Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-00-00-200-004-B00 Engine General - Examine (Borescope) The HPT Stage 1 Blades And Duct Segments, Inspection-004

General

All Fig/item numbers in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures refer to SPM TASK 70-41-00-400-501, SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

Special torque data is identified with the symbol * after the torque value.

Assembly tolerances are included in this procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

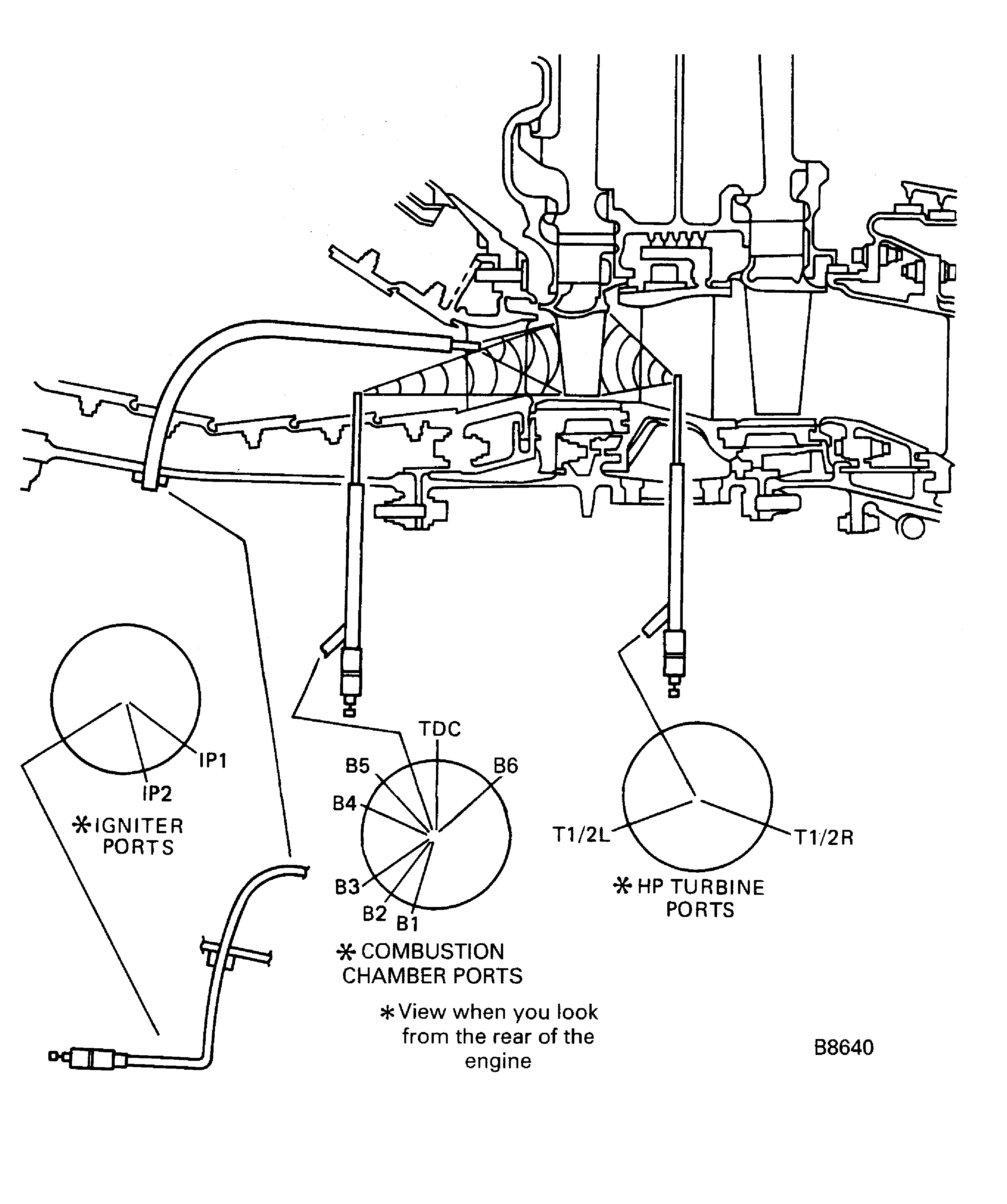

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Definitions and General Information

This TASK is for A5 basic (non SelectOne) engines only, which have not incorporated SBE 72-0562. This TASK gives the procedure for the borescope inspection stage 1 HPT blades and duct segments. This TASK recommends the use of a flexible borescope. You can use a rigid borescope to inspect for general damage to the blades, but a rigid borescope will not permit you to see sufficient detail to inspect the blades or duct segments to the limits in this TASK.

