Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-32-200-010 LPC/Intermediate Case Module - Examine The Fan Frame Assembly (Level 2 Inspection Limits), Inspection-010

General

This TASK gives the procedure for the inspection of the fan frame assembly below major soft time and scheduled for a level 2 inspection, as given in the Maintenance Management Program.

Where applicable, these inspections are to be done in conjunction with those given in the interface inspections. Refer to TASK 72-00-32-220-003-A00.

The module will be sufficiently disassembled (TASK 72-32-00-030-015) for the components to be examined as specified in accordance with this procedure.

The policy necessary for the inspection is given in the SPM TASK 70-20-00-200-501.

Clean the fan frame assembly. Degrease the fan frame assembly, make sure that all dirt and debris were removed before doing the inspection. Refer to the SPM TASK 70-11-03-300-503.

NOTE

Preliminary Requirements

Pre-Conditions

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure.

More than in Step

Galled.

More than in Step

Nicked.

Other than the torque limits as given in the SPM TASK 70-42-01-400-501

Locking torque of the wire thread inserts.

Other than the torque limits as given in the SPM TASK 70-42-01-400-501

Locking torque of the self locking nuts.

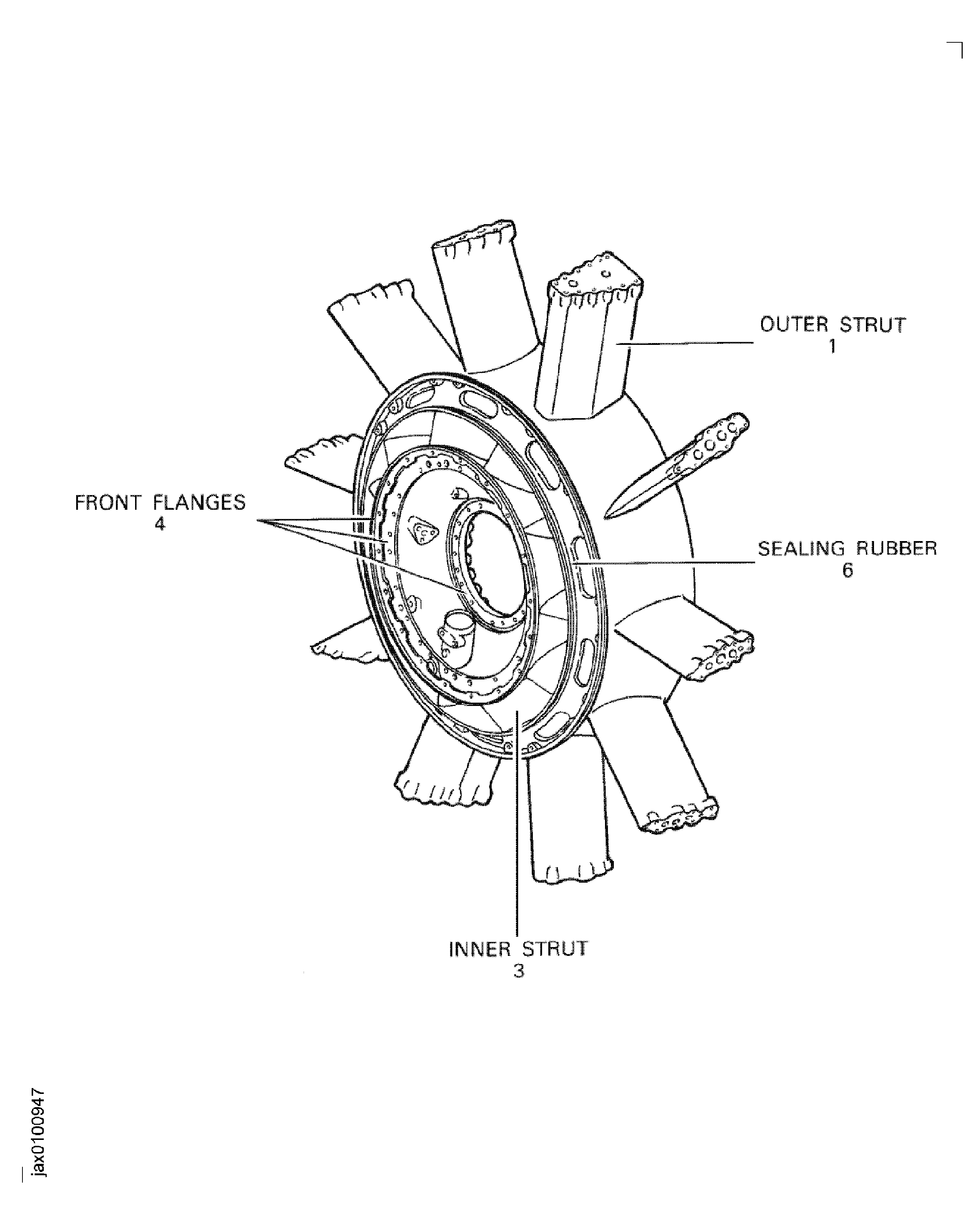

Examine the front flanges at Location 4.

