Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5 and Post SBE 72-0560 and Post SBE 72-0561

Common Information

TASK 72-00-00-200-002-B00 Engine General - Examine (Borescope) The HP Compressor (HPC), Inspection-002

General

This TASK gives the procedure for the borescope inspection of HP compressor rotor blades and rotor ceramic lining for A5 engines and engines which have SBE 72-0560 (SelectOne Retrofit Standard) and (SelectOne Production Standard) incorporated.

This TASK is only required after engine pass off test. Any damage found must be reported to IAE Technical Services department.

For engines that require no further strip of the HP compressor. Refer to TASK 72-00-00-200-802 SPECIAL PROCEDURES-002.

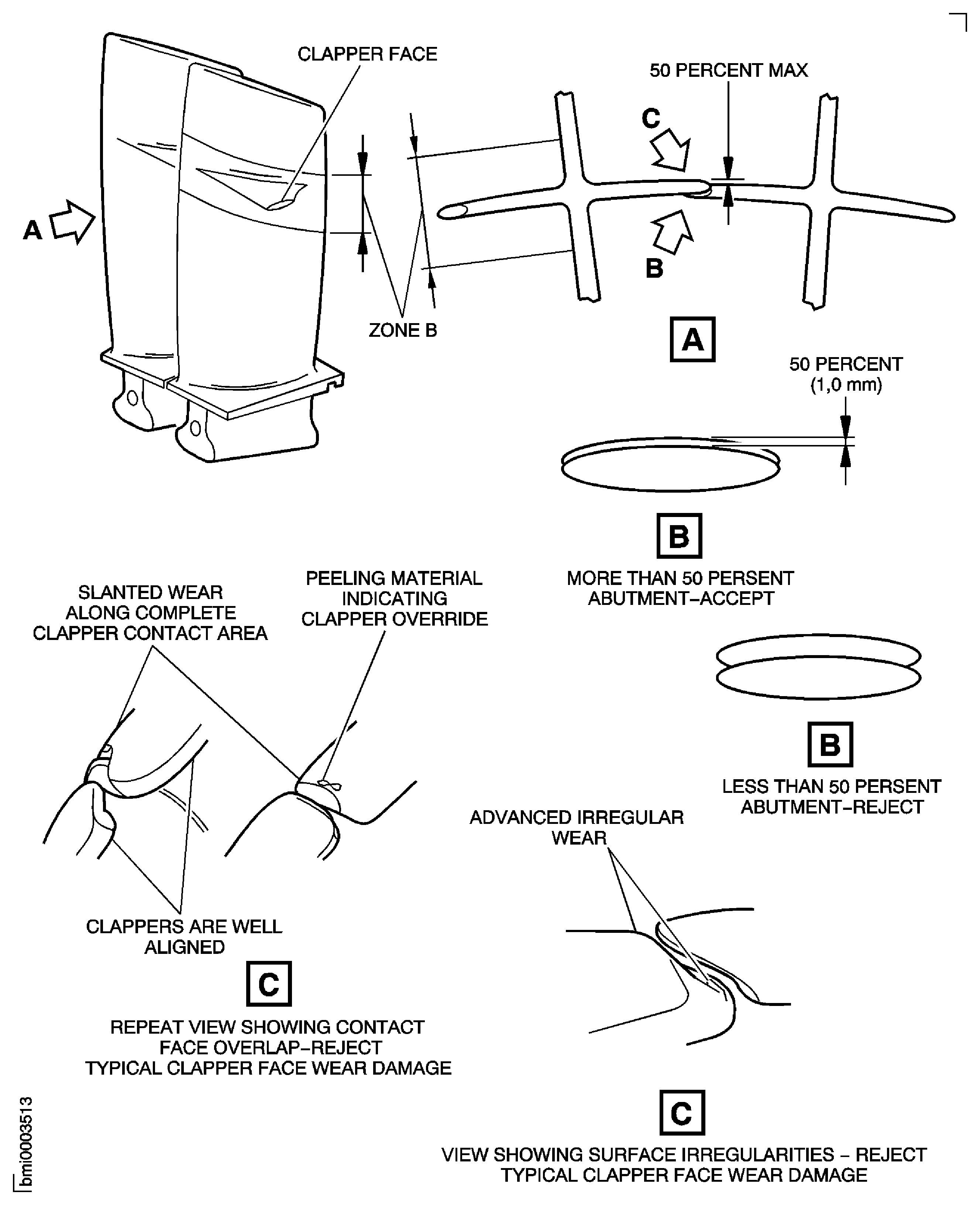

It is also required that all pass off engines R3 clappers are inspected for overlap, if found report to IAE Technical Services department.

Nicks and dents on airfoils, 0.005 in. (0.127 mm) or less, are considered minor. Minor nicks and dents are acceptable. There is no limit to the number of minor nicks and dents allowed.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all the parts identified in a different Chapter/Section/Subject the applicable Chapter/Section/Subject comes before the Fig/item number.

For the torque tightening procedures refer to SPM TASK 70-41-01-400-501.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| ACR Torq-Set bit 212-1/4-ACR | LOCAL | Torq-Set | ||

| IAE 2F10057 Rotator Kit | 0AM53 | IAE 2F10057 | 1 | |

| IAE 6F10408 Borescope | 0AM53 | IAE 6F10408 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-003 SOLVENT, DELETED | X111X | CoMat 01-003 | ||

| CoMat 01-076 METHYL ETHYL KETONE | LOCAL | CoMat 01-076 | ||

| CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE | LOCAL | CoMat 04-004 | ||

| CoMat 04-011 JOINTING COMPOUND | LOCAL | CoMat 04-011 | ||

| CoMat 10-070 ANTI-SEIZE COMPOUND | X222X | CoMat 10-070 | ||

| CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) | K6835 | CoMat 10-072 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| GASKET | 0AM53 | 6A4139 | 3 | 72-41-00, 02-108 |

