Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-00-500-002 Engine General - Prepare The Engine For Storage, Storage-002

General

Refer to TASK 72-00-00-500-001 (STORAGE-001, CONFIG-001) General Data for Engine Storage.

To identify the consumable materials, refer to the Consumable Materials Index.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Spray Can with Nozzle Extension | LOCAL | Spray Can with Nozzle Extension | ||

| IAE 1F10077 Protective cover | 0AM53 | IAE 1F10077 | 1 | |

| IAE 1N20008 Protective cover | 0AM53 | IAE 1N20008 | 1 | |

| IAE 1N20400 Protective cover | 0AM53 | IAE 1N20400 | 1 | |

| IAE 1N20435 Protective blank | 0AM53 | IAE 1N20435 | 1 | |

| IAE 1N20436 Protective blank | 0AM53 | IAE 1N20436 | 1 | |

| IAE 1N20443 Protective blank | 0AM53 | IAE 1N20443 | 1 | |

| IAE 5F10060 Closure kit | 0AM53 | IAE 5F10060 | 1 | |

| IAE 5F10351 Shipping cover | 0AM53 | IAE 5F10351 | 1 | |

| IAE 5J12080 Rear cover | 0AM53 | IAE 5J12080 | 1 | |

| IAE 5J12083 Front cover | 0AM53 | IAE 5J12083 | 1 | |

| IAE 5J12142 Protective cover | 0AM53 | IAE 5J12142 | 1 | |

| IAE 5J13353 Protective cover | 0AM53 | IAE 5J13353 | 1 | |

| IAE 5J13354 Protective cover | 0AM53 | IAE 5J13354 | 1 | |

| IAE 5J13500 Protective closure | 0AM53 | IAE 5J13500 | 1 | |

| IAE 5P16183 Shipping closure | 0AM53 | IAE 5P16183 | 4 | |

| IAE 5R18304 Transportation cover | 0AM53 | IAE 5R18304 | 1 | |

| IAE 5R18305 Transportation cover | 0AM53 | IAE 5R18305 | 4 | |

| IAE 5R18306 Transportation cover | 0AM53 | IAE 5R18306 | 2 | |

| IAE 5R18307 Transportation cover | 0AM53 | IAE 5R18307 | 1 | |

| IAE 5R18310 Transportation plug | 0AM53 | IAE 5R18310 | 3 | |

| IAE 5R18311 Transportation cap | 0AM53 | IAE 5R18311 | 1 | |

| IAE 5R18312 Transportation cap | 0AM53 | IAE 5R18312 | 1 | |

| IAE 5R18317 Transportation plug | 0AM53 | IAE 5R18317 | 1 | |

| IAE 5R18318 Transportation plug | 0AM53 | IAE 5R18318 | 1 | |

| Cap | LOCAL | CD-5 | 2 | |

| Plug | LOCAL | ADP-5 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-297 SOLVENT | LOCAL | CoMat 01-297 | ||

| CoMat 01-298 ENGINE CLEANING SOLUTION | LOCAL | CoMat 01-298 | ||

| CoMat 02-041 MOISTURE RESISTANT TAPE | 80769 | CoMat 02-041 | ||

| CoMat 10-014 ANTI-CORROSION INHIBITING FLUID | LOCAL | CoMat 10-014 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 | ||

| CoMat 10-095 MINERAL OIL | 0AM53 | CoMat 10-095 | ||

| CoMat 12-004 P.V.C. SHEET | LOCAL | CoMat 12-004 | ||

| CoMat 12-013 PRINTED, WAXED, VCI COATED PAPER | LOCAL | CoMat 12-013 | ||

| CoMat 12-033 AIR BUBBLE SHEET | U1297 | CoMat 12-033 | ||

| CoMat 12-034 FIBREBOARD BOX | 6L812 | CoMat 12-034 | ||

| CoMat 12-035 FIBREBOARD BOX | 92500 | CoMat 12-035 |

Safety Requirements

NONEProcedure

Apply CoMat 10-077 APPROVED ENGINE OILS to TASK 70-60-21, 01-100 packing 1 off and the threads of the oil tank drain plug.

Install the new packing on the oil tank drain plug. Refer to the SPM TASK 70-44-01-400-501.