SUBTASK 72-00-32-220-154 Examine the Fan Frame Assembly Front Flanges

Refer to Figure.

SUBTASK 72-00-32-220-155 Examine the Fan Frame Assembly Sealing Rubber

Refer to Figure.

More than in Step

Nicked.

Other than the torque limits as given in the SPM TASK 70-42-01-400-501

Locking torque of the wire thread inserts.

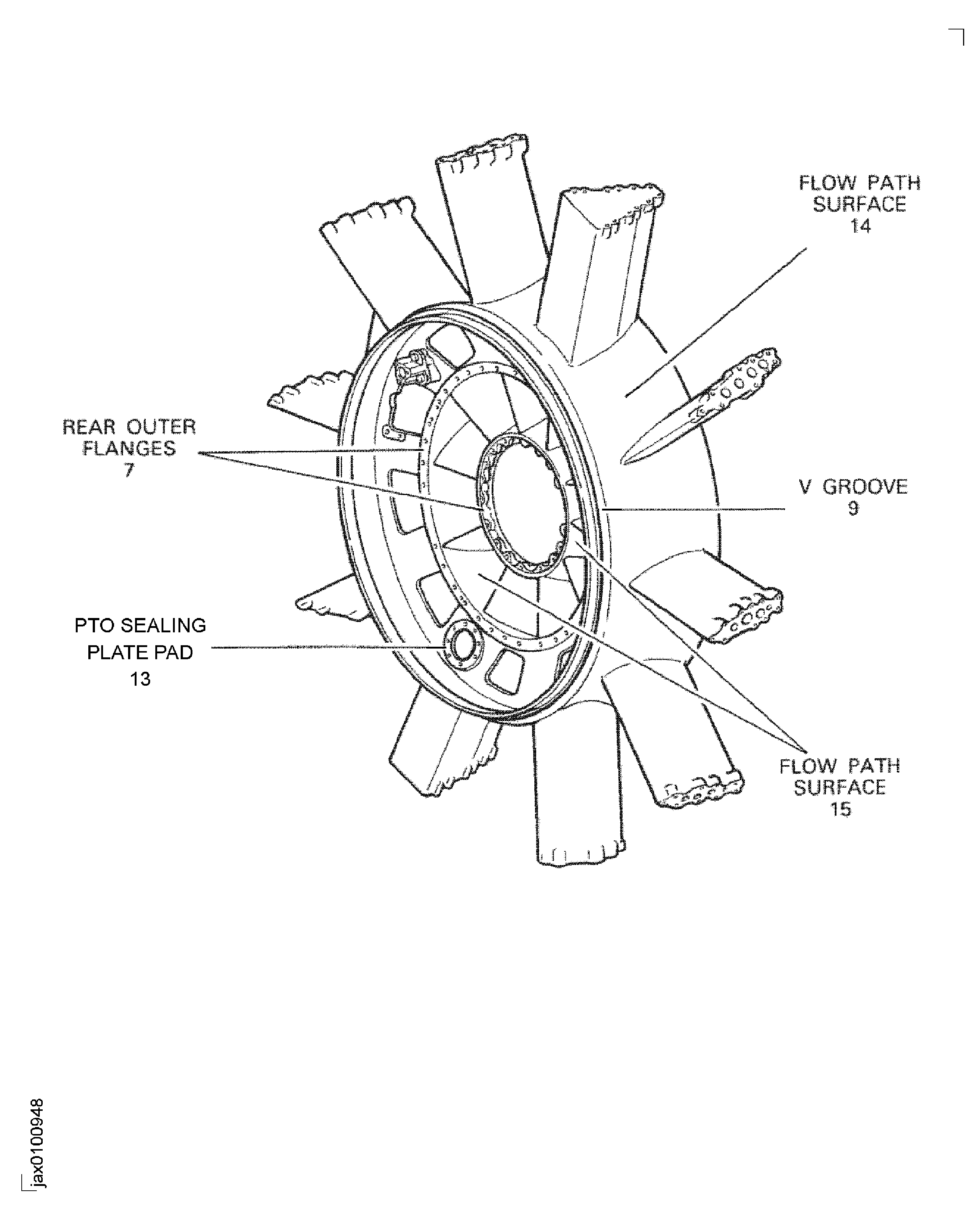

Examine the rear flanges at Location 7.

