Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-00-500-001 Engine General - General Data For Engine Storage, Storage-001

General

This TASK gives details of the necessary procedures for preservation and storage of the engine or QEC unit that is to be stored or transported.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

CAUTION

CAUTION

Procedure

Refer to TASK 72-00-00-500-002 (STORAGE-002).

NOTE

The use of VMI bags affords maximum protection to the engine/QEC unit and must be used wherever possible, regardless of the storage environment and time period.NOTE

Desiccant must be used in accordance with TASK 72-00-00-500-005 (STORAGE-005) SUBTASK 72-00-00-550-053 , and the integrity of the engine covers must be checked. Refer to TASK 72-00-00-500-005 (STORAGE-005), SUBTASK 72-00-00-210-054.Refer to TASK 72-00-00-500-004 (STORAGE-004), SUBTASK 72-00-00-620-058, Inhibit the Engine Fuel System in the Transportation Stand, will not fully inhibit the fuel system. Where possible the engine is to be inhibited on wing or in a test cell. Refer to TASK 72-00-00-500-004 (STORAGE-004), SUBTASK 72-00-00-620-060.

Refer to TASK 72-00-00-500-003 (STORAGE-003), SUBTASK 72-00-00-620-056, Preservation of Mainline Bearings can only be done with the engine or QEC unit installed in a test cell or on wing. This procedure is only applicable to engines that are stored directly after a period of service operation. It is not applicable to new engines or overhauled engines.

Refer to the V2500 Illustrated Tool and Equipment (ITEM) Pub.ref. ITE-V2500-1IA, for the illustrations of the special tools given in this procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS unless other lubricants are referred to in the procedure.

Make sure that all flange faces and tool faces that touch are very clean.

For standard torque data and procedures, refer to SPM TASK 70-41-01-400-501.

Prepare the Engine for Storage

After 12 months of storage, open the VMI bag and replace the desiccant as per TASK 72-00-00-500-005 (STORAGE-005).

Storage for not more than 24 months:

The preservation counter can be reset to zero if a successful engine test is completed with subsequent preservation at any time until the 24 months storage limit.

Make sure the storage procedure mentioned in Step was completed.

Remove the engine from storage after 24 months as per TASK 72-00-00-500-007 (STORAGE-007).

NOTE

Do not do the procedures for engine fuel inhibition and main line bearing preservation.Do a visual inspection of the engine for signs of external corrosion. If corrosion is found, contact IAE for more recommendations.

Replace the desiccant for the anticipated further storage time as per TASK 72-00-00-500-005 (STORAGE-005), SUBTASK 72-00-00-550-053. The inspection of the humidity indicators must be started with the initial frequency again as per TASK 72-00-00-500-005 (STORAGE-005).

Do the preservation procedure again.

NOTE

Do not do the procedures for engine fuel inhibition and main line bearing preservation.The engine must be stored in accordance to Step.

Collect and analyze oil sample from the accessory gearbox prior to any oil servicing. Confirm water content is <1000ppm for continued service; if greater than 1000ppm, further action may be required. Contact IAE Tech Services.

NOTE

If the Karl Fischer test is not successful contact IAE Tech Services.

Before performing engine testing, do a Karl Fischer as per ASTMD-6304-04ae1.

Following the successful Karl Fischer test, do a successful engine performance test.

When the engine is sent back to service after a storage period of more than 24 months, do an inspection of the master MCD at regular intervals as per TASK 72-00-00-500-007 (STORAGE-007). Refer to TASK 72-00-00-200-008 (INSPECTION-008) for MCD check.

If the engine has been stored for more than 24 months but less than 36 months, the preservation can be reset to zero if the following requirements are met:

Storage for more than 24 months and not more than 36 months:

If the engine was stored for not more than 24 months in accordance with Step, the storage time can be extended for not more than 36 months without an engine test and with the steps that follow:

NOTE

If the engine is sent back to service after a storage period of more than 24 months, do an inspection of the master MCD again at regular intervals as per TASK 72-00-00-500-007 (STORAGE-007). Refer to TASK 72-00-00-200-008 (INSPECTION-008) for MCD check.Reject the engine for disassembly and detailed inspection of the No. 1, No. 2, No. 3, No. 4 and No. 5 bearing compartments and level 1 maintenance inspection of all modules as a minimum.

