Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-00-500-004 Engine General - Inhibit The Fuel System, Storage-004

General

Step Inhibit the Engine Fuel System in the Transportation Stand, will not fully inhibit the fuel system. Where possible the engine is to be inhibited on wing or on the test bed.

If the engine is to be inhibited in the test bed refer to Step.

Refer to TASK 72-00-00-500-001 (STORAGE-001, CONFIG-001) General Data for Engine Storage.

To identify the consumable materials, refer to the Consumable Materials Index.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1R18685 Inhibiting rig adapter | 0AM53 | IAE 1R18685 | 1 | |

| IAE 1R18757 Inhibiting rig | 0AM53 | IAE 1R18757 | 1 | |

| IAE 2F10057 Rotator Kit | 0AM53 | IAE 2F10057 | 1 | |

| IAE 2F10066 Rotator Kit | 0AM53 | IAE 2F10066 | 1 | |

| IAE 5R18311 Transportation cap | 0AM53 | IAE 5R18311 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-041 MOISTURE RESISTANT TAPE | 80769 | CoMat 02-041 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 | ||

| CoMat 10-103 MINERAL OIL | LOCAL | CoMat 10-103 | ||

| CoMat 10-103A MINERAL OIL | LOCAL | CoMat 10-103A | ||

| CoMat 10-103B MINERAL OIL | 1PWD8 | CoMat 10-103B | ||