| GASKET | 0AM53 | 6A4181 | 1 | 72-41-23, 02-108 |

| PACKING - PREFORMED | U1653 | AS3209-122 | 1 | 72-60-21, 01-280 |

Safety Requirements

NONEProcedure

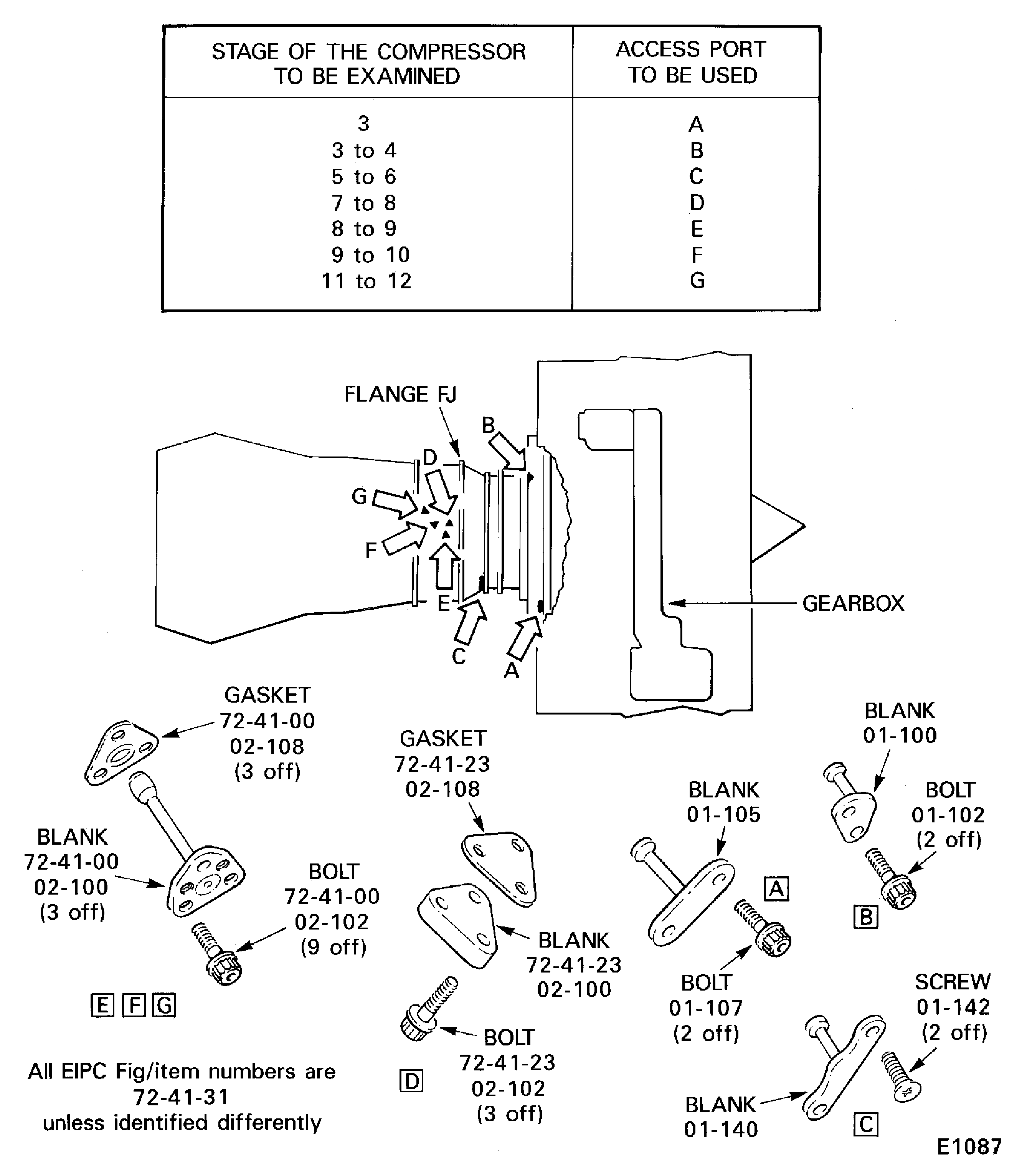

Remove the two bolts HP COMPRESSOR SPLIT CASE (72-41-31, 01-107) that attach inspection port blank A HP COMPRESSOR SPLIT CASE (72-41-31, 01-105) to the compressor case.

Remove the stage 3 borescope access port blanks from HP compressor split case.

Remove the two bolts HP COMPRESSOR SPLIT CASE (72-41-31, 01-102) that attach inspection port blank B HP COMPRESSOR SPLIT CASE (72-41-31, 01-100) to the compressor case.

Remove the stage 3 and 4 borescope access port blanks from HP compressor split case.

Remove the two bolts HP COMPRESSOR SPLIT CASE (72-41-31, 01-142) that attach inspection port blank C HP COMPRESSOR SPLIT CASE (72-41-31, 01-140) to the compressor case.

Remove the stage 5 and 6 borescope access port blanks from HP compressor split case.

Remove the three bolts HPC Rear Outer Case And Related Parts (72-41-23, 02-102) that attach the inspection port blank D HPC Rear Outer Case And Related Parts (72-41-23, 02-100) and the gasket HPC Rear Outer Case And Related Parts (72-41-23, 02-108) to the compressor case.

Remove the stage 7 and 8 borescope access port blanks from HP compressor rear outer case.

Remove the three bolts ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-102) that attach the inspection port blank ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-100) and the gasket ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-108) to the compressor case.

