Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-42-420-002-002 Combustion System - Install The Outer Combustion Chamber Assembly (Vertical) - Method 2, Installation-002

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

For lockwire data and procedures refer to SPM TASK 70-42-05-400-501.

Special torque data and assembly tolerances are included in this procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to SPM TASK 70-44-01-400-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Transportation covers/blanks must be removed immediately before the installation of the components.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1P16092 Igniter immersion gage | 0AM53 | IAE 1P16092 | 1 | |

| IAE 1P16102 Lift sling | 0AM53 | IAE 1P16102 | 1 | |

| IAE 1P16231 Alignment pin | 0AM53 | IAE 1P16231 | 2 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-141 LOCKWIRE | LOCAL | CoMat 02-141 | ||

| CoMat 10-003 COLLOIDAL GRAPHITE DRY FILM LUBRICANT | LOCAL | CoMat 10-003 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Install the two IAE 1P16231 Alignment pins, equally spaced, to the bosses on the outer diameter of the diffuser case and retract the inner portion of the pins.

Install three doweled end bolts to attach the outer combustion chamber to the diffuser case and torque the bolts to 550 to 650 lbf.in (62.1 to 73.4 Nm). Safety with CoMat 02-141 LOCKWIRE.

Remove one alignment pin at a time and install the remaining doweled end bolts. Torque the bolts to 550 to 650 lbf.in (62.142 to 73.440 Nm). Safety with CoMat 02-141 LOCKWIRE.

SUBTASK 72-00-42-420-065 Install the Outer Combustion Chamber

Refer to Figure.

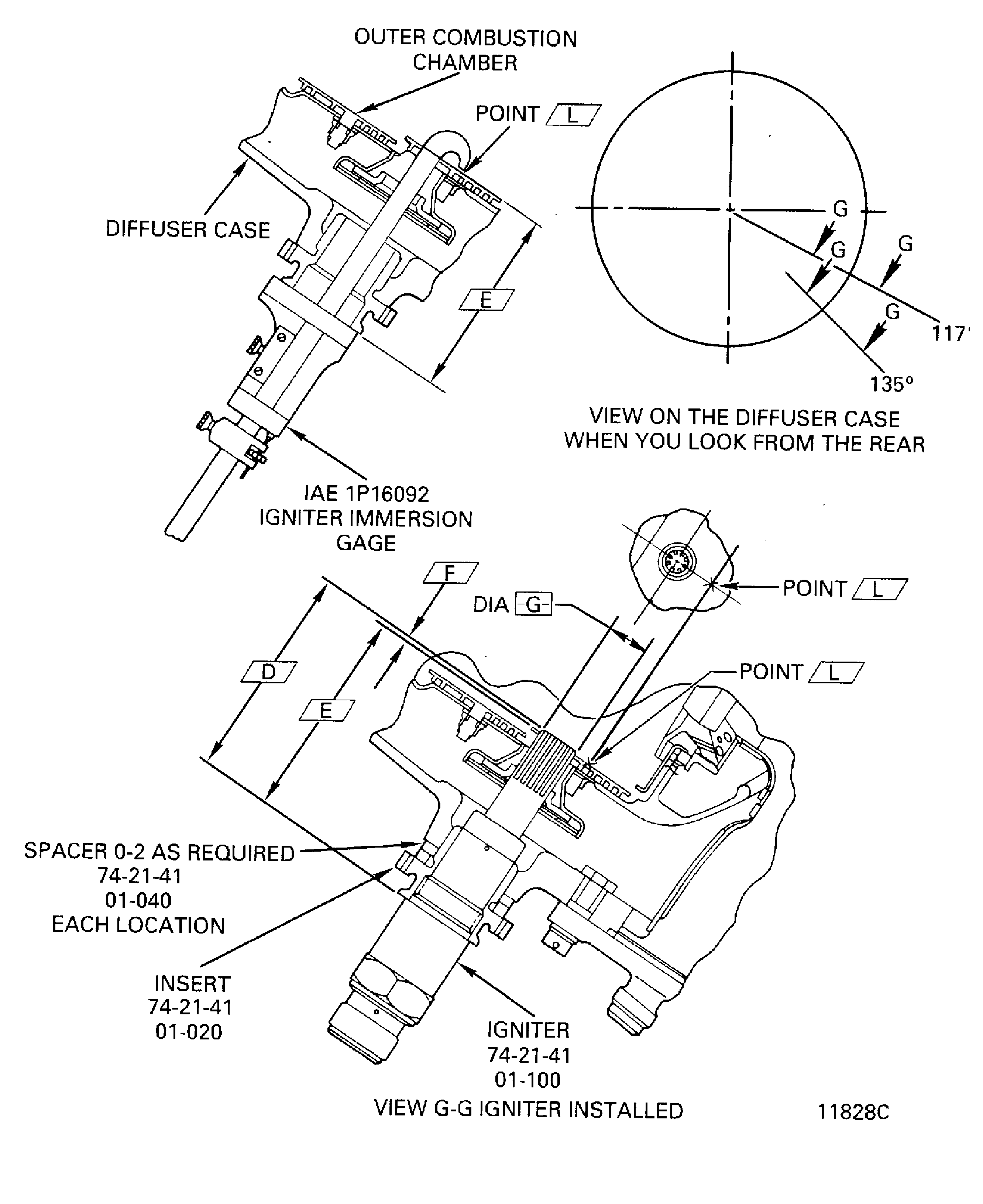

Measure distance E from the top of the insert to point L on the outer combustion chamber nearest the fuel nozzle. Use the IAE 1P16092 Igniter immersion gage 1 off.

Apply CoMat 10-003 COLLOIDAL GRAPHITE DRY FILM LUBRICANT to the insert. Remove all excess compound.

Safety the insert with CoMat 02-141 LOCKWIRE.

If depth F is not 0.040 to 0.080 in. (1.02 to 2.03 mm), do the steps that follow:

CAUTION

DO NOT BEND THE ELECTRICAL CABLE CONDUITS TOO MUCH WHEN YOU CONNECT THE ELECTRICAL CONNECTOR. THE CONDUIT CAN BE DAMAGED AND CAN CAUSE ELECTRICAL CIRCUIT DEFECTS.

CAUTION

APPLY ANTI-SEIZE COMPOUND MODERATELY TO THE PLUG THREADS. IF TOO MUCH COMPOUND IS APPLIED IT COULD GO THROUGH IN TO THE ENGINE.NOTE

If you replace only the igniter plug, you do not have to check the igniter plug immersion depth.Check the igniter plug immersion depth.

SUBTASK 72-00-42-420-066 Install the Igniter Plugs

Install the stage 1 turbine nozzle assembly. Refer to TASK 72-00-44-420-001-001 (INSTALLATION-001) or TASK 72-00-44-420-001-002 (INSTALLATION-002).

.

SUBTASK 72-00-42-420-069 Install the Stage 1 Turbine Nozzle Assembly

Figure: Install the Outer Combustion Chamber

Install the Outer Combustion Chamber

Figure: Install the igniter plugs

Install the igniter plugs