Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

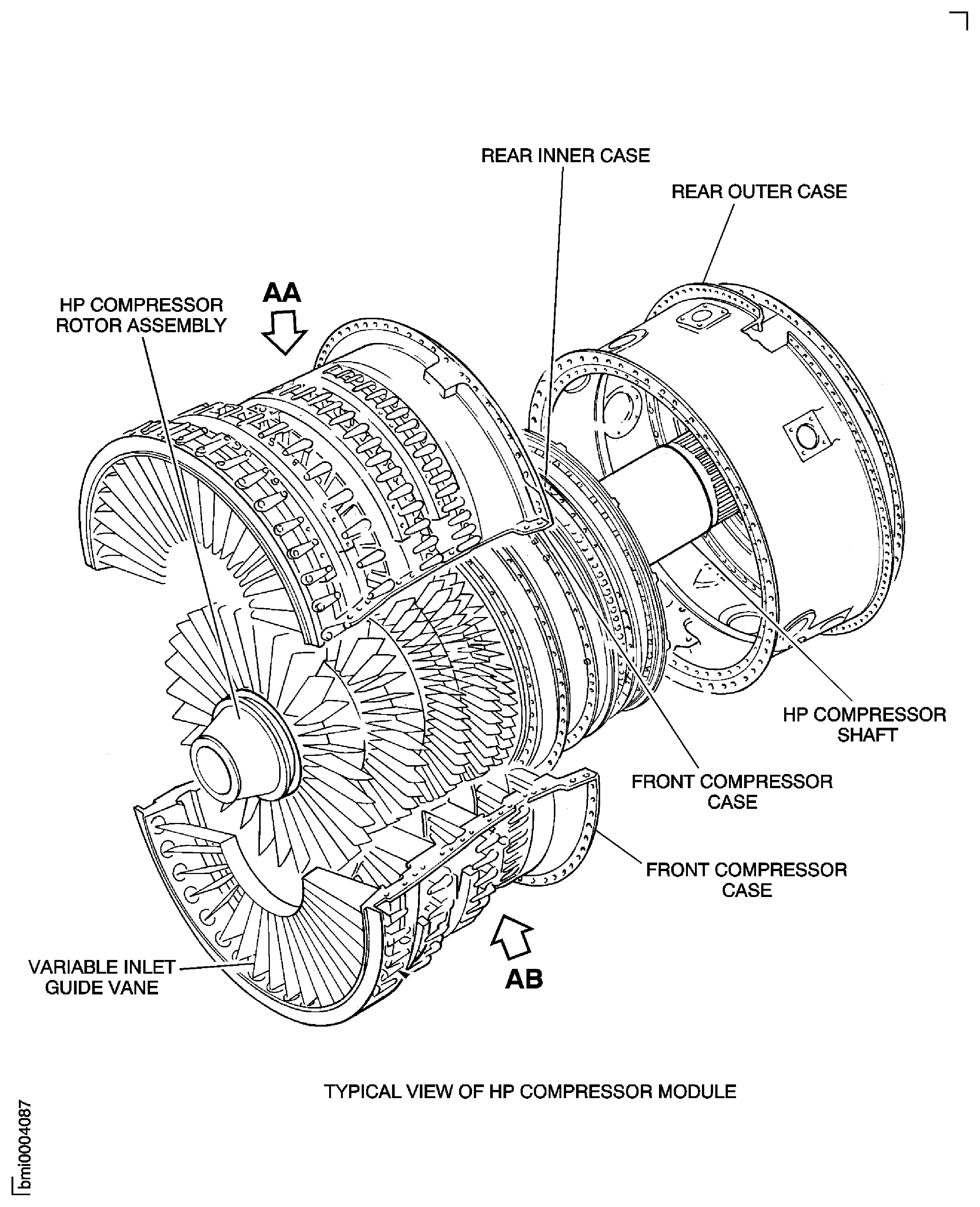

TASK 72-00-41-300-002 HPC Assembly - HPC Front Case - Replace Missing And/or Damaged Helicoil Insert(s), Repair-002 (VRS6521)

General

This repair must only be done when the instruction to do so is given in 72-00-41-200-001 Inspection/Check (Special Procedure 01).

This TASK gives the procedure to repair missing and/or damaged helicoil insert(s) in the HP compressor front case assembly, by replacement.

