Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-50-020-004 LPT Module - Remove The LPT Module Without The Turbine Exhaust Case (TEC) - Method 2, Removal-005

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

Apply the approved penetrating oil before the removal of threaded parts. Let the parts soak before the removal. For the approved oils and procedures, refer to SPM TASK 70-64-00-640-501.

Remove and discard the lockwire before parts are disconnected or removed.

Discard all rubber seal rings, cotter pins and keywashers removed in this procedure.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Hot Air Gun | LOCAL | Hot Air Gun | ||

| IAE 1F10016 Mechanical wrench | 0AM53 | IAE 1F10016 | 1 | |

| IAE 1F10019 Mechanical wrench | 0AM53 | IAE 1F10019 | 1 | |

| IAE 1R19787 Sling | 0AM53 | IAE 1R19787 | 1 | |

| IAE 1F10026 Hydraulic hand pump | 0AM53 | IAE 1F10026 | 1 | |

| IAE 1F10052 Two cables sling | 0AM53 | IAE 1F10052 | 1 | |

| IAE 1F10074 Guide pogo stick | 0AM53 | IAE 1F10074 | 1 | |

| IAE 1F10075 Support pedestal | 0AM53 | IAE 1F10075 | 2 | |

| IAE 1F10080 Horizontal stand | 0AM53 | IAE 1F10080 | 1 | |

| IAE 1J12260 Spanner wrench | 0AM53 | IAE 1J12260 | 1 | |

| IAE 1J12269 Guide support | 0AM53 | IAE 1J12269 | 1 | |

| IAE 1J12280 Guide bar | 0AM53 | IAE 1J12280 | 1 | |

| IAE 1J12277 Guide support | 0AM53 | IAE 1J12277 | 1 | |

| IAE 1J12282 Expanding pliers | 0AM53 | IAE 1J12282 | 1 | |

| IAE 1M14000 Lifting fixture | 0AM53 | IAE 1M14000 | 1 | |

| IAE 1M14002 Support fixture | 0AM53 | IAE 1M14002 | 1 | |

| IAE 1M14003 Support arm | 0AM53 | IAE 1M14003 | 2 | |

| IAE 1M14005 Torque wrench | 0AM53 | IAE 1M14005 | 1 | |

| IAE 1M14006 Immobilizing fixture | 0AM53 | IAE 1M14006 | 1 | |

| IAE 1M14086 Supporting fixture | 0AM53 | IAE 1M14086 | 1 | |

| IAE 1M14127 Support plate | 0AM53 | IAE 1M14127 | 2 | |

| IAE 1M14139 Immobilizing fixture | 0AM53 | IAE 1M14139 | 1 | |

| IAE 1M14143 Support fixture | 0AM53 | IAE 1M14143 | 1 | |

| IAE 1M14461 Supporting fixture | 0AM53 | IAE 1M14461 | 1 | |

| IAE 1M14146 Support plate | 0AM53 | IAE 1M14146 | 1 | |

| IAE 1P16377 Guide support | 0AM53 | IAE 1P16377 | 1 | |

| IAE 1J12220 Hydraulic pusher/puller | 0AM53 | IAE 1J12220 | 1 | |

| IAE 1J12512 Hydraulic pusher | 0AM53 | IAE 1J12512 | 1 | |

| IAE 1J12270 Guide puller | 0AM53 | IAE 1J12270 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-149 DRY ICE | LOCAL | CoMat 02-149 |

Spares

NONESafety Requirements

NONEProcedure

Remove the module dressings. Refer to TASK 72-00-50-020-001 (REMOVAL-001).

SUBTASK 72-00-50-020-063 Remove the Module Dressings

Remove the TEC. Refer to TASK 72-00-50-020-003 (REMOVAL-004).

SUBTASK 72-00-50-020-064 Remove the Turbine Exhaust Case

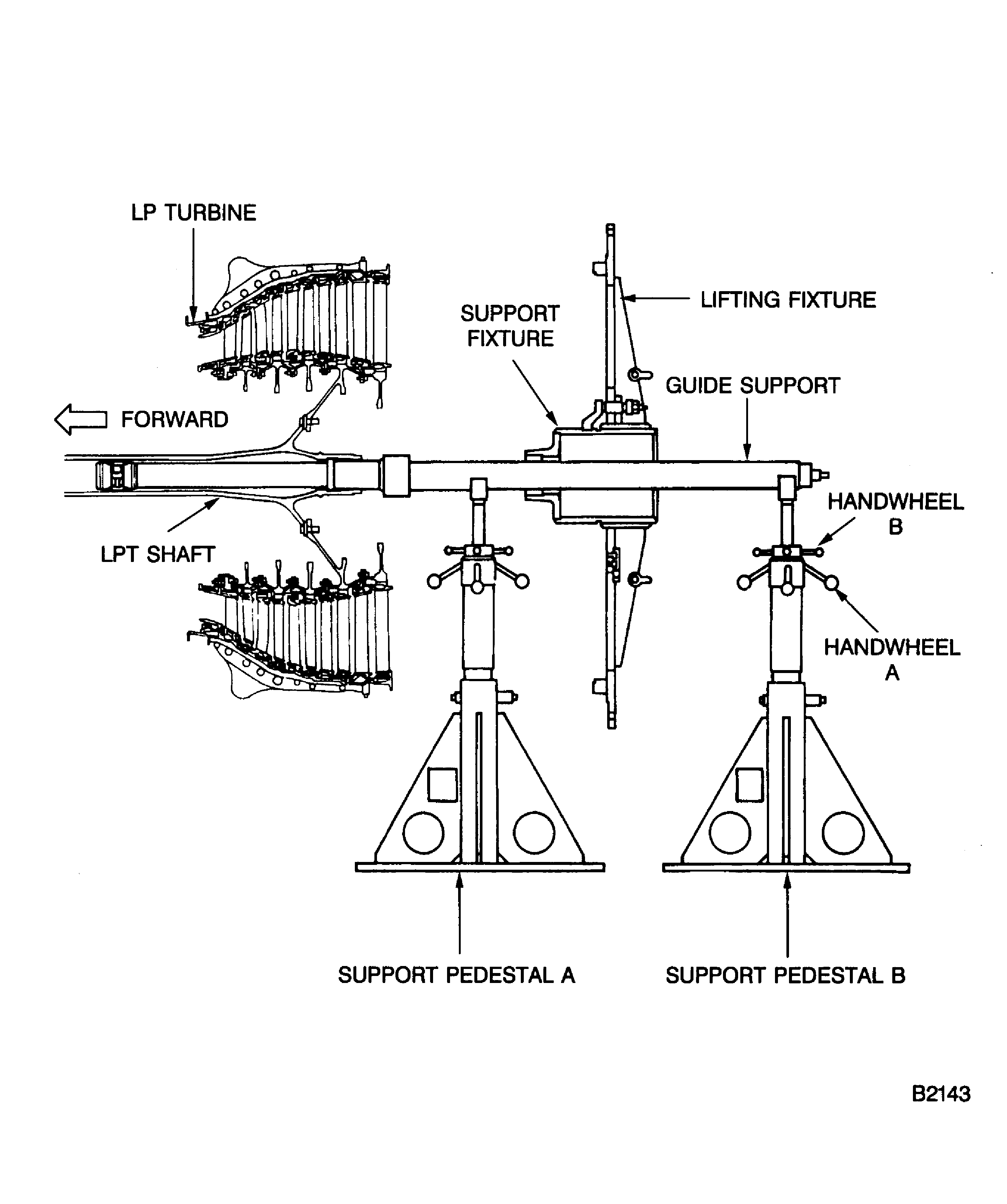

Refer to Figure.

