Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-31-11-300-007 LPC Fan Blade - Repair The Airfoil Damage, Repair-007 (VRS1002)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-300 | 6A3494 |

01-300 | 6A3971 |

01-300 | 6A5485 |

01-300 | 6A6519 |

01-300 | 6A7403 |

01-300 | 6A7613 |

01-300 | 6A7649 |

01-300 | 6A7650 |

01-300 | 6A7651 |

01-300 | 6A7652 |

01-300 | 6A7653 |

01-300 | 6A7656 |

01-300 | 6A7658 |

General

Deterioration of SFC and fan balance will occur when fan blades are dressed to this TASK.

The maximum number of dressed blades for a given fan set is the equivalent of three blades dressed to the maximum limits. All the remaining blades not to be dressed. This maximum number of dressed blades must be obeyed to prevent a risk of blade vibration.

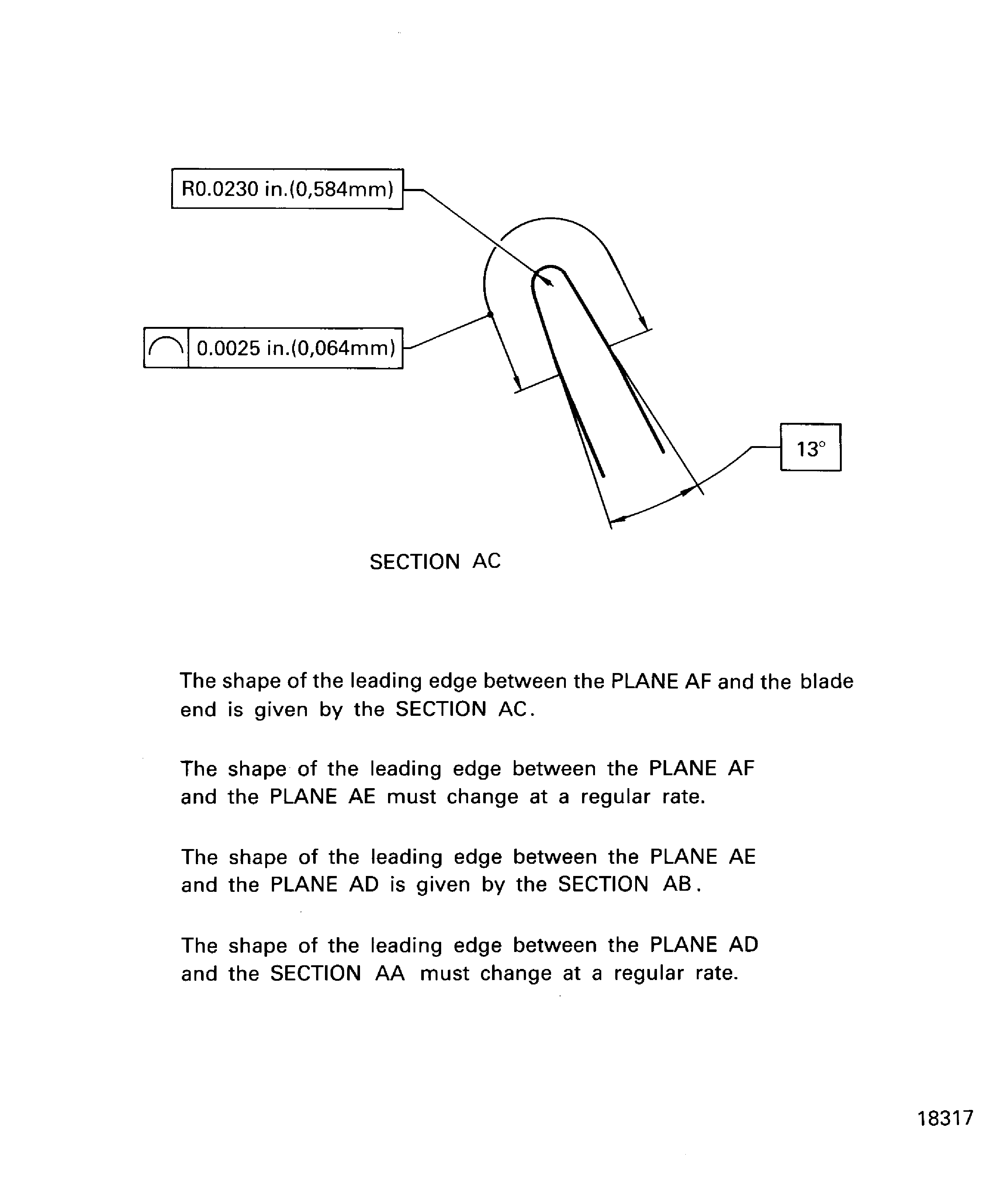

Scallops and crops are permitted on the same blade, refer to Figure.

