Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-60-300-004 External Gearbox Module - Front Link - Replace The Spherical Bearing, Repair-004 (VRS5384)

General

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Arbor Press | LOCAL | Arbor press | ||

| Cutting tool | LOCAL | Cutting tool | ||

| IAE 3F10377 Base, remove/install | 0AM53 | IAE 3F10377 | 1 | |

| IAE 3F10378 Drifts, remove/install | 0AM53 | IAE 3F10378 | 1 | |

| Oven | LOCAL | Oven | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 02-099 LINT-FREE CLOTH | X222X | CoMat 02-099 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | X222X | CoMat 06-063 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| BEARING, SPHERICAL | 0AM53 | 4T0130 | A/R | |

| BEARING, SPHERICAL | 0AM53 | 4T0131 | A/R | |

| BEARING, SPHERICAL | 0AM53 | 4T0132 | A/R |

Safety Requirements

NONEProcedure

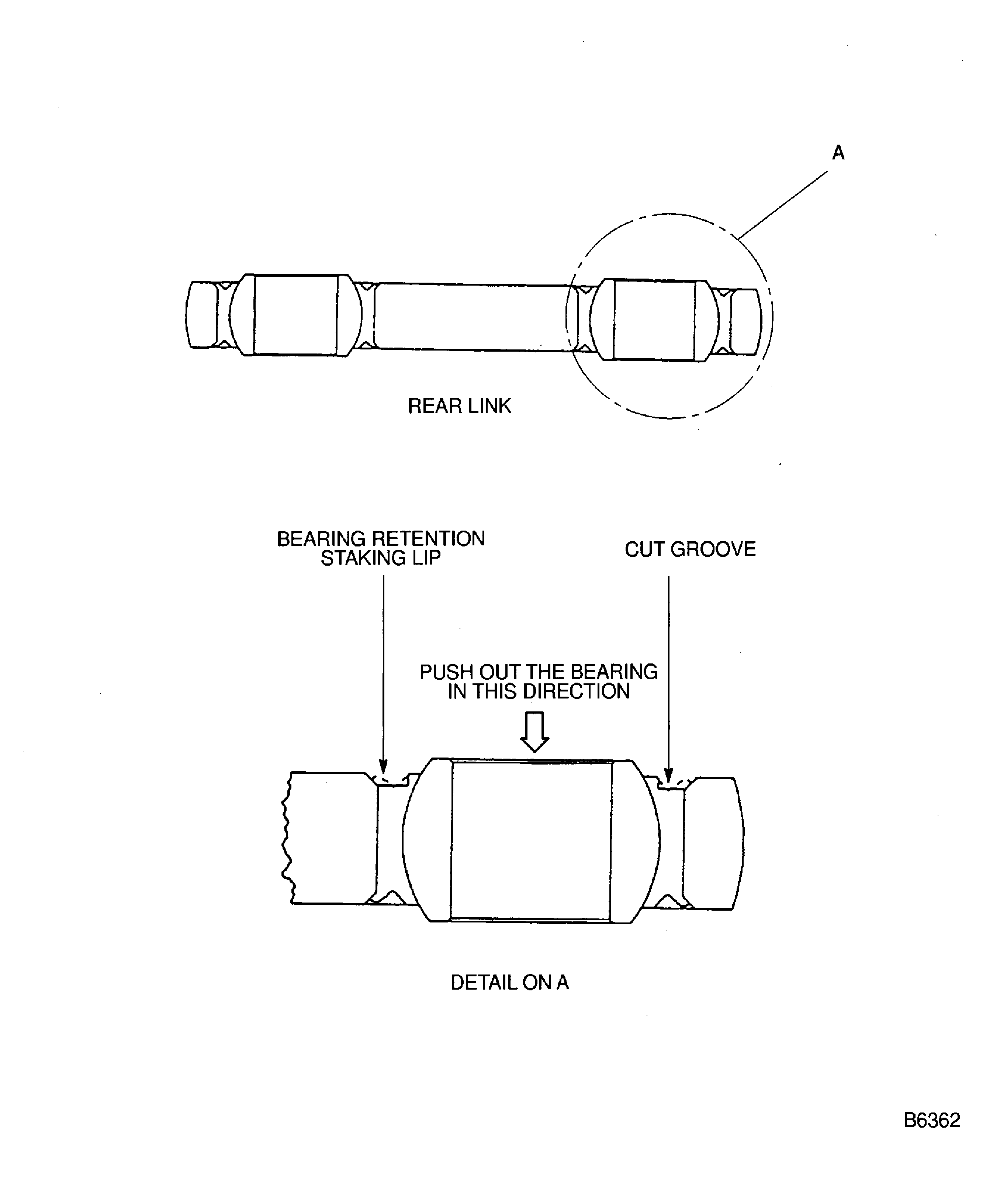

Refer to Figure.

Use IAE 3F10377 Base, remove/install 1 off.

CAUTION

DO NOT PERMIT THE CUTTING TOOL TO TOUCH THE LINK. THIS WILL CAUSE DAMAGE TO THE LINK.

CAUTION

REMOVE ALL STAKING LIP PIECES BEFORE YOU PUSH OUT THE BEARING. THESE MIGHT CAUSE DAMAGE TO THE LINK BORE.Install the front link in the base.

Push the spherical bearing on the side where the staking lip has been removed.

Use IAE 3F10378 Drifts, remove/install 1 off.

Push out the bearing.

SUBTASK 72-00-60-350-064 Remove the Bearing

Refer to the SPM TASK 70-23-01-230-501.

Use CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) with penetrant crack test equipment.

Examine one bore at a time.

Cracks are not permitted.

Do a penetrant crack test.

SUBTASK 72-00-60-220-086 Examine the Front Link Bearing Bore

Use CoMat 02-099 LINT-FREE CLOTH made moist with CoMat 01-124 ISOPROPYL ALCOHOL.

Clean the link and the bearing.

SUBTASK 72-00-60-110-066 Clean the Link and the New Bearing

