Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-00-00-200-001-B00 Engine General - Examine (Borescope) The LP Compressor (LPC), Inspection-001

General

This TASK gives the procedure for the borescope inspection of the LP compressor rotor blades.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 2J12030 Guide tube | 0AM53 | IAE 2J12030 | 1 | |

| IAE 6F10056 Borescope equipment, 4 mm or 6 mm, video borescope | 0AM53 | IAE 6F10056 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 06-069 MARKER | IE207 | CoMat 06-069 |

Safety Requirements

NONEProcedure

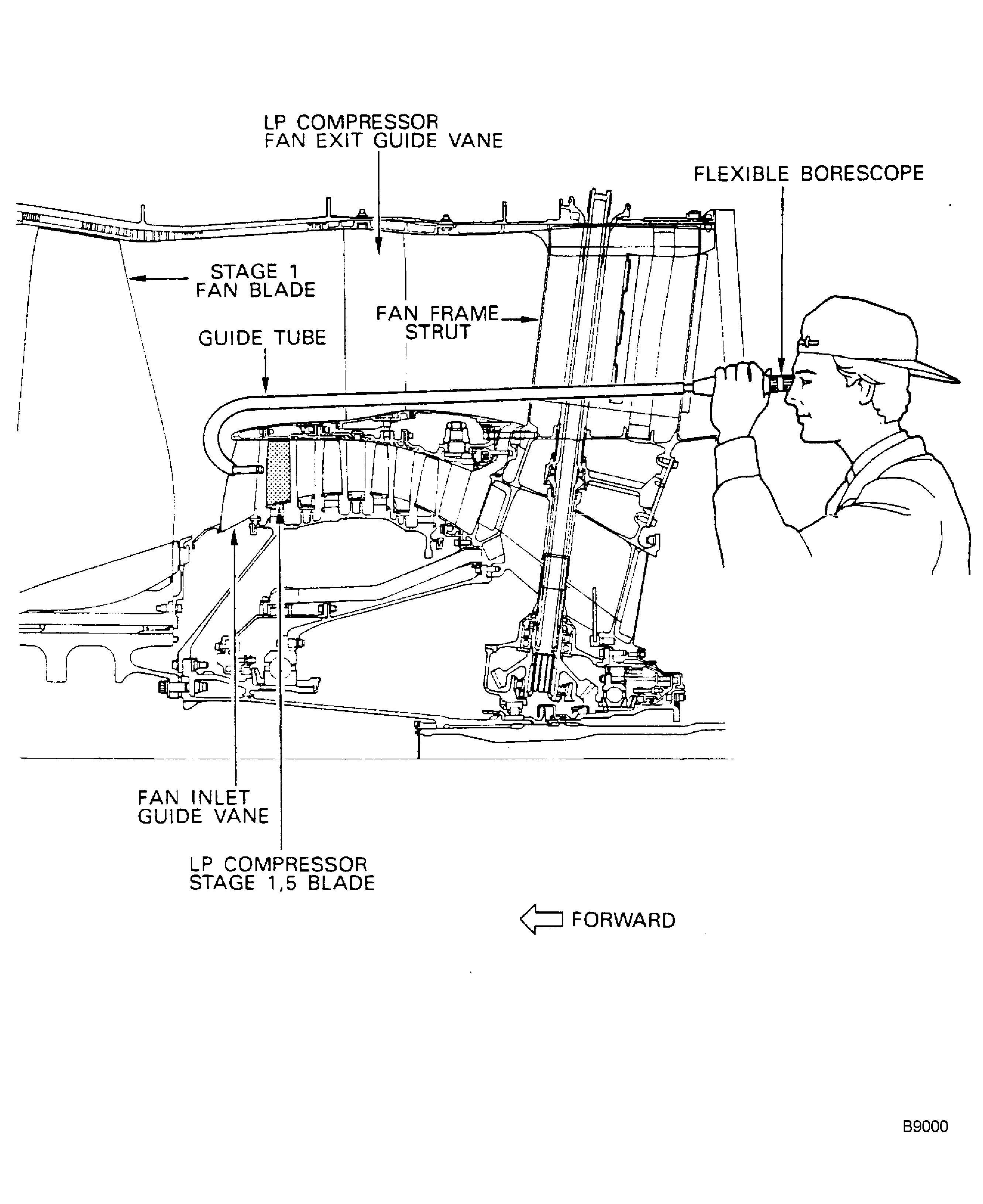

Put the IAE 2J12030 Guide tube in position through the fan frame strut, LP compressor outlet guide vanes and the LP compressor inlet guide vane at approximately the 3 o'clock position.

Put the IAE 6F10056 Borescope equipment, 4 mm or 6 mm, video borescope in to the guide tube until the stage 1.5 compressor blade can be examined.