SUBTASK 72-00-32-220-156 Examine the Fan Frame Assembly Rear Flange

Refer to Figure.

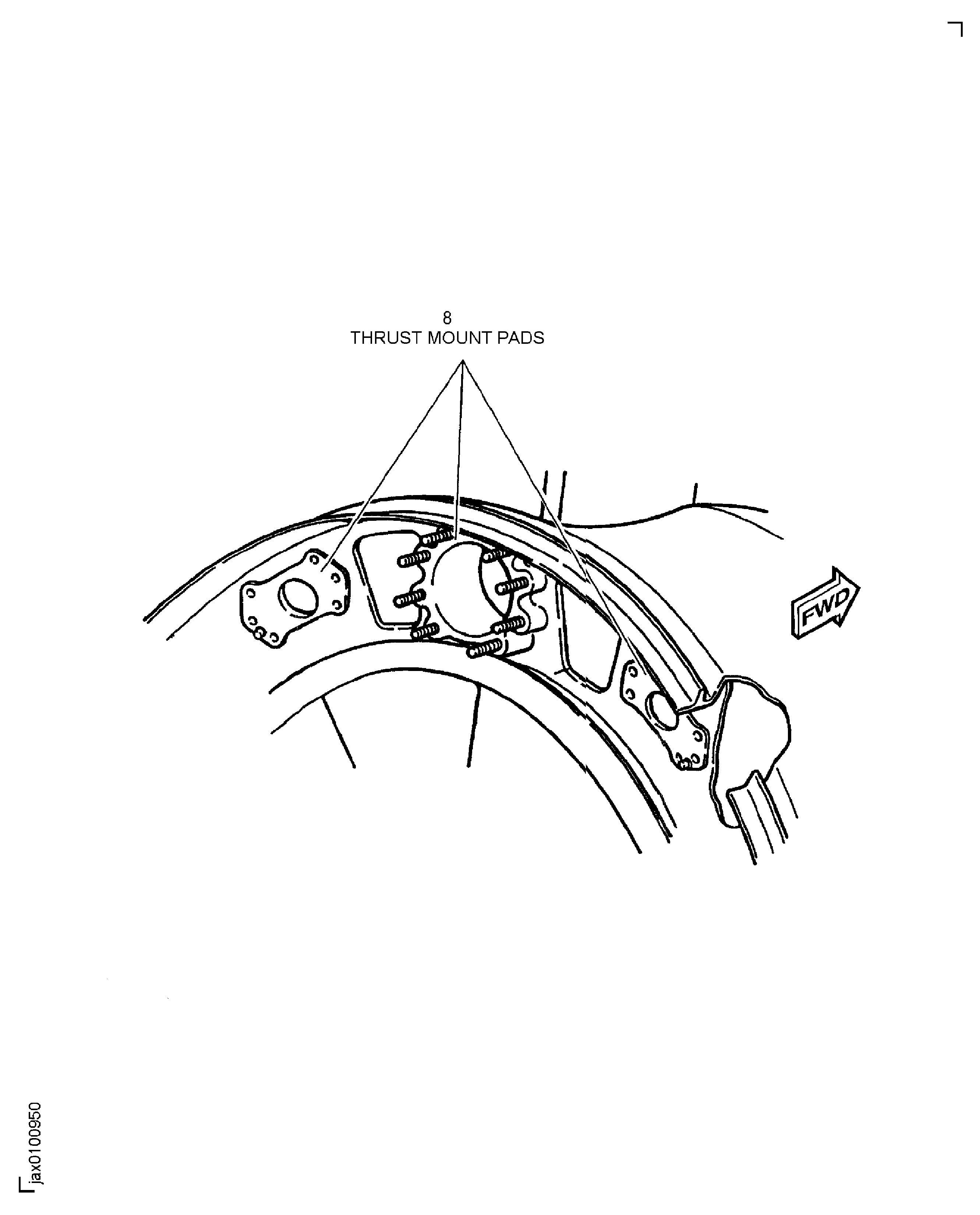

SUBTASK 72-00-32-220-157 Examine the Fan Frame Assembly Thrust Mount Pads

Refer to Figure.