SUBTASK 72-00-00-050-059 Drain the Oil Tank

WARNING

DO NOT GET THE SYNTHETIC LUBRICATION OIL ON YOUR SKIN OR IN YOUR EYES. IF YOU GET THE SYNTHETIC LUBRICATION OIL ON YOUR SKIN OR IN YOUR EYES, FLUSH IT AWAY WITH WATER. GET MEDICAL HELP IF YOUR SKIN OR EYES BECOME IRRITATED.NOTE

Make sure solvent or cleaning solution does not collect in the engine air inlets or any openings.Clean the engine externally and nose cowl, common nozzle assembly (if fitted) with CoMat 01-297 SOLVENT or CoMat 01-298 ENGINE CLEANING SOLUTION.

SUBTASK 72-00-00-550-056 Clean the Engine for Storage

NOTE

This procedure is only applicable where engines/QEC units have accumulated substantial dirt/contamination due to service operation. This procedure does not apply to new engines or overhauled engines that have been cleaned recently.Protect the engine external surfaces by applying a coating of CoMat 10-014 ANTI-CORROSION INHIBITING FLUID.

SUBTASK 72-00-00-550-057 Protect the Engine External Surfaces

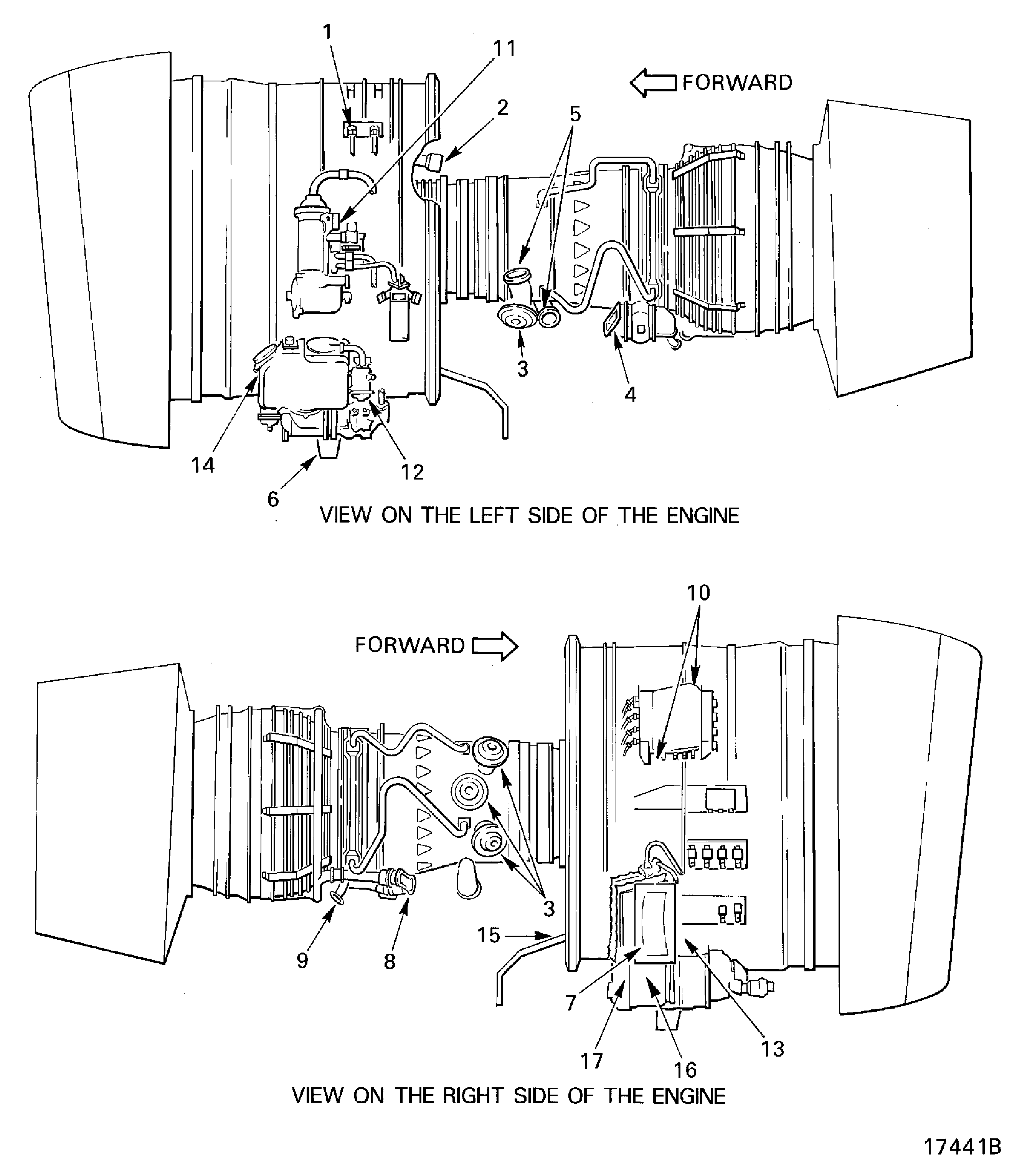

Refer to Figure.

Position 1, IAE 5R18312 Transportation cap 1 off to the fuel return pipe.

Position 2,IAE 5J12142 Protective cover 1 off to the front mount tube.

Position 3,IAE 5R18305 Transportation cover 4 off to the handling off-takes.

Position 4,IAE 5J13353 Protective cover 1 off to the No4 bearing compartment aircooler inlet.

Position 5,IAE 5R18306 Transportation cover 2 off to the cabin off-takes.

Position 6,IAE 1N20443 Protective blank 1 off to the drains mast.

Position 7,IAE 5R18304 Transportation cover 1 off to the ACOC modulating valve.

Position 8,IAE 5J13500 Protective closure 1 off to the ACC duct inlet.

Position 9,IAE 5J13354 Protective cover 1 off to the No4 bearing compartment air cooler outlet.