The blades repaired on installed engines must be glass bead peened at the next shop visit.

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Portablegrinding equipment | LOCAL | Portable grinding equipment | ||

| Glass bead peening equipment | LOCAL | Glass bead peening equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| IAE 3R19016 LE profile gage | 0AM53 | IAE 3R19016 | 1 | |

| IAE 3R19017 LE profile gage | 0AM53 | IAE 3R19017 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-075 WATERPROOF SILICON CARBIDE | IE241 | CoMat 05-075 | ||

| CoMat 05-076 WATERPROOF SILICON CARBIDE | K3895 | CoMat 05-076 | ||

| CoMat 05-077 WATERPROOF SILICON CARBIDE | K6835 | CoMat 05-077 | ||

| CoMat 05-078 WATERPROOF SILICON CARBIDE | K3895 | CoMat 05-078 | ||

| CoMat 05-079 WATERPROOF SILICON CARBIDE | K3895 | CoMat 05-079 | ||

| CoMat 05-080 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-080 | ||

| CoMat 05-081 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-081 | ||

| CoMat 05-082 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-082 | ||

| CoMat 05-083 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-083 | ||

| CoMat 05-084 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-084 | ||

| CoMat 05-085 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-085 |

Spares

NONESafety Requirements

CAUTION

Procedure

Refer to the SPM TASK 70-23-03-230-501.

Use penetrant crack test facility or local crack test equipment, if repair is to be done on-wing.

CAUTION

DO NOT PUT THE PART FULLY INTO THE SOLUTION IF THE LP COMPRESSOR BLADE ASSEMBLY IS POST SB72-0375 OR POST SB72-0384. ENSURE THAT THE PENETRANT FLUIDS DO NOT MAKE CONTACT WITH THE BLADE ROOT DOVETAIL FACES.Do a penetrant crack test to find all the damage.

SUBTASK 72-31-11-230-054 Examine the LPC Rotor Blade Assembly for Cracks

Cutaway until all damage is removed.

CAUTION

TITANIUM COMPONENTS. SILICON CARBIDE TYPE WHEELS, STONES AND ABRASIVE PAPERS ARE TO BE USED FOR THIS REPAIR.ALUMINUM OXIDE TYPES MUST NOT BE USED.THE MATERIAL WILL OXIDIZE AND CRACK IF MECHANICAL CUTTERS ARE USED HEAVILY. THIS HAS OCCURRED IF THE COMPONENT SHOWS DARK STRAW TO BLUE DISCOLORATION. IF AT ANY TIME THIS COLORATION OCCURS THE BLADE MUST BE REJECTED.Cutaway to remove cracks and/or damage.

SUBTASK 72-31-11-350-052 Remove the Damage from the LPC Rotor Blade Assembly

SUBTASK 72-31-11-350-053 Repair the Leading Edge

Refer to the SPM TASK 70-23-03-230-501.

Use penetrant crack test facility or local crack test equipment, if repair is to be done on-wing.

CAUTION

DO NOT PUT THE PART FULLY INTO THE SOLUTION IF THE LP COMPRESSOR BLADE ASSEMBLY IS POST SB72-0375 OR POST SB72-0384. ENSURE THAT THE PENETRANT FLUIDS DO NOT MAKE CONTACT WITH THE BLADE ROOT DOVETAIL FACES.Do a penetrant crack test for the repaired area.

SUBTASK 72-31-11-220-060 Examine the LPC Rotor Blade Assembly

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 72-09-00-400-001.

Make a mark VRS1002 adjacant to the part number.