SUBTASK 72-00-32-220-158 Examine the Fan Frame Assembly V Groove

Refer to Figure.

Other than the torque limits as given in SPM TASK 70-42-01-400-501

Locking torque of the damaged wire thread inserts.

Examine the PTO sealing plate pad at Location 13.

SUBTASK 72-00-32-220-159 Examine the Fan Frame Assembly PTO Sealing Plate Pads

Refer to Figure.

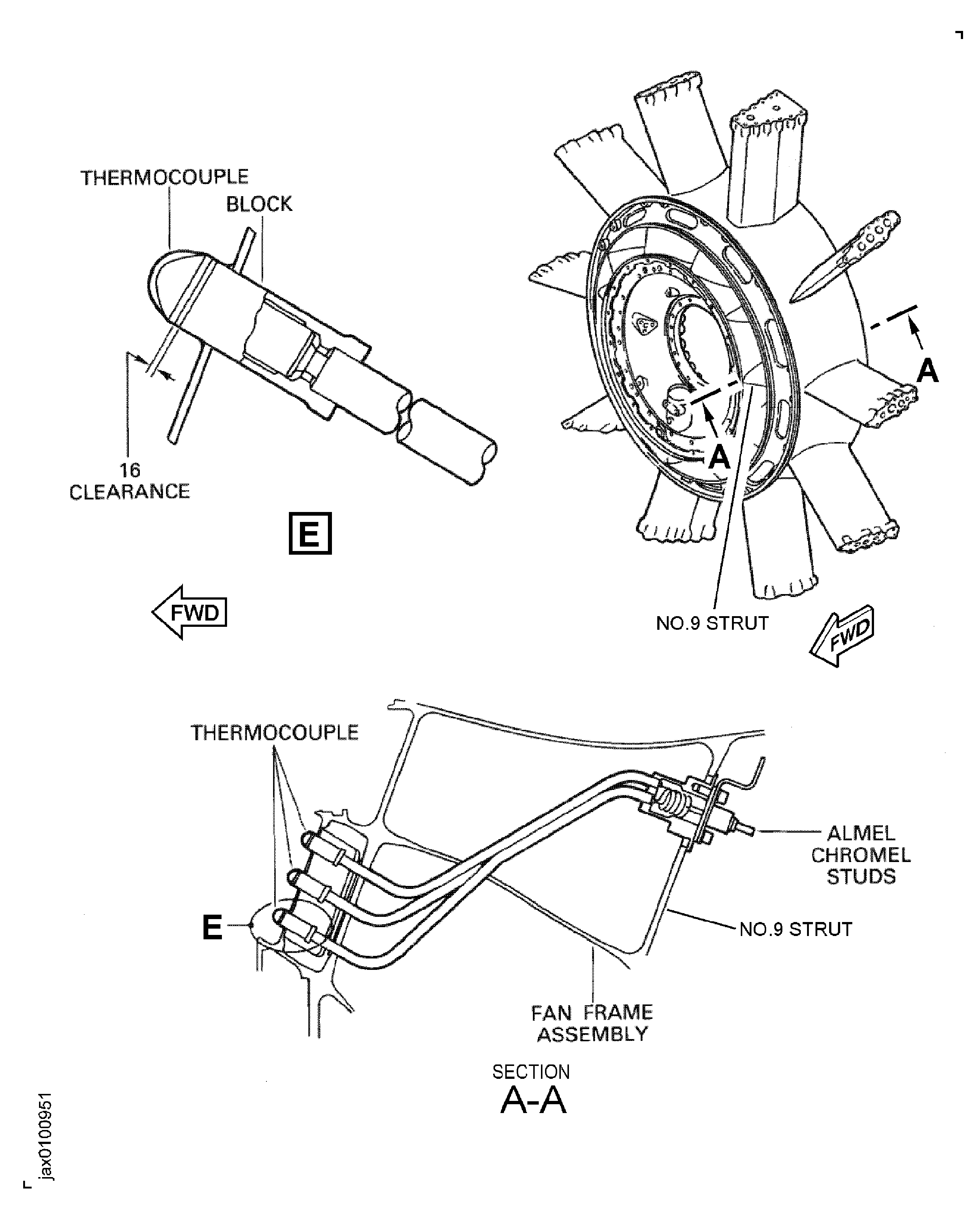

SUBTASK 72-00-32-220-161 Examine the Fan Frame Assembly Thermocouple

Refer to Figure.