Storage for more than 36 months:

Preserve the Engine

Check the humidity indicators regularly in accordance with TASK 72-00-00-500-005 (STORAGE-005), SUBTASK 72-00-00-230-052.

Check the integrity of the engine covers regularly at the times of the humidity indicator checks, refer to TASK 72-00-00-500-005 (STORAGE-005), SUBTASK 72-00-00-210-054.

Regular Checks During Storage

If an accessory is removed from a stored engine, the adjacent pipe connections must be blanked using a suitable cover to prevent the ingress of dirt and moisture and prevent drainage of further inhibiting fluid.

Replacement of the accessory before the end of the storage period is not required.

After closure of the VMI bag or engine cover for any access to the engine, the inspection of the humidity indicators must be started with the initial frequency again, refer to TASK 72-00-00-500-005 (STORAGE-005), SUBTASK 72-00-00-210-054.

Accessory Removal During Storage

Figure: Additional Storage Requirements

Additional Storage Requirements

Figure: Off-wing Inside Preservation Procedure

Off-wing Inside Preservation Procedure

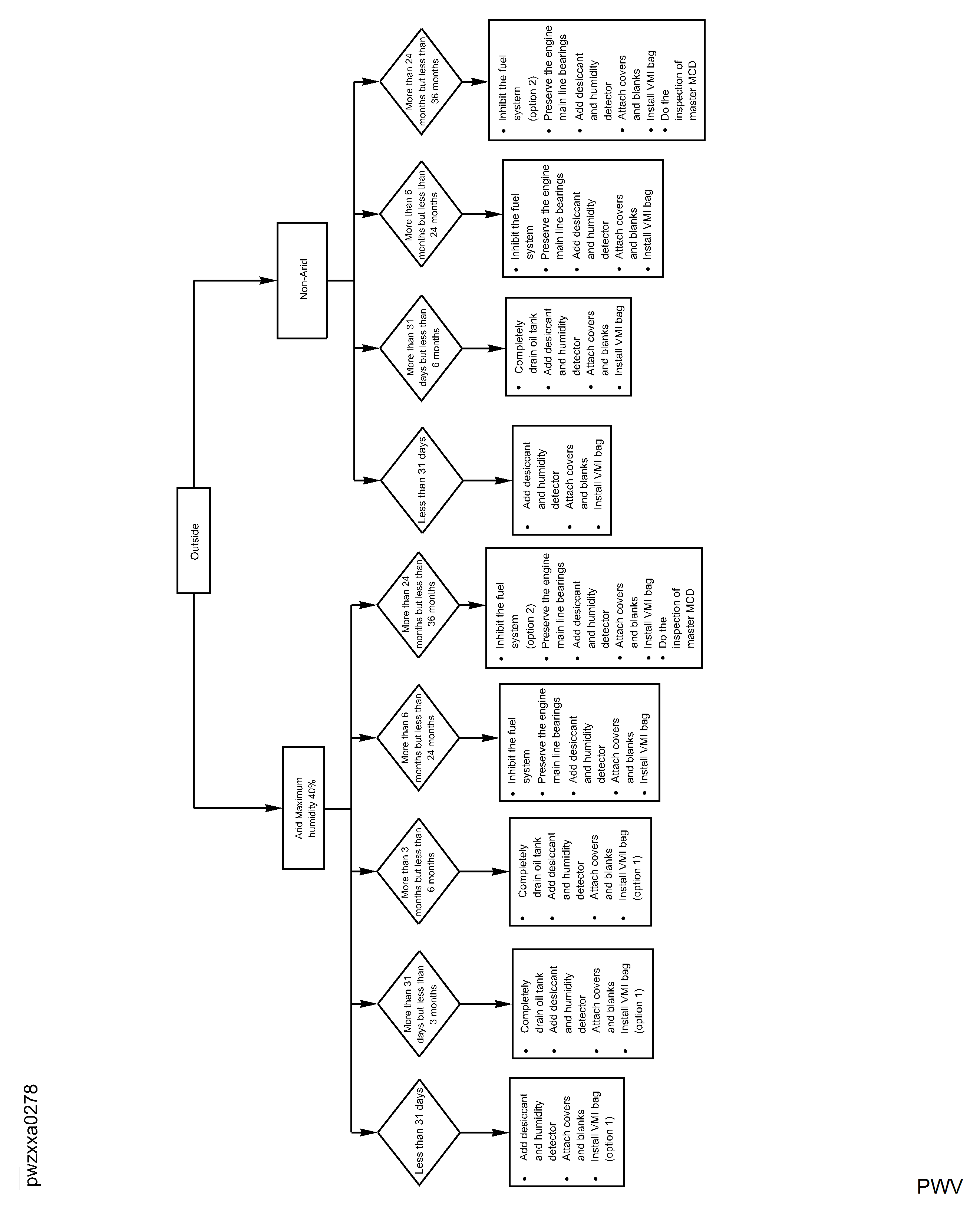

Figure: Off-wing Outside Preservation Procedure

Off-wing Outside Preservation Procedure

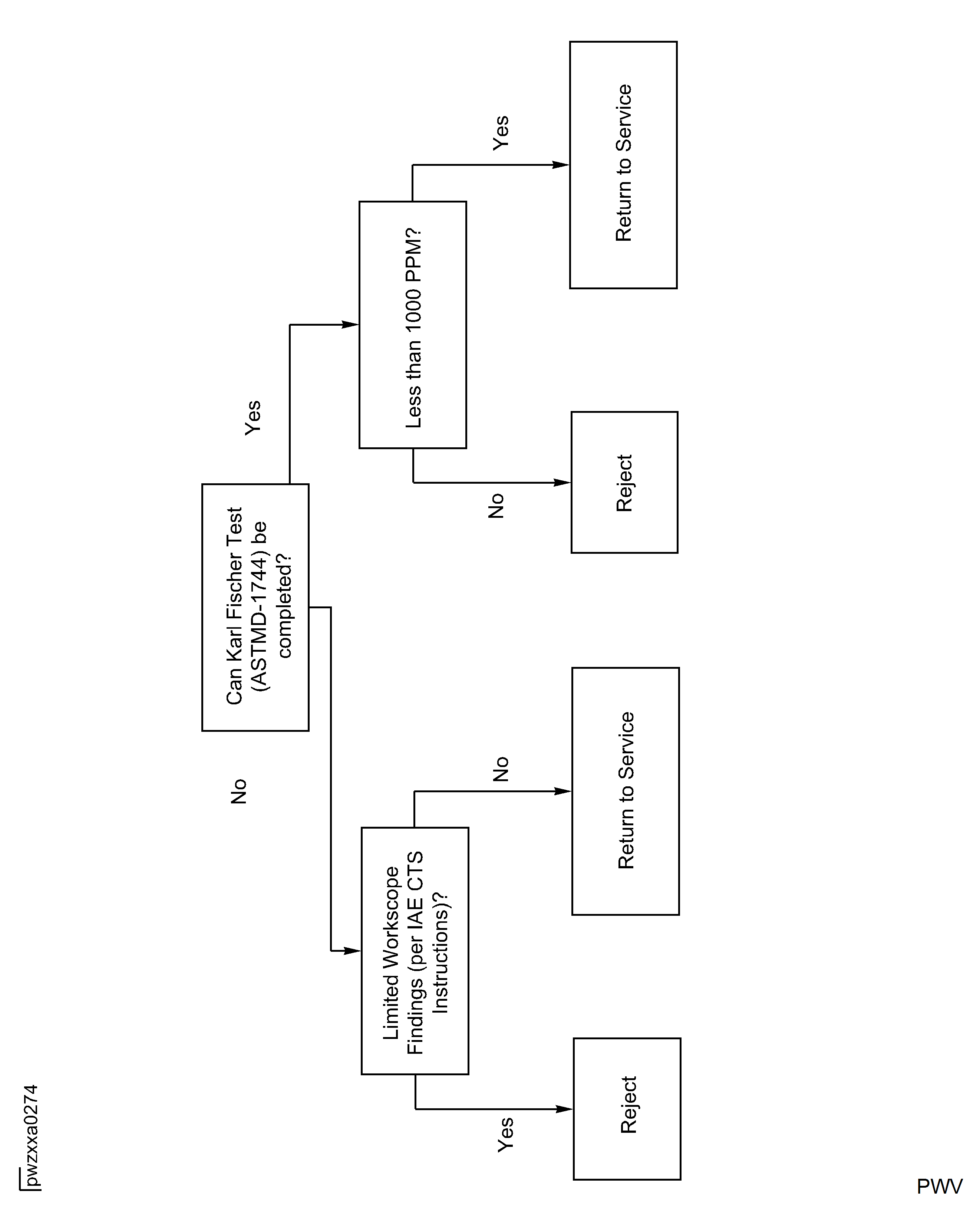

Figure: Nonconforming Preservation within the First 31 Days of Storage

Nonconforming Preservation within the First 31 Days of Storage

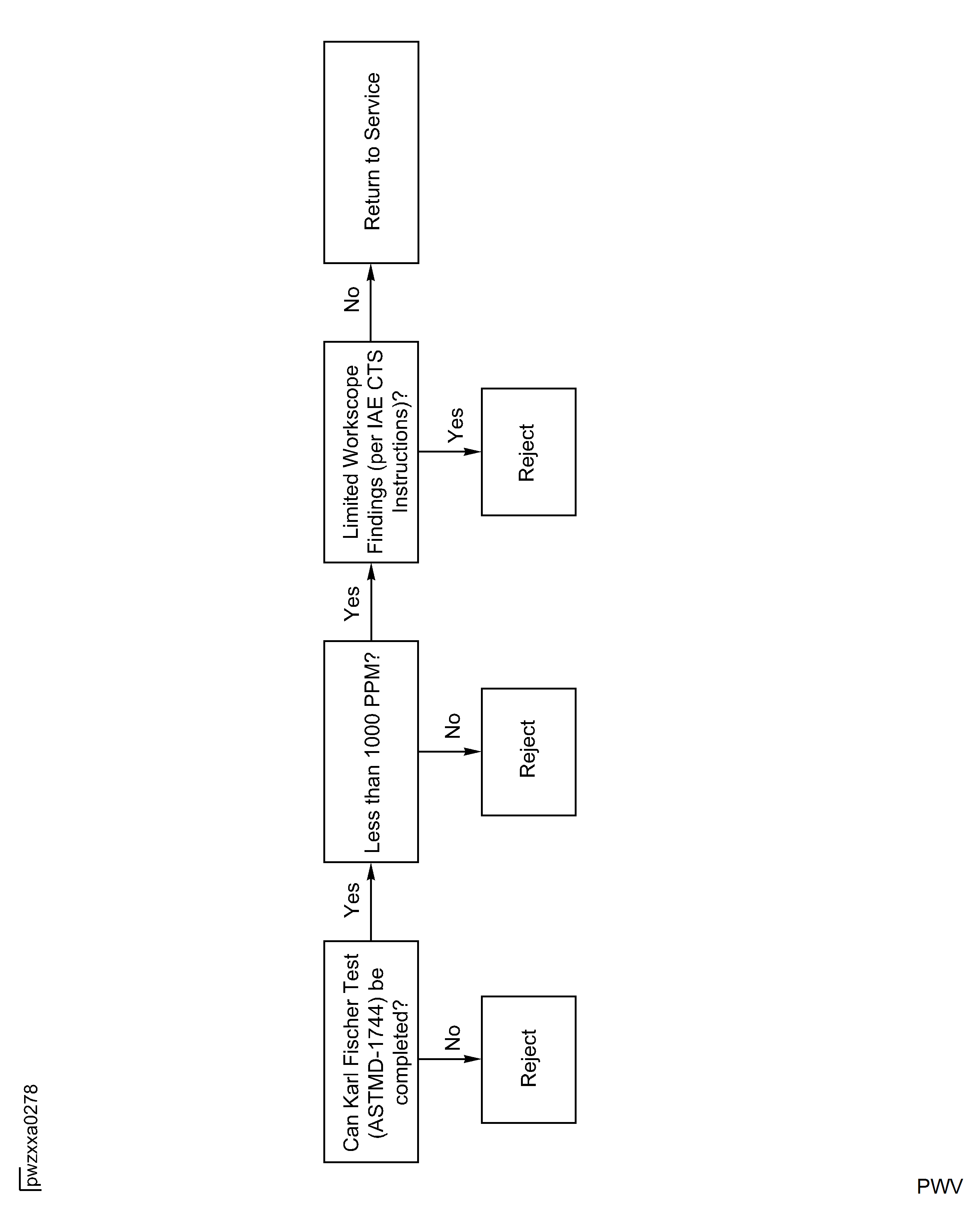

Figure: Nonconforming Preservation Greater Than the First 31 Days of Storage

Nonconforming Preservation Greater Than the First 31 Days of Storage