Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-00-500-007 Engine General - Remove The Engine From Storage, Storage-007

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501 and TASK 70-41-01-400-501.

Special torque data is identified with the symbol * after the torque value.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Safety Requirements

NONEProcedure

Refer to Figure.

WARNING

THE AIRCRAFT HYDRAULIC FLUID AND THE VAPOR ARE DANGEROUS THROUGH ABSORPTION AND INGESTION. THE HYDRAULIC FLUID CAN CAUSE EYE, NOSE AND SKIN IRRITATION. DO NOT BREATHE THE VAPOR.DO NOT GET HYDRAULIC FLUID ON YOUR SKIN OR IN YOUR EYES. YOU MUST USE PROTECTIVE GOGGLES AND GLOVES. YOU MUST OBEY THE MAKERS SPECIAL SAFETY INSTRUCTIONS.CLEAN YOUR EYES IMMEDIATELY WITH CLEAN COLD WATER IF HYDRAULIC FLUID GETS INTO THEM AND GET MEDICAL AID. USE SOAP AND HOT WATER TO IMMEDIATELY CLEAN THE AREA OF SKIN TOUCHED BY THE HYDRAULIC FLUID.

CAUTION

REMOVE HYDRAULIC FLUID IMMEDIATELY WITH A DRY CLOTH AND WASH THE AREA OF CONTAMINATION WITH MILD CLEANER, REFER TO THE SPM TASK 70-11-03-300-503. THE HYDRAULIC FLUID USED IN THIS SYSTEM WILL CAUSE DAMAGE TO A LARGE RANGE OF MATERIALS SUCH AS RUBBER, COPPER, DIFFERENT PLASTICS AND PAINT.Remove air bubble sheet from all locations on which it has been installed.

Install the pneumatic starter valve. Refer to TASK 72-00-32-450-008.

Connect the electrical connector 400KS-A to the pneumatic starter vale. Refer to TASK 72-00-32-450-008.

Install the pneumatic starter valve.

Remove applicable blanks or the VPI impregnated paper and the moisture resistant tape from positions 1 to 10. Refer to Figure.

SUBTASK 72-00-00-540-051-001 Remove the Blanks from the Engine Build-Up Unit

Refer to Figure.

WARNING

THE AIRCRAFT HYDRAULIC FLUID AND THE VAPOR ARE DANGEROUS THROUGH ABSORPTION AND INGESTION. THE HYDRAULIC FLUID CAN CAUSE EYE, NOSE AND SKIN IRRITATION. DO NOT BREATHE THE VAPOR.DO NOT GET HYDRAULIC FLUID ON YOUR SKIN OR IN YOUR EYES. YOU MUST USE PROTECTIVE GOGGLES AND GLOVES. YOU MUST OBEY THE MAKERS SPECIAL SAFETY INSTRUCTIONS.CLEAN YOUR EYES IMMEDIATELY WITH CLEAN COLD WATER IF HYDRAULIC FLUID GETS INTO THEM AND GET MEDICAL AID. USE SOAP AND HOT WATER TO IMMEDIATELY CLEAN THE AREA OF SKIN TOUCHED BY THE HYDRAULIC FLUID.

CAUTION

REMOVE HYDRAULIC FLUID IMMEDIATELY WITH A DRY CLOTH AND WASH THE AREA OF CONTAMINATION WITH MILD CLEANER, REFER TO THE SPM TASK 70-11-03-300-503. THE HYDRAULIC FLUID USED IN THIS SYSTEM WILL CAUSE DAMAGE TO A LARGE RANGE OF MATERIALS SUCH AS RUBBER, COPPER, DIFFERENT PLASTICS AND PAINT.Remove air bubble sheet from all locations on which it has been installed.

Remove the applicable blanks or VPI impregnated paper and the moisture resistant tape from positions 1 to 6. Refer to Figure.

SUBTASK 72-00-00-540-051-003 Remove the Blanks from the Demountable Power Plant Engine

Refer to Figure.

Remove the applicable blanks from positions 7 and 8. Refer to Figure.

Do Step.

SUBTASK 72-00-00-540-051-004 Remove the Blanks from the Quick Engine Change Unit (QECU)

NOTE

The procedure to remove the blanks from the quick engine change unit (QECU) is almost the same as the procedure to remove the blanks from the demountable power plant engine. Although the QECU does not have the VSCF generator or the hydraulic pump.Fill the oil tank. Refer to TASK 71-00-00-600-002 (SERVICING-002).

SUBTASK 72-00-00-640-051 Fill the Oil Tank

Refer to Figure.