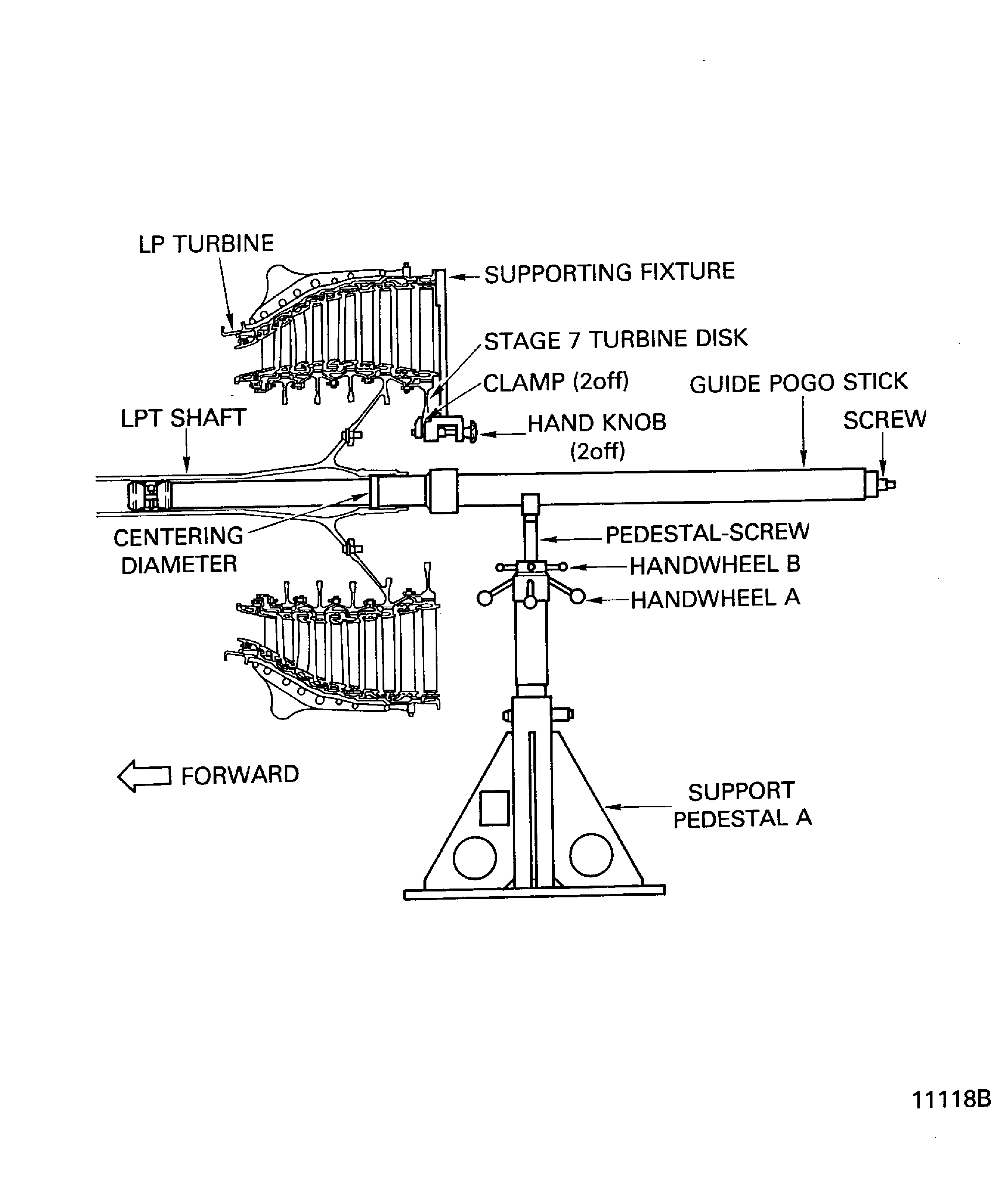

Install the IAE 1F10074 Guide pogo stick 1 off (V2500-A1) to the inner diameter of the LP turbine shaft. Use an applicable webbing sling.

Put the IAE 1F10075 Support pedestal 1 off below the guide pogo stick. Move the support pedestal A near to the rear flange of the LP turbine case.

SUBTASK 72-00-50-020-065-A00 V2500-A1: Install the Guide Pogo Stick to the LP Turbine Shaft

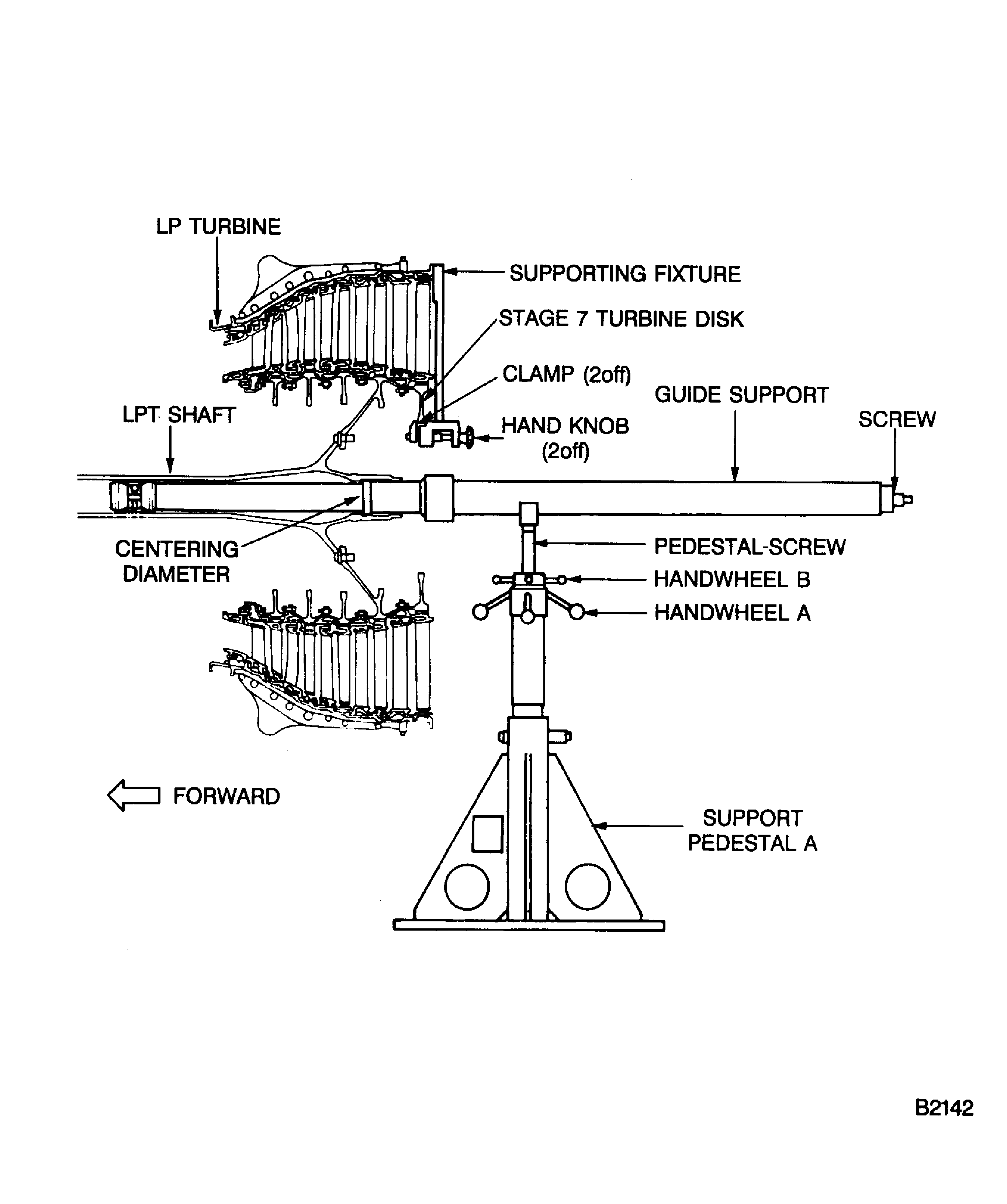

Refer to Figure.

Install the IAE 1P16377 Guide support 1 off to the inner diameter of the LP turbine shaft. Use an applicable webbing sling.

Put the IAE 1F10075 Support pedestal 1 off below the guide support. Move the support pedestal A near to the rear flange of the LP turbine case.

SUBTASK 72-00-50-020-065-B00 V2500-A5: Install the Guide Support to the LP Turbine Shaft

Refer to Figure.