CAUTION

BE CAREFUL DURING INSTALLATION AND REMOVAL OF THE GUIDE TUBE AS NOT TO CAUSE DAMAGE TO THE OUTER OR INNER OUTLET GUIDE VANES.Put the guide tube and borescope probe in position to examine the stage 1.5 blades.

SUBTASK 72-00-00-490-055 Install the Support Equipment to Examine the Stage 1.5 Blades

Refer to Figure.

Make a mark on a fan blade and the adjacent fan case using the CoMat 06-069 MARKER to identify the start position of the inspection.

SUBTASK 72-00-00-220-131 Examine the Stage 1.5 LP Compressor Blades

NOTE

Do this operation with two persons: One person in the fan case to adjust the position of the guide tube and to turn the stage 1 fan blades. The other person at the right side of the engine to examine the compressor blades.Refer to Figure.

SUBTASK 72-00-00-220-132 Examine the Front Surface of Each Stage 1.5 LP Compressor Blade

Refer to Figure.

SUBTASK 72-00-00-220-133 Remove the Borescope Probe and Guide Tube

Refer to Figure.

Make a mark on a fan blade and adjacent fan case using the CoMat 06-069 MARKER to identify the start position of the inspection.

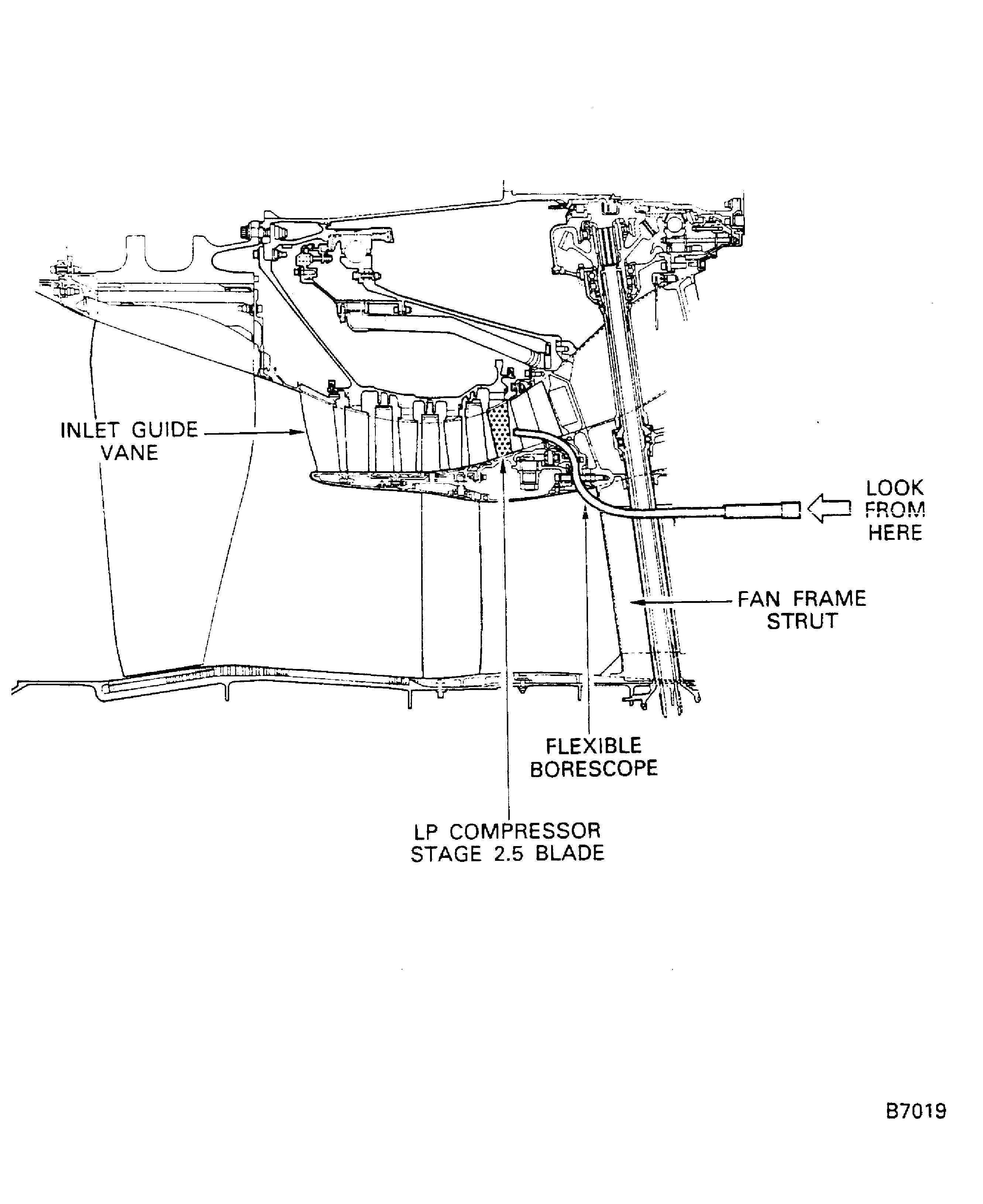

SUBTASK 72-00-00-220-134 Examine the Stage 2.5 LP Compressor Blades

NOTE

Do this operation with two persons: One person to turn the stage 1 fan blades. The other person at the right side of the engine to examine the LP compressor blades.Refer to Figure.