SUBTASK 72-31-11-350-054 Identify the Repair on the LPC Rotor Blade Assembly

Figure: Fan blade cropping

Fan blade cropping

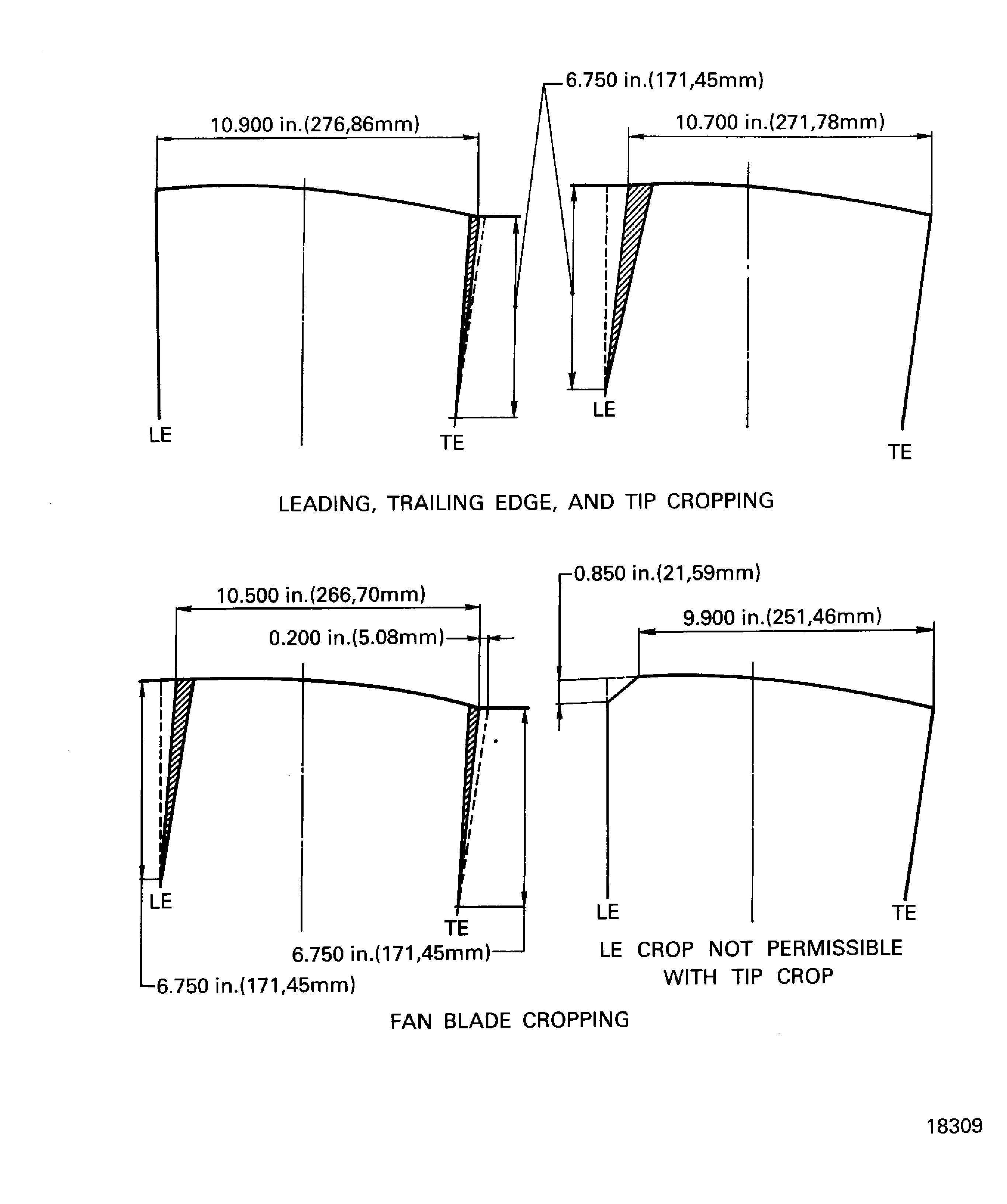

Figure: Fan blade scalloping limits