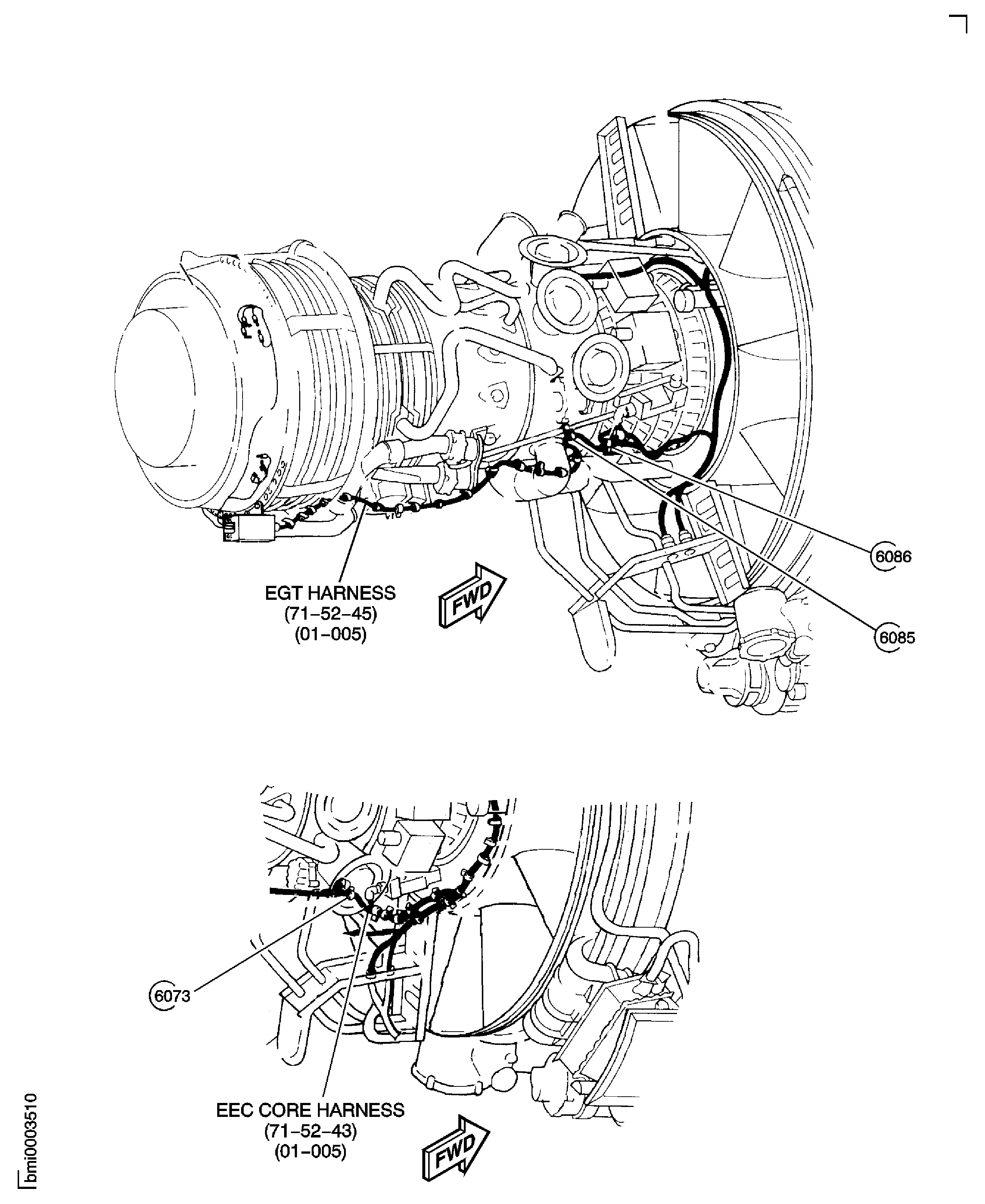

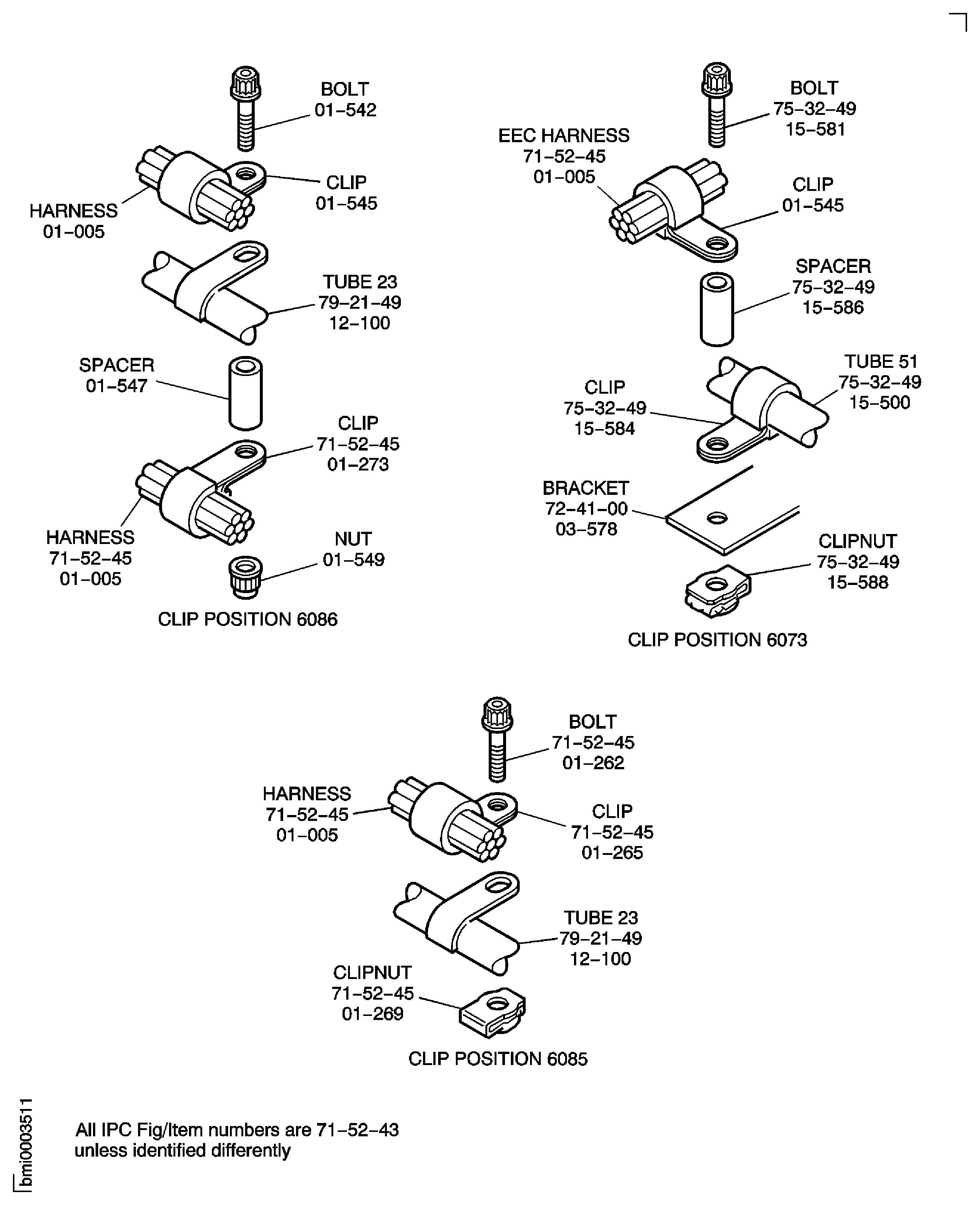

NOTE

For easier access to the stage 8 to 9 inspection port E, and to avoid damage to the adjacent harness, you can remove clipping points C/P6085, C/P6086 and loosen C/P6073 on the EEC harness.Remove the stages 8 and 9, stages 9 and 10 and stages 11 and 12 borescope access port blanks from HP compressor rear outer case.