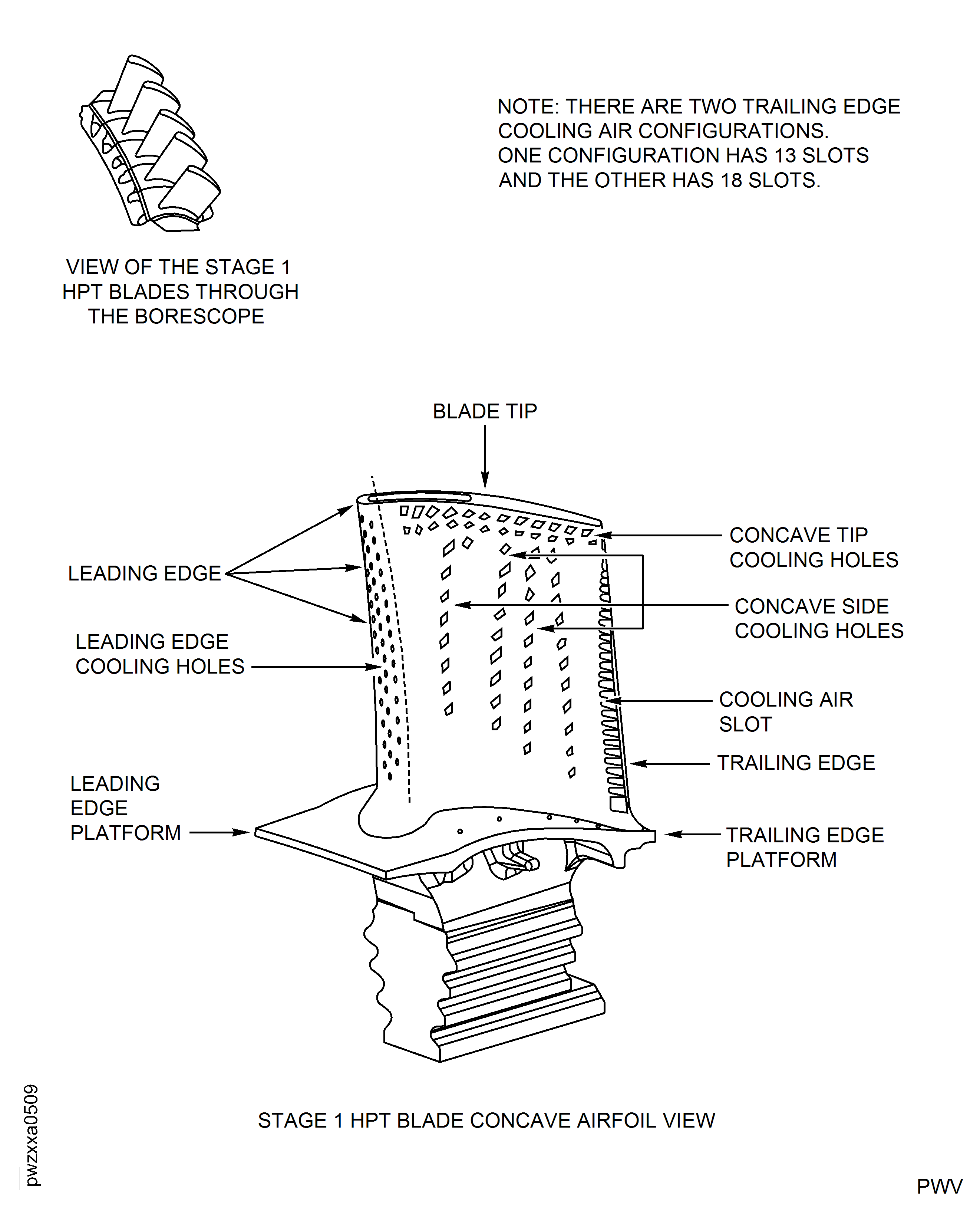

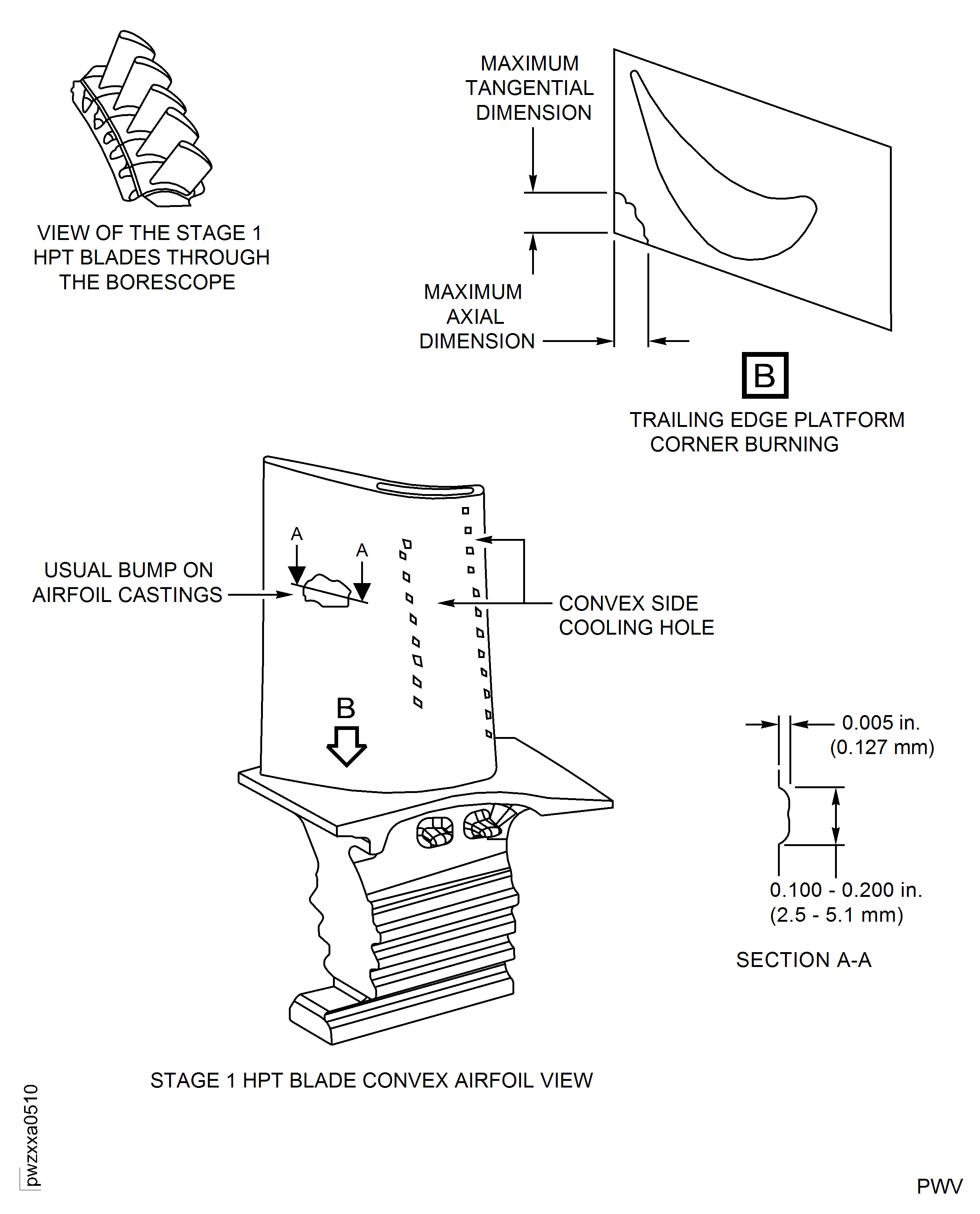

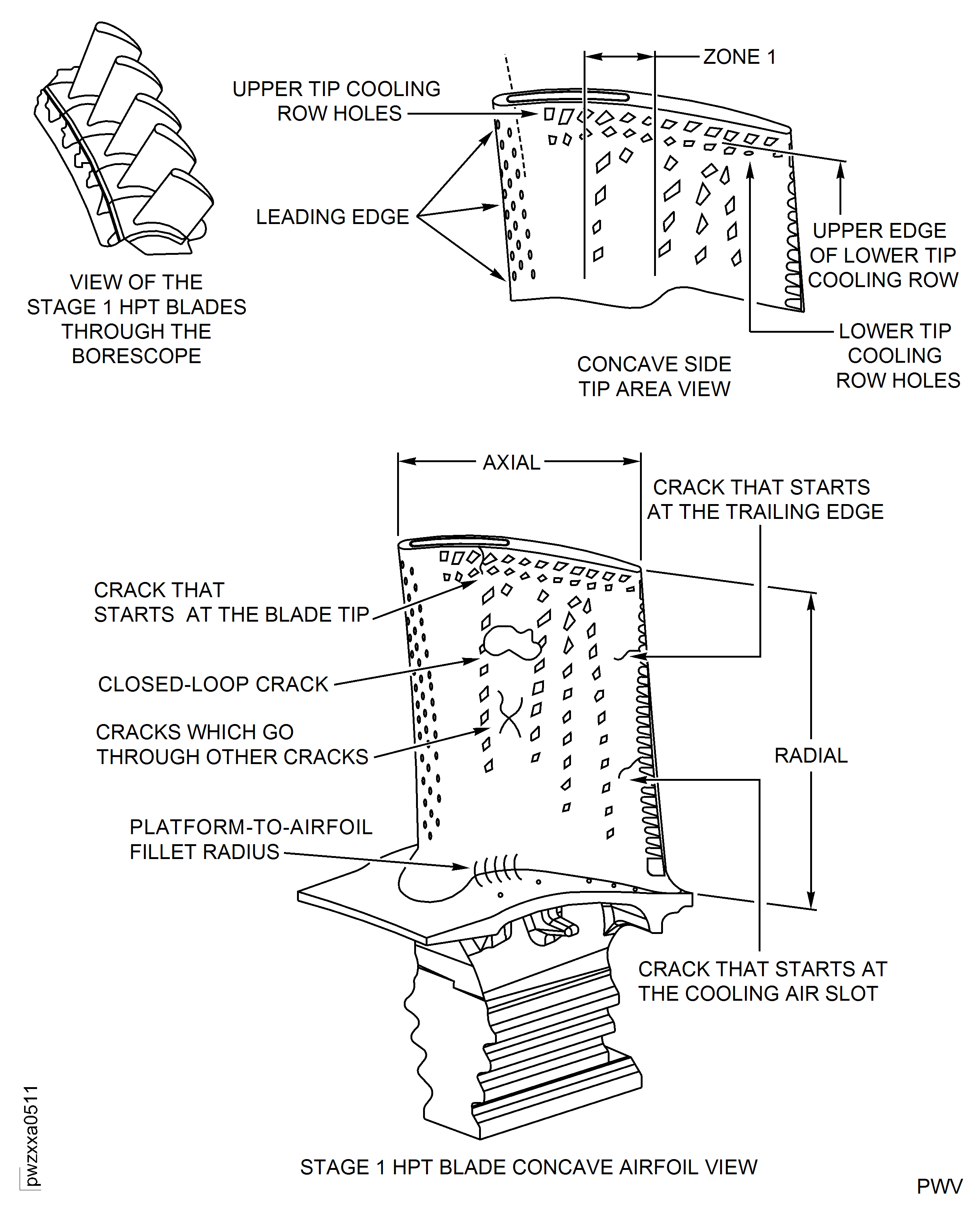

The names of the different parts and areas of the Stage 1 HPT blades are shown Figure.

Use the names which follow when you identify a blade condition seen at borescope inspection:

Erosion: A local area where material has been removed by causes other than heat distress.

Leading Edge Hole: A hole in the leading edge open to the cooling air passage (can be caused by impact or burning).

Burns: A local area where material has been removed because of heat distress.

Coating damage: Chipping, flaking, blistering, peeling or oxidation of blade confined to coating.

Trailing edge metal loss: A burn through the convex trailing edge wall that causes a shorter airfoil chord length.

Nick: A small surface imperfection having sharp edges, corners or bottom caused by the impact of some object.

Dent: A surface depression normally having rounded edges, corners and bottom caused by the impact of some object.