Fan blade scalloping limits

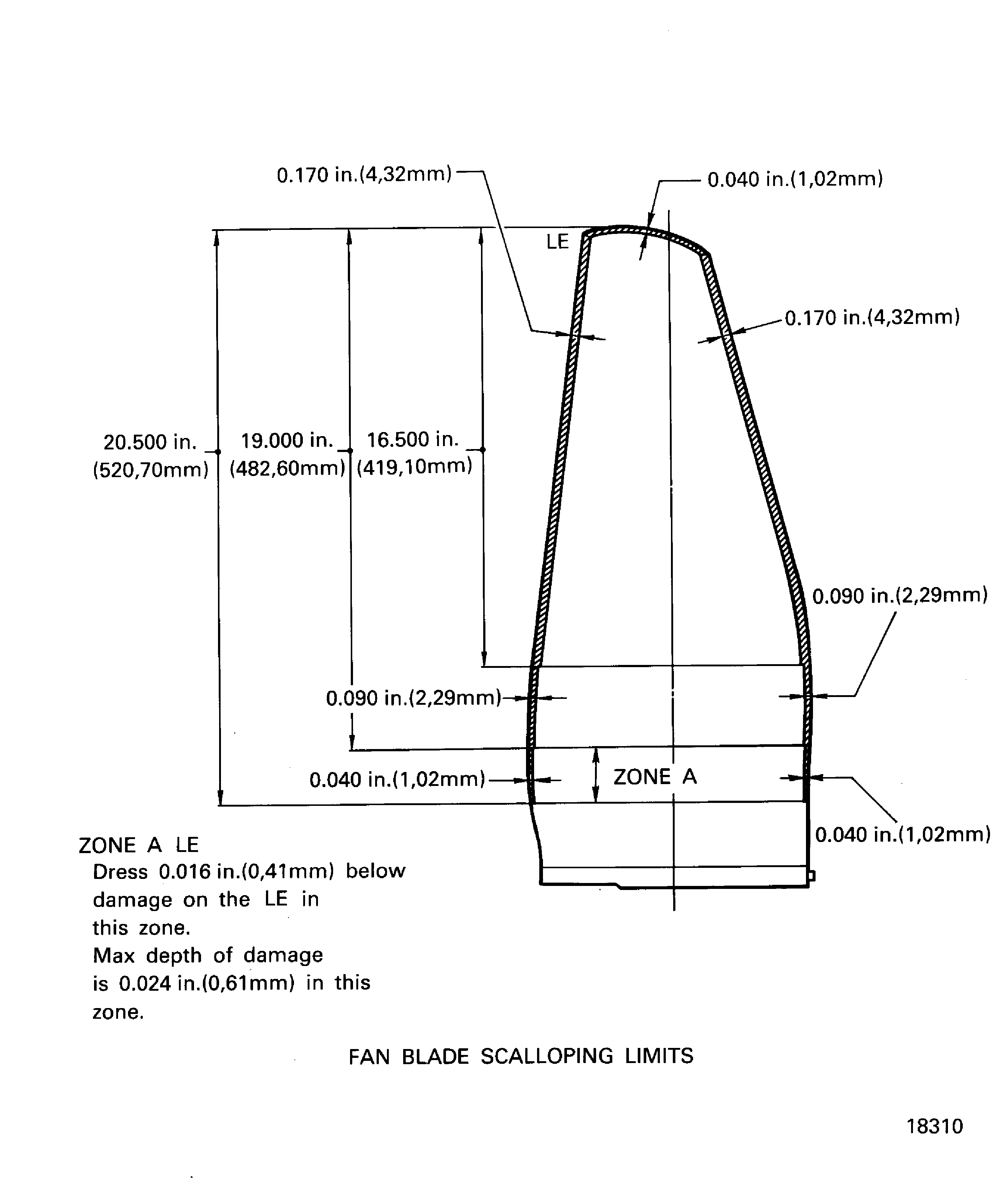

Figure: Fan blade scalloping limits

Fan blade scalloping limits

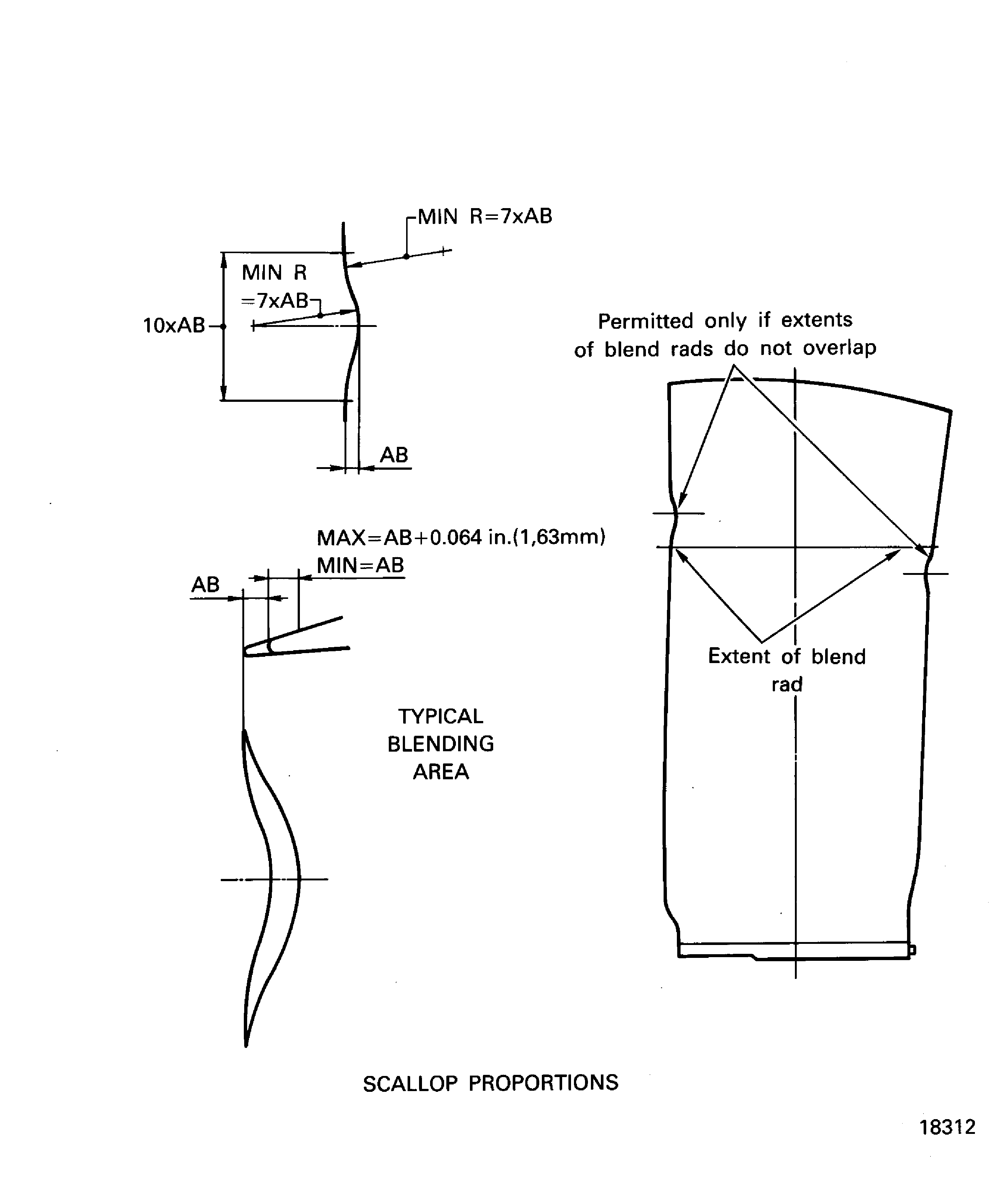