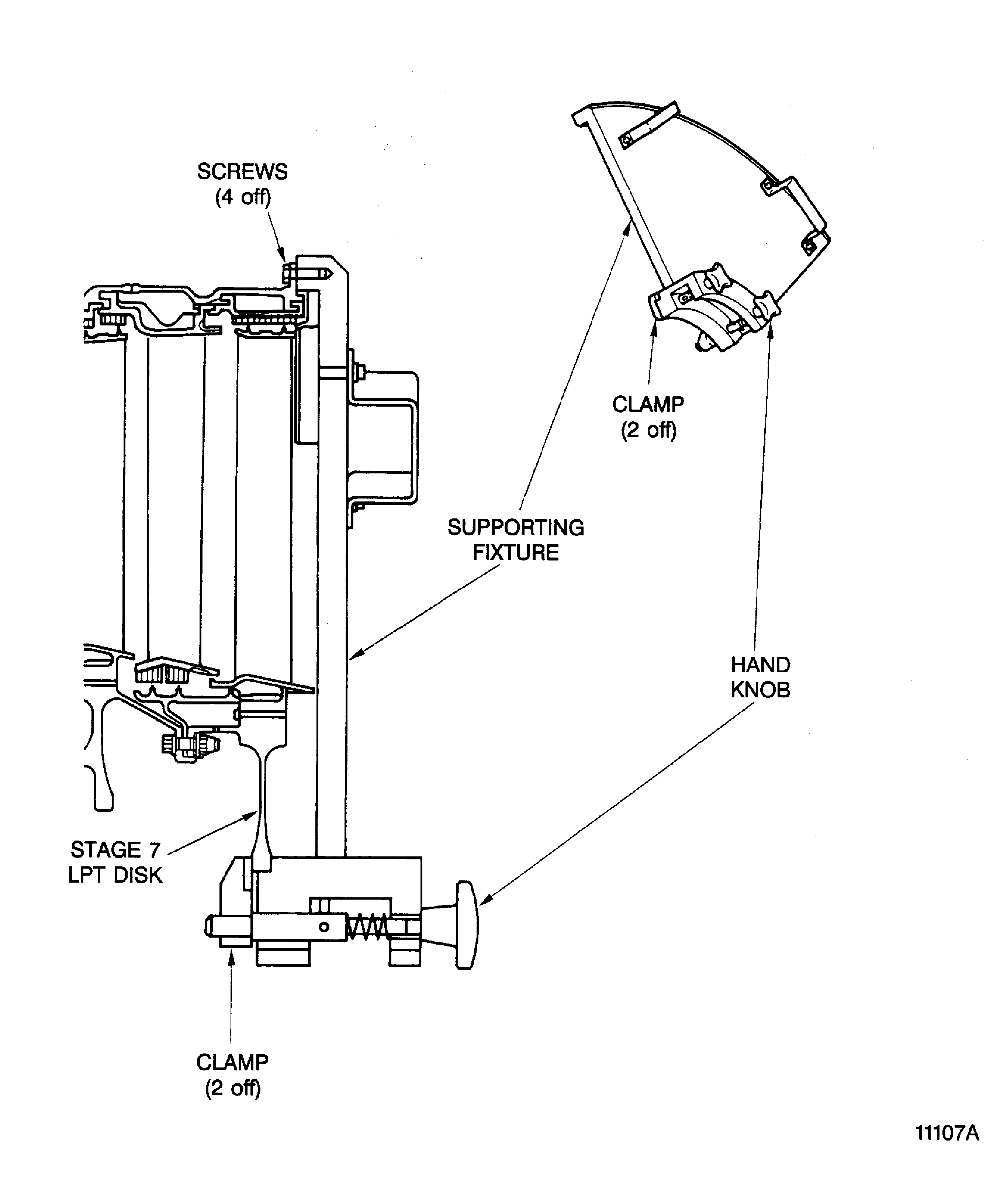

Release the two hand knobs that attach the two clamps, part of IAE IAE 1M14086 Supporting fixture or of the IAE 1M14461 Supporting fixture 1 off to the stage 7 turbine disk.

SUBTASK 72-00-50-020-066-A00 V2500-A1: Remove the Supporting Fixture

Refer to Figure.

Release the two hand knobs that attach the two clamps, part of the IAE 1M14143 Support fixture or of the IAE 1M14461 Supporting fixture 1 off, to the stage 7 turbine disk.

SUBTASK 72-00-50-020-066-B00 V2500-A5: Remove the Supporting Fixture

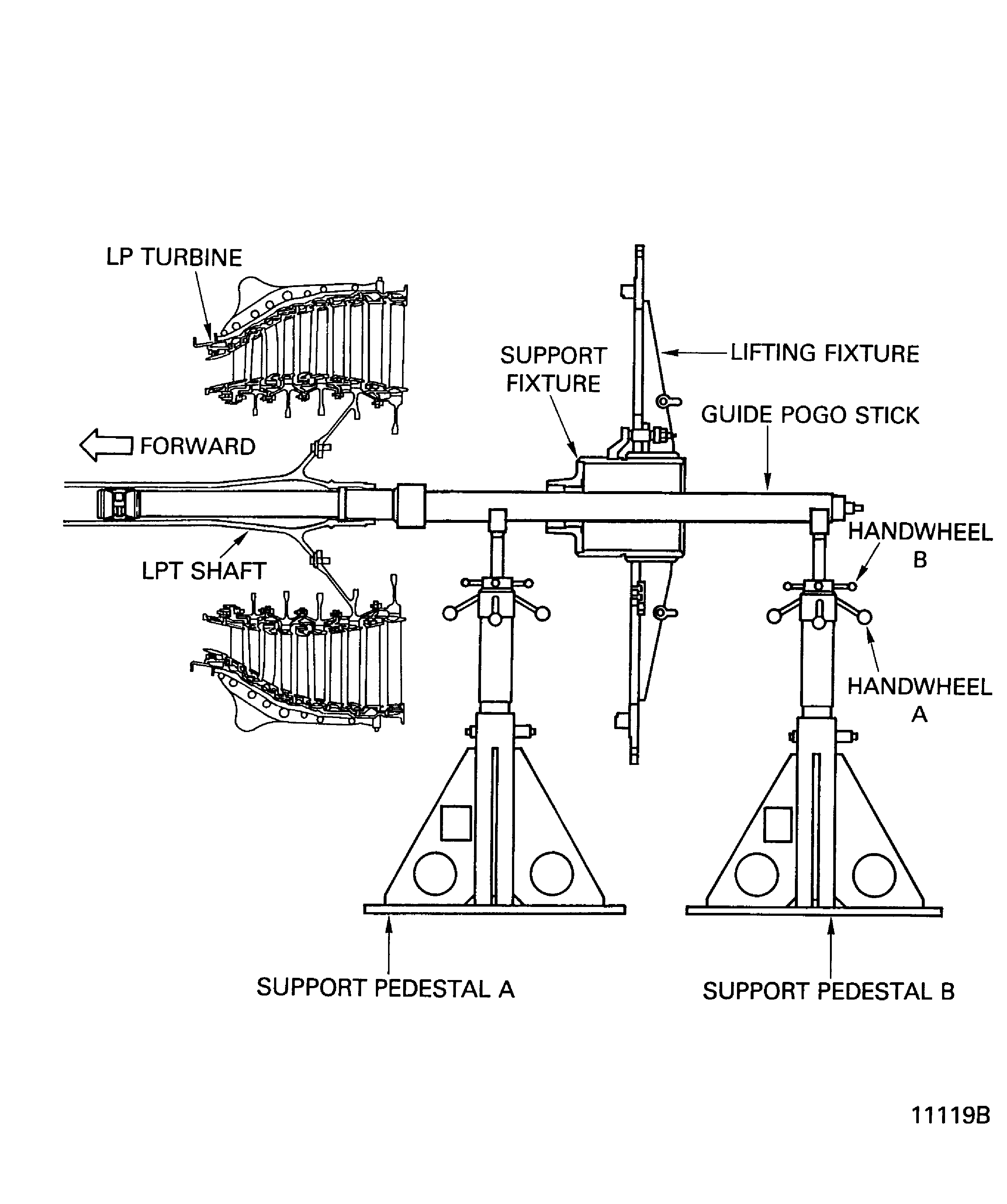

Refer to Figure.