SUBTASK 72-00-00-220-136 Remove the Support Equipment

Refer to Figure.

Remove the inlet cone. Refer to TASK 72-38-11-020-001 (Removal-001).

Remove the LP compressor (FAN) module. Refer to TASK 72-00-31-020-001 (Removal-001).

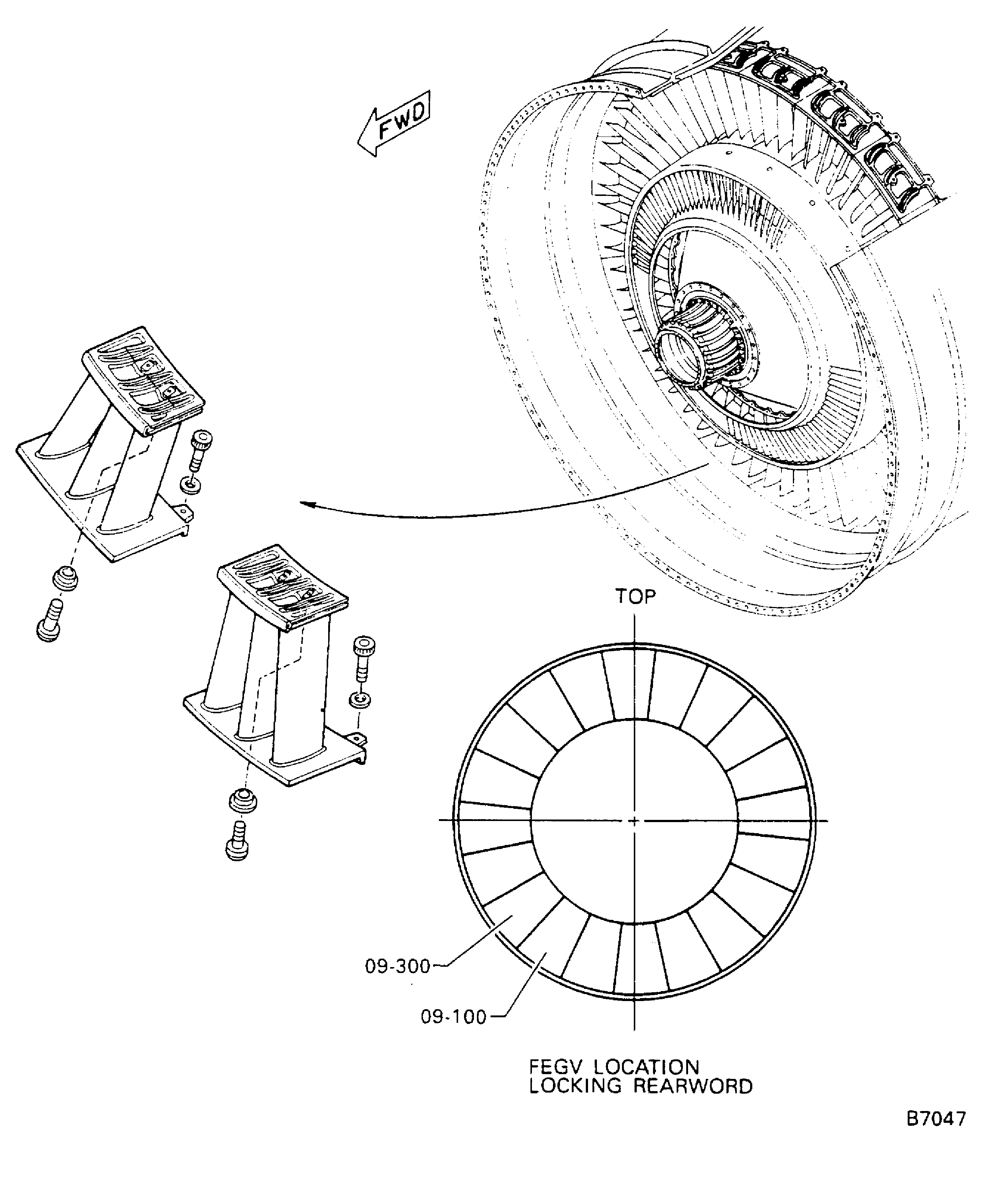

Remove the two segments (72-32-88,09-100) and (72-32-88,09-300) at approximately 5 o'clock position.