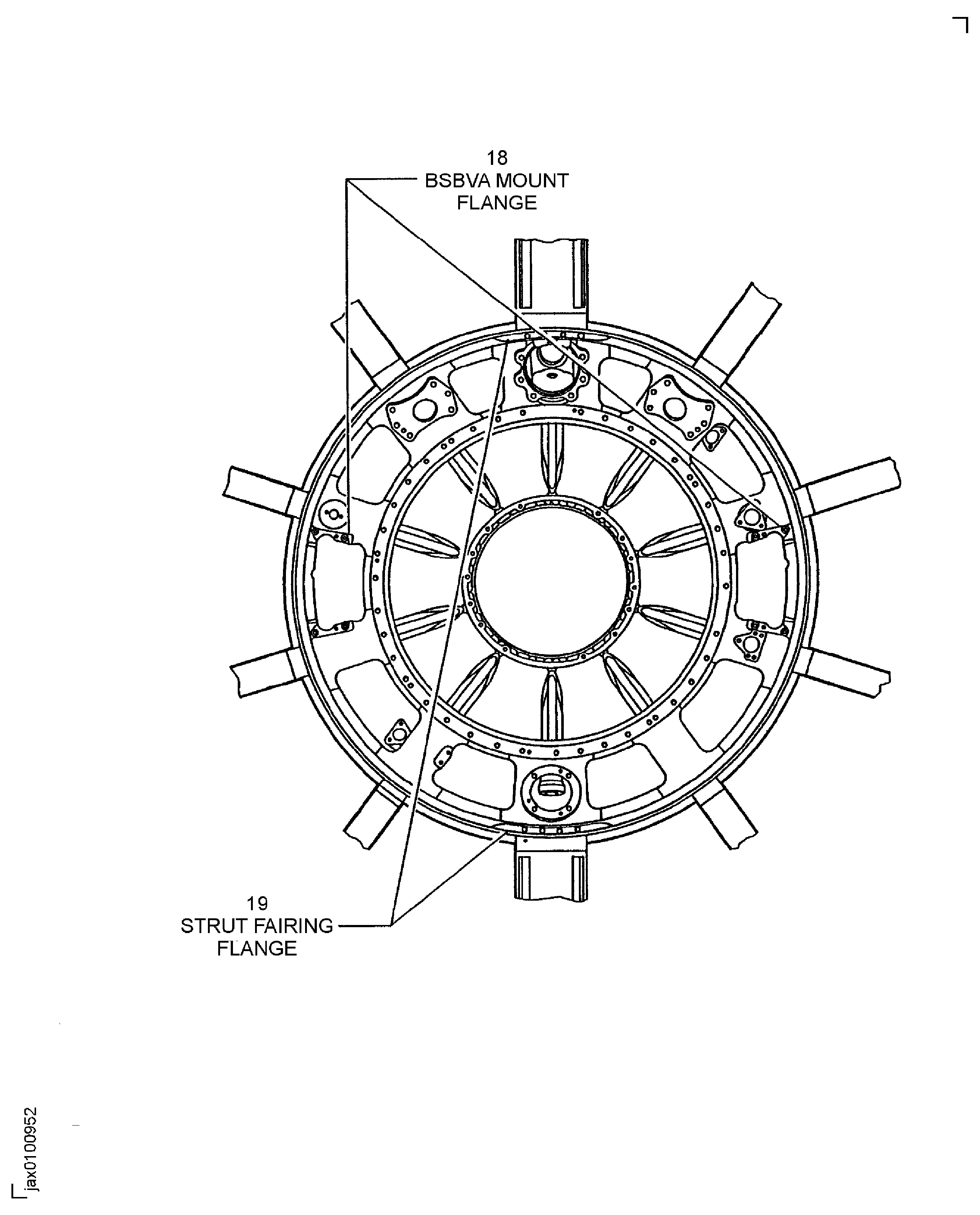

SUBTASK 72-00-32-220-162 Examine the Fan Frame Assembly Booster Stage Bleed Valve Actuator (BSBVA) Mount Flange

Refer to Figure.