Engage IAE 1M14000 Lifting fixture 1 off on to the IAE 1M14002 Support fixture 1 off. Turn back the three guide sleeves, part of the lifting fixture, until the support fixture touches the lifting fixture.

Install the IAE 1M14003 Support arm 2 off to the lifting fixture. Attach each support arm with the eight washers and screws.

Use hoist equipment to install the IAE 1F10052 Two cables sling 1 off to the rear spools of the support arms.

SUBTASK 72-00-50-020-102 Install the Support Fixture in to the Lifting Fixture

Refer to Figure.

Put the IAE 1F10075 Support pedestal 1 off below the rear end of the guide pogo stick. Refer to SUBTASK 72-00-50-020-065.

Remove the IAE 1F10075 Support pedestal 1 off.

Loosen the three nuts that hold the guide sleeves (part of the IAE 1M14000 Lifting fixture 1 off). Turn the guide sleeves clockwise until the support fixture is correctly installed to the LP turbine shaft. Tighten the three nuts. Refer to Figure.

CAUTION

MAKE SURE THE SUPPORT FIXTURE IS CORRECTLY INSTALLED AT THE LP TURBINE SHAFT AND LOCKED ON THE LIFTING FIXTURE. IF THE FIXTURES ARE NOT CORRECTLY LOCKED THE LP TURBINE CASE AND ROTOR PARTS CAN BE DAMAGED DURING THE HANDLING OF THE LP TURBINE MODULE.Remove the support pedestal B. Remove the guide pogo stick through the support fixture.

SUBTASK 72-00-50-020-067-A00 V2500-A1: Install the Assembled Lifting Fixture and Remove the Guide Pogo Stick

Refer to Figure.

Put the IAE 1F10075 Support pedestal 1 off below the rear end of the guide support. Refer to SUBTASK 72-00-50-020-065.

Remove the IAE 1F10075 Support pedestal 1 off.

Loosen the three nuts that hold the guide sleeves (Part of IAE 1M14000 Lifting fixture 1 off). Turn the guide sleeves clockwise until the support fixture is correctly installed to the LP turbine shaft. Tighten the three nuts. Refer to Figure.

CAUTION

MAKE SURE THAT THE SUPPORT FIXTURE IS CORRECTLY INSTALLED AT THE LP TURBINE SHAFT AND LOCKED ON THE LIFTING FIXTURE. IF THE FIXTURES ARE NOT CORRECTLY LOCKED THE LP TURBINE CASE AND ROTOR PARTS CAN BE DAMAGED DURING HANDLING OF THE LP TURBINE MODULE.Remove the support pedestal B. Remove the guide support through the support fixture.

SUBTASK 72-00-50-020-067-B00 V2500-A5: Install the Assembled Lifting Fixture and Remove the Guide Support

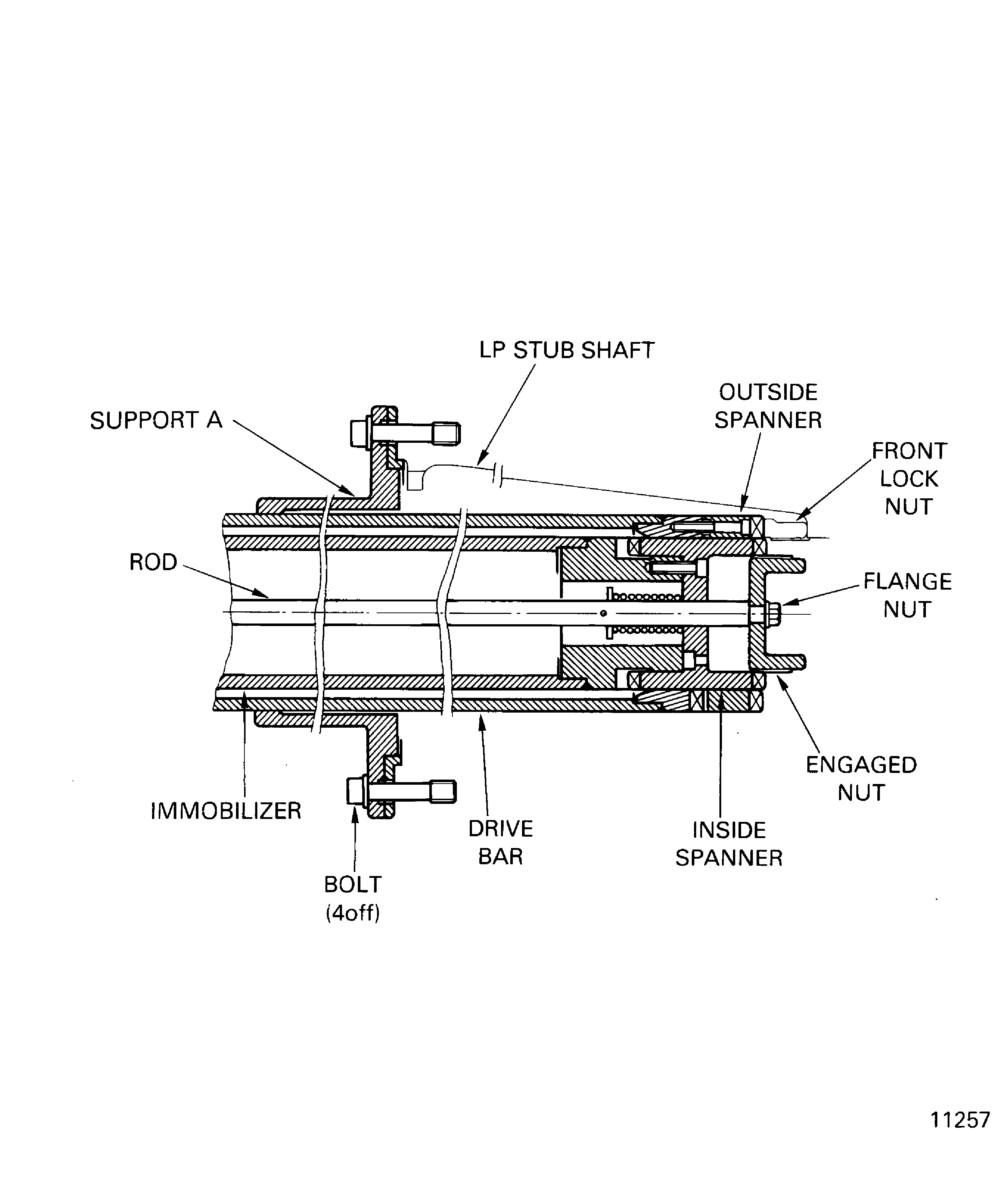

Refer to Figure.

Install the ring nut part of the IAE 1M14002 Support fixture 1 off on to the rear end of the LP turbine shaft.

Install the IAE 1M14005 Torque wrench 1 off to the ring nut.

Assemble the IAE 1F10019 Mechanical wrench 1 off with the IAE 1R19787 Sling 1 off to the torque wrench.

Install the IAE 1M14006 Immobilizing fixture 1 off on to the rear end of the LP turbine shaft. Lock the immobilizing fixture to the mechanical wrench with the immobilizer plate.

SUBTASK 72-00-50-020-068-A00 V2500-A1: Safety the Assembled Lifting Fixture to the LP Turbine Module without the Turbine Exhaust Case

Refer to Figure.

Install the ring nut part of IAE 1M14002 Support fixture 1 off on to the rear end of the LP turbine shaft.

Install the IAE 1M14005 Torque wrench 1 off to the ring nut.

Assemble the IAE 1F10019 Mechanical wrench 1 off with the IAE 1R19787 Sling 1 off to the torque wrench.

Install the IAE 1M14139 Immobilizing fixture 1 off on to the rear end of the LP turbine shaft. Lock the immobilizing fixture to the mechanical wrench with the immobilizer plate.