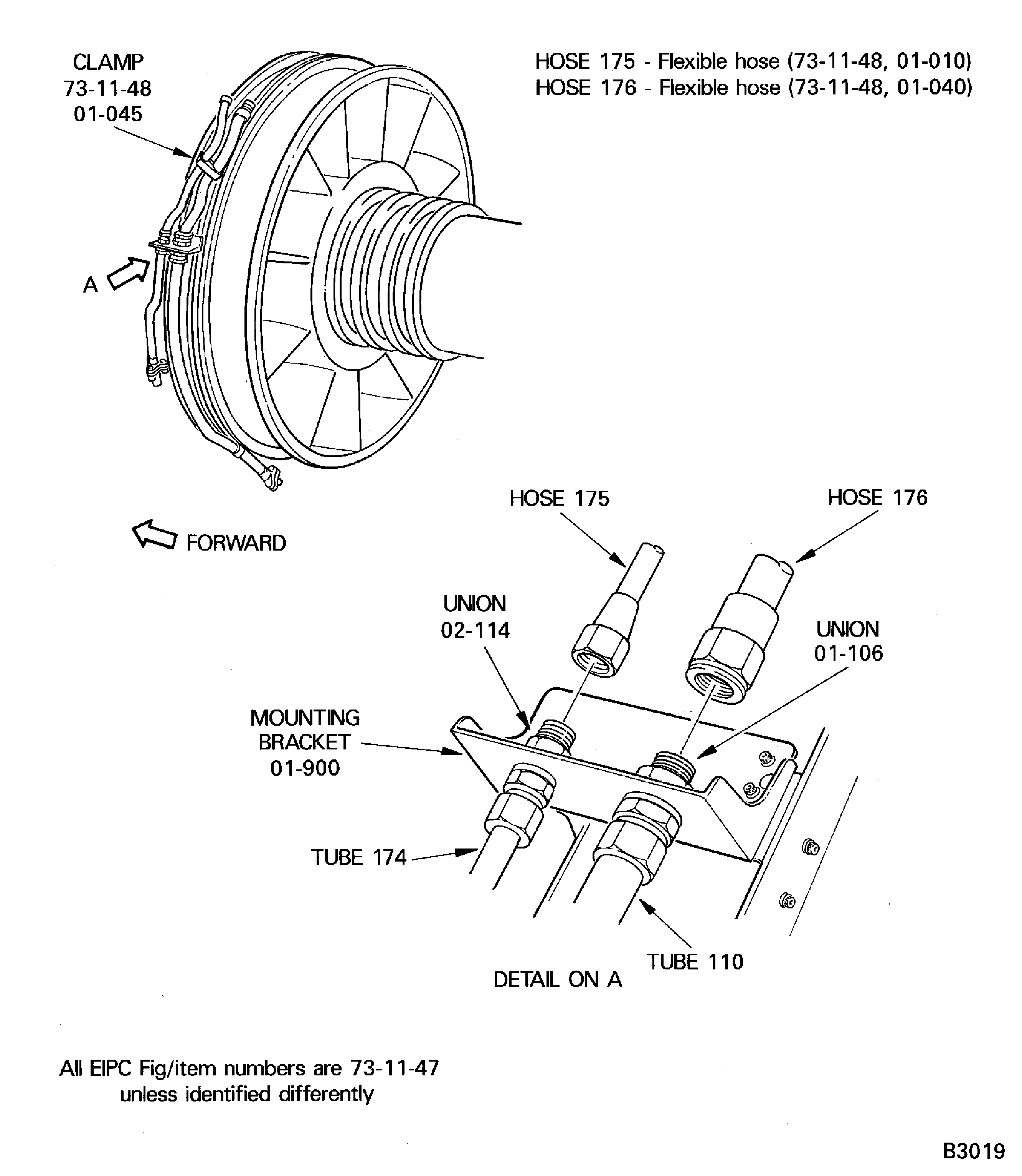

Remove hose 175, hose 176 and attached clamp FUEL SYSTEM TUBES (FLEXIBLE)-POWER PLANT (73-11-48, 01-045) from the fan case struts.

Lightly lubricate the threads of the unions Main Fuel Supply Fuel Tubes (73-11-47, 01-106 and FUEL SYSTEM TUBES (RIGID)-POWER PLANT 02-114) and the threads of hoses 175 and 176 with CoMat 10-077 APPROVED ENGINE OILS.

Connect the hose 175 to the union FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-114) and torque to 470 to 510* lbf.in (53 to 58 Nm).

Connect the hose 176 to the union Main Fuel Supply Fuel Tubes (73-11-47, 01-106) and torque to 1520 to 1680* lbf.in (172 to 190 Nm).

.

SUBTASK 72-00-00-450-060 Connect Hoses 175 and 176

Figure: Remove the blanks from the engine build-up unit and the spareable engine

Remove the blanks from the engine build-up unit and the spareable engine

Figure: Remove the blanks from the demountable power plant and the quick engine change unit

Remove the blanks from the demountable power plant and the quick engine change unit

Figure: Connect hoses 175 and 176

Connect hoses 175 and 176