SUBTASK 72-00-32-220-163 Examine the Fan Frame Assembly Strut Fairing Mount Flange

Figure: Inspection of the Fan Frame Assembly

Inspection of the Fan Frame Assembly

Figure: Inspection of the Fan Frame Assembly

Inspection of the Fan Frame Assembly

Figure: Inspection of the Fan Frame Assembly

Inspection of the Fan Frame Assembly

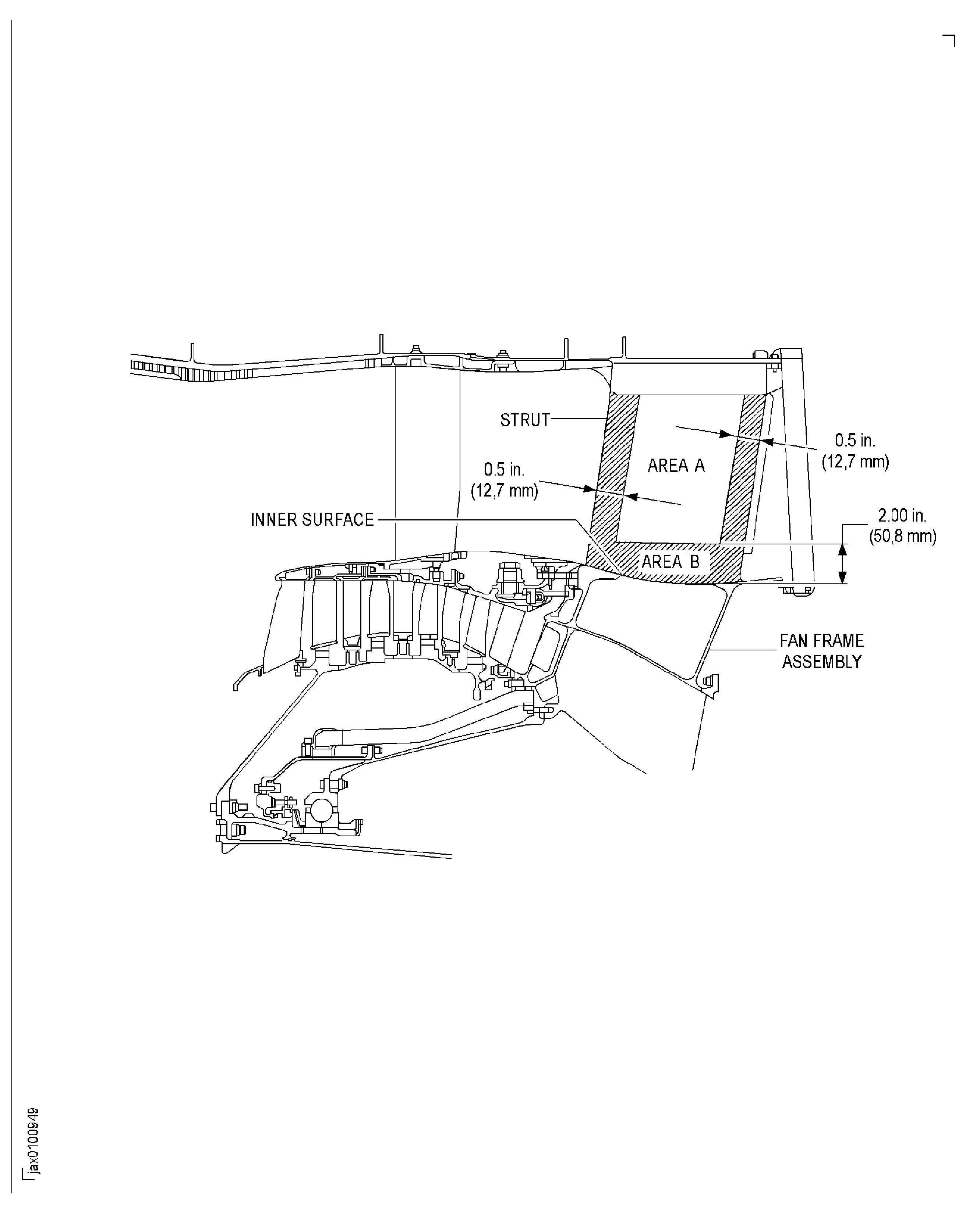

Figure: Inspection of the Fan Frame Assembly

Inspection of the Fan Frame Assembly

Figure: Inspection of the Fan Frame Assembly

Inspection of the Fan Frame Assembly

Figure: Inspection of the Fan Frame Assembly

Inspection of the Fan Frame Assembly