Use the names which follow when you identify a duct segment condition seen at borescope inspection:

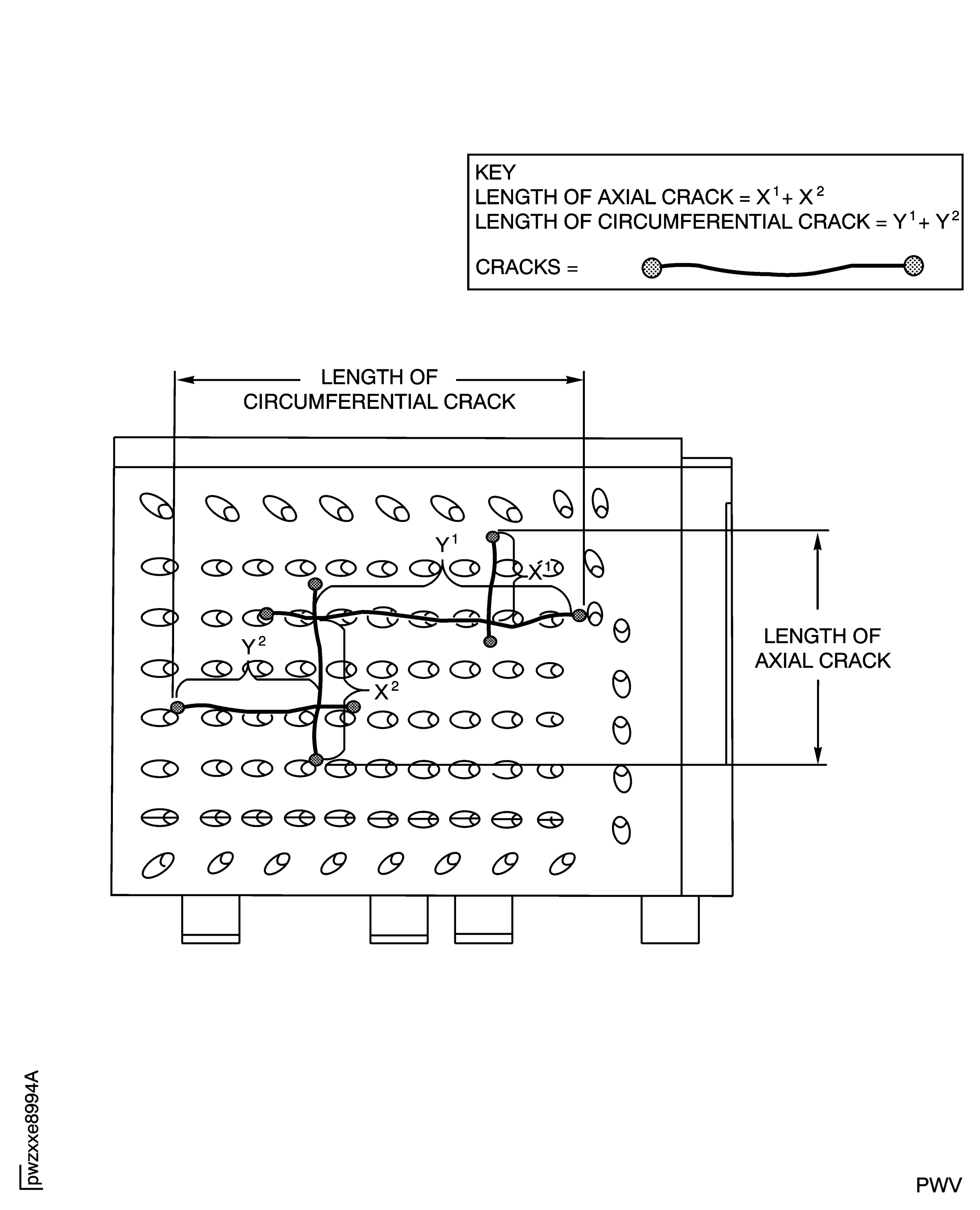

Cracks: A linear opening that can easily be seen and which can cause the material to break.

Closed loop of cracks: Adjoining cracks that close in on themselves.

Intersecting cracks: One or more axial or circumferential cracks that go through each other.

Burns: A local area where material was removed because of heat distress.

Burn-Through: A hole in the duct segment gas path side which is open to the cavity behind it.

Erosion: A local area where material was removed by causes other than heat distress.

Leading edge (LE) lifting: When the duct segment leading edge has become loose and can move radially inward.

Impingement plate: The wall that seals the internal cavity from the backside of the duct segment.

Shiplap: Location where adjoining duct segments overlap.

NOTE

NOTE

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Cover (eye) | LOCAL | |||

| Flexible borescope (probe dia. 0.24 to 0.31 in. (6.0 to 8.0 mm) with view capability of 180 degrees up and down) | LOCAL | Flexible Borescope | ||

| Motor Drive Unit | LOCAL | |||

| Rigid borescope | LOCAL | |||

| Torque wrench, range 0 to 250 lbfin (0 to 20 Nm) | LOCAL | Torque Wrench 0-250 | ||

| IAE 1P16184 Puller | 0AM53 | IAE 1P16184 | 1 | |

| IAE 2P16204 Guide Tube | 0AM53 | IAE 2P16204 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-024 MASKING TAPE (CREPE PAPERBACKING) | LOCAL | CoMat 02-024 | ||

| CoMat 02-141 LOCKWIRE | LOCAL | CoMat 02-141 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 | ||

| CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL | LOCAL | CoMat 10-094 | ||

| CoMat 10-129 ANTI-SEIZE PASTE | 34568 | CoMat 10-129 |

Safety Requirements

WARNING

CAUTION

Procedure

Refer to Figure.

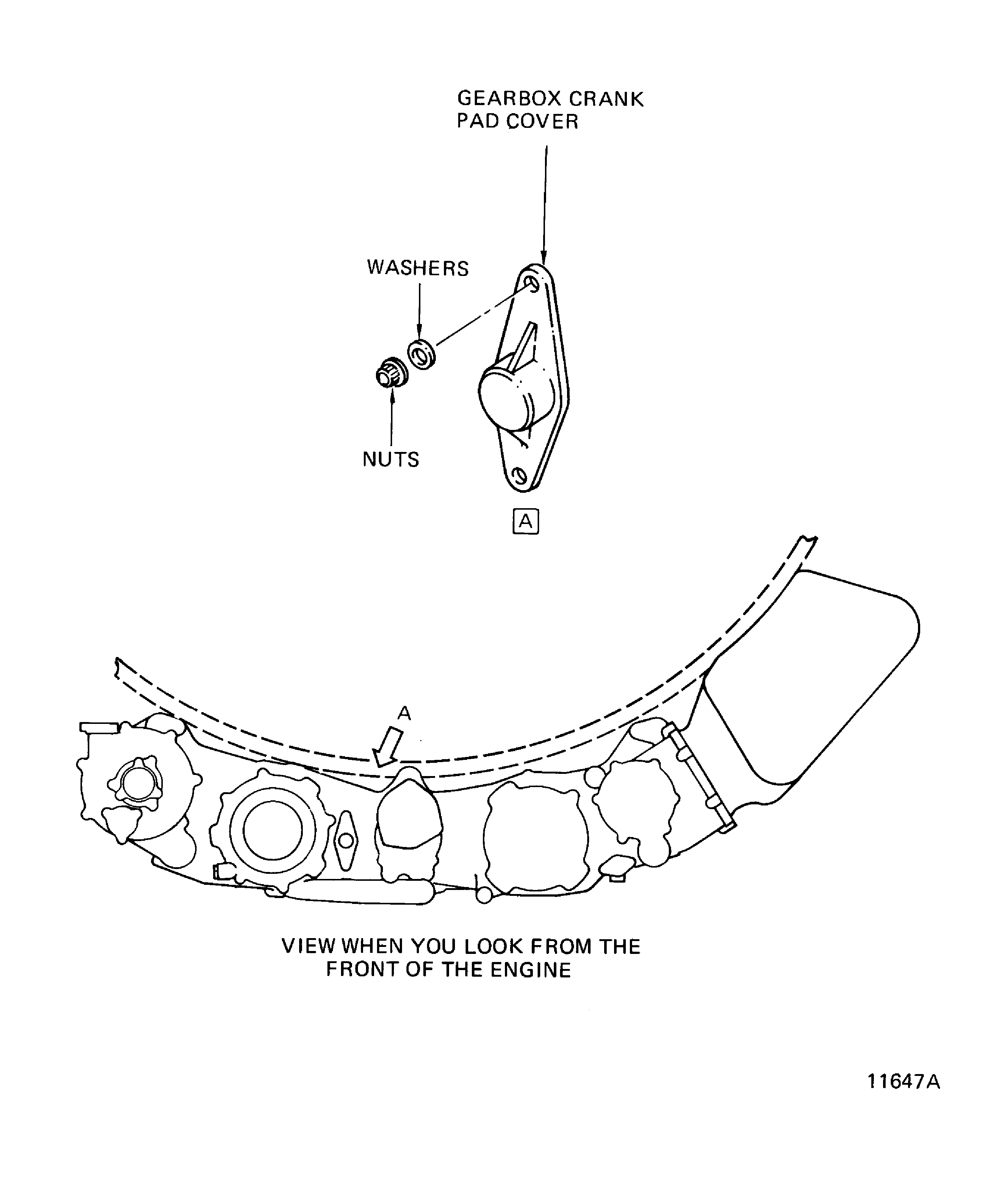

SUBTASK 72-00-00-420-079 Install the Foot-Operated Motor Drive Unit to the Gearbox Crank Pad

Put the flexible borescope into the IAE 2P16204 Guide Tube 1 off until the end of the borescope is even with the end of the tube. This will be a limit mark on the borescope so you will not insert the borescope too far and cause damage to the borescope.