SUBTASK 72-00-50-020-068-B00 V2500-A5: Safety the Assembled Lifting Fixture to the LP Turbine Module without the Turbine Exhaust Case

Refer to Figure.

Install the support B, part of the IAE 1J12260 Spanner wrench 1 off to the retaining ring of the LP compressor fan disk. Attach the support B with the four bolts.

Assemble the IAE 1F10016 Mechanical wrench 1 off with hoist to the spanner wrench.

SUBTASK 72-00-50-020-069 Remove the Turbine Shaft Front Lock Nut

Refer to Figure.

CAUTION

HOLD THE BOLTS IN THEIR POSITION IF YOU LOOSEN AND REMOVE THE NUTS FROM THE BOLTS. DO NOT TURN THE BOLTS OR MAKE TO AND FRO MOVEMENTS. THE LP TURBINE CASE/HP TURBINE CASE FLANGE AND/OR THE BOLTS CAN BE DAMAGED.Remove the 100 nuts and bolts which attach the LP turbine case to the HP turbine case. Remove the seven brackets from the flange.

NOTE

The procedure in Step makes the release of the inner subassembly from the LP turbine shaft in step G easy.Hold the LP turbine shaft rear end and turn the inner subassembly counter clockwise by one turn to loosen it.

Install the inner subassembly of the hydraulic pusher/puller (which has a spanner, a plunger and a nut) into the threaded hole of the LP turbine shaft.

NOTE

Make sure that the hydraulic connection of the hydraulic cylinder is at the opposite side of the cylinder.Attach the outer subassembly of the hydraulic pusher/puller (which has a guide, a cylinder and a hydraulic cylinder) to the front flange of the LP stub shaft. The four stoppers of the guide must be in line with the scallops of the LP stub shaft.

Install the IAE 1J12220 Hydraulic pusher/puller 1 off to the front flange of the LP turbine stub shaft as follows:

Connect the IAE 1F10026 Hydraulic hand pump 1 off to the hydraulic connection on the hydraulic pusher/puller.

CAUTION

DO NOT SUPPLY THE HYDRAULIC PUSHER/PULLER WITH MORE THAN 7000 PSI (483 BAR) PRESSURE. TOO MUCH HYDRAULIC PRESSURE CAN CAUSE DAMAGE TO THE HYDRAULIC PUSHER/PULLER.NOTE

Tighten the jackscrews and operate the hydraulic pump at the same time to prevent overloading of the lifting fixture.Operate the hydraulic pump stepwise to disconnect the spline area between LP stub shaft and LP turbine shaft. During the same time tighten the jackscrews to break the tight fit. Apply an equal amount of force all around the flange to disengage the flanges smoothly.

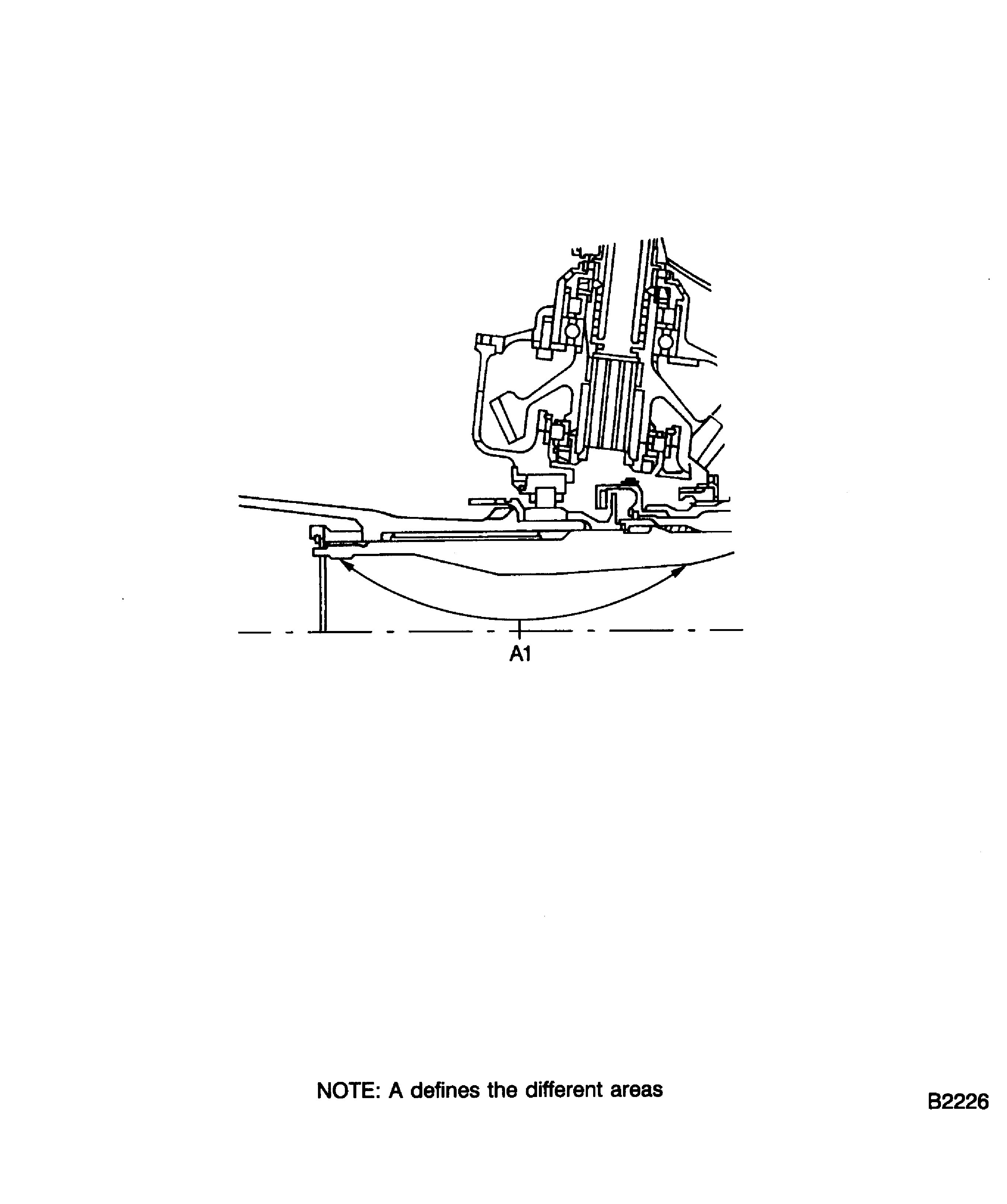

Put the dry ice on the area A1. Refer to Figure.

WARNING

DO NOT TOUCH THE DRY ICE WITHOUT PROTECTIVE GLOVES. DRY ICE CAN CAUSE REDDENING AND BLISTERING OF THE SKIN IF THE HANDS ARE NOT PROTECTED.Use CoMat 02-149 DRY ICE if you cannot disconnect the spline with 7000 psi (483 bar) pressure.

Loosen and remove the four screws which attach the pins to the guide of the IAE 1J12220 Hydraulic pusher/puller 1 off.

Remove the hydraulic pusher/puller from the LP stub shaft as follows:

SUBTASK 72-00-50-020-070-A01 V2500-A1 Method 1: Release the LP Turbine Module without the Turbine Exhaust Case from the LP Compressor/Intermediate Case Module

Refer to Figure.

CAUTION

HOLD THE BOLTS IN THEIR POSITION WHEN YOU REMOVE THE NUTS FROM THE BOLTS. DO NOT TURN THE BOLTS OR MAKE TO-AND-FRO MOVEMENTS. THE SHAFT/DISK FLANGE AND/OR THE BOLTS CAN BE DAMAGED BY SCORES.Remove the 100 nuts and bolts which attach the LP turbine case to the HP turbine case. Remove the seven brackets from the flange.

Install IAE 1J12512 Hydraulic pusher 1 off to the front flange of the LP stub shaft as follows:

Connect the IAE 1F10026 Hydraulic hand pump 1 off to the hydraulic connection on the hydraulic pusher.