SUBTASK 72-00-00-020-067 Remove the Borescope Access Port Blanks

Repair, VRS9170 TASK 72-00-00-300-013 (REPAIR-013) with KEENSERTS or Repair, VRS6518 TASK 72-00-41-300-001 (REPAIR-001) with thinwall inserts. KEENSERTS must be replaced at next HPC overhaul.

Broken, loose, worn, crossed threaded or stripped thread.

Accept, until next HPC overhaul.

Inspect for installed KEENSERTS.

SUBTASK 72-00-00-220-179 Examine the HP Compressor Rear Case Screw Thread Inserts

Refer to Figure.

Use a non metallic scraper and a lint free cloth made moist with CoMat 01-003 SOLVENT, DELETED or CoMat 01-076 METHYL ETHYL KETONE. Remove all the used jointing compound from around the access ports.

Remove the used jointing compound from the access ports.

SUBTASK 72-00-00-160-056 Clean the Borescope Access Ports

WARNING

WHEN YOU USE CoMat 01-003 SOLVENT, DELETED OR CoMat 01-076 METHYL ETHYL KETONE YOU MUST USE THE CORRECT PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.

CAUTION

DO NOT LET JOINTING COMPOUND GET IN TO THE ENGINE THROUGH THE ACCESS PORTS, CONTAMINATION OF HP COMPRESSOR AND COMPONENT DAMAGE CAN OCCUR.Refer to Figure.

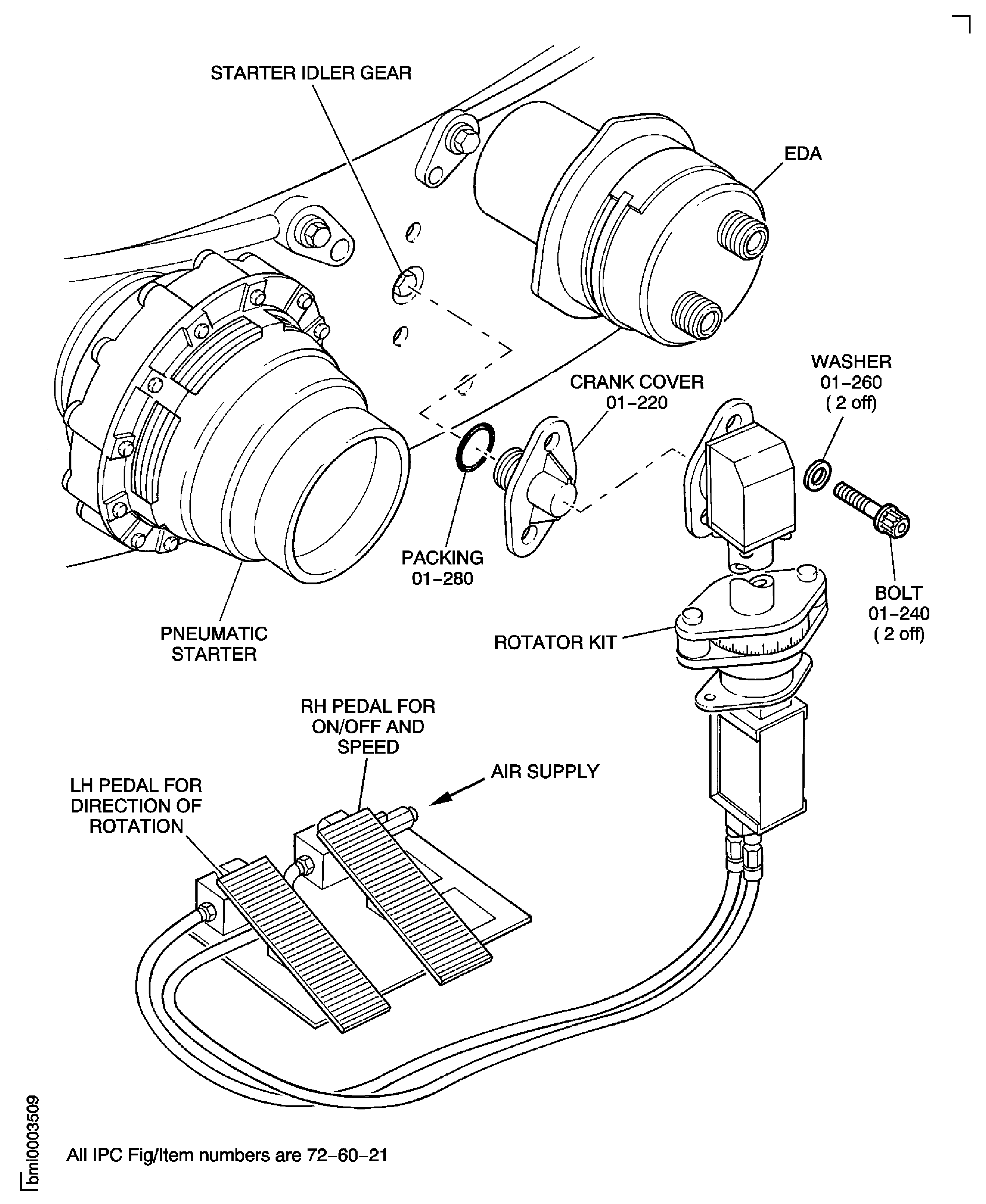

Remove the two bolts ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-240) that attach the crank cover to the external gearbox.

Remove the crank cover and discard the packing ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-280).

NOTE

The crank cover is installed on the front face of the external gearbox between the engine dedicated alternator (EDA) and the pneumatic starter.Remove the crank cover ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-220) from the external gearbox.

Install the two bolts ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-240) and two washers ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-260). Tighten the two bolts to 85 lbf.in to 105 lbf.in (10 Nm to 12 Nm) in accordance with SPM TASK 70-41-00-400-501.

Install the IAE 2F10057 Rotator Kit 1 off.

SUBTASK 72-00-00-420-076 Install the Rotator Kit

Refer to Figure.