Figure: Scallop proportions

Scallop proportions

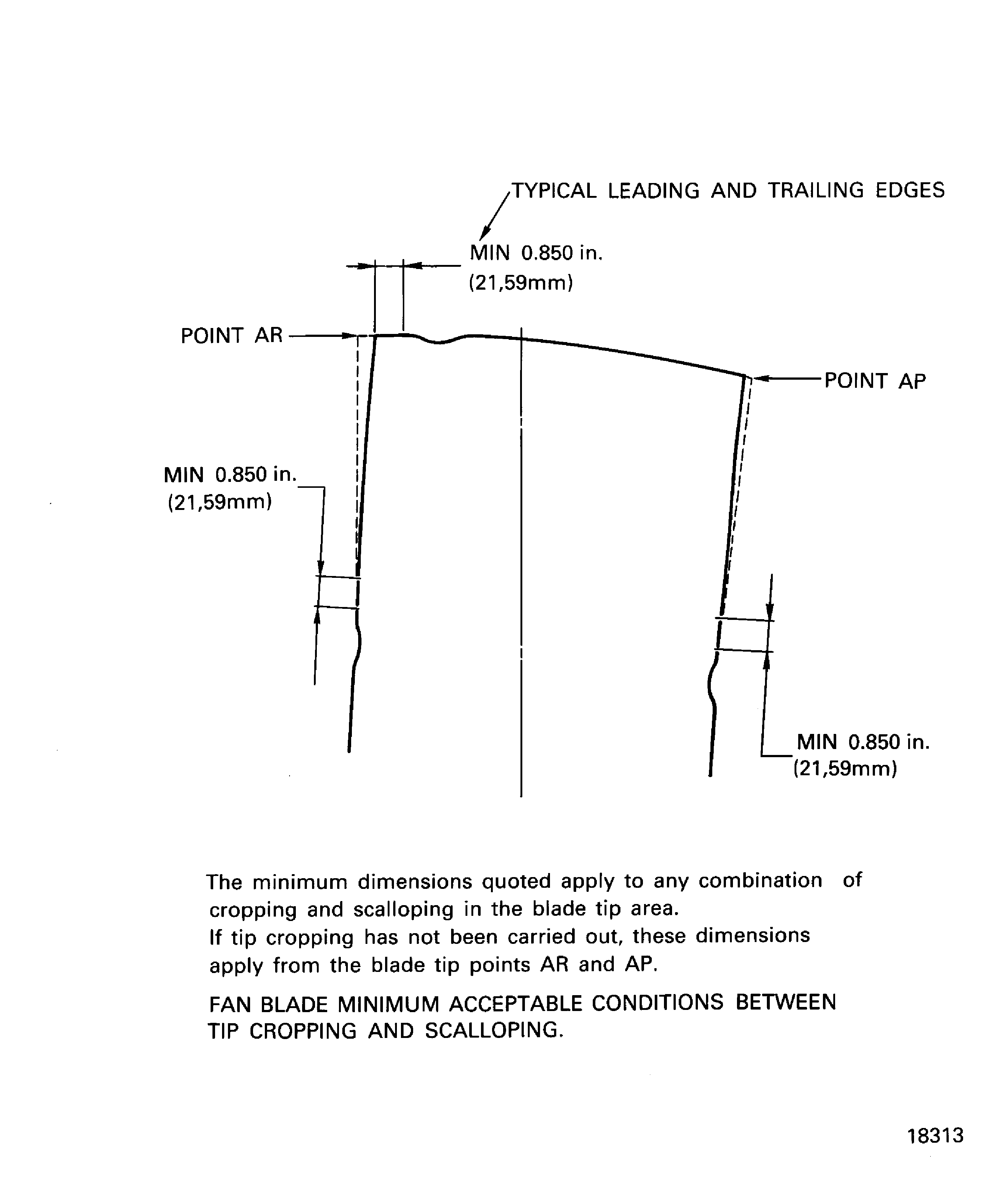

Figure: Fan blade minimum acceptable conditions between tip cropping and scalloping