Remove the fan exit guide vanes. Refer to TASK 72-32-00-030-002-B00 (Disassembly-002).

SUBTASK 72-00-00-090-053 Remove the LP Compressor (Fan) Module and the Fan exit Guide Vanes to Remove Plug

Refer to Figure.

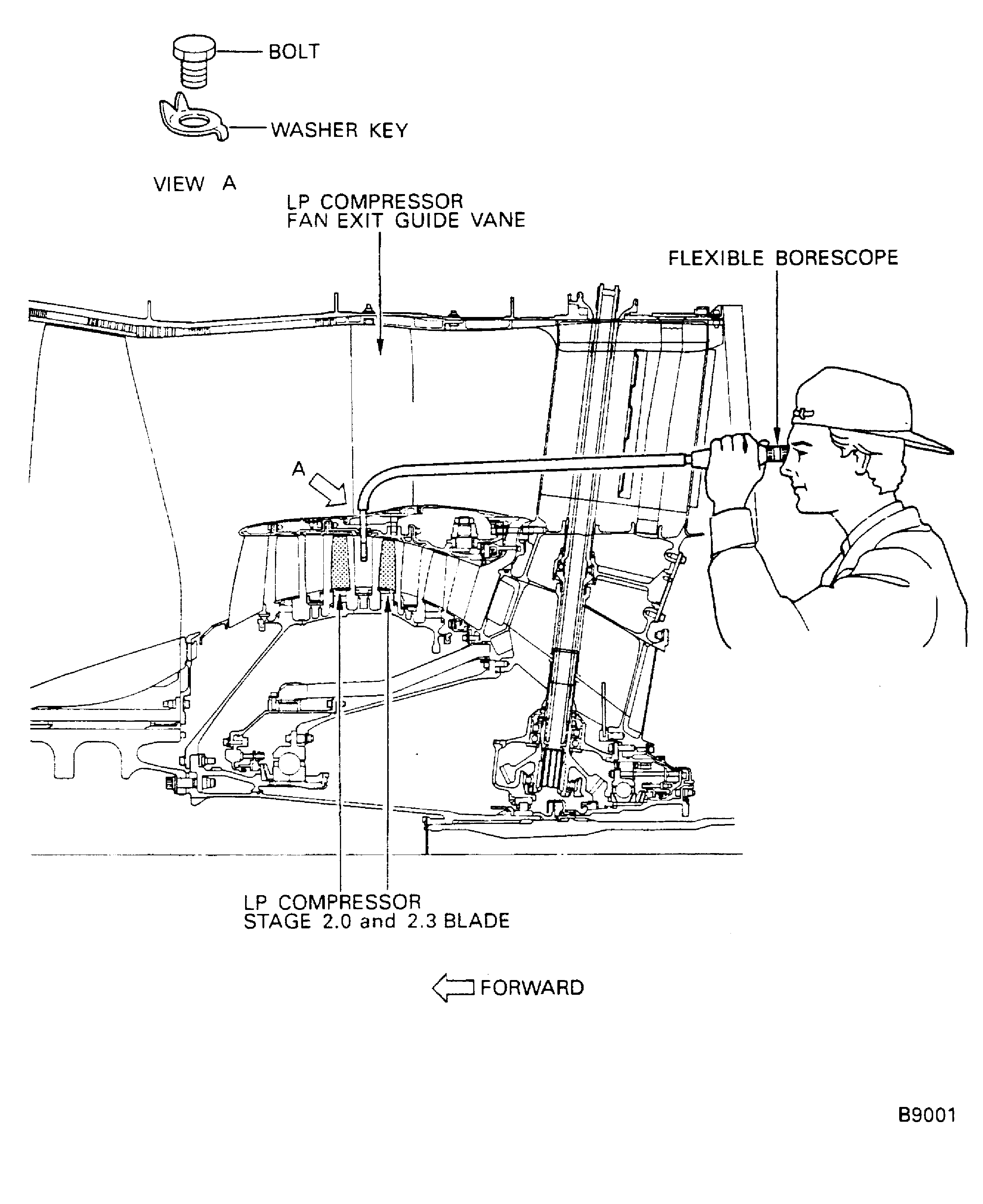

Bend back to flat the tab of the key washer.

Remove the plug and the key washer from hole on the LP compressor rear case. Discard the key washer.

SUBTASK 72-00-00-090-054 Remove the Plug from the LP Compressor Rear Case

Refer to Figure.

Put the borescope probe through the borescope inspection hole at approximately 5 o'clock position.

Put the borescope into the borescope inspection hole until the stage 2.0 and 2.3 compressor blades can be examined.

SUBTASK 72-00-00-490-057 Install the Borescope Probe to Examine the Stage 2.0 and 2.3 LP Compressor Blades

NOTE

Do this operation with two persons: One person in the fan case to turn the stage 1 fan rotor. The other person at the right side of the engine to examine the compressor blades.Refer to Figure.

