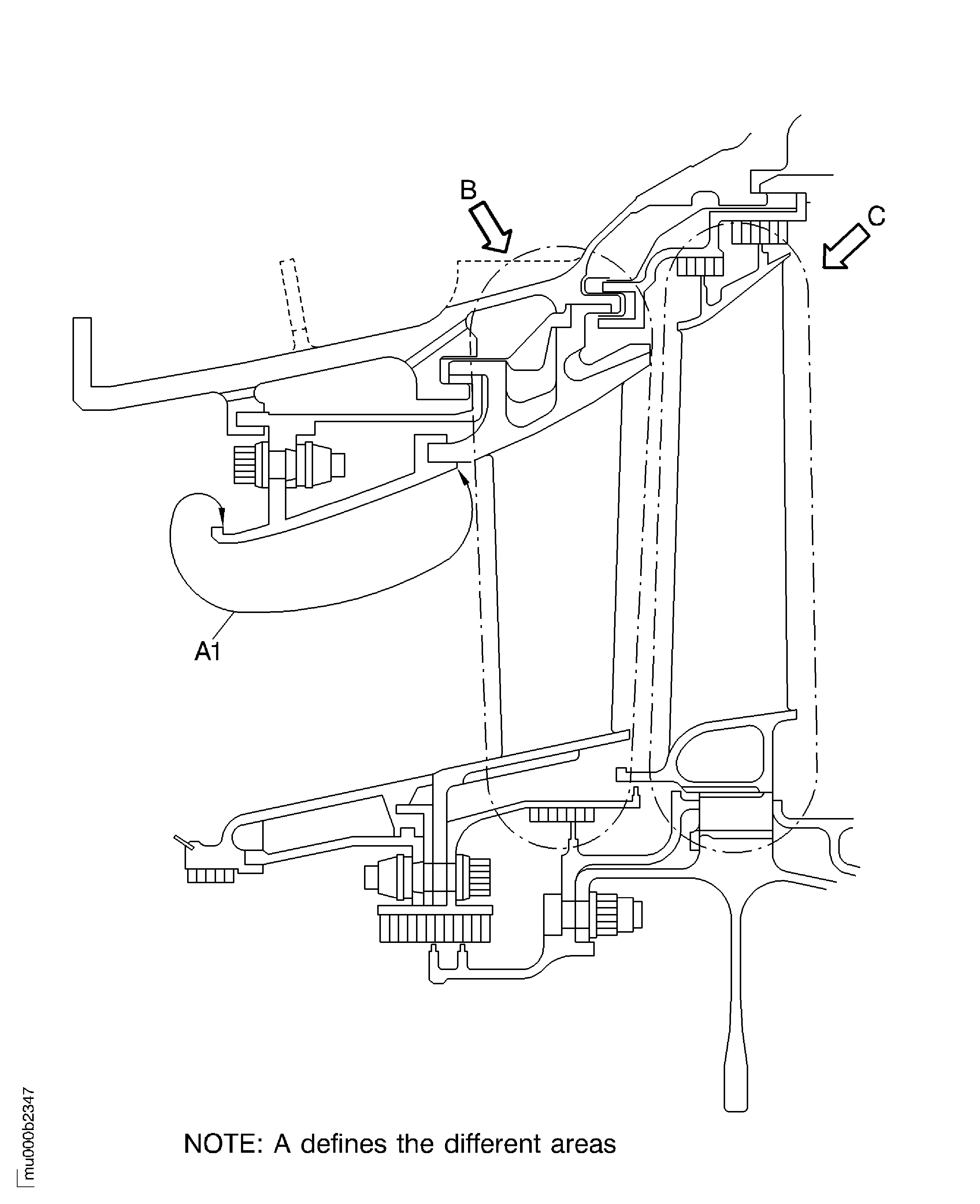

Figure: Blend repair the LP-turbine module

Blend repair the LP-turbine module

Figure: Blend repair the stage 3 turbine vanes

Blend repair the stage 3 turbine vanes

Figure: Blend repair the stage 3 turbine blades

Blend repair the stage 3 turbine blades

Figure: Details for the blend repair of the stage 3 turbine vanes and blades

Details for the blend repair of the stage 3 turbine vanes and blades