Install the IAE 6F10408 Borescope 1 off in the access port of the stage of the compressor you want to examine.

SUBTASK 72-00-00-420-072 Install the Borescope Probe Stages 3 and 3 to 4

Refer to Figure.

Install the IAE 6F10408 Borescope 1 off in the access port of the stage of the compressor you want to examine.

SUBTASK 72-00-00-420-073 Install the Borescope Probe Stages 5 and 6

Refer to Figure.

Install the IAE 6F10408 Borescope 1 off in the access port of the stage of the compressor you want to examine.

SUBTASK 72-00-00-420-074 Install the Borescope Probe Stages 7 and 8

Refer to Figure.

Install the IAE 6F10408 Borescope 1 off in the access port of the stage of the compressor you want to examine.

SUBTASK 72-00-00-420-075 Install the Borescope Probe Stages 8 to 9, Stages 9 to 10 and Stages 11 to 12

Refer to Figure.

NOTE

100 percent ceramic coating detachment is same as one complete stage liner loss. 200 percent ceramic coating detachment is same as two complete stage liner loss.

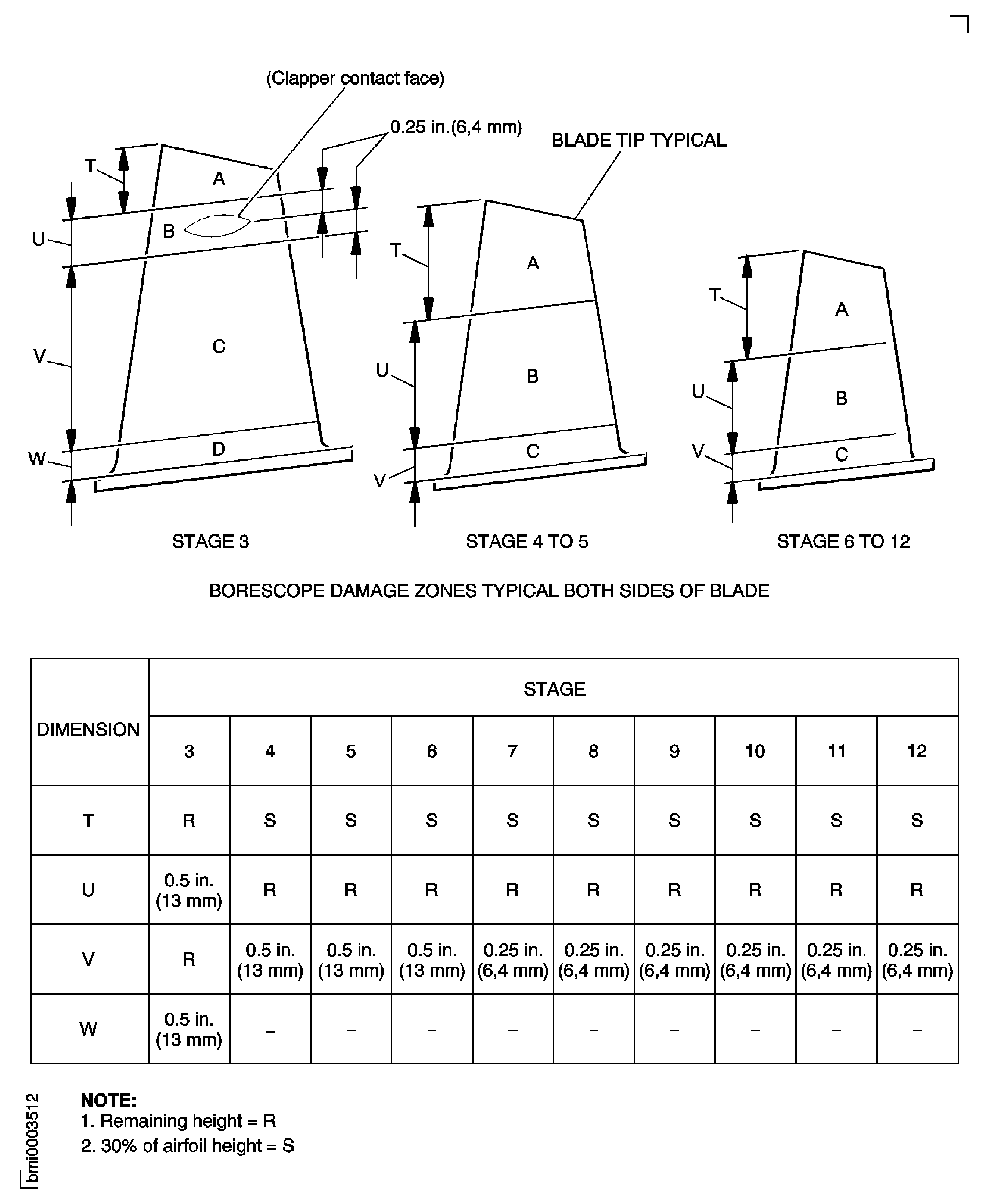

SUBTASK 72-00-00-210-065 Examine the HP Compressor Rotor Drum Stage 6 to 11 Stator Paths

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Nicks and tears more than Step but not more than 0.200 in. (5.08 mm).

More than Step.

Nicked.

Zone A.

Reject.

More than Step.

Nicked

Zone B.

Less than Step.

Clapper face contact.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Nicks and tears more than Step but not more than 0.200 in. (5.08 mm).

More than Step.

Nicked.

Zone C.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.050 in. (1.270 mm) in depth located on either leading or trailing edge. A minimum distance of 0.205 in. (5.207 mm) from the top (Outer Diameter) of the blade platform measured from the corner closest to the leading edge and trailing edge must be kept. Keep out of fillet area.

Reject.

More than Step.

Nicked.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.050 in. (1.270 mm) in depth located on either leading or trailing edge. A minimum distance of 0.205 in. (5.207 mm) from the top (Outer Diameter) of the blade platform measured from the corner closest to the leading edge and trailing edge must be kept. Keep out of fillet area.

Reject.

More than Step.

Dented (not related to cracks, nicks or tears).

Zone D.

More than Step.

Bent or curled (not related to cracks or tears).

Blade tips.

SUBTASK 72-00-00-220-073 Examine the Stage 3 HP Compressor Rotor Blade Damage

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Nicks and tears more than Step but not more than 0.180 in. (4.57 mm).

More than Step.