Put a piece of CoMat 02-024 MASKING TAPE (CREPE PAPERBACKING) on the borescope fiber bundle 3.250in. (82.55 mm) from the other end of the guide tube.

Push the guide tube in until it touches the stop.

NOTE

In this position, the slot will be up.

A cover for the eye which is not used will decrease eye tension.

If you use an adjustable clamp to hold the borescope, you will be able to easily move the borescope dial and the fiber bundle.

Some borescope units have closed-circuit television adapters. We highly recommend this unit.

Install the tube into the IP1 port.

SUBTASK 72-00-00-420-080 Install the Guide Tube and the Flexible Borescope into the IP1 Borescope Port to Examine the Stage 1 HPT Blades,thru

For a close up inspection, do the procedure in the paragraph above.

An eye cover for the eye which is not used will decrease eye tension.

Removal of the plugs at both of the locations will permit you to examine both leading and trailing edges.

Put the IAE 1P16184 Puller 1 off in to the center hole of the plug (use if required).

WARNING

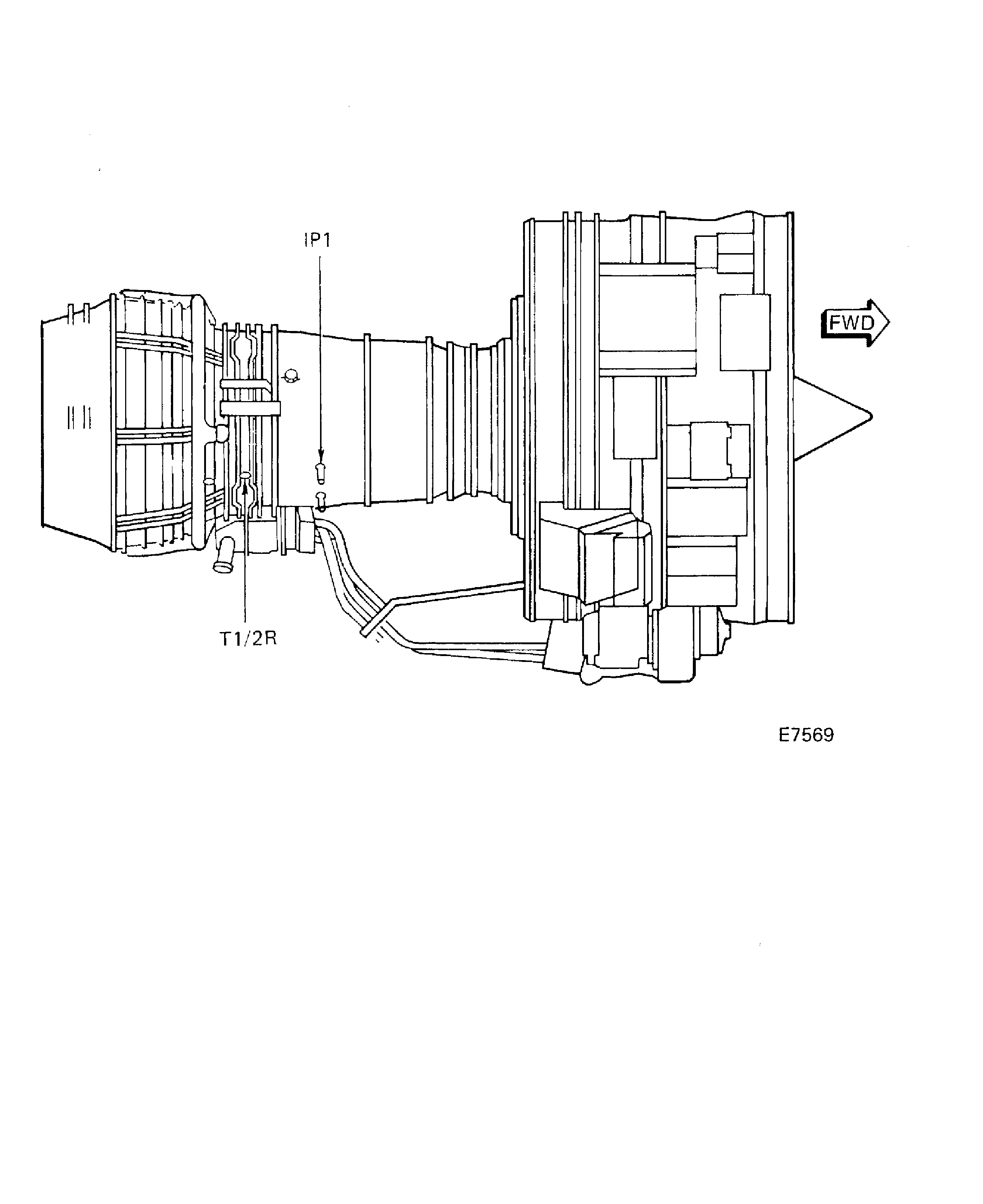

MAKE SURE THAT THE BLANKING PLUG IS COOL BEFORE YOU REMOVE IT. THE PLUG STAYS HOT FOR A SHORT TIME AFTER THE ENGINE IS SHUTDOWN.Get access to the stage 1 HPT blades through the T1/2L and the T1/2R ports, Figure.

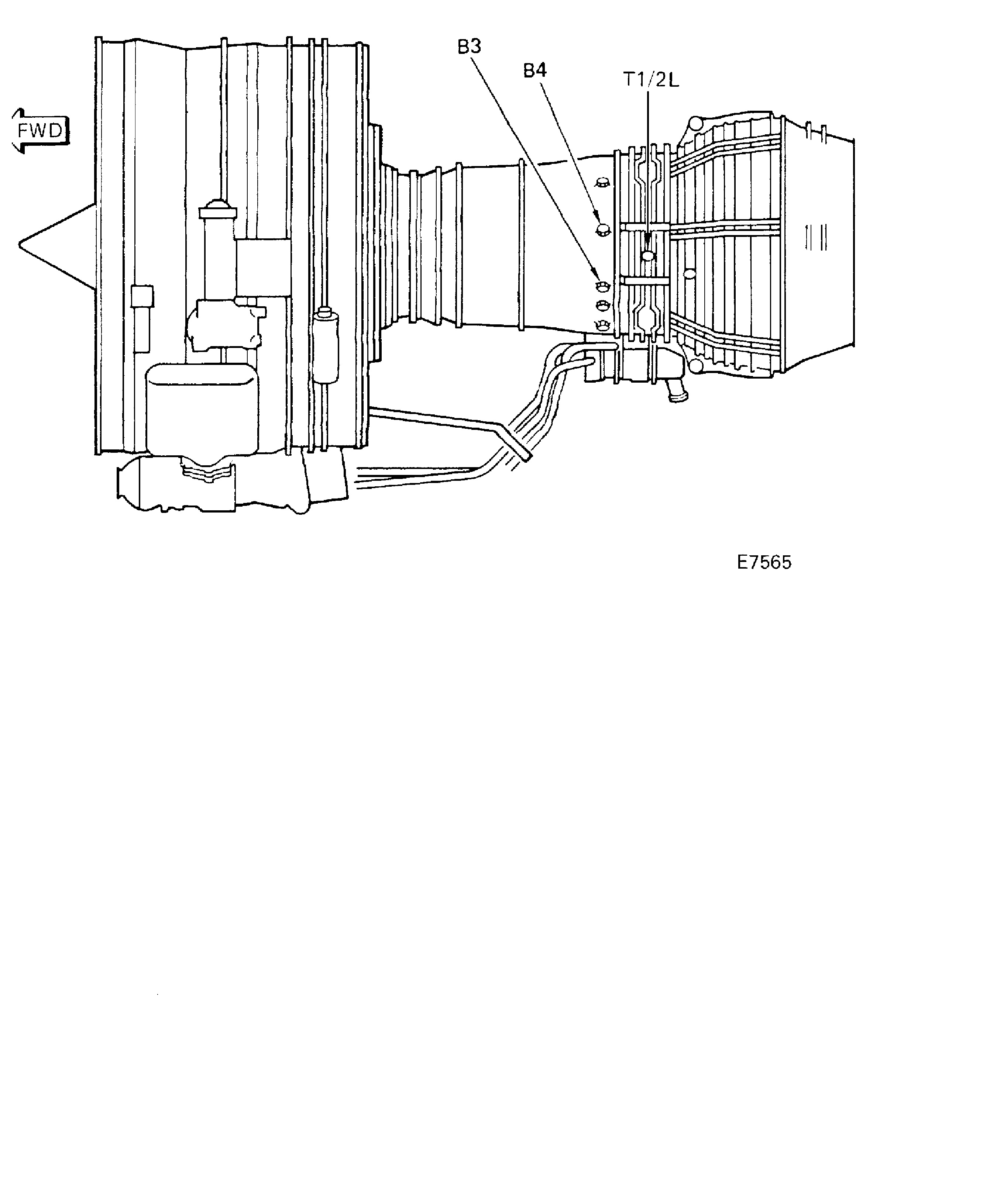

Put a rigid borescope through the B3 or B4 port, Figure.