Refer to Figure.

CAUTION

DO NOT TOUCH THE HOT PARTS WITHOUT PROTECTIVE GLOVES.HOT PARTS CAN CAUSE REDDENING AND BLISTERING OF THE SKIN IF THE HANDS ARE NOT PROTECTED.IMMERSE THE CONTACTED AREA IN COLD WATER FOR 10 MINUTES IF THE SKIN IS BURNED, IMMEDIATELY GET THE MEDICAL ATTENTION IF PAIN OR BLISTERING PERSISTS.Increase the temperature of the link.

Use a brush to apply a coat of CoMat 10-077 APPROVED ENGINE OILS to the link bore surface and to the outside surface of the bearing.

Apply the engine oil.

Use IAE 3F10377 Base, remove/install 1 off.

Install the link on the base.

Use an arbor press and IAE 3F10378 Drifts, remove/install 1 off, to press the bearing in to the link bore.

Apply a maximum load of 1101.5 lbf (500 kg).

CAUTION

DO NOT PRESS ON THE BALL OF THE BEARING.Install the bearing.

SUBTASK 72-00-60-350-065 Install the New Spherical Bearing

Refer to Figure.

Use IAE 3F10377 Base, remove/install 1 off.

Install the link on the guide of the base (1st calking).

Use IAE 3F10378 Drifts, remove/install 1 off and an arbor press.

Apply a gradually increasing load until the bearing retention staking lip is bent sufficiently. Load must not be more than 17624 lbf (8000 kg).

Initially stake the bearing.

Use IAE 3F10378 Drifts, remove/install and an arbor press.

Apply a gradually increasing load until the retention lip of the bearing race contacts the bore chamfer of the link. Load must not be more than 17624 lbf (8000 kg).

Finally stake the bearing.

SUBTASK 72-00-60-350-066 Fasten the Bearing to the Link

Refer to Figure.

SUBTASK 72-00-60-350-067 Examine the Assembled Bearing

Refer to Figure.

Refer to the SPM TASK 70-09-00-400-501.

Make a mark VRS5384 adjacent to the part number.

SUBTASK 72-00-60-350-068 Identify the Repair

Figure: Repair details and dimensions

Repair details and dimensions