| CoMat 12-033 AIR BUBBLE SHEET | U1297 | CoMat 12-033 |

Safety Requirements

NONEProcedure

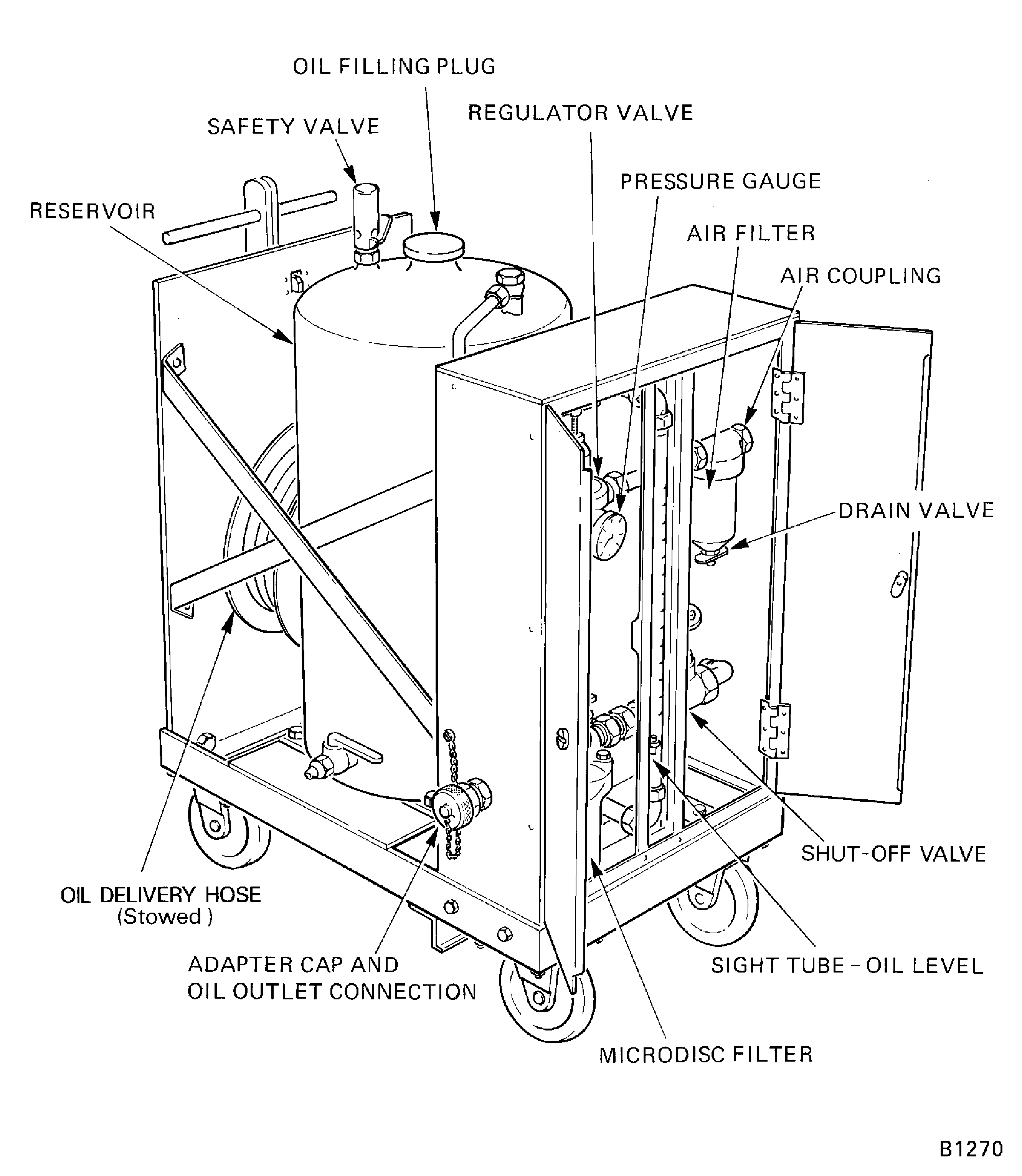

Refer to Figure.

Fill the reservoir with CoMat 10-103 MINERAL OIL or CoMat 10-103A MINERAL OIL or CoMat 10-103B MINERAL OIL until a maximum of 8 gal (36.4l) is shown in the sight tube.

Fill up the IAE 1R18757 Inhibiting rig 1 off reservoir.

SUBTASK 72-00-00-620-051 Prepare the Inhibiting Rig

Refer to Figure.

If the engine is installed with hose 175 FUEL SYSTEM TUBES (FLEXIBLE)-POWER PLANT (73-11-48, 01-010) and hose 176

FUEL SYSTEM TUBES (FLEXIBLE)-POWER PLANT (73-11-48, 01-040) do steps A and B.

If the engine is not installed with hose 175 FUEL SYSTEM TUBES (FLEXIBLE)-POWER PLANT (73-11-48, 01-010) and hose 176

FUEL SYSTEM TUBES (FLEXIBLE)-POWER PLANT (73-11-48, 01-040) do step B.

Cover the two hoses with CoMat 12-033 AIR BUBBLE SHEET.

Attach the two hoses to the fan case struts with CoMat 02-041 MOISTURE RESISTANT TAPE.

CAUTION

UNWANTED MATERIAL MUST NOT GO INTO THE FUEL SYSTEM.NOTE

Engine installed with hoses 175 and 176.

Attach IAE IAE 1R18685 Inhibiting rig adapter 1 off to the main fuel inlet pipe union.

Engine not installed with hoses 175 and 176.

