Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-32-220-008 LPC/Intermediate Case Module - Examine The Splitter Fairing (Level 2 Inspection Limits), Inspection-008

General

This TASK gives the procedure for the inspection of the splitter fairing below major soft time and scheduled for a level 2 inspection, as given in the Maintenance Management Program.

Where applicable, these inspections are to be done in conjunction with those given in the interface inspections. Refer to TASK 72-00-32-220-001-B00.

The module will be sufficiently disassembled (TASK 72-31-00-030-001) for the components to be examined as specified in accordance with this procedure.

The policy necessary for the inspection is given in the SPM TASK 70-20-00-200-501.

Clean the splitter fairing. Degrease the splitter fairing, make sure that all dirt and debris were removed before doing the inspection. Refer to the SPM TASK 70-11-03-300-503.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure.

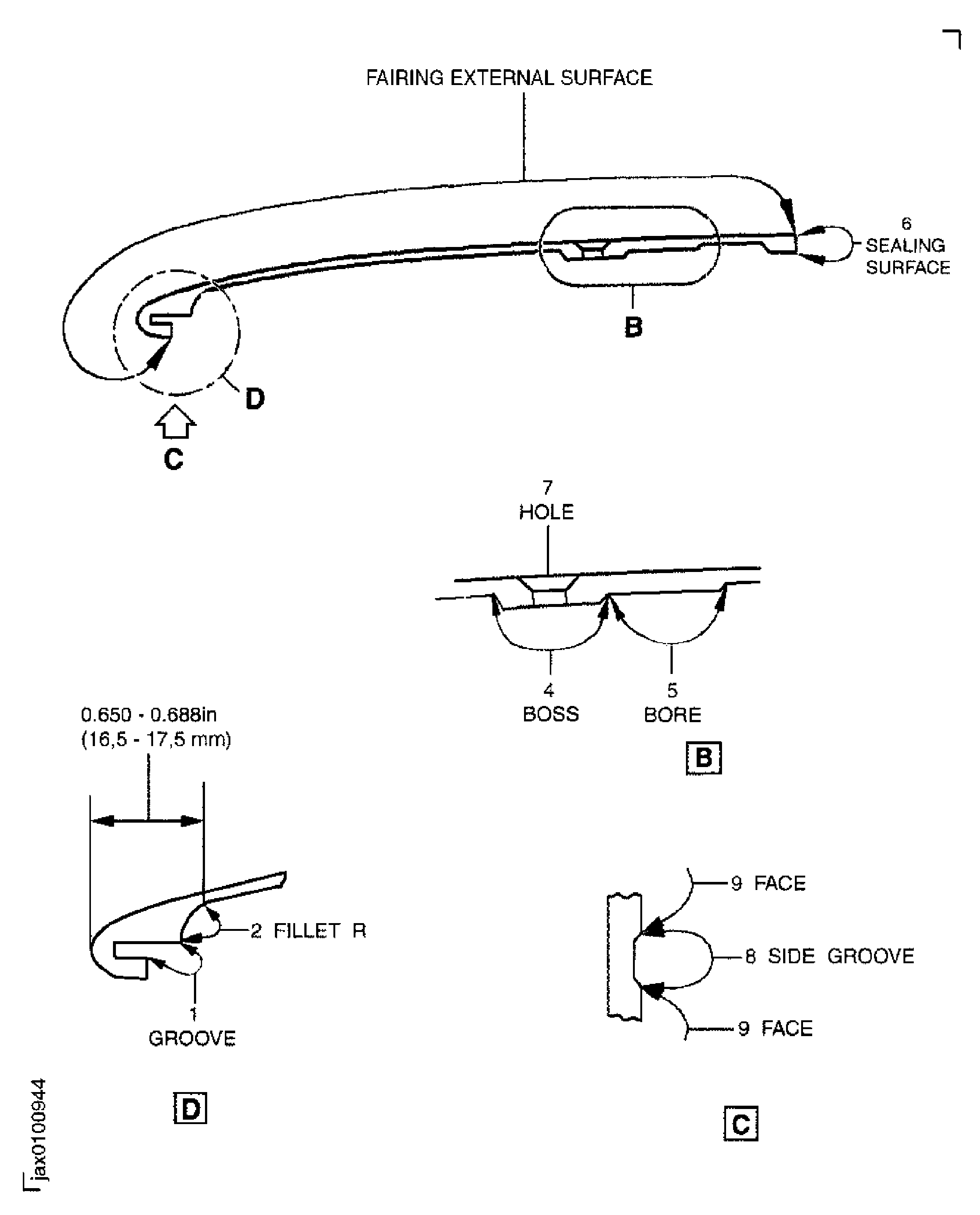

SUBTASK 72-00-32-220-132 Examine the Splitter Fairing Front Location Land

Refer to Figure.

SUBTASK 72-00-31-220-196 Examine the Splitter Fairing Fillet R

Refer to Figure.

SUBTASK 72-00-31-220-198 Examine the Splitter Fairing Bore

Refer to Figure.

SUBTASK 72-00-31-220-199 Examine the Splitter Fairing Sealing Surface

Refer to Figure.

SUBTASK 72-00-31-220-201 Examine the Splitter Fairing Slide Groove

Refer to Figure.

SUBTASK 72-00-31-220-202 Examine the Splitter Fairing Face

Refer to Figure.

SUBTASK 72-00-31-220-203 Examine the Splitter Fairing all Remaining Surfaces

Figure: Inspection of the Splitter Fairing

Inspection of the Splitter Fairing