Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 71-71-49-300-001 Fuel Drain Tubes - Repair A Bent Support Bracket, Repair-001 (VRS2944)

Effectivity

FIG/ITEM | PART NO. |

01-500 | 740-5277-503 |

01-500 | 740-5277-505 |

02-100 | 740-5279-505 |

02-100 | 740-5279-507 |

02-500 | 740-5278-503 |

02-500 | 740-5278-505 |

02-500 | 740-5278-507 |

General

This repair can be done to the support brackets attached to the Fuel drain tube. It can be done during engine overhaul.

Price and availability - none.

The practices and processes referred to in the procedures by the TASK numbers are in the Standard Practices and Processes Manual (SPM).

A backing-block must be locally manufactured from a square piece of stainless steel block. One face of the backing-block must be smooth and flat and must have no burrs.

If the support bracket has been repaired before, do not do this repair.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Pliers | LOCAL | Pliers | ||

| Steel rule | LOCAL | Steel rule | which have smooth jaws | |

| Straight edge | LOCAL | Straight edge | which is 6.0in. (152.4 mm) long | |

| Nylon mallet | LOCAL | Nylon mallet |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Use the backing-block.

Put the face of the backing-block against the support bracket.

Make sure that this face of the backing-block is smooth and flat and has no burrs.

Use the Nylon mallet and the Pliers.

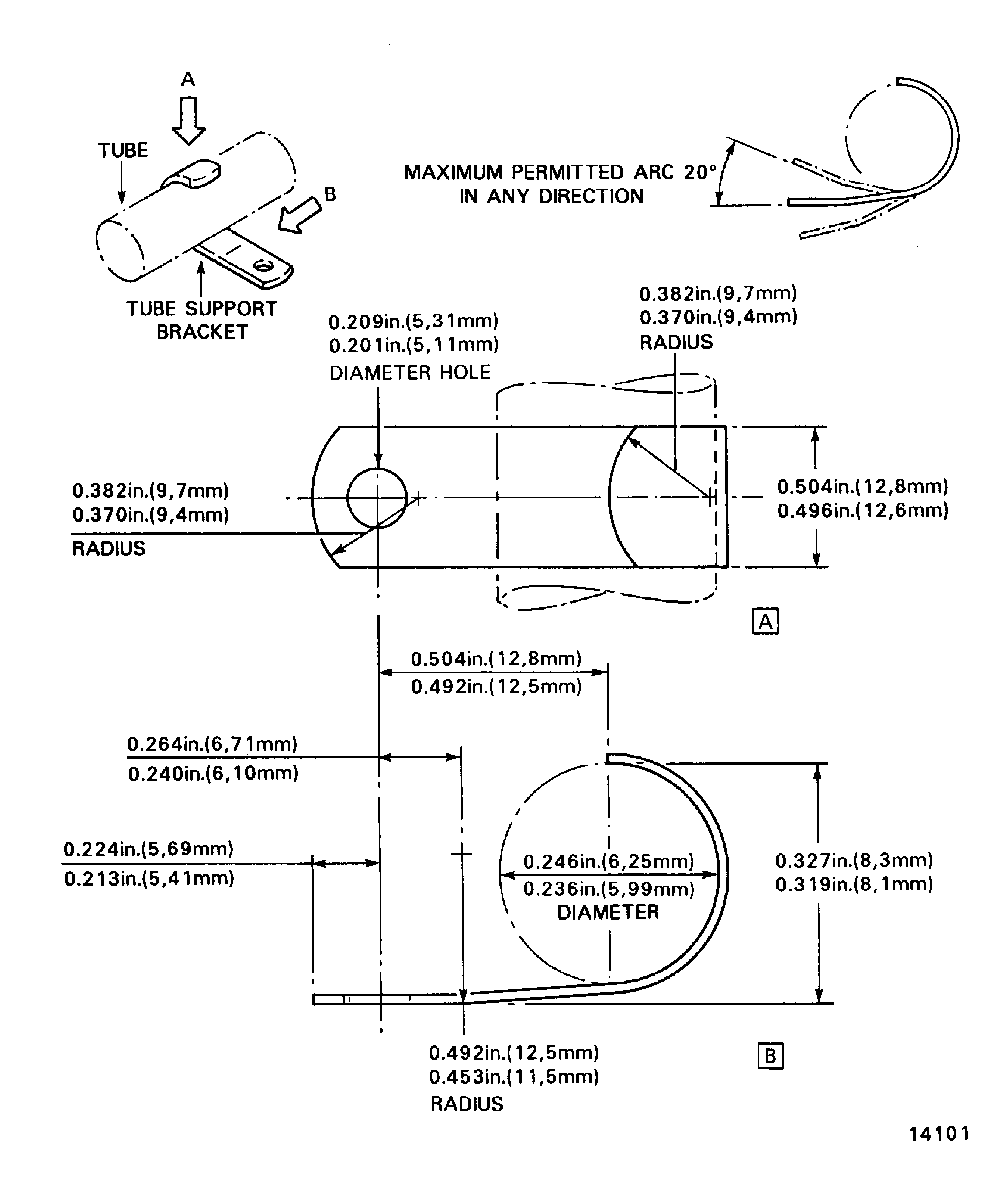

Refer to Figure and change the shape of the support bracket to the correct shape.

Use no more force than is necessary to change the shape of the support bracket.

If the support bracket must be moved through more than 20 degrees during the repair, discard the support bracket.

Repair the support bracket.

SUBTASK 71-71-49-350-051 Repair the Support Bracket

CAUTION

MAKE SURE THAT THERE ARE NO BURRS OR SHARP EDGES ON THE BACKING BLOCK. MAKE SURE THAT THERE ARE NO UNWANTED PARTICLES, DIRT OR GRIT ON THE BACKING-BLOCK OR ON THE SUPPORT BRACKET. THESE COULD CAUSE SCRATCHES OR CRACKS DURING THE REPAIR.Refer to Figure.

Use the Straight edge.

Refer to Figure and make sure that these segments are straight.

Examine the straight segments of the support bracket.

Use the Steel rule.

Make sure that the dimensions of the support bracket are correct.

SUBTASK 71-71-49-210-051 Examine the Shape of the Support Bracket

Refer to SPM TASK 70-23-05-230-501.

Do a dye penetrant test on the support bracket.

SUBTASK 71-71-49-230-051 Examine the Repaired Support Bracket

Refer to SPM TASK 70-09-00-400-501 and use the electro-etch method.

Mark the repair scheme number VRS2944 on the support bracket, adjacent to the repair area.

SUBTASK 71-71-49-350-052 Put the Repair Scheme Number on the Support Bracket

Figure: Support Bracket Repair - Dimensions

Support Bracket Repair - Dimensions