NOTE

Tighten the jackscrews and operate the hydraulic pump at the same time to prevent overloading of the handling fixture.Slowly operate the hydraulic pump to disconnect the spline between the LP stub shaft and the LP turbine shaft. At the same time tighten the jackscrews to break the tight fit at the LP turbine case. Apply an equal amount of force all around the flange to disengage the flanges smoothly.

Remove the hydraulic pusher (Refer to Step).

Put the dry ice on to area A1. Refer to Figure.

Install the hydraulic pusher (Refer to Step).

WARNING

DO NOT TOUCH DRY ICE WITHOUT PROTECTIVE GLOVES. DRY ICE CAN CAUSE REDDENING AND BLISTERING OF THE SKIN IF THE HANDS ARE NOT PROTECTED.Cool the LP turbine shaft with CoMat 02-149 DRY ICE.

SUBTASK 72-00-50-020-070-A02 V2500-A1 Method 2: Release the LP Turbine Module from the LP Compressor/Intermediate Case Module.

Refer to Figure.

CAUTION

HOLD THE BOLTS IN THEIR POSITION WHEN YOU REMOVE THE NUTS FROM THE BOLTS. DO NOT TURN THE BOLTS OR MAKE TO-AND-FRO MOVEMENTS. THE LP TURBINE CASE/HP TURBINE CASE FLANGE AND/OR THE BOLTS CAN BE DAMAGED.Remove the 100 nuts and bolts which attach the LP turbine case to the HP turbine case. Remove the seven brackets from the flange.

NOTE

Make sure that the hydraulic connection of the hydraulic cylinder is at the opposite side of the cylinder.Attach the outer subassembly of the hydraulic pusher/puller (which has a guide, a cylinder and a hydraulic cylinder) to the front flange of the LP stub shaft. The four stoppers of the guide must be in line with the scallops of the LP stub shaft.

Install theIAE 1J12220 Hydraulic pusher/puller 1 off together with IAE 1J12270 Guide puller 1 off to the front flange of the LP turbine stub shaft as follows:

Connect the IAE 1F10026 Hydraulic hand pump 1 off to the hydraulic connection on the hydraulic pusher/puller.

CAUTION

DO NOT SUPPLY THE HYDRAULIC PUSHER/PULLER WITH MORE THAN 7000 PSI (483 BAR) PRESSURE. TOO MUCH HYDRAULIC PRESSURE CAN CAUSE DAMAGE TO THE HYDRAULIC PUSHER/PULLER.NOTE

Tighten the jackscrews and operate the hydraulic pump at the same time to prevent overloading of the lifting fixture.Operate the hydraulic pump stepwise to disconnect the spline area between LP stub shaft and the LP turbine shaft. At the same time tighten the jackscrews to break the tight fit. Apply an equal amount of force all around the flange to disengage the flanges smoothly.

Put the dry ice on the area A1. Refer to Figure.

Do Step.

WARNING

DO NOT TOUCH DRY ICE WITHOUT PROTECTIVE GLOVES. DRY ICE CAN CAUSE REDDENING AND BLISTERING OF THE SKIN IF THE HANDS ARE NOT PROTECTED.Use CoMat 02-149 DRY ICE if you cannot disconnect the spline with 7000 psi (483 bar) pressure.

Loosen and remove the four screws which attach the pins to the guide of the IAE 1J12220 Hydraulic pusher/puller 1 off together with the IAE 1J12270 Guide puller.

Remove the hydraulic pusher/puller from the LP stub shaft as follows:

SUBTASK 72-00-50-020-070-B01 V2500-A5 Method 1: Release the LP Turbine Module without the Turbine Exhaust Case from the LP Compressor/Intermediate Case Module

Refer to Figure.

CAUTION

HOLD THE BOLTS IN THEIR POSITION WHEN YOU REMOVE THE NUTS FROM THE BOLTS. DO NOT TURN THE BOLTS OR MAKE TO-AND-FRO MOVEMENTS. THE SHAFT/DISK FLANGE AND/OR THE BOLTS CAN BE DAMAGED BY SCORES.Remove the 100 nuts and bolts which attach the LP turbine case to the HP turbine case. Remove the seven brackets from the flange.

Install IAE 1J12512 Hydraulic pusher 1 off to the front flange of the LP stub shaft as follows:

Connect the IAE 1F10026 Hydraulic hand pump 1 off to the hydraulic connection on the hydraulic pusher.

If the LP turbine shaft does not move within the maximum pressure, stop pressure supply. Go to Step.

NOTE

Tighten the jackscrews and operate the hydraulic pump at the same time to prevent overloading of the handling fixture.Slowly operate the hydraulic pump to disconnect the spline between the LP stub shaft and the LP turbine shaft. At the same time tighten the jackscrews to break the tight fit at the LP turbine case. Apply an equal amount of force all around the flange to disengage the flanges smoothly.

Remove the hydraulic pusher (Refer to Step).

Put the dry ice on to area A1. Refer to Figure.

Install the hydraulic pusher (Refer to Step).

WARNING

DO NOT TOUCH DRY ICE WITHOUT PROTECTIVE GLOVES. DRY ICE CAN CAUSE REDDENING AND BLISTERING OF THE SKIN IF THE HANDS ARE NOT PROTECTED.Cool the LP turbine shaft with CoMat 02-149 DRY ICE.

SUBTASK 72-00-50-020-070-B02 V2500-A5 Method 2: Release the LP Turbine Module from the LP Compressor/Intermediate Case Module.

