Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

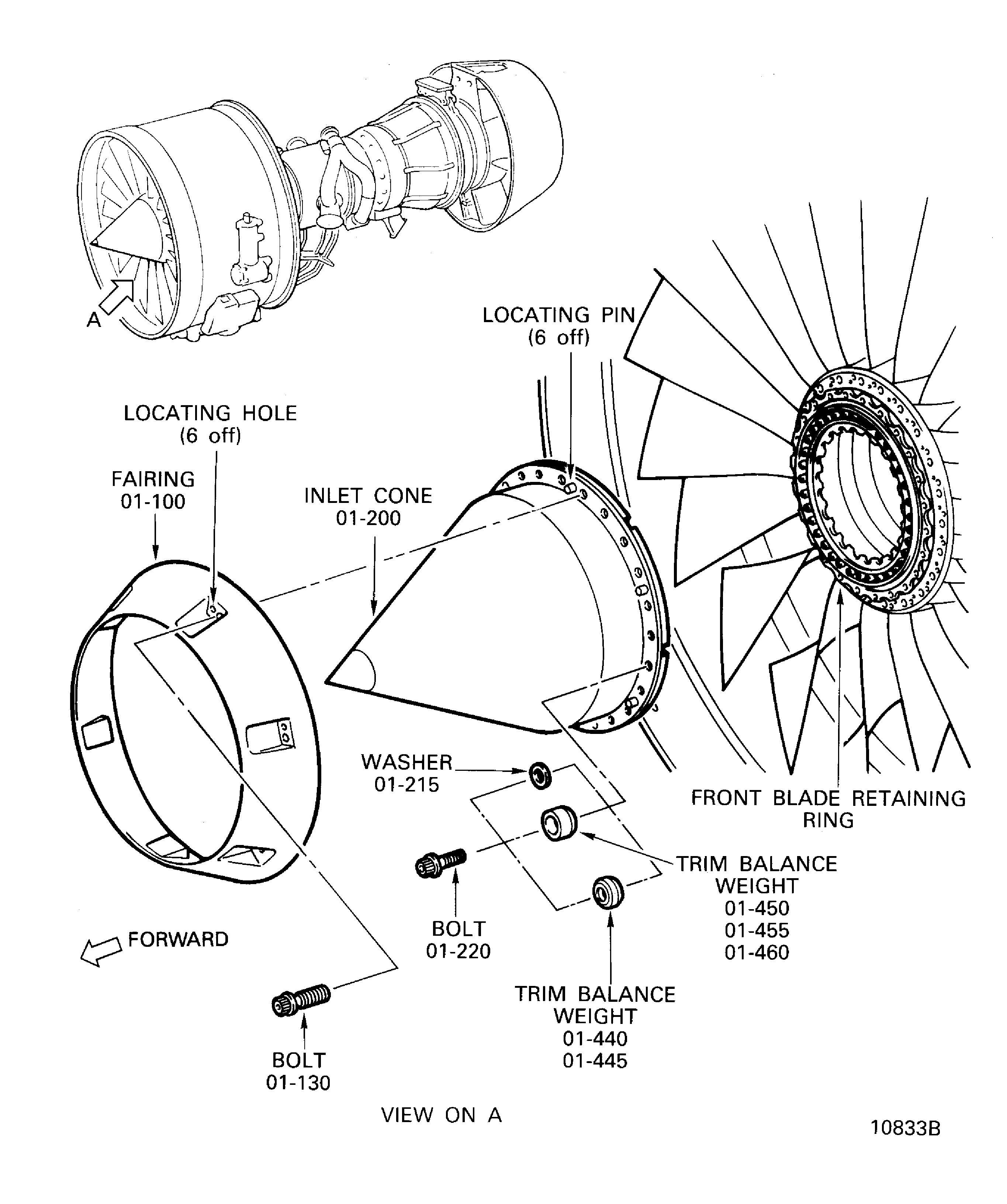

TASK 72-38-11-020-001 Inlet Cone Assembly And Inlet Cone Fairing - Remove The Inlet Cone, Removal-001

General

This TASK gives the procedure to remove the inlet cone from the front blade retaining ring.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

Apply the approved penetrating oil before the removal of threaded parts. Let the parts soak before removal. For the approved oils and procedures, refer to the SPM TASK 70-64-00-640-501.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1J12020 Puller leer | 0AM53 | IAE 1J12020 | 1 | (Alternative to IAE 1J12121) |

| IAE 1J12121 Puller leer | 0AM53 | IAE 1J12121 | 1 | (Alternative to IAE 1J12020) |

| IAE 1J12125 Sliding hammer | 0AM53 | IAE 1J12125 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 06-069 MARKER | IE207 | CoMat 06-069 |