Make a mark on a fan rotor and adjacent fan case using the CoMat 06-069 MARKER to identify the start position of the inspection.

SUBTASK 72-00-00-220-137 Examine the Stage 2.0 LP Compressor Blades

Refer to Figure.

Reject

Cracked

Reject

Torn

Zone B

Reject

Cracked

Reject

Torn

Reject

Missing piece

Reject

NOTE

The subsequent blade stages must be examined for damage if leading or trailing edge tips are lost.Overheated (related to tip rib)

Leading or trailing edge blade tips

Reject

More than in Step

Blade tips

Zone C

SUBTASK 72-00-00-220-138 Examine the Rear Surface of Each Stage 2.0 LP Compressor Blade

Refer to Figure.

Make a mark on a fan rotor and adjacent fan case using the CoMat 06-069 MARKER to identify the start position of the inspection.

SUBTASK 72-00-00-220-139 Examine the Stage 2.3 LP Compressor Blades

NOTE

Do this operation with two persons: One person in the fan case to turn the stage 1 fan rotor. The other person at the right side of the engine to examine the compressor blades.Refer to Figure.

Reject

Cracked

Reject

Torn

Zone B

Reject

Cracked

Reject

Torn

Reject

NOTE

The subsequent blade stages must be examined for damage if leading or trailing edge tips are lost.

Missing piece

Reject

Overheated (related to tip rub)

Leading or trailing edge blade tips

Reject

More than in Step

Blade tips

Zone C

SUBTASK 72-00-00-220-140 Examine the Front Surface of Each Stage 2.3 LP Compressor Blade

Refer to Figure.

Remove the borescope probe from the rear case.

SUBTASK 72-00-00-220-141 Remove the Support Equipment

Refer to Figure.

Install the plug and a new key washer to the inspection hole of the stage 2.0 and 2.3 compressor blades.

Torque the plug to 102 lbfin to 111 lbfin (11.50 Nm to 12.50 Nm).

Bend the new key washer to lock.

SUBTASK 72-00-00-430-083 Install the Plug in to the Rear Case

Refer to Figure.

Install the fan exit guide vanes. Refer to TASK 72-32-00-430-014-B00(ASSEMBLY-014).

Install the LP compressor (fan) module. Refer to TASK 72-00-31-420-001 (INSTALLATION-001).

Install the inlet cone. Refer to TASK 72-38-11-420-001 (INSTALLATION-001).

SUBTASK 72-00-00-410-051 Install the Fan Exit Guide Vanes and LP Compressor (FAN) Module