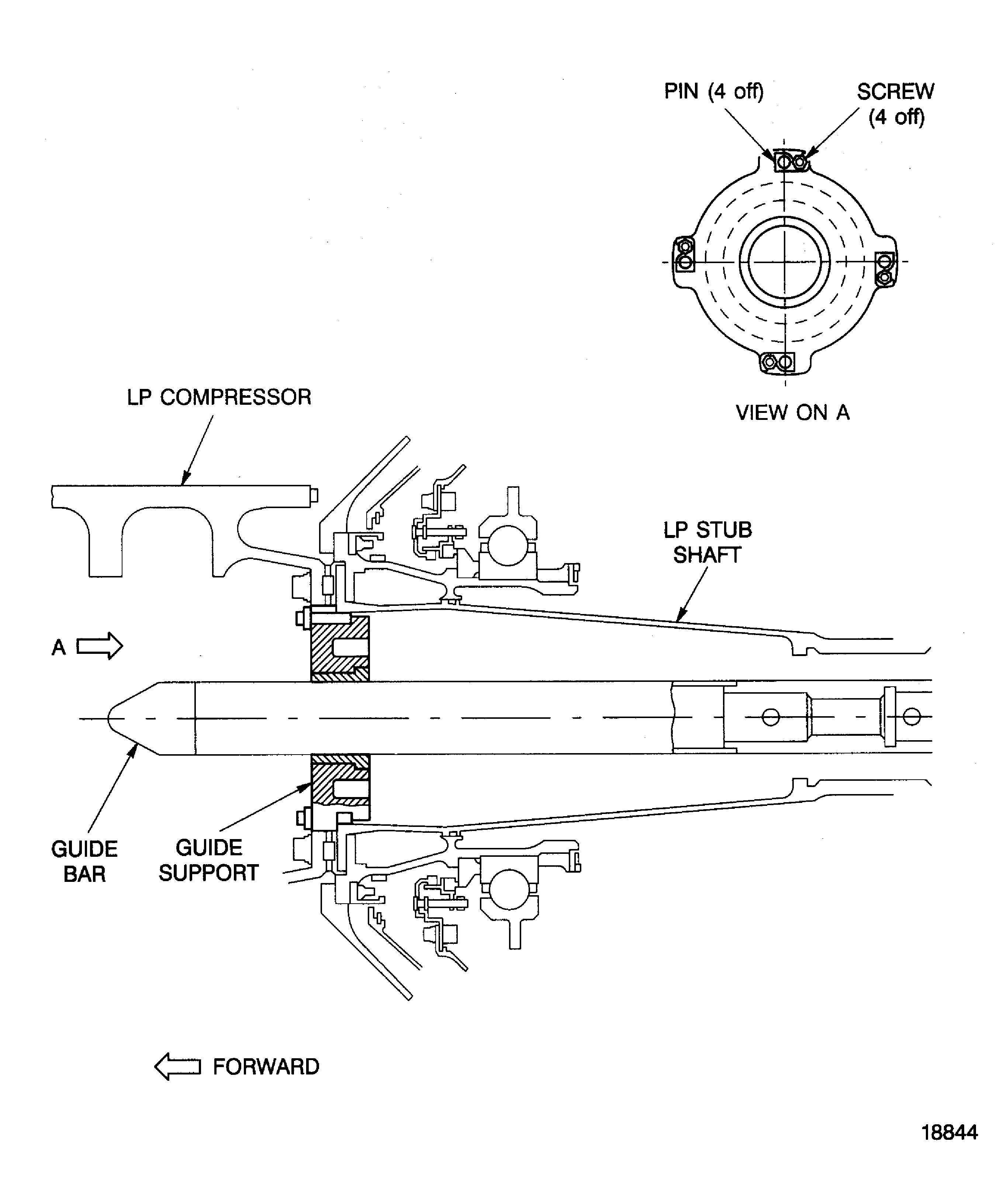

Divide the IAE 1J12280 Guide bar 1 off into the two guide bars. Connect the guide bar of which two ends are flat to the inner thread of the LP turbine shaft.

Install IAE 1J12277 Guide support 1 off (V2500-A1) to the stub shaft front flange as follows: Refer to Figure.

Install the guide ring A2 (part of the IAE 1J12280 Guide bar 1 off) on to the lock nut at the rear face of the stage 2 turbine disk as follows: Refer to Figure.

Install the IAE 1M14127 Support plate 2 off in the six o-clock and 12 o-clock position onto the LP turbine case front flange. Connect each support plate with the seven bolts and nuts. Refer to Figure.

SUBTASK 72-00-50-020-071-A00 V2500-A1: Prepare the LP Turbine Module without the Turbine Exhaust Case for Removal

Divide the IAE 1J12280 Guide bar 1 off into the two guide bars. Connect the guide bar of which two ends are flat to the inner thread of the LP turbine shaft.

Install IAE 1J12269 Guide support 1 off (V2500-A5) to the stub shaft front flange as follows: Refer to Figure.

Install the guide ring A2 (part of the IAE 1J12280 Guide bar 1 off) on to the lock nut at the rear face of the stage 2 turbine disk. Refer to Figure.

Install the IAE 1M14146 Support plate 2 off in the six o-clock and twelve o-clock position on the LP turbine case front flange. Connect each support plate with the seven bolts and nuts. Refer to Figure.

SUBTASK 72-00-50-020-071-B00 V2500-A5: Prepare the LP Turbine Exhaust Case, for Removal

Remove the guide ring A2 and install the guide ring A3 to the lock nut at the rear flange of the stage 2 disk. Refer to Figure.

Remove the guide ring A3 and install the guide ring A1 to the lock nut at the rear flange of the stage 2 turbine disk. Refer to Figure.

Remove the adjusting ring from the LP turbine shaft. Use the IAE 1J12282 Expanding pliers 1 off. Refer to Figure.

CAUTION

INCREASE THE TEMPERATURE OF THE LP TURBINE SHAFT IMMEDIATELY AFTER THE LPT MODULE REMOVAL. IF THE LP TURBINE SHAFT STAYS COOL FOR A LONG TIME, CONDENSATION CAN BE CAUSED ON THE SHAFT.

CAUTION

DO NOT USE A BURNER. THE USE OF A BURNER CAN DAMAGE THE LP TURBINE SHAFT.Increase the metal temperature of the LP turbine shaft in the area A1 to room temperature with a hot air gun. Refer to Figure.

Remove the dry ice if it is used.

SUBTASK 72-00-50-020-072 Remove the LP Turbine Module without the Turbine Exhaust Case

Refer to Figure.

Open the block of the front support (part of the IAE 1F10080 Horizontal stand 1 off). Remove the shaft.

Tighten the ring nuts A and B to the support to hold the LP Turbine shaft of the LP turbine module without the turbine exhaust case in the horizontal stand. Refer to Figure.

SUBTASK 72-00-50-020-103 Install the LP Turbine Module without the Turbine Exhaust Case to the Horizontal Stand

Loosen and remove the four screws which attach the pins to the IAE 1J12277 Guide support 1 off.

Remove the guide support from the engine.

SUBTASK 72-00-50-020-073-A00 V2500-A1: Remove the Tools from the LP Turbine Module without the Turbine Exhaust Case

Loosen and remove the four screws which attach the pins to the IAE 1J12269 Guide support 1 off.

Remove the guide support from the engine.

SUBTASK 72-00-50-020-073-B00 V2500-A5: Remove the Tools from the LP Turbine Module without the Turbine Exhaust Case

Refer to Figure.

Install the IAE 1M14005 Torque wrench 1 off to the ring nut part of the IAE 1M14002 Support fixture 1 off.

Assemble the IAE 1F10019 Mechanical wrench 1 off with the IAE 1R19787 Sling 1 off to the torque wrench.

Install the IAE 1M14006 Immobilizing fixture 1 off on to the rear end of the LP turbine shaft. Lock the immobilizing fixture to the mechanical wrench with the immobilizer plate.

SUBTASK 72-00-50-020-104-A00 V2500-A1: Release the Assembled Lifting Fixture from the LP Turbine Module without the Turbine Exhaust Case

Refer to Figure.

Install the IAE 1M14005 Torque wrench 1 off to the ring nut (part of the IAE 1M14002 Support fixture 1 off).

Assemble the IAE 1F10019 Mechanical wrench 1 off with the IAE 1R19787 Sling 1 off to the torque wrench.

Install the IAE 1M14139 Immobilizing fixture 1 off on to the rear end of the LP turbine shaft. Lock the immobilizing fixture to the mechanical wrench with the immobilizer plate.

SUBTASK 72-00-50-020-104-B00 V2500-A5: Release the Assembled Lifting Fixture from the LP Turbine Module without the Turbine Exhaust Case

Refer to Figure.

Install the IAE 1F10074 Guide pogo stick 1 off to the inner diameter of the LP turbine shaft. Use applicable webbing sling.

Put the IAE 1F10075 Support pedestal 1 off below the guide pogo stick near to the rear end of the guide pogo stick.

Install the IAE 1F10075 Support pedestal 1 off between the rear flange of the LP turbine case and the lifting fixture.

SUBTASK 72-00-50-020-074-A00 V2500-A1: Install the Guide Pogo Stick and remove the Lifting Fixture

Refer to Figure.

Install the IAE IAE 1P16377 Guide support 1 off to the inner diameter of the LP turbine shaft. Use an applicable webbing sling.

Put the IAE IAE 1F10075 Support pedestal 1 off below the guide support near to the rear end of the guide support.

Install the IAE IAE 1F10075 Support pedestal 1 off between the rear flange of the LP turbine case and the lifting fixture.

SUBTASK 72-00-50-020-074-B00 V2500-A5: Install the Guide Support and Remove the Lifting Fixture

Refer to Figure.

Install the IAE 1M14086 Supporting fixture or the IAE 1M14461 Supporting fixture 1 off at the 12 o-clock position to the LP turbine case. Attach the supporting fixture with the four screws.

SUBTASK 72-00-50-020-075-A00 V2500-A1: Install the Supporting Fixture

NOTE

Measure the inner hub diameter of Stage 7 Disk before you install the supporting fixture.NOTE

If the inner hub diameter is 12.595 in. (319.9 mm) use IAE 1M14086 Supporting fixtureIf the inner hub diameter is 12.441 in. (316 mm) use IAE 1M14461 Supporting fixtureRefer to Figure.

Install the IAE 1M14143 Support fixture or the IAE 1M14461 Supporting fixture 2 off at the 12 o-clock position to the LP turbine case. Attach the supporting fixture with the four screws.

SUBTASK 72-00-50-020-075-B00 V2500-A5: Install the Supporting Fixture

NOTE

Measure the inner hub diameter of Stage 7 Disk before you install the supporting fixture.NOTE

If the inner hub diameter is 12.595 in. (319.9 mm) use IAE 1M14143 Support fixtureIf the inner hub diameter is 12.441 in. (316 mm) use IAE 1M14461 Supporting fixtureRefer to Figure.