Spares

NONESafety Requirements

NONEProcedure

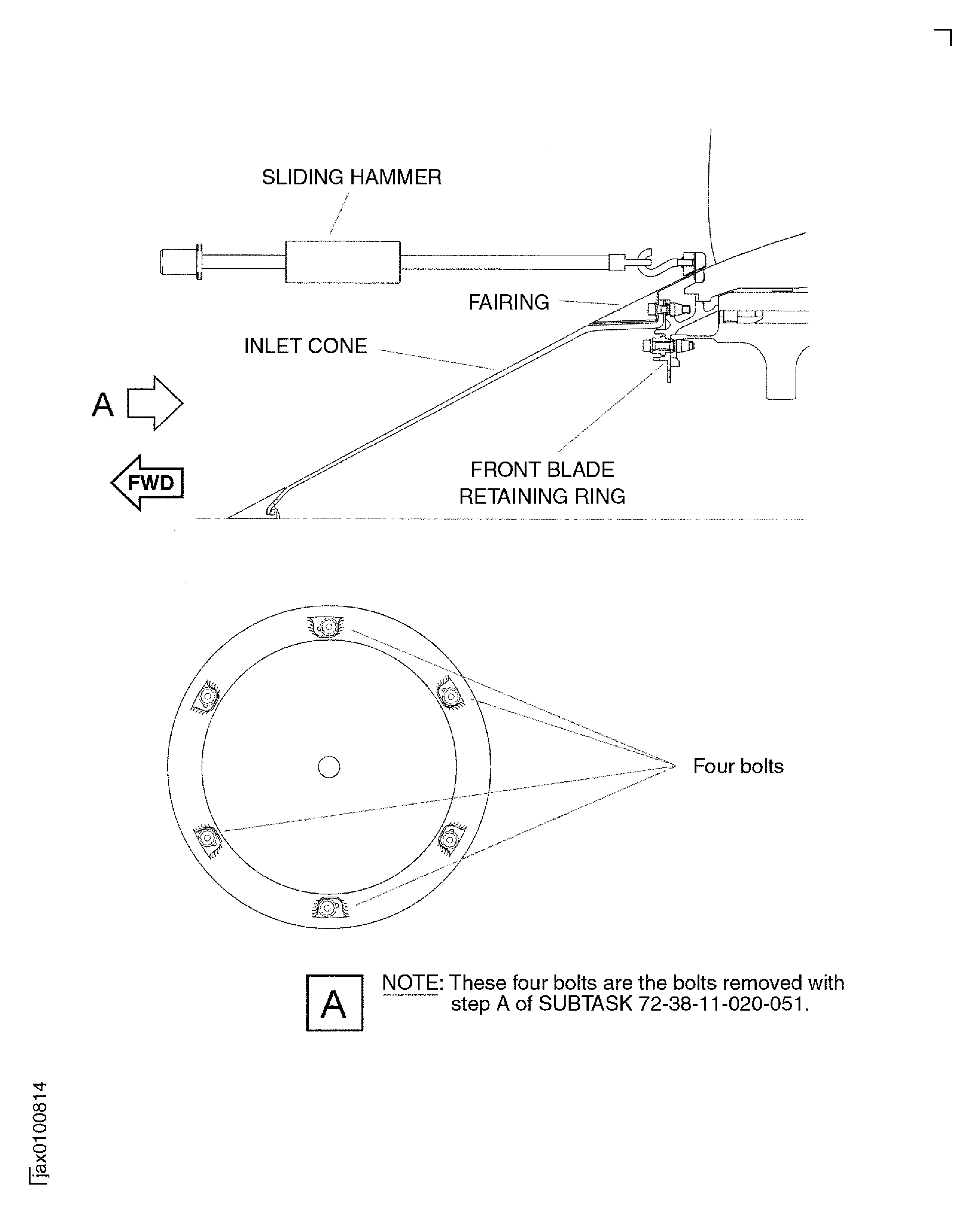

Use IAE 1J12125 Sliding hammer 1 off to release the inlet cone fairing from the flange of the front blade retaining ring.

SUBTASK 72-38-11-020-051 Remove the Inlet Cone Fairing

NOTE

Make sure that each correlation number of the trim balance weights to the front blade retaining ring is aligned.Give correlation numbers, with the CoMat 06-069 MARKER, to the trim balance weights to show their initial position to the front blade retaining ring.

Do the subsequent steps to make sure the installation of the trim balance weights in the same bolt holes during installation if they are installed.

NOTE

Hold the inlet cone while you loosen the bolts. This prevents rotation of the fan rotor.Use identification tags to keep the trim balance weights removed and their correlation number.Remove the 18 bolts, the washers (if installed) and the trim balance weights (if installed) which attach the inlet cone to the front blade retaining ring.

NOTE

Hold the inlet cone before it is released.Use IAE 1J12020 Puller leer 1 off or IAE 1J12121 Puller leer 1 off to release the inlet cone from the flange of the front blade retaining ring.

SUBTASK 72-38-11-020-052 Remove the Inlet Cone and the Trim Balance Weights (if installed)

Examine the inlet cone (non-modular) at interface A and the LP compressor (fan) module front face at interface A-31. Refer to TASK 72-00-00-200-000 (INSPECTION/CHECK-000).

SUBTASK 72-38-11-220-051 Examine the Interfaces

Figure: Remove the inlet cone

Sheet 1

Figure: Remove the inlet cone fairing

Sheet 2

Figure: Remove the inlet cone with the puller lever

Remove the inlet cone with the puller lever