Put a rigid borescope through the T1/2L or T1/2R port, Figure.

SUBTASK 72-00-00-020-071 Install a Rigid Borescope to Examine the Stage 1 HPT Blades through the B3 or B4 and T1/2L or T1/2R Ports,thru

NOTE

There is a nick or dent with cracks on the leading edge outer 50 percent span which has a total radial or axial length of up to 0.20 in. (5.08 mm).

Accept with an inspection each 750 hours if:

There is a nick or dent with cracks on the leading edge outer 50 percent span which has a total axial length up to 0.27 in. (6.8 mm) and a total radial length of greater than 0.20 in. (5.08 mm) and up to a total radial length of 0.50 in. (12.7 mm).

Accept with an inspection each 300 hours if:

SUBTASK 72-00-00-220-119 Examine the Stage 1 HPT Blades for Nicks or Dents on the Airfoil

NOTE

There will be unwanted material on the airfoil because of the casting procedure. Refer to Figure. During borescope inspection, this material will look like small bumps on the concave and convex surfaces of the airfoil. These bumps are usually round or oval, are between 0.100 to 0.200 in. (2.54 to 5.08 mm) wide and are 0.005 in. (0.13 mm) high. These bumps are acceptable. No action is necessary.

Tip zone - lower edge of upper tip cooling holes to tip. In this zone a crack going through another crack is permitted.

The crack on the leading edge (in the outer 50 percent span) extends from a burned area or burn-through and the combination of a burn or burn-through plus a crack is more than or equal to 0.20 in. (5.08 mm) in the radial direction and the crack is less than 0.45 in. (3.81 mm) in the radial direction.

Accept with an inspection each 150 hours if:

SUBTASK 72-00-00-220-120 Examine the Stage 1 HPT Blades for Cracks on the Airfoil

Refer to Figure.

NOTE

It is acceptable to have small pieces of the Stage 1 HPT seal HPT Stage 1 Blade And Related Parts (72-45-14,01-060) out between the rear platform of the Stage 1 HPT blade HPT Stage 1 Blade And Related Parts (72-45-14,01-010) and the Stage 1 HPT air seal ENGINE-STAGE 1 AIR SEAL (REAR) (72-45-15,01-020).

SUBTASK 72-00-00-220-121 Examine the Stage 1 HPT Blades for Cracks on the Platform

NOTE

The newest standard of Stage 1 HPT blades has an outer ceramic coating and protective coatings underneath the ceramic coating. Erosion or chipping of the ceramic outer coating is acceptable. A reduced inspection interval or engine removal is not necessary until burning or erosion of the base material of the blade occurs as specified below. Thus, it is not necessary to remove the engine or reduce the inspection interval because of coating loss.The leading edge hole beyond the 75 percent span is less than 0.10 in. (2.54 mm) axially and 0.15 in. (3.81 mm) radially.

Accept with an inspection each 1500 hours if:

The leading edge hole beyond the 50 percent span is less than 0.10 in. (2.54 mm) axially and less than 0.20 in. (5.08 mm) radially.

Accept with an inspection each 750 hours if:

There is material that is burned away or missing on the blade trailing edge tip that is more than 0.070 in. (1.78 mm) axially from the trailing edge.

NOTE

The blade trailing edge tip is 0.150 in. (3.81 mm) radially from the tip and 0.100 in. (2.54 mm) from the trailing edge and burning or erosion is permitted in this area.

Accept with an inspection each 600 hours if:

SUBTASK 72-00-00-220-122 Examine the Stage 1 HPT Blades for Erosion or Burns on the Airfoil or Platform

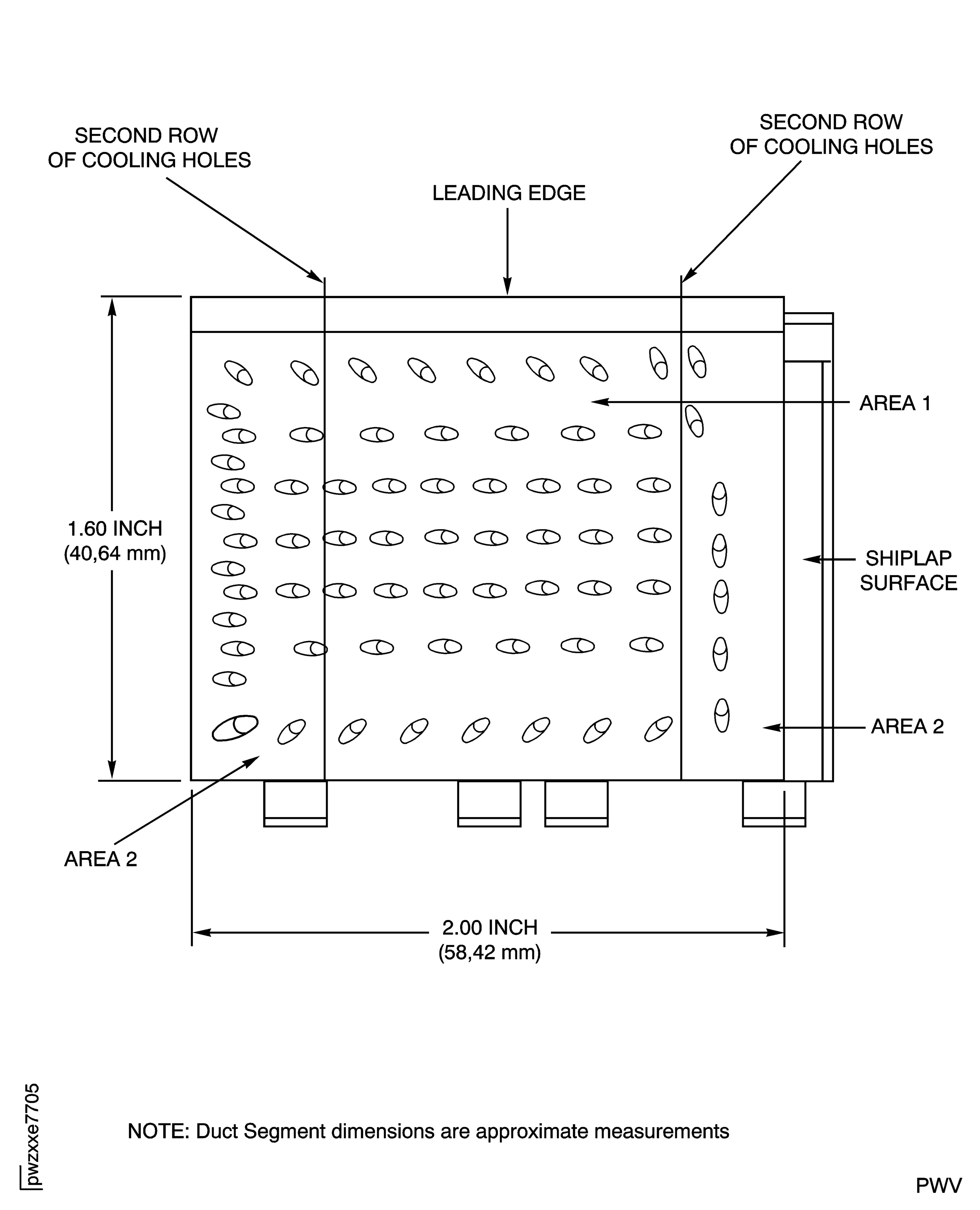

Damage in columns A and B will need reduced on-wing inspections of either 300 hours or 125 hours if you do not replace the damaged duct segments. It is recommended that, because of the reduced inspection intervals, you review the timing of the next maintenance interval for the HPT and find out if you must replace the duct segments before you return the engine to service.

Damage in Column C means you must replace the duct segments before you return the engine to service.

NOTE

The HPT Stage 1 BOAS has a protective coating underneath the ceramic coating. Chipping and spalling of the ceramic coating is acceptable without a decrease in borescope inspection interval. The smearing of blade tip material on the HPT Stage 1 BOAS is acceptable without a decrease in the borescope inspection interval.CONDITION

A.

300-HR. INSPECTION

B.

125-HR. INSPECTION

C.