Position 10,IAE 5P16183 Shipping closure 4 off to the EEC cooling manifold.

Position 11,IAE 5R18310 Transportation plug 1 off to the diverter valve.

Position 12,IAE 5R18310 Transportation plug 1 off to the FMU drain.

Position 13,Cap 1 off to the air modulating valve drain.

Position 14,Cap 1 off to the oil tank overflow.

Position 15,Plug 1 off to the core common drain tube.

WARNING

THE AIRCRAFT HYDRAULIC FLUID AND THE VAPOR ARE DANGEROUS THROUGH ABSORPTION AND INGESTION. THE HYDRAULIC FLUID CAN CAUSE EYE, NOSE AND SKIN IRRITATION. DO NOT BREATHE THE VAPOR.DO NOT GET HYDRAULIC FLUID ON YOUR SKIN OR IN YOU EYES. YOU MUST USE PROTECTIVE GOGGLES AND GLOVES. YOU MUST OBEY THE MAKERS SPECIAL INSTRUCTIONS.CLEAN YOUR EYES IMMEDIATELY WITH CLEAN COLD WATER IF HYDRAULIC FLUID GETS INTO THEM AND GET MEDICAL AID. USE SOAP AND HOT WATER TO IMMEDIATELY CLEAN THE AREA OF SKIN TOUCHED BY THE HYDRAULIC FLUID.

CAUTION

REMOVE HYDRAULIC FLUID IMMEDIATELY WITH A DRY CLOTH AND WASH THE AREA OF CONTAMINATION WITH MILD CLEANER, REFER TO THE SPM TASK 70-11-03-300-503. THE HYDRAULIC FLUID USED IN THIS SYSTEM WILL CAUSE DAMAGE TO A LARGE RANGE OF MATERIALS SUCH AS RUBBER, COPPER, DIFFERENT PLASTICS AND PAINT.Attach applicable blanks to the subsequent positions:

Where blanks are not available cover the opening with CoMat 12-013 PRINTED, WAXED, VCI COATED PAPER, safety with CoMat 02-041 MOISTURE RESISTANT TAPE.

Blank all the disconnected harness connectors and make a cover with CoMat 12-033 AIR BUBBLE SHEET. Then attach the harness to an adjacent structure to prevent damage.

Use CoMat 12-013 PRINTED, WAXED, VCI COATED PAPER to make a cover for the inlet cowl.