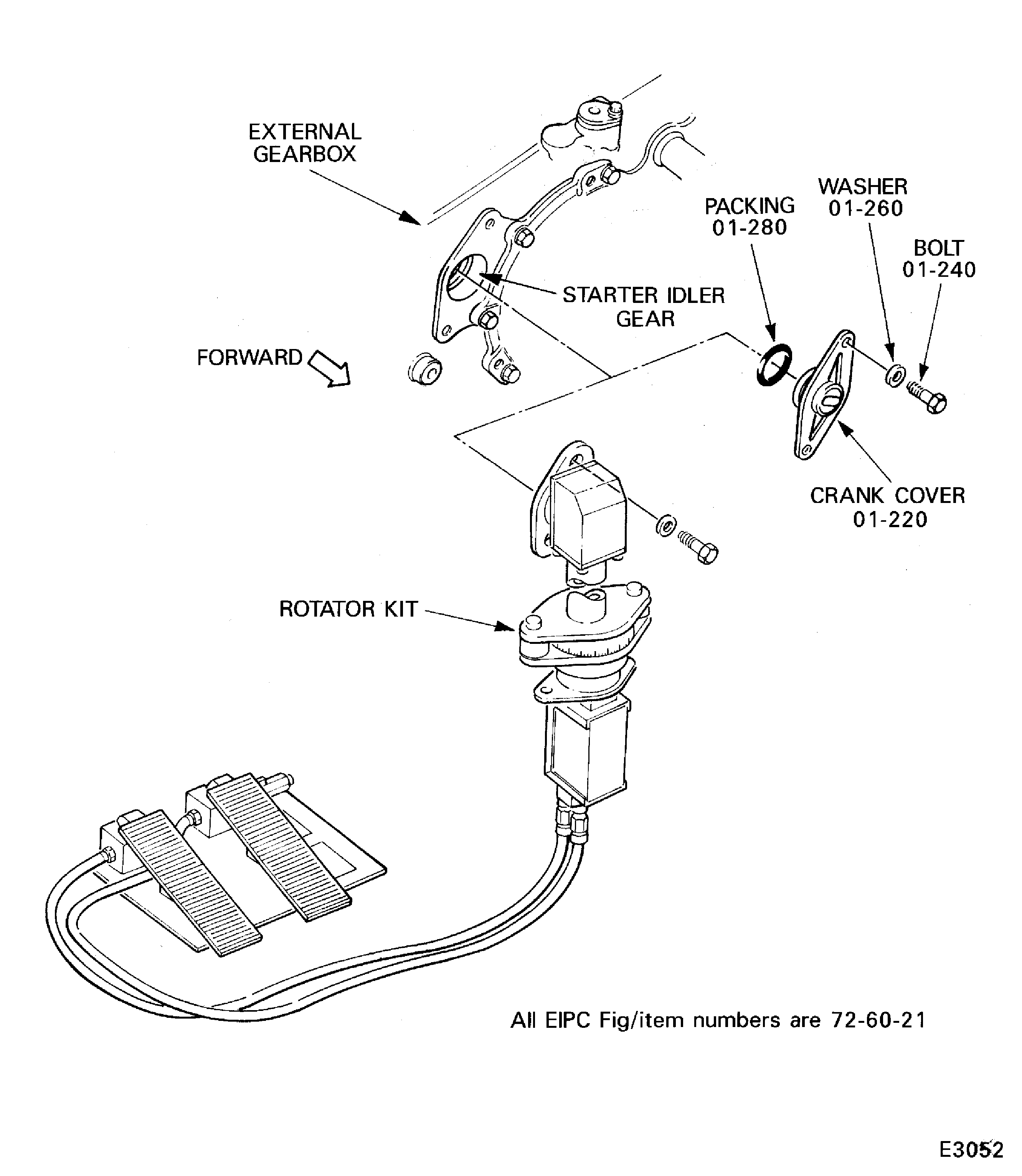

As an alternative the engine can be turned by the use of standard hand tools.

The crank cover is on the front face of the external gearbox between the dedicated alternator and the pneumatic starter.

NOTE

Remove the crank cover ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-220) from the external gearbox.

Install the two washers ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-260) and the two nuts ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-240). Tighten the two nuts.

Remove the four bolts that attach tube 102 Control Fuel Tubes (73-11-49, 05-100) to the HP fuel pump. Pull tube 102 to allow clearance between the tube and the HP fuel pump.

Install the IAE 2F10057 Rotator Kit or IAE 2F10066 Rotator Kit 1 off.

NOTE

If the engine cannot be turned, step D must not be done.Install the rotator kit, Figure.

SUBTASK 72-00-00-620-057 Prepare the Engine for Inhibiting in the Transportation Stand

Attach IAE IAE 5R18311 Transportation cap 1 off to the main fuel inlet and tighten to safety.

Disconnect the inhibiting rig.

Lightly lubricate a new ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-280) packing 1 off with CoMat 10-077 APPROVED ENGINE OILS and install it on the crank cover ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-220).

Attach the crank cover on the external gearbox with the two washers ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-260) and the two bolts ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-240). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

Remove the rotator kit from the external gearbox.

SUBTASK 72-00-00-620-059 Disconnect the Inhibiting Rig and Rotator Kit

Connect the main fuel inlet line to a supply of CoMat 10-103 MINERAL OIL or CoMat 10-103A MINERAL OIL or CoMat 10-103B MINERAL OIL oil at an inlet pressure of 5 to 50 PSIG (34.5 to 344.7 KPA) and a minimum temperature of 60 deg.F. (15.6 deg.C.).

Attach the IAE IAE 5R18311 Transportation cap 1 off to the main fuel inlet and tighten to safety.

Remove the engine from the test bed. Refer to TASK 71-00-00-700-021.

SUBTASK 72-00-00-620-060 Inhibit the Engine Fuel System in the Test Bed

Figure: Inhibiting rig

Inhibiting rig

Figure: Install the rotator kit

Install the rotator kit

Figure: Connect hoses 175 and 176

Connect hoses 175 and 176