REPLACE THE DUCT SEGMENT

Axial cracks

One crack is longer than 0.250 in. (6.35 mm) and shorter than 0.500 in. (12.70 mm)

One crack is longer than or equal to 0.500 in. (12.70 mm) but shorter than 1.20 in. (30.50 mm)

One crack is longer than or equal to 1.20 in. (30.5 mm)

Circumferential cracks

One crack is longer than 0.375 in. (9.53 mm) and is shorter than 0.500 in. (12.70 mm)

One crack is longer than or equal to 0.500 in. (12.70 mm) but shorter than 1.50 in. (38.10 mm)

One crack is longer than or equal to 1.50 in. (38.10 mm)

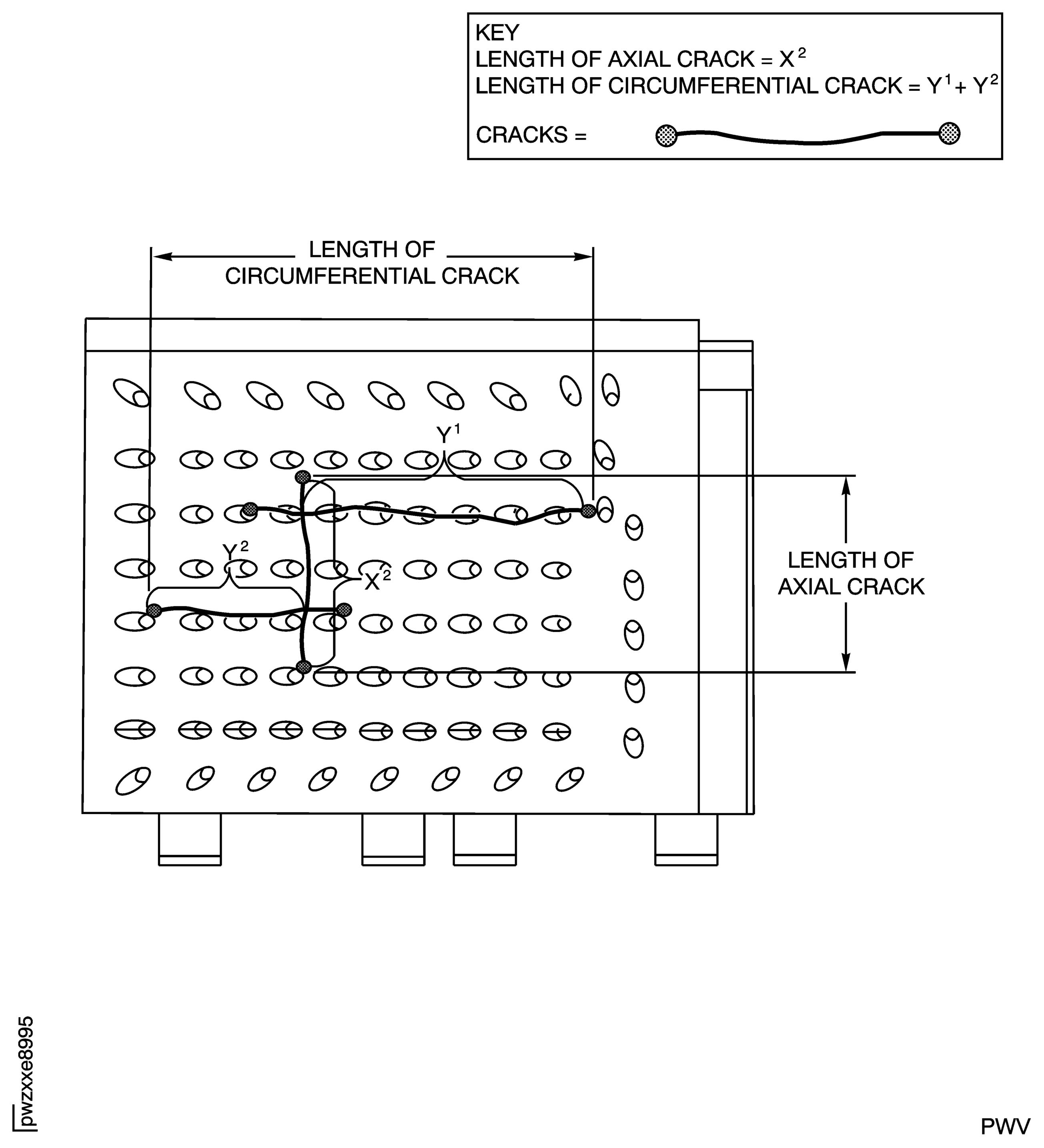

Intersecting cracks

A combined crack that is longer than 0.250 in. (6.35 mm) and shorter than 0.500 in. (12.70 mm) axially or longer than 0.375 in. (9.53 mm) and shorter than 0.500 in. (12.70 mm) circumferentially.

A combined crack that is longer than or equal to 0.500 in. (12.70 mm) and shorter than 1.20 in. (30.48 mm) axially or longer than or equal to 0.500 in. (12.70 mm) and shorter than 1.500 in. (38.10 mm) circumferentially.

A combined crack that is longer than or equal to 1.20 in. (30.48 mm) axially or 1.500 in. (38.10 mm) circumferentially.

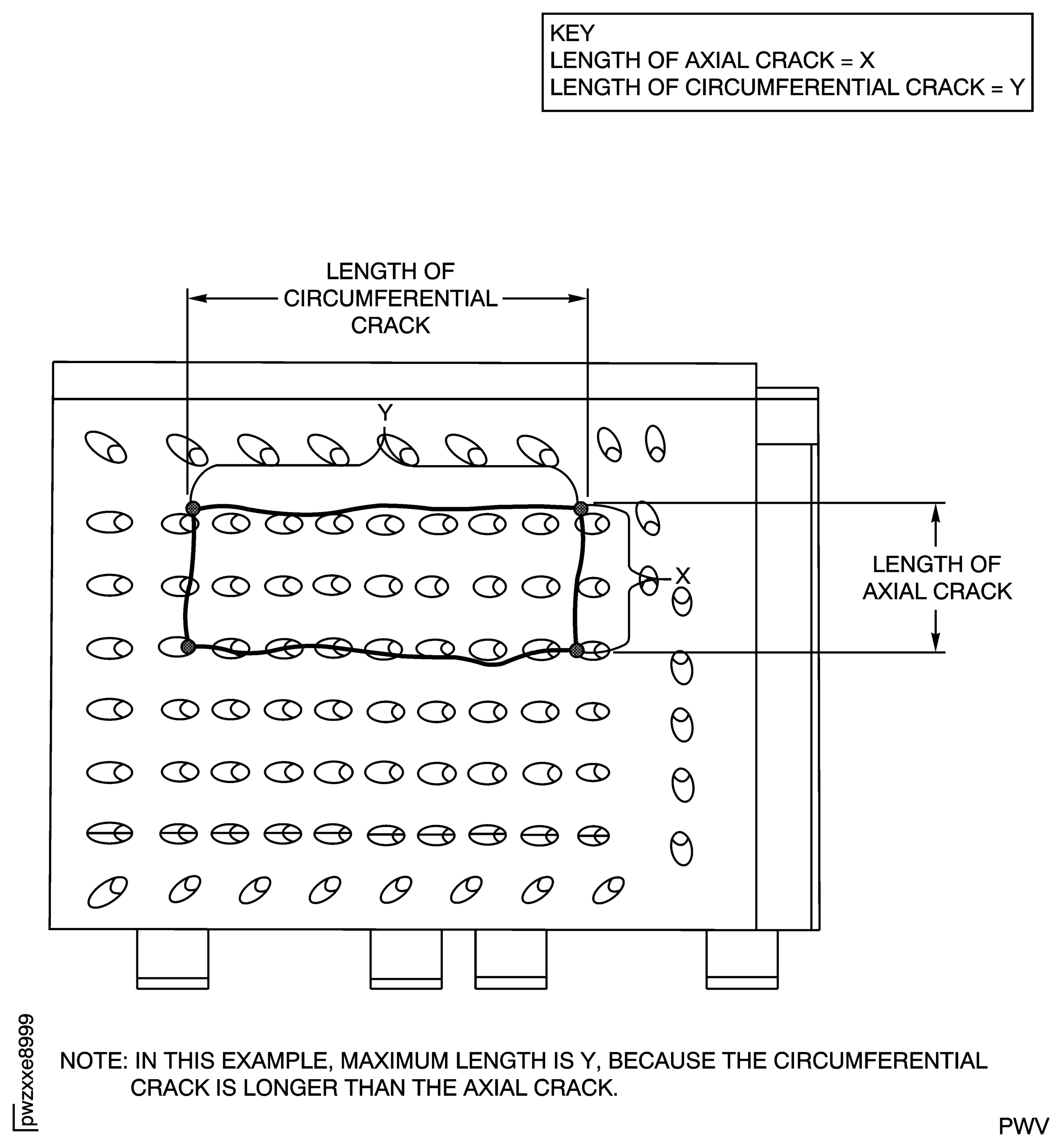

Closed loop of cracks

Does not apply

Maximum length in X or Y direction that is less than 0.500 in. (12.70 mm).