Install IAE 1N20400 Protective cover to the inlet cowl.

Attach IAE 1N20400 Protective cover 1 off to the inlet cowl.

Use CoMat 12-013 PRINTED, WAXED, VCI COATED PAPER to make a cover for the rear of the fan case.

Put the coated side of the VPI impregnated paper to the rear of the fan case radial support struts and safety with CoMat 02-041 MOISTURE RESISTANT TAPE.

Install IAE 5J12080 Rear cover to the fan case outlet.

Attach IAE 5J12080 Rear cover 1 off to the fan case outlet.

Use CoMat 12-013 PRINTED, WAXED, VCI COATED PAPER to make a cover for the common nozzle assembly.

Install IAE 1N20008 Protective cover to the common nozzle assembly.

Attach IAE 1N20008 Protective cover 1 off to the common nozzle assembly.

Install IAE 1N20435 Protective blank 1 off to the nose cowl ventilation inlet and IAE 1N20436 Protective blank 1 off to the nose cowl TAI outlet grill.

Install CoMat 12-033 AIR BUBBLE SHEET on all locations and brackets that can possibly make a hole in the VMI bag or storage cover.

NOTE

Blanks from the closure kit that have not been used must be put in the canvas bag and positioned in the storage cover or VMI bag.Position IAE 5F10060 Closure kit 1 off with the engine.

SUBTASK 72-00-00-550-058-001 Blank the Demountable Powerplant Engine

Refer to Figure.

Do Step.

Use applicable blanks from IAE 5F10060 Closure kit 1 off, to blank the integrated drive generator mounting face and hydraulic pump mounting face. Then safety.

Position 16,IAE 5R18318 Transportation plug 1 off to the IDG pipe.

Position 17,IAE 5R18317 Transportation plug 1 off to the IDG pipe.

Attach the applicable blanks.

SUBTASK 72-00-00-550-058-002 Blank the Quick Engine Change Unit (QEC)

NOTE

The procedure to blank the QEC is almost the same as the procedure to blank the demountable power plant engine. Although the QEC does not have the integrated drive generator or the hydraulic pump.Refer to Figure.

Position 1,IAE 5R18312 Transportation cap 1 off to the fuel return pipe.

Position 2,IAE 5J12142 Protective cover 1 off to the front mount tube.

Position 3,IAE 5R18305 Transportation cover 4 off to the handling off-takes.

Position 4,IAE 5J13353 Protective cover 1 off to the No4 bearing compartment air cooler inlet.

Position 5,IAE 5R18306 Transportation cover 2 off to the cabin off-takes.

Position 6, IAE 5F10060 Closure kit 1 off, use hydraulic pump cover.

Position 7,IAE 5R18310 Transportation plug 1 off to the P2 sense EEC.

Position 8, IAE 5F10060 Closure kit 1 off, use intergrated drive generator cover.

Position 9,IAE 5F10351 Shipping cover 1 off to the gearbox breather vent.

Position 10,IAE 5R18304 Transportation cover 1 off to the ACOC modulating valve.

Position 11,IAE 5J13500 Protective closure 1 off to the ACC duct inlet.

Position 12,IAE 5J13354 Protective cover 1 off to the No4 bearing compartment air cooler outlet.

Position 13,IAE 5R18317 Transportation plug 1 off to the IDG pipe.

Position 14,IAE 5R18318 Transportation plug 1 off to the IDG pipe.

Position 15,IAE 5P16183 Shipping closure 4 off to the EEC cooling manifold.

Position 16,IAE 5R18310 Transportation plug 1 off to the diverter valve.

Position 17,IAE 5R18310 Transportation plug 1 off to the FMU drain.

Position 18,Cap 1 off to the air modulating valve drain.

Position 19,Cap 1 off to the oil tank overflow.

Position 20,Plug 1 off to the core common drain tube.

Position 21,IAE 5R18307 Transportation cover 1 off to the anti-icing bleed.

Blank the fuel pump and oil tank with the blanks from theIAE 5F10060 Closure kit 1 off.