Figure: Borescope inspection equipment

Borescope inspection equipment

Figure: Borescope inspection for LP compressor stage 1.5 blade

Borescope inspection for LP compressor stage 1.5 blade

Figure: Borescope inspection for LP compressor stage 2.5 blade

Borescope inspection for LP compressor stage 2.5 blade

Figure: Borescope inspection for LP compressor stage 2.0 and 2.3 blade

Borescope inspection for LP compressor stage 2.0 and 2.3 blade

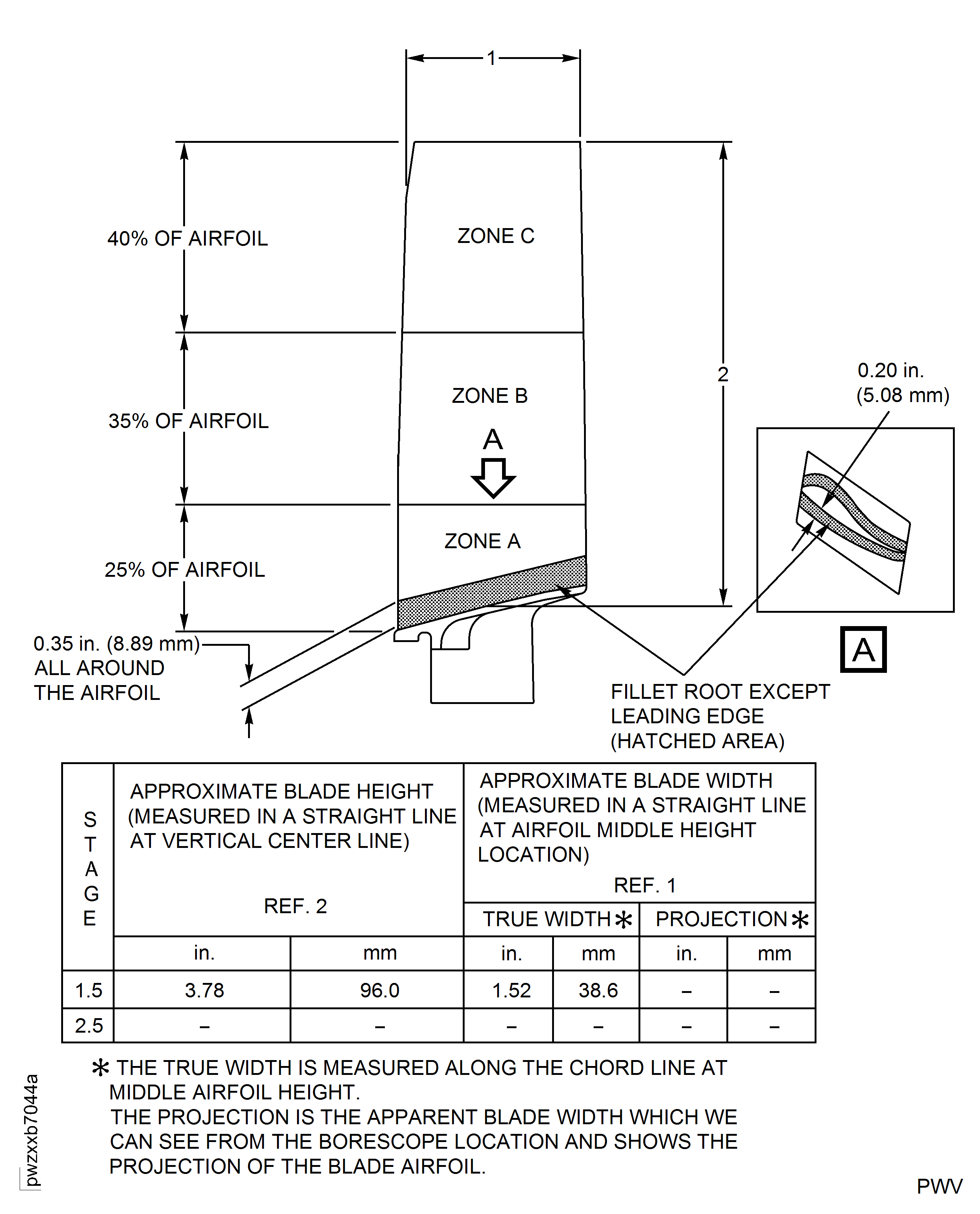

Figure: LP Compressor Stage 1.5 Blade - Maximum Serviceable Limit

LP Compressor Stage 1.5 Blade - Maximum Serviceable Limit

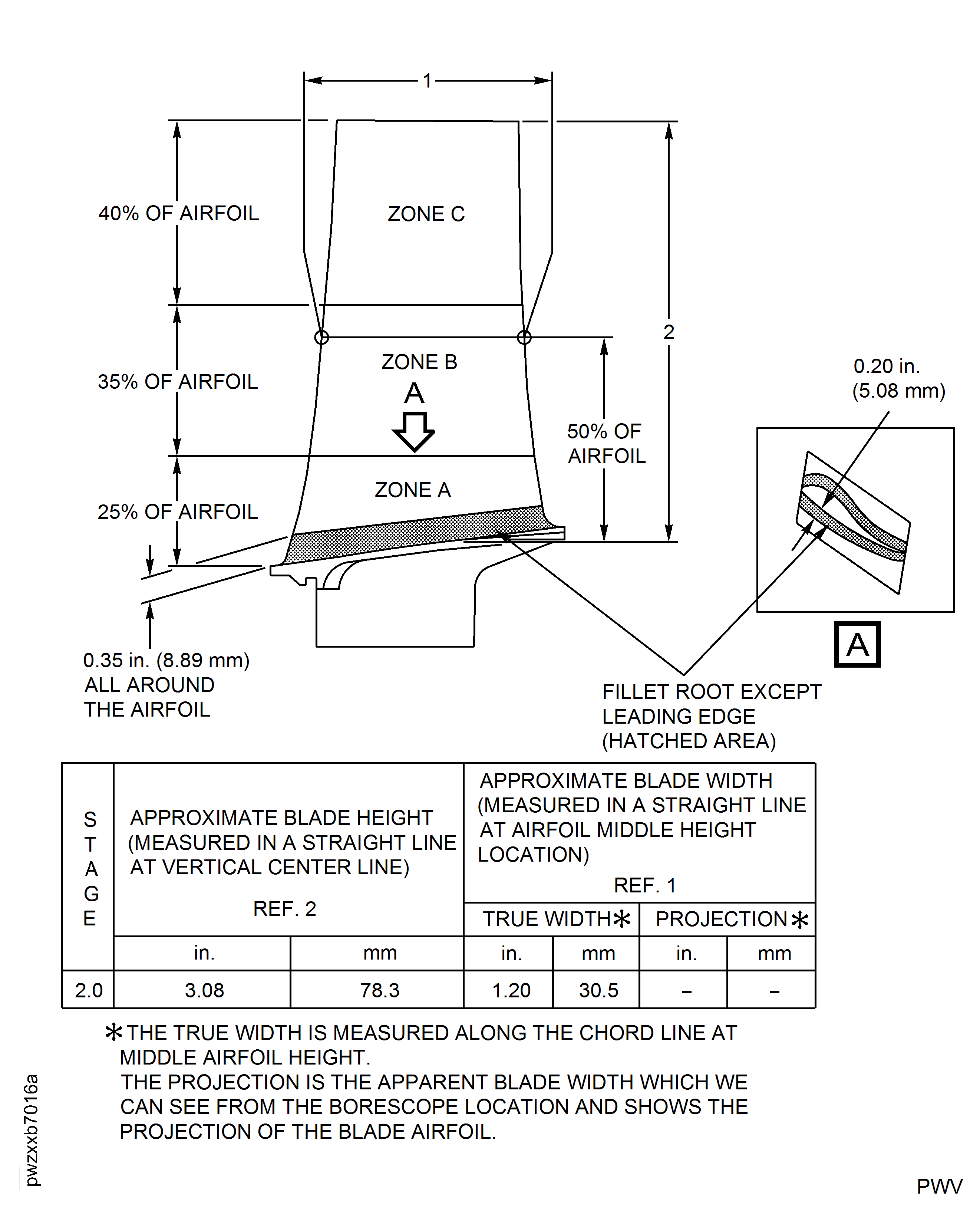

Figure: LP Compressor Stage 2.0 Blade - Maximum Service Limit

LP Compressor Stage 2.0 Blade - Maximum Service Limit

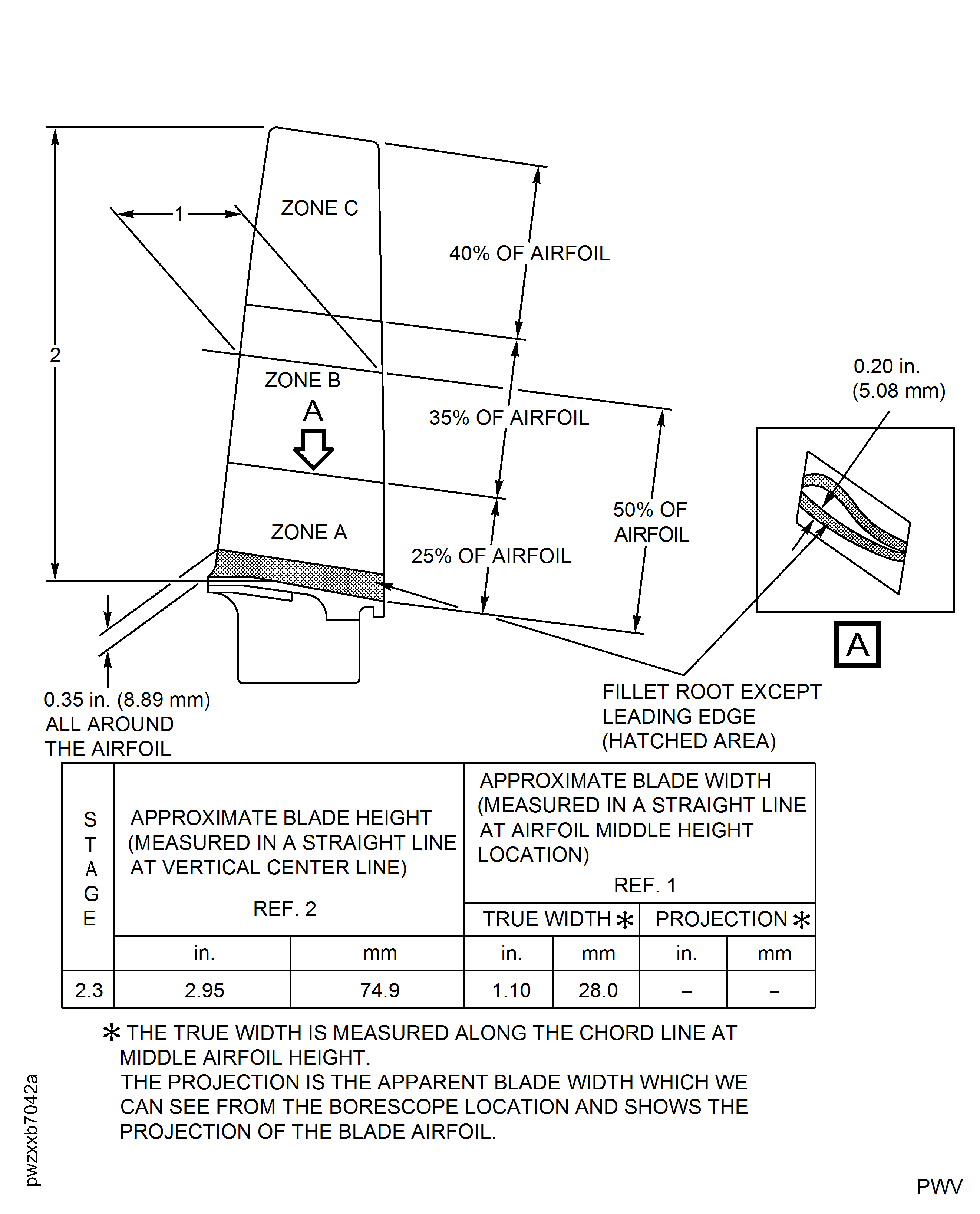