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Approved workshop equipment | LOCAL | Approved workshop equipment | ||

| Chemical Cleaning Equipment | LOCAL | Chemical Cleaning Equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant Crack Test Equipment | ||

| Workshop Inspection Equipment | LOCAL | Workshop Inspection Equipment | ||

| Vacuum cleaning equipment | LOCAL | Vacuum cleaning equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-459 AQUEOUS WIPE CLEANER | 71410 | CoMat 01-459 | ||

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-005 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-005 | ||

| CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON | IE304 | CoMat 02-121 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Insert | AGS3732 | 18 | ||

| Insert | AGS3732 | 16 | ||

| Insert | AGS3733 | 8 |

Safety Requirements

NONEProcedure

Refer to the SPM TASK 70-35-08-300-501, SUBTASK 70-35-08-350-001.

Use Approved workshop equipment 1 off.

SUBTASK 72-00-41-350-009 Remove the Damaged Helicoil Insert(s)

Refer to the SPM TASK 70-11-03-300-503, SUBTASK 70-11-03-300-003.

SUBTASK 72-00-41-110-005 Chemically Clean

Refer to the SPM TASK 70-23-05-230-501.

Use Penetrant Crack Test Equipment 1 off.

Cracks are not permitted.

SUBTASK 72-00-41-230-003 Do a Crack Test

Refer to the SPM TASK 70-11-03-300-503, SUBTASK 70-11-03-300-003.

SUBTASK 72-00-41-110-006 Chemically Clean

Refer to the SPM TASK 70-35-08-300-501, SUBTASK 70-35-08-350-002.