WARNING

THE AIRCRAFT HYDRAULIC FLUID AND THE VAPOR ARE DANGEROUS THROUGH ABSORPTION AND INGESTION. THE HYDRAULIC FLUID CAN CAUSE EYE, NOSE AND SKIN IRRITATION. DO NOT BREATHE THE VAPOR.DO NOT GET HYDRAULIC FLUID ON YOUR SKIN OR IN YOUR EYES. YOU MUST USE PROTECTIVE GOGGLES AND GLOVES. YOU MUST OBEY THE MAKERS SPECIAL INSTRUCTIONS.CLEAN YOUR EYES IMMEDIATELY WITH CLEAN COLD WATER IF HYDRAULIC FLUID GETS INTO THEM AND GET MEDICAL AID. USE SOAP AND HOT WATER TO IMMEDIATELY CLEAN THE AREA OF SKIN TOUCHED BY THE HYDRAULIC FLUID.

CAUTION

REMOVE HYDRAULIC FLUID IMMEDIATELY WITH A DRY CLOTH AND WASH THE AREA OF CONTAMINATION WITH MILD CLEANER, REFER TO THE SPM TASK 70-11-03-300-503. THE HYDRAULIC FLUID USED IN THIS SYSTEM WILL CAUSE DAMAGE TO A LARGE RANGE OF MATERIAL SUCH AS RUBBER, COPPER, DIFFERENT PLASTICS AND PAINT.Attach applicable blanks to the subsequent positions:

Where blanks are not available cover the opening with CoMat 12-013 PRINTED, WAXED, VCI COATED PAPER. Safety with CoMat 02-041 MOISTURE RESISTANT TAPE.

Blank all the disconnected harness connectors and make a cover with CoMat 12-033 AIR BUBBLE SHEET. Then attach the harness to an adjacent structure to prevent damage.

Apply a layer of CoMat 12-033 AIR BUBBLE SHEET to the P2/T2 probe.

Put the P2/T2 probe in a box made of CoMat 12-034 FIBREBOARD BOX or CoMat 12-035 FIBREBOARD BOX.

Attach the box to a fan case strut with CoMat 02-041 MOISTURE RESISTANT TAPE.

Blank the P2/T2 probe.

Apply a layer of CoMat 12-033 AIR BUBBLE SHEET to the starter valve .

Put the starter valve in a box made of CoMat 12-034 FIBREBOARD BOX or CoMat 12-035 FIBREBOARD BOX. Seal the box with moisture resistant tape.

Remove the pneumatic starter valve.

Use CoMat 12-013 PRINTED, WAXED, VCI COATED PAPER to make a cover for the engine inlet.

Put the coated side of the VPI impregnated paper to the compressor fan blades and hold with CoMat 02-041 MOISTURE RESISTANT TAPE.

Install the IAE 5J12083 Front cover to the engine inlet.

Attach IAE 5J12083 Front cover 1 off to the engine inlet.

Use CoMat 12-013 PRINTED, WAXED, VCI COATED PAPER to make a cover for the fan case outlet.

Put the coated side of the VPI impregnated paper to the rear of the fan case struts and safety with CoMat 02-041 MOISTURE RESISTANT TAPE.

Install the IAE 5J12080 Rear cover to the fan case outlet.

Attach IAE 5J12080 Rear cover 1 off to the fan case outlet.

Use CoMat 12-013 PRINTED, WAXED, VCI COATED PAPER to make a cover for the turbine exhaust case.

Install the IAE 1F10077 Protective cover to the turbine exhaust case.

Attach IAE 1F10077 Protective cover 1 off to the turbine exhaust case.

Install CoMat 12-033 AIR BUBBLE SHEET on all locations and brackets that can possibly make a hole in the VMI bag or storage cover.

SUBTASK 72-00-00-550-058-003 Blank Engine Build-Up Unit (EBU)

Refer to Figure.

Do Step.

Blank the pnuematic starter mounting face with applicable blank from the IAE 5F10060 Closure kit 1 off.

SUBTASK 72-00-00-550-058-004 Blank the Spareable Engine

NOTE

The procedure to blank the spareable engine is almost the same as the procedure to blank the engine build-up unit (EBU).

Figure: Blank demountable power plant and quick engine change unit

Blank demountable power plant and quick engine change unit

Figure: Blank engine build up unit and spareable engine

Blank engine build up unit and spareable engine