Fan blade minimum acceptable conditions between tip cropping and scalloping

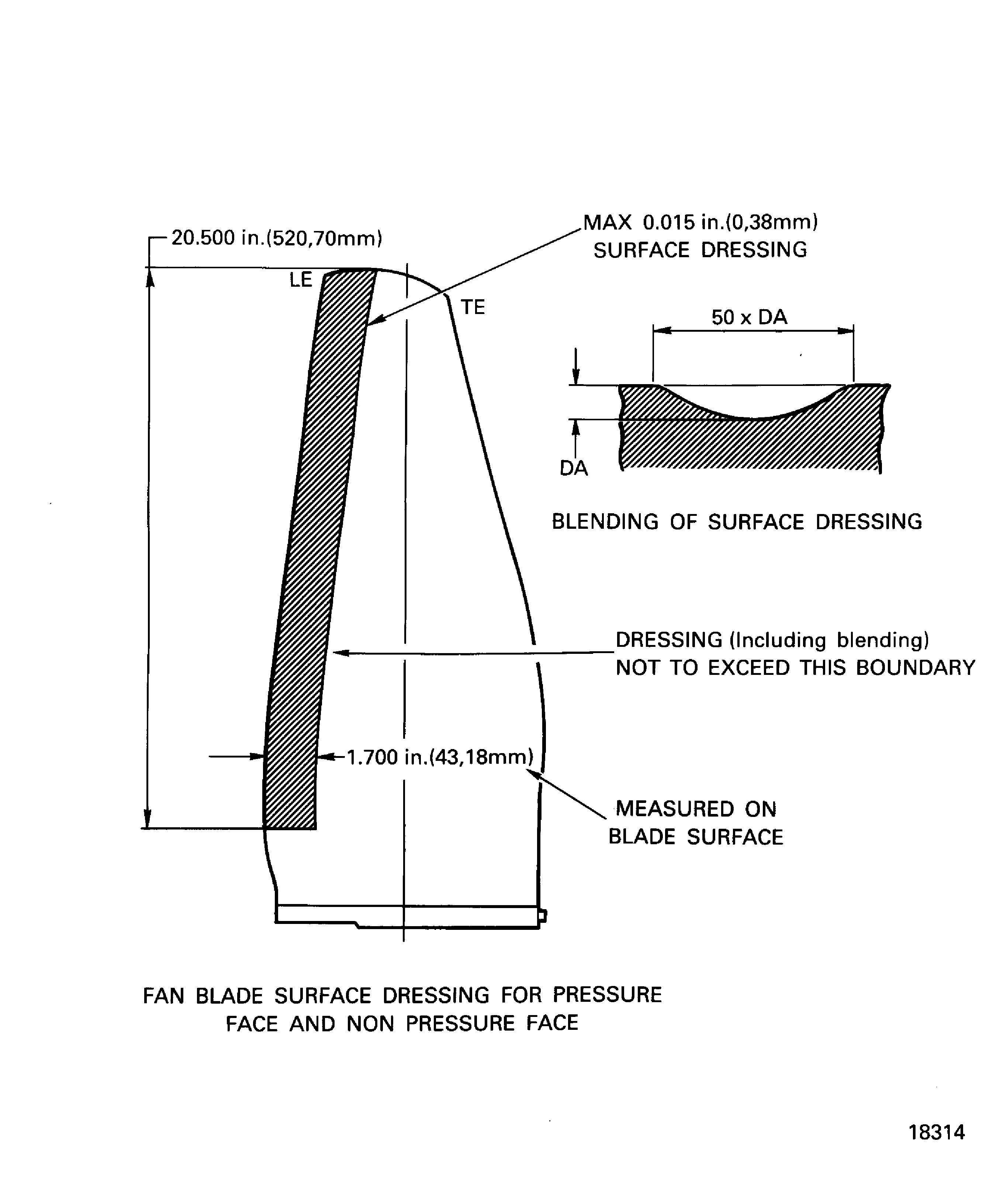

Figure: Fan blade