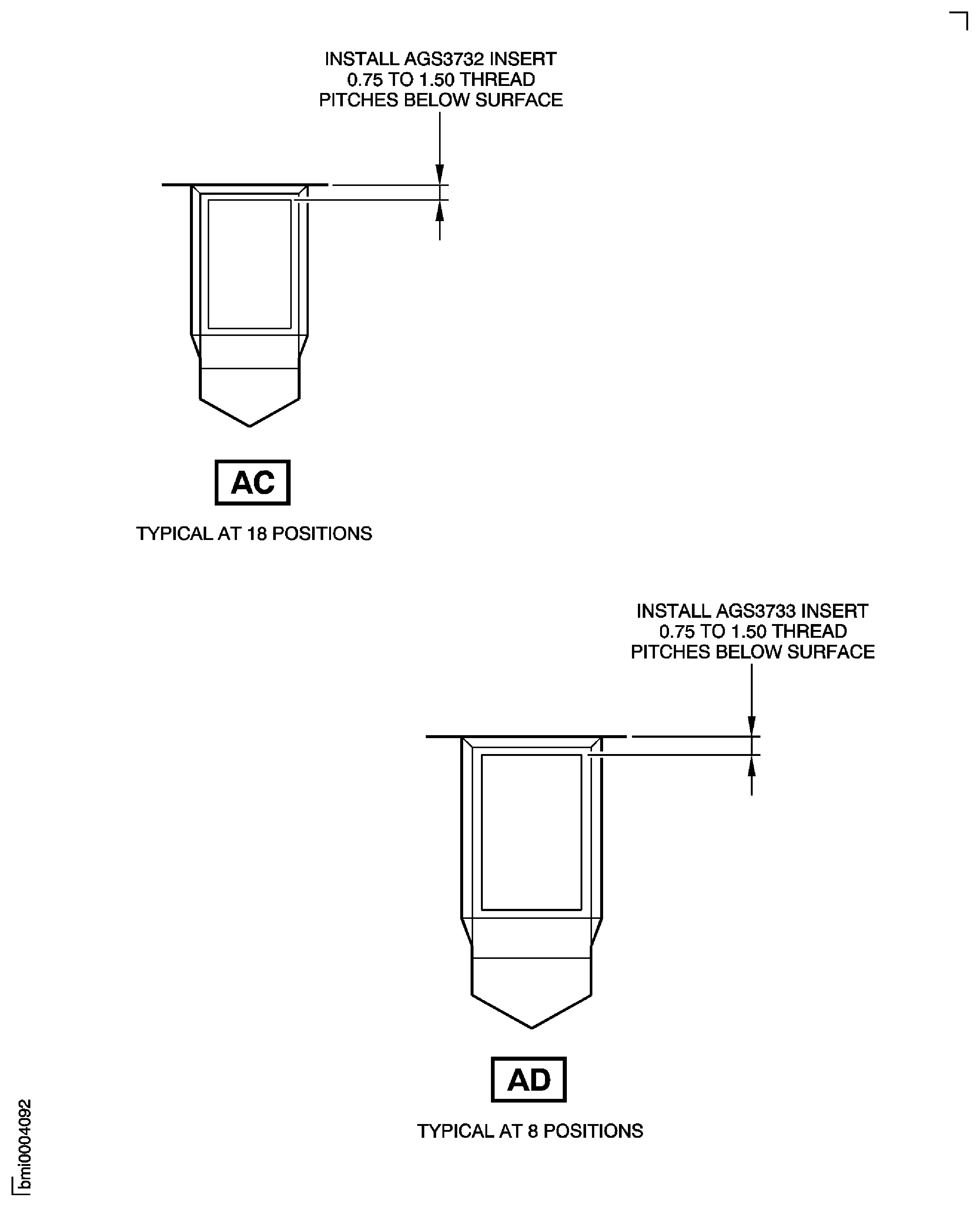

Use insert HP COMPRESSOR SPLIT CASE (72-41-31, 01-432), 18 off and/or insert HP COMPRESSOR SPLIT CASE (72-41-31, 01-613), 8 off as necessary.

Use Approved workshop equipment 1 off.