Nicks and tears.

Zone A.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than Step but not more than 0.180 in. (4.57 mm).

More than Step.

Nicks and tears.

Zone B.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Stage 4 Blades - More than in Step but not more than 0.050 in. (1.270 mm) in depth located on the leading edge. A minimum distance of 0.220 in. (5.588 mm) from the top (Outer Diameter) of the blade platform measured from the corner closest to the leading edge must be kept. Keep out of fillet area.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Stage 5 Blades - More than in Step but not more than 0.050 in. (1.270 mm) in depth located on the trailing edge. A minimum distance of 0.220 in. (5.588 mm) from the top (Outer Diameter) of the blade platform measured from the corner closest to the trailing edge must be kept. Keep out of fillet area.

Reject.

Stage 4 Blades - More than in Step.

Reject.

Stage 5 Blades - More than in Step.

Nicked.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Stage 4 Blades - More than in Step but not more than 0.050 in. (1.270 mm) in depth located on the leading edge. A minimum distance of 0.220 in. (5.588 mm) from the top (Outer Diameter) of the blade platform measured from the corner closest to the leading edge must be kept. Keep out of fillet area.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Stage 5 Blades - More than in Step but not more than 0.050 in. (1.270 mm) in depth located on the trailing edge. A minimum distance of 0.220 in. (5.588 mm) from the top (Outer Diameter) of the blade platform measured from the corner closest to the trailing edge must be kept. Keep out of fillet area.

Reject.

Stage 4 Blades - More than Step.

Reject.

Stage 5 Blades - More than Step.

Dented (not related to cracks, nicks or tears).

Zone C.

More than Step.

Bent or curled (not related to cracks or tears).

Blade tips.

SUBTASK 72-00-00-220-155 Examine the Stage 4 and 5 HP Compressor Rotor Blade Damage

More than Step.

Nicks and tears.

Zone A - Stage 6 Rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Nicks and tears more than Step but not more than 0.075 in. (1.90 mm).

More than Step.

Nicks and tears.

Zone A - stages 7 rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Nicks and tears more than Step but not more than 0.067 in. (1.70 mm).

More than Step.

Nicks and tears.

Zone A - stage 8 rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Nicks and tears more than Step but not more than 0.060 in. (1.52 mm).

More than Step.

Nicks and tears.

Zone A - stage 9 rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Nicks and tears more than Step but not more than 0.050 in. (1.27 mm).

More than Step.

Nicks and tears.

Zone A - stages 10 to 12 rotor blades.

More than Step.

Nicks and tears.

Zone B - Stage 6 Rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Nicks and tears more than Step but not more than 0.075 in. (1.90 mm).

More than Step.

Nicks and tears.

Zone B - stage 7 rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Nicks and tears more than Step but not more than 0.067 in. (1.70 mm).

More than Step.

Nicks and tears.

Zone B - stage 8 rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Nicks and tears more than Step but not more than 0.060 in. (1.52 mm).

More than Step.

Nicks and tears.

Zone B - stage 9 rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Nicks and tears more than Step but not more than 0.050 in. (1.27 mm).

More than Step.

Nicks and tears.

Zone B - stages 10 to 12 rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.026 in. (0.660 mm) in depth located on the trailing edge. A minimum distance of 0.095 in. (2.413 mm) from the top (Outer Diameter) of the blade platform measured from the corner closest to the trailing edge must be kept. Keep out of fillet area.

Reject.

More than Step.

Nicked.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.026 in. (0.660 mm) in depth located on the trailing edge. A minimum distance of 0.095 in. (2.413 mm) from the top (Outer Diameter) of the blade platform measured from the corner closest to the trailing edge must be kept. Keep out of fillet area.

Reject.

More than Step.

Dented (not related to cracks, nicks or tears).

Zone C - Stage 7 rotor blades.

Reject.

Cracked or torn.