Maximum length in X or Y direction that is more than or equal to 0.500 in. (12.70 mm)

Burning or erosion of the base metal at Area 1 (no burn-through)

One amount that is greater than two connecting cooling holes

Does not apply

Does not apply

Burning or erosion of the base metal at Area 2 (no burn-through)

Shiplap burning more than the first row of cooling holes and not more than the second row of cooling holes

Shiplap burning goes through the second row of cooling holes

Does not apply

Burn-through in Areas 1 and 2

Does not apply

Less than 0.500 in. (12.70 mm) of continuous burn-through in Area 1, Area 2 or Areas 1 and 2 together

More than or equal to 0.500 in. (12.70 mm) continuous burn-through in Area 1, Area 2 or Areas 1 and 2 together

Burn-through with adjoining cracks in the axial direction

Does not apply

Combined length of X¹+X²+Z is less than 1.20 in. (30.48 mm) and Z is less than 0.500 in. (12.70 mm) in Area 1, Area 2 or Areas 1 and 2 together

Combined length of X¹+X²+Z is more than or equal to 1.20 in. (30.48 mm) or Z is more than or equal to 0.500 in. (12.70 mm)

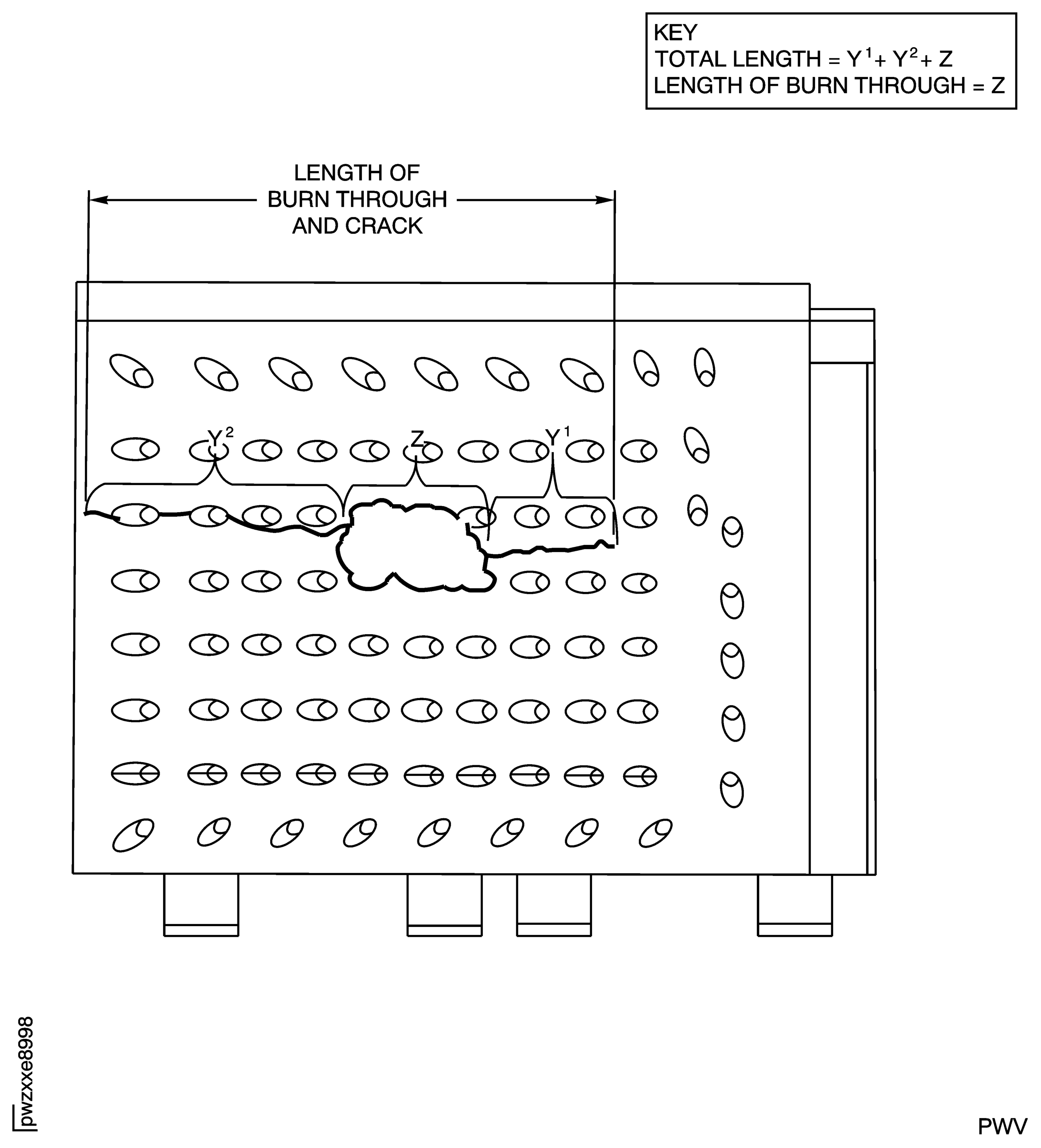

Burn-through with adjoining cracks in the circumferential direction

Does not apply

Combined length of Y¹+Y²+Z is less than 1.50 in. (38.10 mm) and Z is less than 0.500 in. (12.70 mm) in Area 1, Area 2 or Areas 1 and 2 together

Combined length of Y¹+Y²+Z is more than or equal to 1.50 in. (38.10 mm) or Z is more than or equal to 0.500 in. (12.70 mm)

Burn-through the impingement plate

Does not apply

Does not apply

Any amount

Material on the Leading Edge is lifted up

Does not apply

Does not apply

Seal edge is lifted

Loss of Leading Edge Material (parent material loss)

Less than 0.300 in. (7.62 mm)

More than or equal to 0.300 in. (7.62 mm) but less than 0.500 in. (12.70 mm)

More than or equal to 0.500 in. (12.70 mm)

If an engine is in the shop for maintenance other than the HPT, you must do a 360-degree inspection of the stage 1 HPT duct segments.

SUBTASK 72-00-00-220-123 Examine the Stage 1 HPT Duct Segments

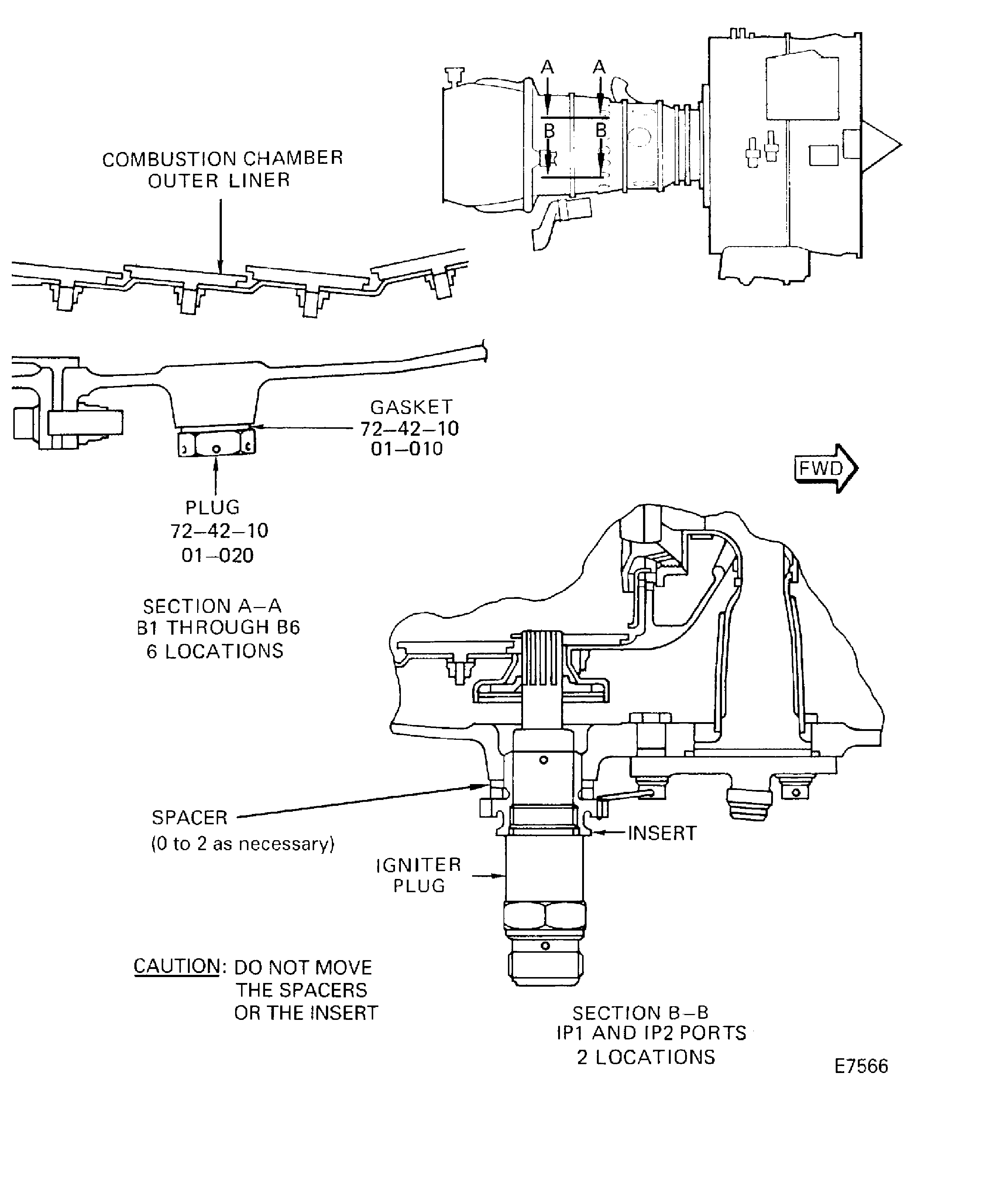

Lubricate the plug threads with CoMat 10-129 ANTI-SEIZE PASTE or CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL. Wipe off excess paste.