Remove the IAE IAE 1F10075 Support pedestal 1 off.

Remove the IAE IAE 1F10074 Guide pogo stick 1 off from the LP turbine shaft.

SUBTASK 72-00-50-020-076-A00 V2500-A1: Remove the Guide Pogo Stick

Refer to Figure.

Remove the IAE IAE 1F10075 Support pedestal 1 off.

Remove the IAE IAE 1P16377 Guide support 1 off from the LP turbine shaft.

SUBTASK 72-00-50-020-076-B00 V2500-A5: Remove the Guide Support

Refer to Figure.

Remove the IAE IAE 1M14003 Support arm 2 off from the IAE IAE 1M14000 Lifting fixture 1 off.

SUBTASK 72-00-50-540-051 Disassemble the Lifting Fixture and the Support Fixture

Figure: V2500-A1: Install the Guide Pogo Stick to the LP Turbine Module Without the Turbine Exhaust Case

V2500-A1: Install the Guide Pogo Stick to the LP Turbine Module Without the Turbine Exhaust Case

Figure: V2500-A5: Install the Guide Support to the LP Turbine Module Without the Turbine Exhaust Case

V2500-A5: Install the Guide Support to the LP Turbine Module Without the Turbine Exhaust Case

Figure: V2500-A1: Install the Lifting Fixture and Remove the Guide Pogo Stick

V2500-A1: Install the Lifting Fixture and Remove the Guide Pogo Stick

Figure: V2500-A5: Install the Lifting Fixture and Remove the Guide Support

V2500-A5: Install the Lifting Fixture and Remove the Guide Support

Figure: Install the Lifting Fixture on to the LP Turbine Module without the Turbine Exhaust Case

Install the Lifting Fixture on to the LP Turbine Module without the Turbine Exhaust Case

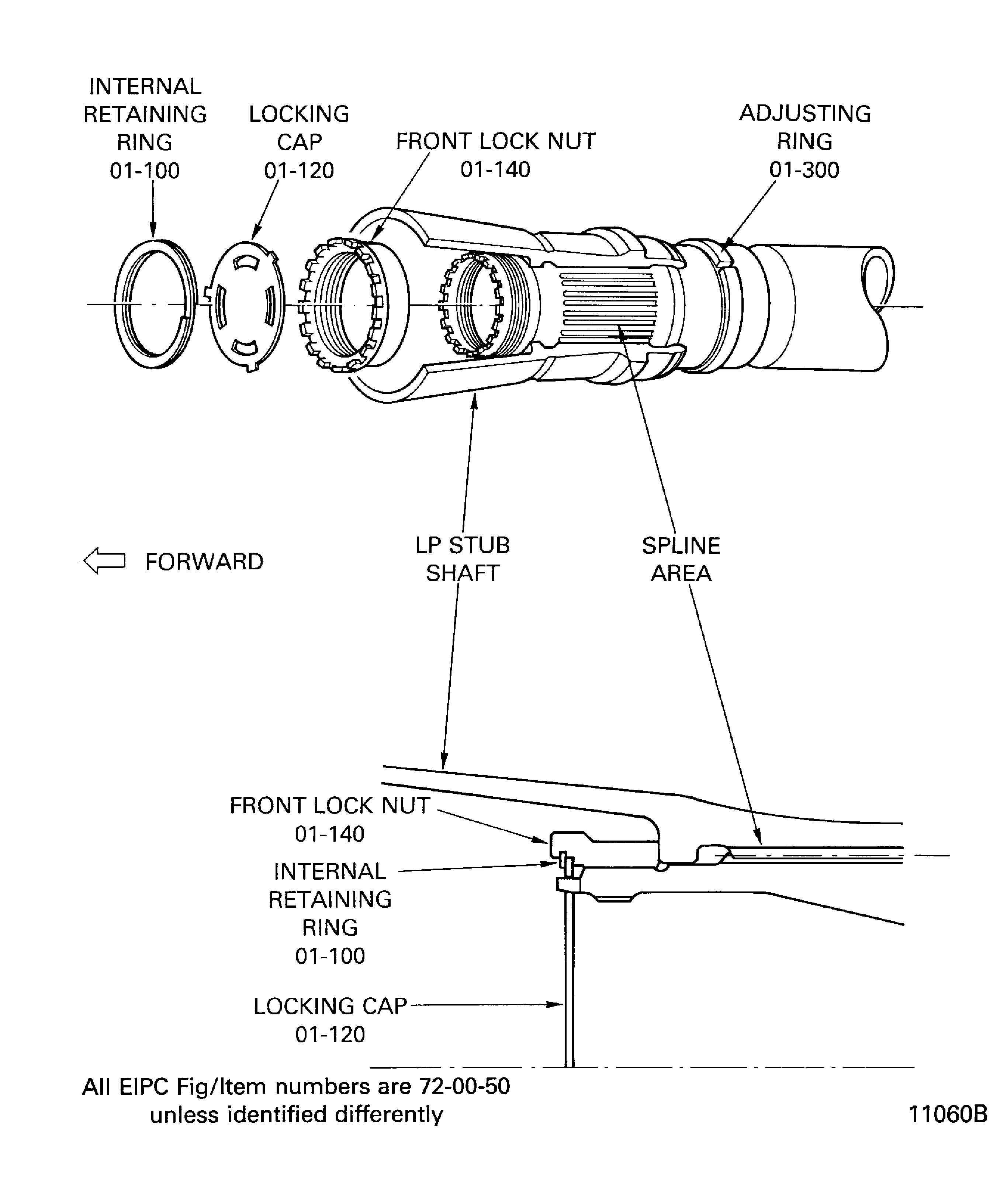

Figure: Remove the Turbine Shaft Front Lock Nut

Remove the Turbine Shaft Front Lock Nut

Figure: Remove the Turbine Shaft Front Lock Nut

Remove the Turbine Shaft Front Lock Nut

Figure: V2500-A1Method 1: Release the LP Turbine Module without the Turbine Exhaust Case from the LP Compressor

V2500-A1Method 1: Release the LP Turbine Module without the Turbine Exhaust Case from the LP Compressor

Figure: V2500-A1 Method 2: Release the LP Turbine Module without the Turbine Exhaust Case from the LP Compressor

V2500-A1 Method 2: Release the LP Turbine Module without the Turbine Exhaust Case from the LP Compressor

Figure: V2500-A5 Method 1: Release the LP Turbine Module without the Turbine Exhaust Case from the LP Compressor

V2500-A5 Method 1: Release the LP Turbine Module without the Turbine Exhaust Case from the LP Compressor

Figure: V2500-A5Method 2: Release the LP Turbine Module without the Turbine Exhaust Case from the LP Compressor

V2500-A5Method 2: Release the LP Turbine Module without the Turbine Exhaust Case from the LP Compressor

Figure: V2500-A1: Installation of the Guide Support and the Guide Bar

V2500-A1: Installation of the Guide Support and the Guide Bar

Figure: V2500-A5: Installation of the Guide Support and the Guide Bar

V2500-A5: Installation of the Guide Support and the Guide Bar

Figure: Installation of the Guide Rings

Installation of the Guide Rings

Figure: Remove the Support Plate

Remove the Support Plate

Figure: Install the Supporting Fixture to the LP Turbine Module without the Turbine Exhaust Case

Install the Supporting Fixture to the LP Turbine Module without the Turbine Exhaust Case

Figure: Installation of the LP Turbine Module without the Turbine Exhaust Case to the Horizontal Stand

Installation of the LP Turbine Module without the Turbine Exhaust Case to the Horizontal Stand

Figure: Installation of the LP Turbine Module without the Turbine Exhaust Case to the Horizontal Stand

Installation of the LP Turbine Module without the Turbine Exhaust Case to the Horizontal Stand

Figure: Removal of the Adjusting Ring

Removal of the Adjusting Ring

Figure: Dry Ice Applied Area

Dry Ice Applied Area