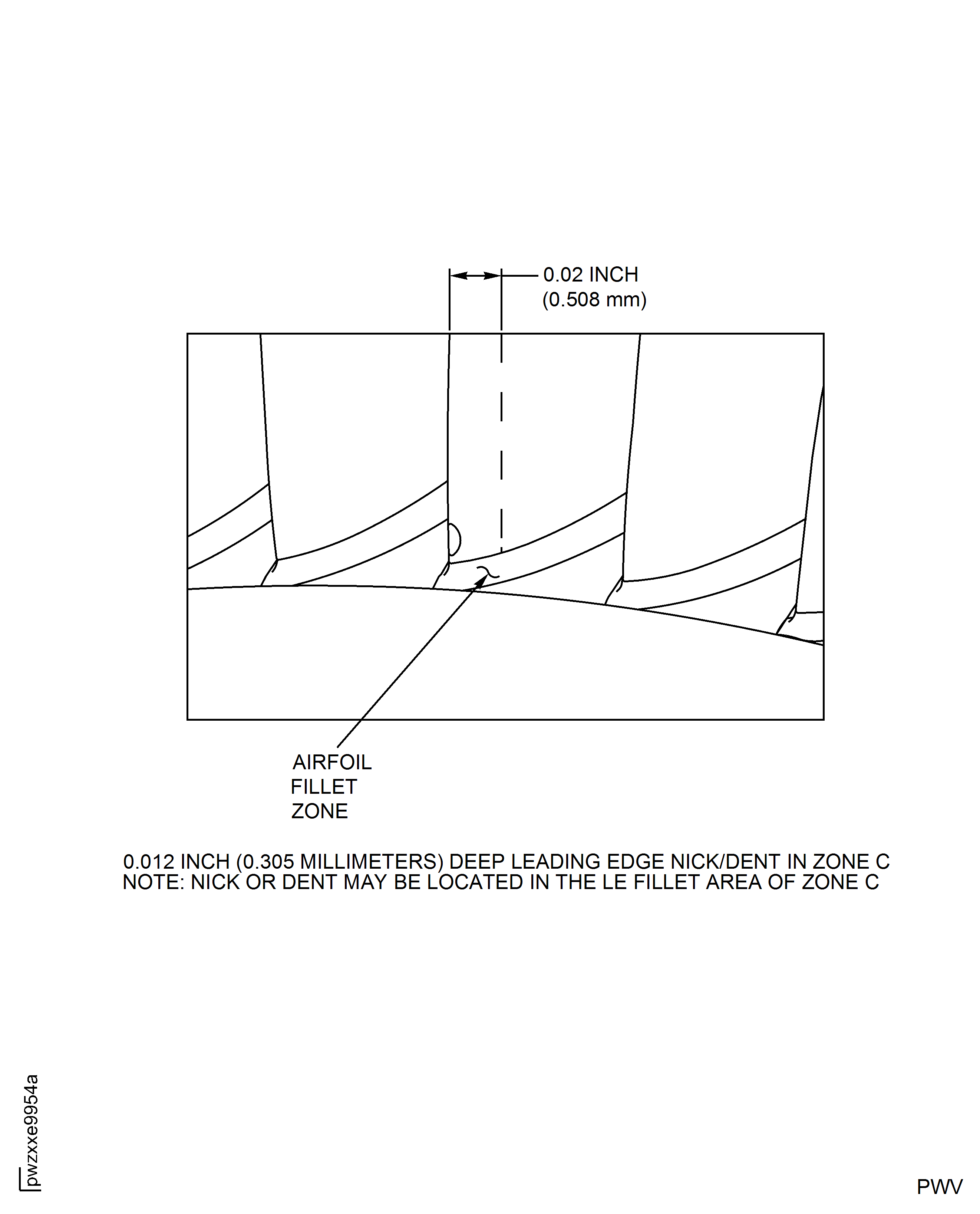

A single nick per blade in Zone C, located on the leading edge or contained in less than 0.020 in. (0.508 mm) from the leading edge.

Not more than three nicks per stage.

NOTE

Alternative option to perform Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004) for damage that meets criteria of Step.

Accept if greater than Step but less than or equal to 0.012 in. (0.305 mm) in depth and all of the following criteria are met:

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.028 in. (0.711 mm) in depth located on the leading edge. A minimum distance of 0.075 in. (1.905 mm) from the top (Outer Diameter) of the blade platform measured from the corner closest to the leading edge must be kept. Keep out of fillet area.

Reject.

More than Step.

Nicked.

A single dent in Zone C, located on the leading edge or contained in less than 0.020 in. (0.508 mm) from the leading edge.

Not more than three dents per stage.

NOTE

Alternative option to perform Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004) for damage that meets criteria of Step.

Accept if greater than Step but less than or equal to 0.012 in. (0.305 mm) in depth and all of the following criteria are met:

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.028 in. (0.711 mm) in depth located on the leading edge. A minimum distance of 0.075 in. (1.905 mm) from the top (Outer Diameter) of the blade platform measured from the corner closest to the leading edge must be kept. Keep out of fillet area.

Reject.

More than Step.

Dented (not related to cracks, nicks or tears).

Zone C - Stage 8 rotor blades.

Reject.

Cracked or torn.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.030 in. (0.762 mm) in depth located on either leading or trailing edge. A minimum distance of 0.075 in. (1.905 mm) from the top (Outer Diameter) of the blade platform measured from the corner closest to the leading edge and trailing edge must be kept. Keep out of fillet area.

Reject.

More than Step.

Nicked.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.030 in. (0.762 mm) in depth located on either leading or trailing edge. A minimum distance of 0.075 in. (1.905 mm) from the top (Outer Diameter) of the blade platform measured from the corner closest to the leading edge and trailing edge must be kept. Keep out of fillet area.

Reject.

More than Step.

Dented (not related to cracks, nicks or tears).

Zone C - Stage 9 rotor blades.

Reject.

Cracked or torn.

A single nick per blade in Zone C, located on the leading edge or in less than 0.040 in. (1.0 mm) from the leading edge.

Not more than three nicks per stage.

NOTE

Alternative option to perform Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004) for damage that meets criteria of Step.

Accept if greater than Step but less than or equal to 0.018 in. (0.457 mm) in depth and all of the following criteria are met:

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.030 in. (0.762 mm) in depth located on the leading edge. A minimum distance of 0.075 in. (1.905 mm) from the top (Outer Diameter) of the blade platform measured from the corner closest to the leading edge must be kept. Keep out of fillet area.

Reject.

More than Step.

Nicked.

A single dent in Zone C, located on the leading edge or contained in less than 0.040 in. (1.0 mm) from the leading edge.

Not more than three dents per stage.

NOTE

Alternative option to perform Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004) for damage that meets criteria of Step.

Accept if greater than Step but less than or equal to 0.018 in. (0.457 mm) in depth and all of the following criteria are met:

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.030 in. (0.762 mm) in depth located on the leading edge. A minimum distance of 0.075 in. (1.905 mm) from the top (Outer Diameter) of the blade platform measured from the corner closest to the leading edge must be kept. Keep out of fillet area.

Reject.

More than Step.

Dented (not related to cracks, nicks or tears).

Zone C - Stage 10 rotor blades.

Reject.

Cracked or torn.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Stage 11 - More than in Step but not more than 0.030 in. (0.762 mm) in depth located on the trailing edge. A minimum distance of 0.077 in. (1.956 mm) from the top (Outer Diameter) of the blade platform measured from the corner closest to the trailing edge must be kept. Keep out of fillet area.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Stage 12 - More than in Step but not more than 0.030 in. (0.762 mm) in depth located on the leading edge. A minimum distance of 0.075 in. (1.905 mm) from the top (Outer Diameter) of the blade platform measured from the corner closest to the leading edge must be kept. Keep out of fillet area.

Reject.

Stage 11 - More than Step.

Reject.

Stage 12 - More than Step.

Nicked.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Stage 11 - More than in Step but not more than 0.030 in. (0.762 mm) in depth located on the trailing edge. A minimum distance of 0.077 in. (1.956 mm) from the top (Outer Diameter) of the blade platform measured from the corner closest to the trailing edge must be kept. Keep out of fillet area.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Stage 12 - More than in Step but not more than 0.030 in. (0.762 mm) in depth located on the leading edge. A minimum distance of 0.075 in. (1.905 mm) from the top (Outer Diameter) of the blade platform measured from the corner closest to the leading edge must be kept. Keep out of fillet area.

Reject.

Stage 11 - More than Step.

Reject.

Stage 12 - More than Step.

Dented (not related to cracks, nicks or tears).

Zone C - Stages 11 to 12 rotor blades.

Reject.

Missing piece - Stage 6, 7, 9, 10, 11 and 12 rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Not more than 0.060 in. (1.524 mm).

Reject.

More than Step.

Missing piece - Stage 8 rotor blades only.