Install the plug Diffuser Case Assembly And Fittings (72-42-10,01-020) and the Diffuser Case Assembly And Fittings (72-42-10, 01-010) gasket 1 off, Figure.

Safety the plug with CoMat 02-141 LOCKWIRE.

For the B3 or B4 port proceed as follows:

NOTE

It is permissible to correct minor thread damage to the threaded hole with a 0.5625-18UNF-3B die.Put the HP Turbine (HPT) Rotor And Stator Assembly (72-45-00, 01-120) gasket 1 off in the case recess, Figure.

CAUTION

USE CAUTION WHEN INSTALLING PLUG. IF THE PLUG BREAKS DURING INSTALLATION AND FALLS INTO 2ND STAGE VANE CAVITY, REMOVE PLUG PIECE PRIOR TO RETURNING ENGINE TO SERVICE. IF NECESSARY, ACCESS TO THE CAVITY CAN BE OBTAINED BY REMOVING THE TCA TUBE.Put the gasket on the plug (2) HP Turbine (HPT) Rotor And Stator Assembly (72-45-00, 01-140) and install it in the case.

NOTE

It is permissible to correct minor thread damage to the threaded hole with a 0.5625-18UNF-3B die.Lubricate the bolt threads with CoMat 10-129 ANTI-SEIZE PASTE or CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL. Wipe off excess paste.

NOTE

Make sure that the borescope plug is correctly installed and bolt holes are aligned prior to continuing to next step.Safety the bolts with CoMat 02-141 LOCKWIRE.

For the T1/T2 and T1/2R port proceed as follows:

SUBTASK 72-00-00-420-081 Close the Borescope Inspection Ports after the Borescope Inspection is Completed

Figure: Crank Pad Location

Crank Pad Location

Figure: HP Turbine Borescope Locations for Inspection of the Stage 1 HPT Blades (Left Side)

HP Turbine Borescope Locations for Inspection of the Stage 1 HPT Blades (Left Side)

Figure: HP Turbine Borescope Ports for Inspection of the Stage 1 HPT blades (Right Side)

HP Turbine Borescope Ports for Inspection of the Stage 1 HPT blades (Right Side)

Figure: HP Turbine Ports for Inspection of the Stage 1 HPT Blades

HP Turbine Ports for Inspection of the Stage 1 HPT Blades

Figure: Borescope Equipment

Borescope Equipment

Figure: Borescope Ports

Borescope Ports

Figure: Borescope Ports

Borescope Ports

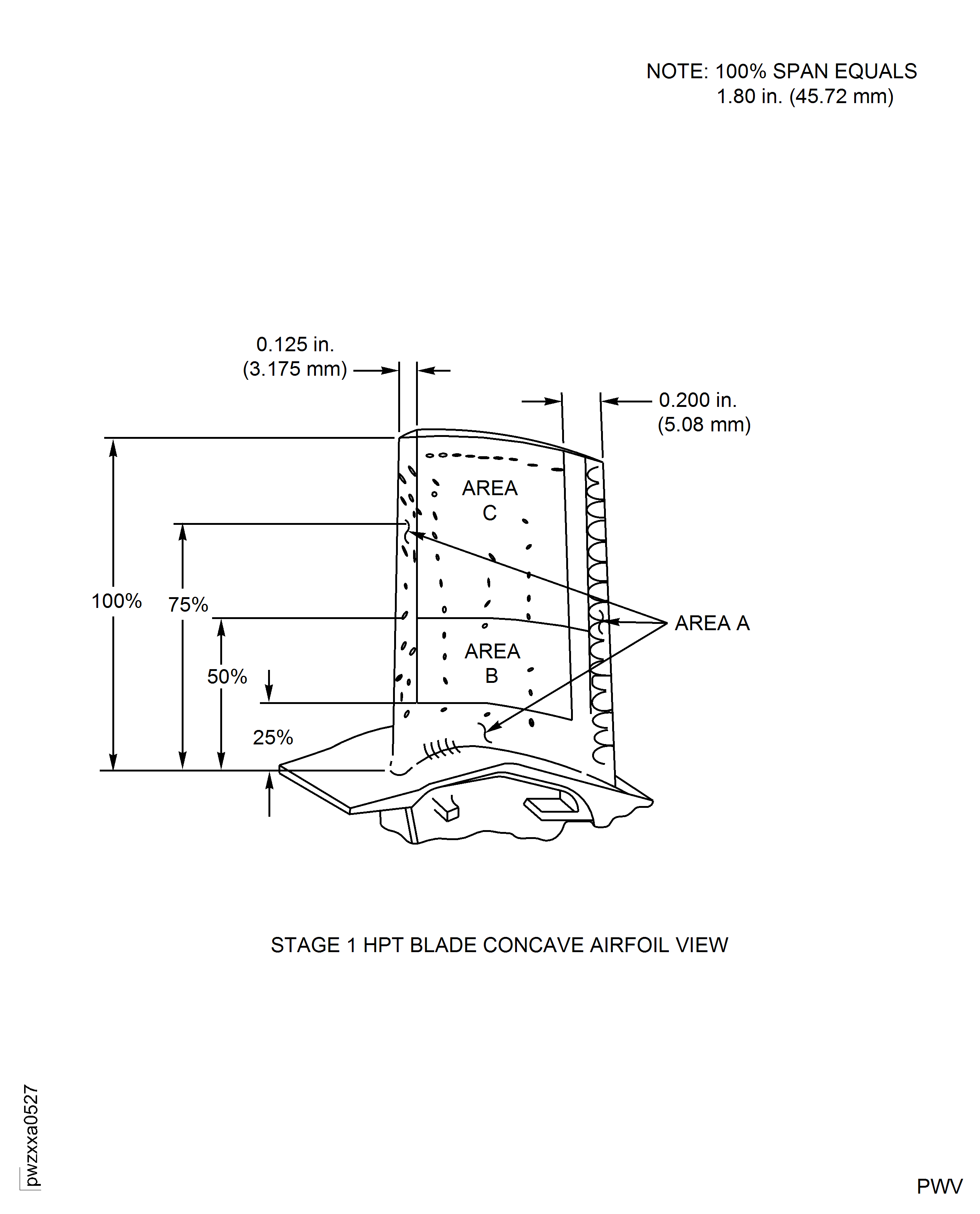

Figure: Stage 1 HPT Blade Inspection Areas

Stage 1 HPT Blade Inspection Areas

Figure: Stage 1 HPT Blade Inspection Areas

Stage 1 HPT Blade Inspection Areas

Figure: Stage 1 HPT Blade Inspection Areas

Stage 1 HPT Blade Inspection Areas

Figure: Stage 1 HPT Blade Inspection Areas

Stage 1 HPT Blade Inspection Areas

Figure: Stage 1 HPT Duct Segment Inspection Locations

Stage 1 HPT Duct Segment Inspection Locations

Figure: Stage 1 HPT Duct Segment Inspection Locations

Stage 1 HPT Duct Segment Inspection Locations

Figure: Stage 1 HPT Blade Inspection Areas

Stage 1 HPT Blade Inspection Areas

Figure: HPT Stage 1 Duct Segment Intersecting Cracks

HPT Stage 1 Duct Segment Intersecting Cracks

Figure: HPT Stage 1 Duct Segment Intersecting Cracks

HPT Stage 1 Duct Segment Intersecting Cracks

Figure: HPT Stage 1 Duct Segment Intersecting Cracks

HPT Stage 1 Duct Segment Intersecting Cracks

Figure: Burn Through with Adjoining Cracks in Axial Direction

Burn Through with Adjoining Cracks in Axial Direction

Figure: Burn Through with Adjoining Cracks in Cirumferential Direction

Burn Through with Adjoining Cracks in Cirumferential Direction

Figure: Closed Loop of Cracks

Closed Loop of Cracks