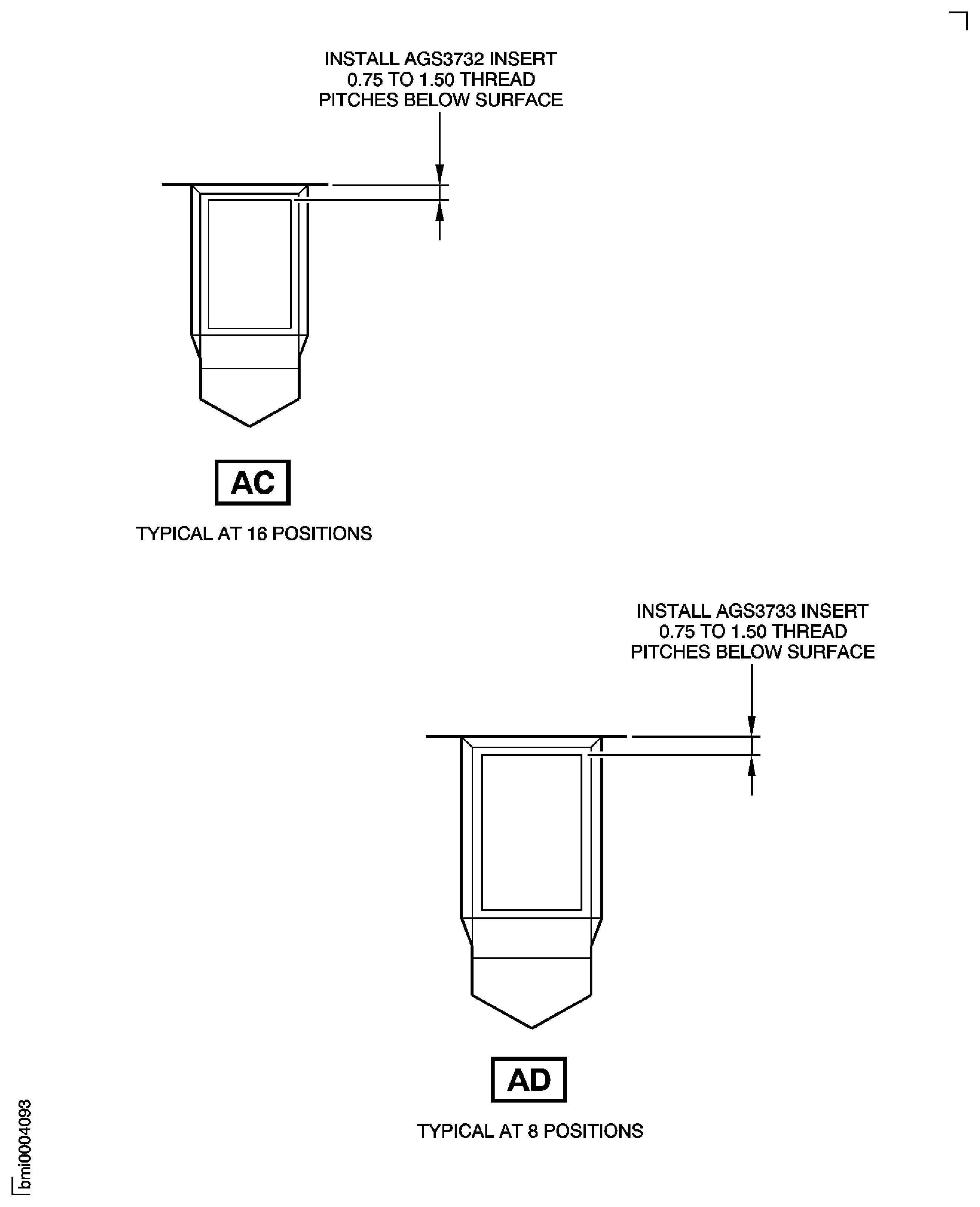

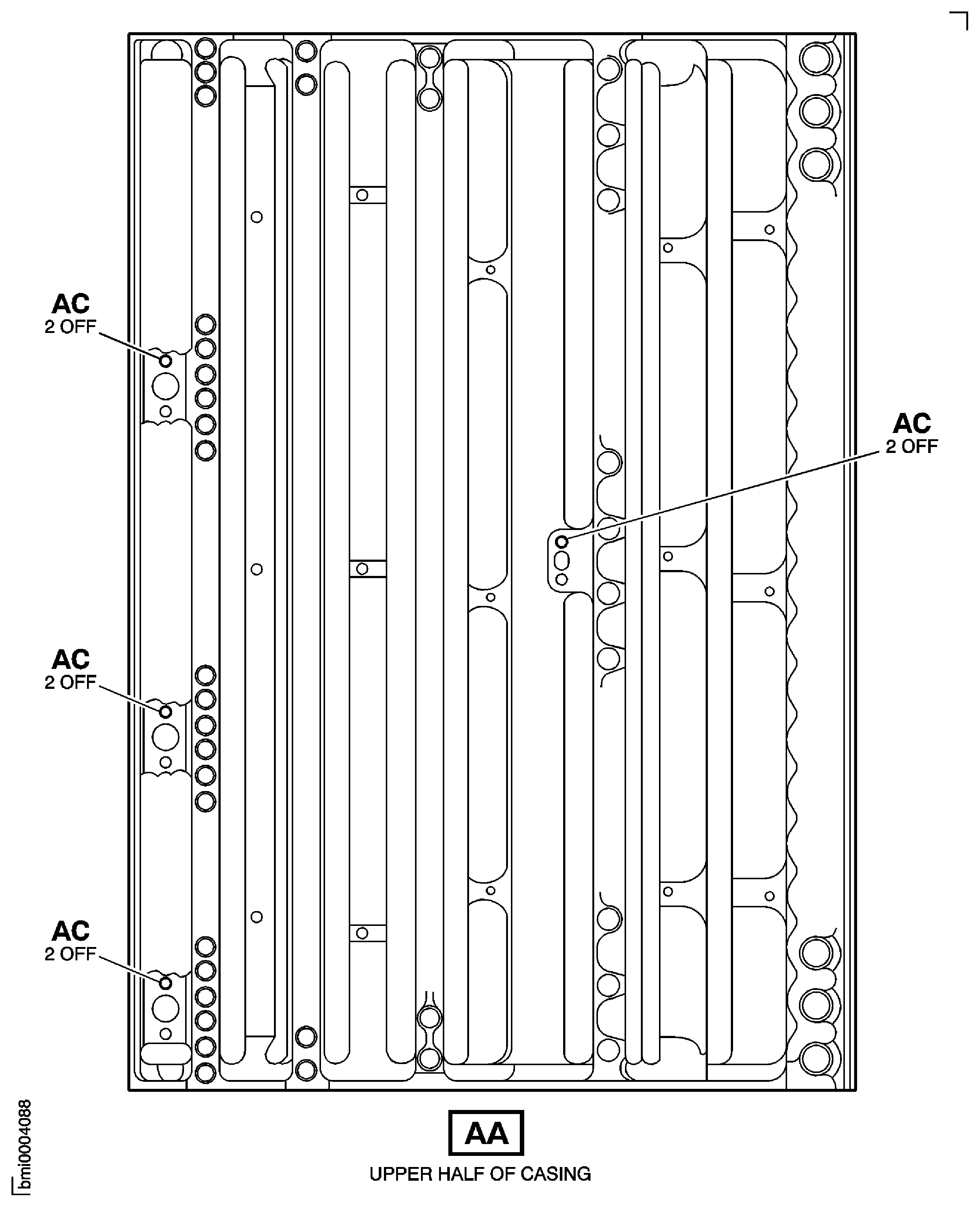

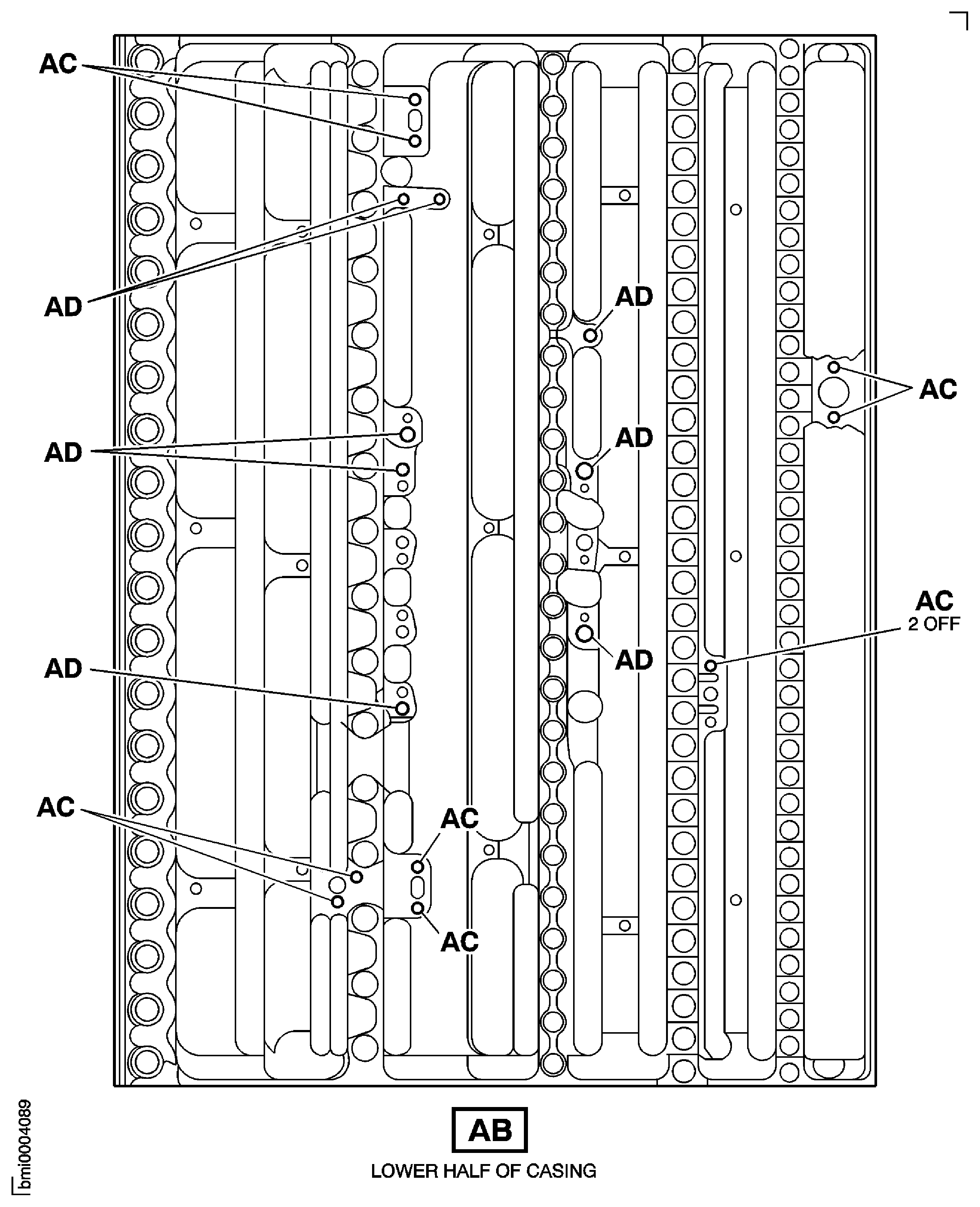

SUBTASK 72-00-41-350-010-A00 Install the Helicoil Insert(s), Assembly A

Refer to the SPM TASK 70-35-08-300-501, SUBTASK 70-35-08-350-002.