More than Step.

Bent or curled (not related to cracks or tears).

Blade tips.

SUBTASK 72-00-00-220-156 Examine the Stage 6 to 12 HP Compressor Rotor Blade Damage

Refer to Figure.

Lightly lubricate a new ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-280) packing 1 off with CoMat 10-077 APPROVED ENGINE OILS and assemble in the crank cover ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-220) groove.

Attach the crank cover ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-220) on the external gearbox with the two bolts ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-240) and two washers ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-260). Torque the bolts to 85 lbf.in to 105 lbf.in (10 Nm to 12 Nm) in accordance with the SPM TASK 70-41-00-400-501.

Install the crank cover.

Remove the rotator kit from the external gearbox.

SUBTASK 72-00-00-020-068 Remove the Support Equipment

Refer to Figure.

Use a non metallic scraper and a lint free cloth made moist with CoMat 01-003 SOLVENT, DELETED or CoMat 01-076 METHYL ETHYL KETONE.

Remove the used jointing compound from the mating faces of the access port blanks.

SUBTASK 72-00-00-160-057 Clean the Borescope Access Port Blanks

WARNING

WHEN YOU USE CoMat 01-003 SOLVENT, DELETED OR CoMat 01-076 METHYL ETHYL KETONE YOU MUST USE THE CORRECT PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Apply a thin layer of CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE to the mating faces of the access ports and access port blanks with a stiff bristle brush or pallet knife. Do not apply jointing compound nearer than 0.12 in. to 0.16 in. (3.0 mm to 4.1 mm) around the access port aperture.

Apply CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) or CoMat 10-070 ANTI-SEIZE COMPOUND to the two bolts HP COMPRESSOR SPLIT CASE (72-41-31, 01-107) which attach the access port blank to the compressor case.

Install the stage 3 access port blank A HP COMPRESSOR SPLIT CASE (72-41-31, 01-105) at location A and attach with two bolts HP COMPRESSOR SPLIT CASE (72-41-31, 01-107).

Install the stage 3 and 4 access port blank B HP COMPRESSOR SPLIT CASE (72-41-31, 01-100) at location B and attach with two bolts HP COMPRESSOR SPLIT CASE (72-41-31, 01-102).

Install the borescope access port blanks at locations A (stage 3) and B (stage 3 and 4).

Apply a thin layer of CoMat 04-011 JOINTING COMPOUND to the mating faces of the access ports and access port blanks with a stiff bristle brush or pallet knife. Do not apply jointing compound nearer than 0.12 in. to 0.16 in. (3.0 mm to 4.1 mm) around the access port aperture.

Apply CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) or CoMat 10-070 ANTI-SEIZE COMPOUND to the two bolts HP COMPRESSOR SPLIT CASE (72-41-31, 01-142) which attach the access port blank to the compressor case.

Install the access port blank HP COMPRESSOR SPLIT CASE (72-41-31, 01-140) and attach the two bolts HP COMPRESSOR SPLIT CASE (72-41-31, 01-142).

Install the stage 5 and 6 borescope access port blank at location C.

Apply CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) or CoMat 10-070 ANTI-SEIZE COMPOUND to the two bolts HPC Rear Outer Case And Related Parts (72-41-23, 02-102) which attach the access port blank to the compressor case.

Install the stage 7 and 8 access port blank HPC Rear Outer Case And Related Parts (72-41-23, 02-100) at location D with a new gasket HPC Rear Outer Case And Related Parts (72-41-23, 02-108) and attach with three bolts HPC Rear Outer Case And Related Parts (72-41-23, 02-102).

Install the stage 7 and 8 borescope access port blanks at locations D.

Apply CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) or CoMat 10-070 ANTI-SEIZE COMPOUND to the nine bolts ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-102) which attach the access port blank to the compressor case.

Install the stage 8 and 9, stage 9 and 10 and stage 11 and 12 access port blank ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-100) at location E, F and G with the three new gasket HPC Rear Outer Case And Related Parts (72-41-23, 02-108) and attach with nine bolts ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-102).

Install the borescope access port blanks at locations E (stage 8 and 9), F (stage 9 and 10) and G (stage 11 and 12).

SUBTASK 72-00-00-420-077 Install the Borescope Access Port Blanks

CAUTION

DO NOT LET JOINTING COMPOUND GET IN TO THE ENGINE THROUGH THE ACCESS PORTS, CONTAMINATION OF HP COMPRESSOR AND COMPONENT DAMAGE CAN OCCUR.Install the bolt, clamps and nut at clip locations CP6085 and CP6086 on EGT harness Exhaust Gas Temperature (EGT) Harness (71-52-45, 01-005).

Clamp EEC core harness in designed routing at clip location CP6073 on EEC core harness EEC Core Harness And Voltage Divider Harness Assembly (71-52-43, 01-005).

If recommendation in Step is followed, then:

SUBTASK 72-00-00-420-086 Install the Removed and Loosened Clipping Points

SUBTASK 72-00-00-220-174 Examine the HP Compressor Stage 6 Rotor Path Coating

Reject.

Damper wire visible.

SUBTASK 72-00-00-220-175 Stages 6, 7 and 8 Front and Rear Damper Wires

Figure: HP Compressor Borescope Access Ports

HP Compressor Borescope Access Ports

Figure: Stage 7 and 8 Borescope Access Ports

Stage 7 and 8 Borescope Access Ports

Figure: Stage 7 and 8 Borescope Access Ports

Stage 7 and 8 Borescope Access Ports

Figure: HP Compressor Rotor Blade Dimensions

HP Compressor Rotor Blade Dimensions

Figure: HP Compressor Rotor Blade Damage Zones

HP Compressor Rotor Blade Damage Zones

Figure: HP Compressor Stage 3 Rotor Blade Clapper Face Damage Zones

HP Compressor Stage 3 Rotor Blade Clapper Face Damage Zones

Figure: Install the Rotator Kit

Install the Rotator Kit

Figure: Typical Leading Edge Nicks and Dents in Zone C (For Stage 8 Rotor Blades Only)

Typical Leading Edge Nicks and Dents in Zone C (For Stage 8 Rotor Blades Only)

Figure: Typical Leading Edge Nicks and Dents in Zone C (For Stage 10 rotor blades only)

Typical Leading Edge Nicks and Dents in Zone C (For Stage 10 rotor blades only)