Figure: LP Compressor Stage 2.3 Blade - Maximum Service Limit

LP Compressor Stage 2.3 Blade - Maximum Service Limit

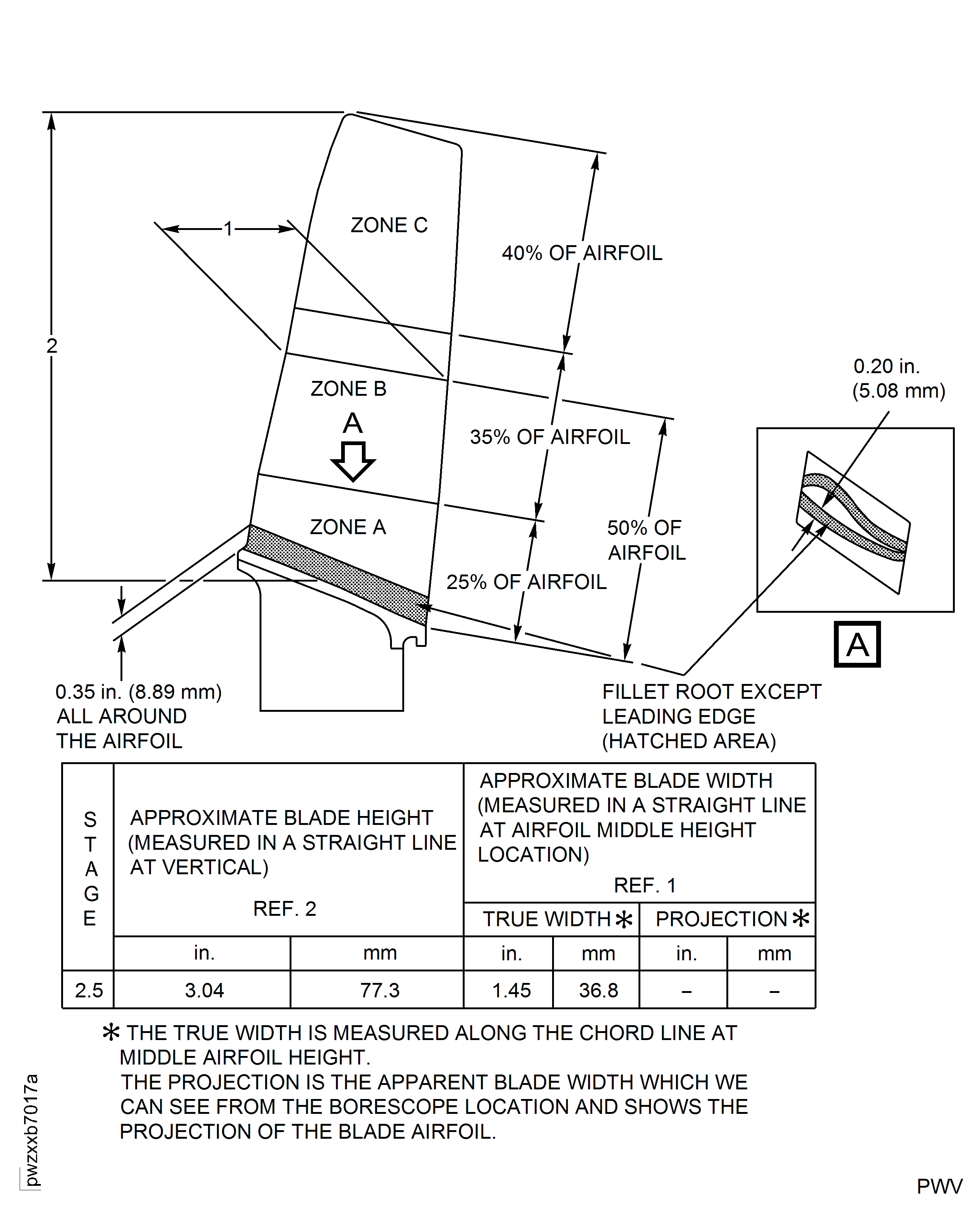

Figure: LP Compressor Stage 2.5 Blade - Maximum Service Limit

LP Compressor Stage 2.5 Blade - Maximum Service Limit

Figure: Remove the Fan Exit Guide Vanes from the Fan Case Assembly

Remove the Fan Exit Guide Vanes from the Fan Case Assembly