Use insert HP COMPRESSOR SPLIT CASE (72-41-31, 01-432), 16 off and/or insert HP COMPRESSOR SPLIT CASE (72-41-31, 01-613), 8 off as necessary.

Use approved workshop equipment.

SUBTASK 72-00-41-350-010-B00 Install the Helicoil Insert(s), Assembly B

Refer to the SPM TASK 70-35-08-300-501.

Make sure the insert is installed 0.75 to 1.50 thread pitch below the surface.

Use workshop inspection equipment.

SUBTASK 72-00-41-220-053 Examine the Helicoil Insert(s)

Figure: Repair Details and Dimensions - Assembly A and Assembly B

Repair Details and Dimensions - Assembly A and Assembly B

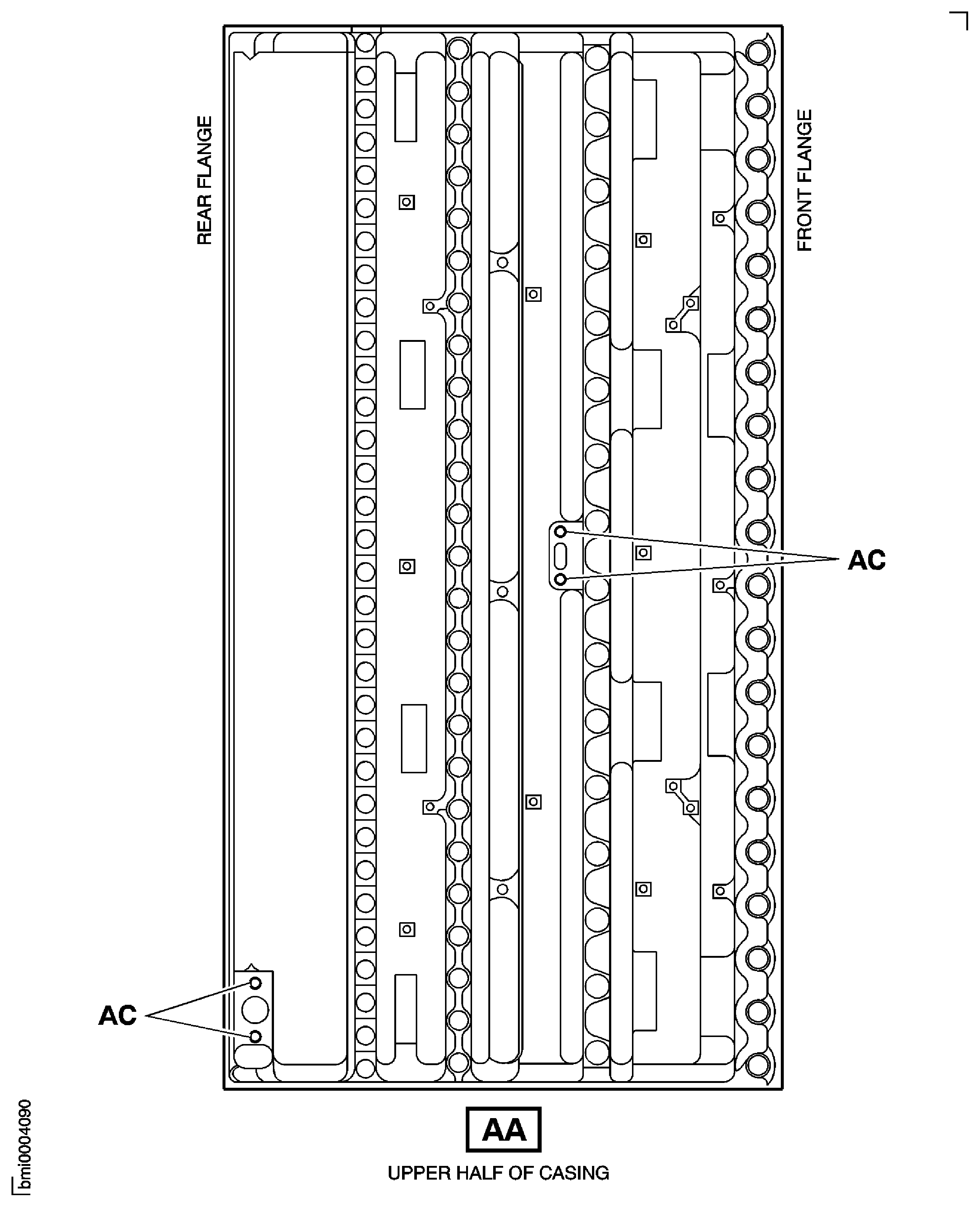

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

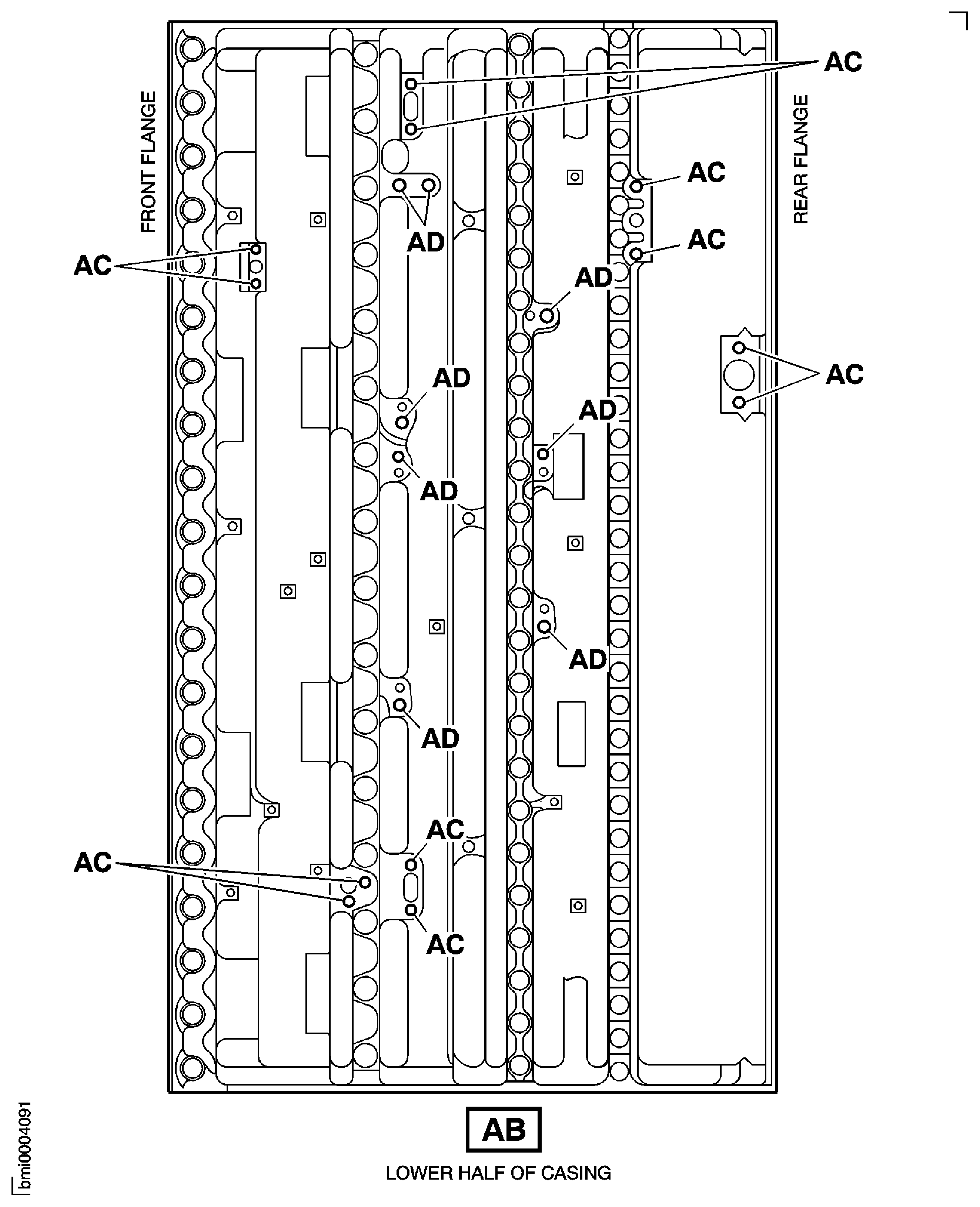

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B

Figure: Repair Details and Dimensions - Assembly A

Repair Details and Dimensions - Assembly A

Figure: Repair Details and Dimensions - Assembly B

Repair Details and Dimensions - Assembly B