surface dressing for pressure face and non pressure face

Fan blade surface dressing for pressure face and non pressure face

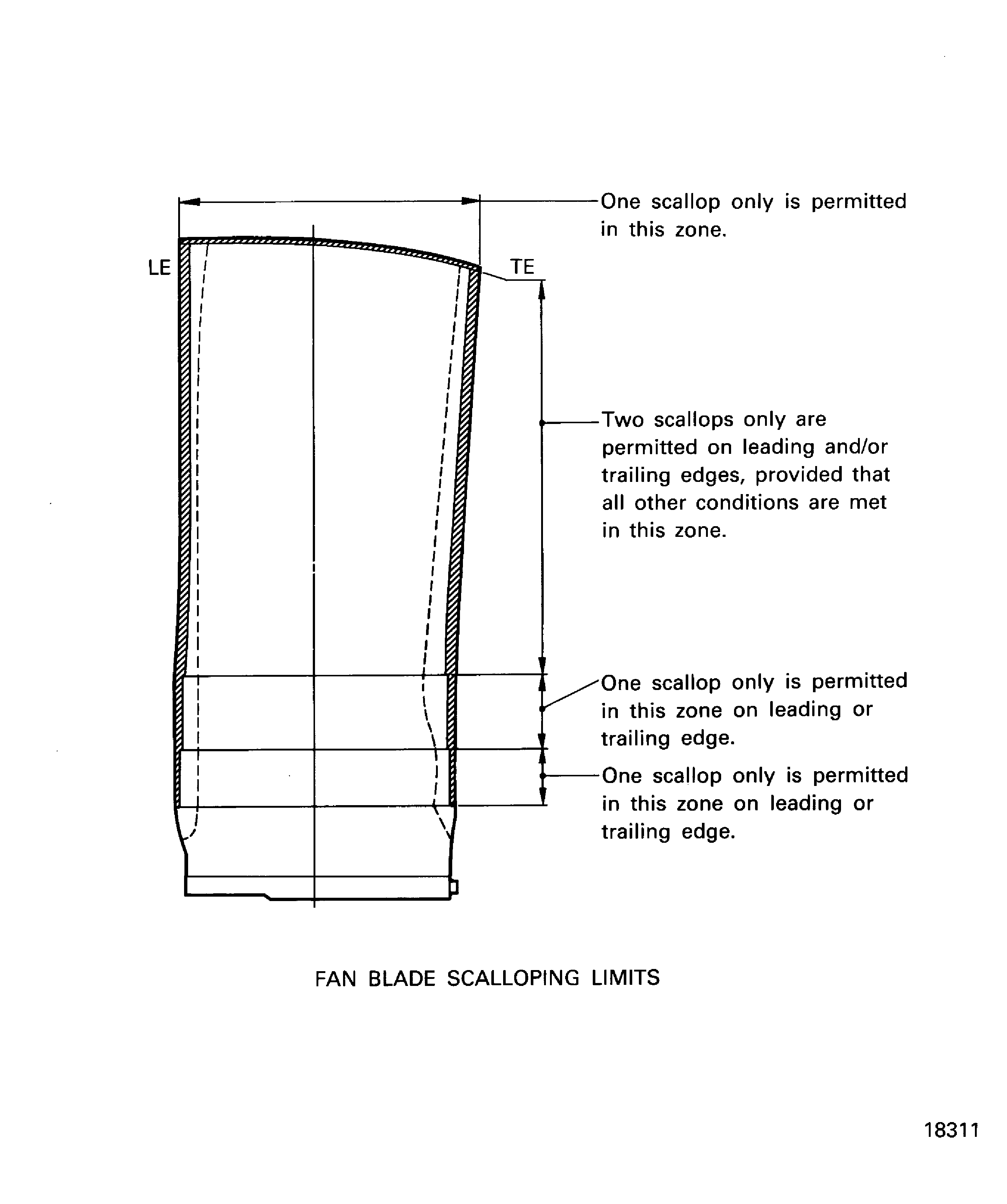

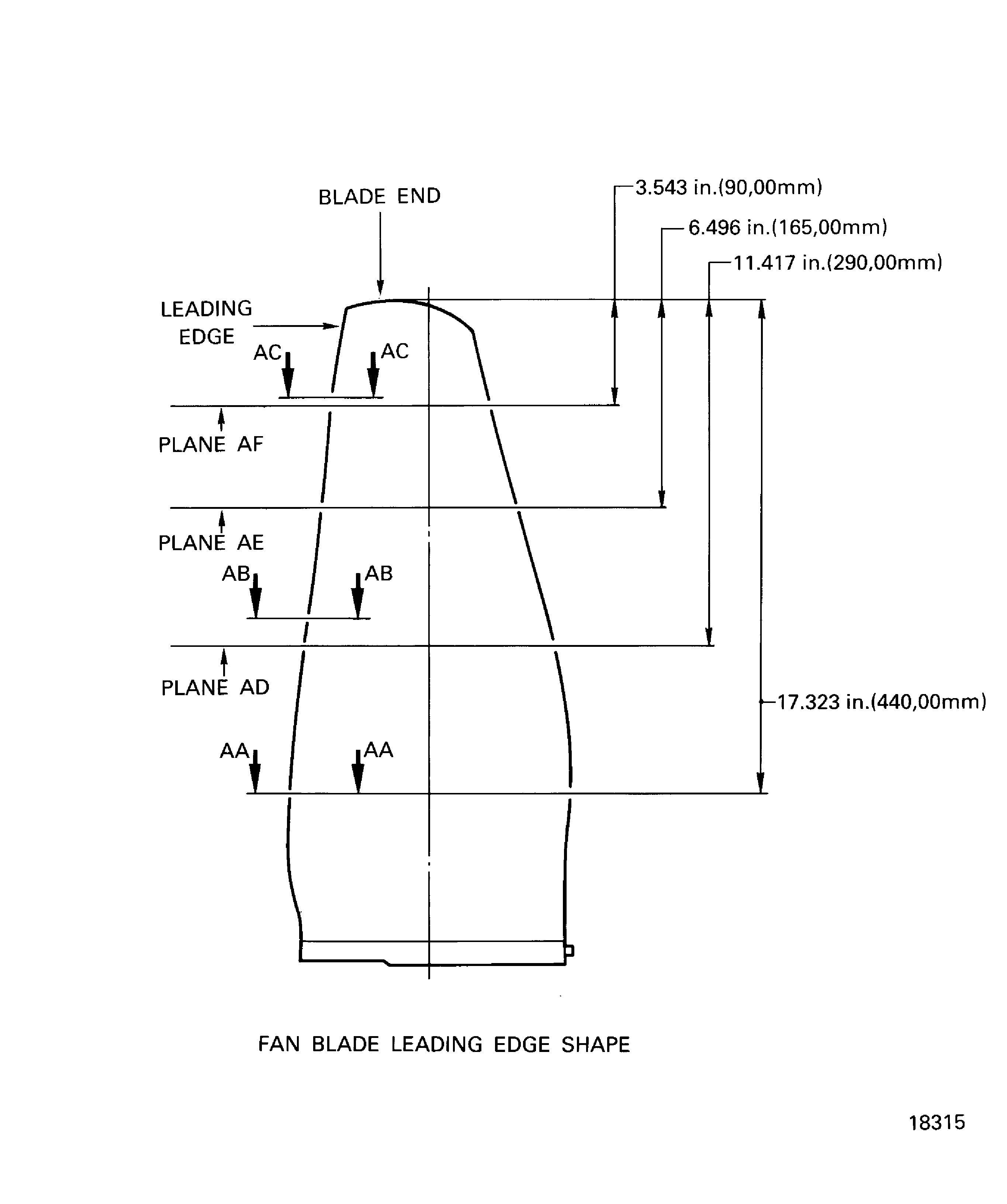

Figure: The fan blade leading edge shape

The fan blade leading edge shape

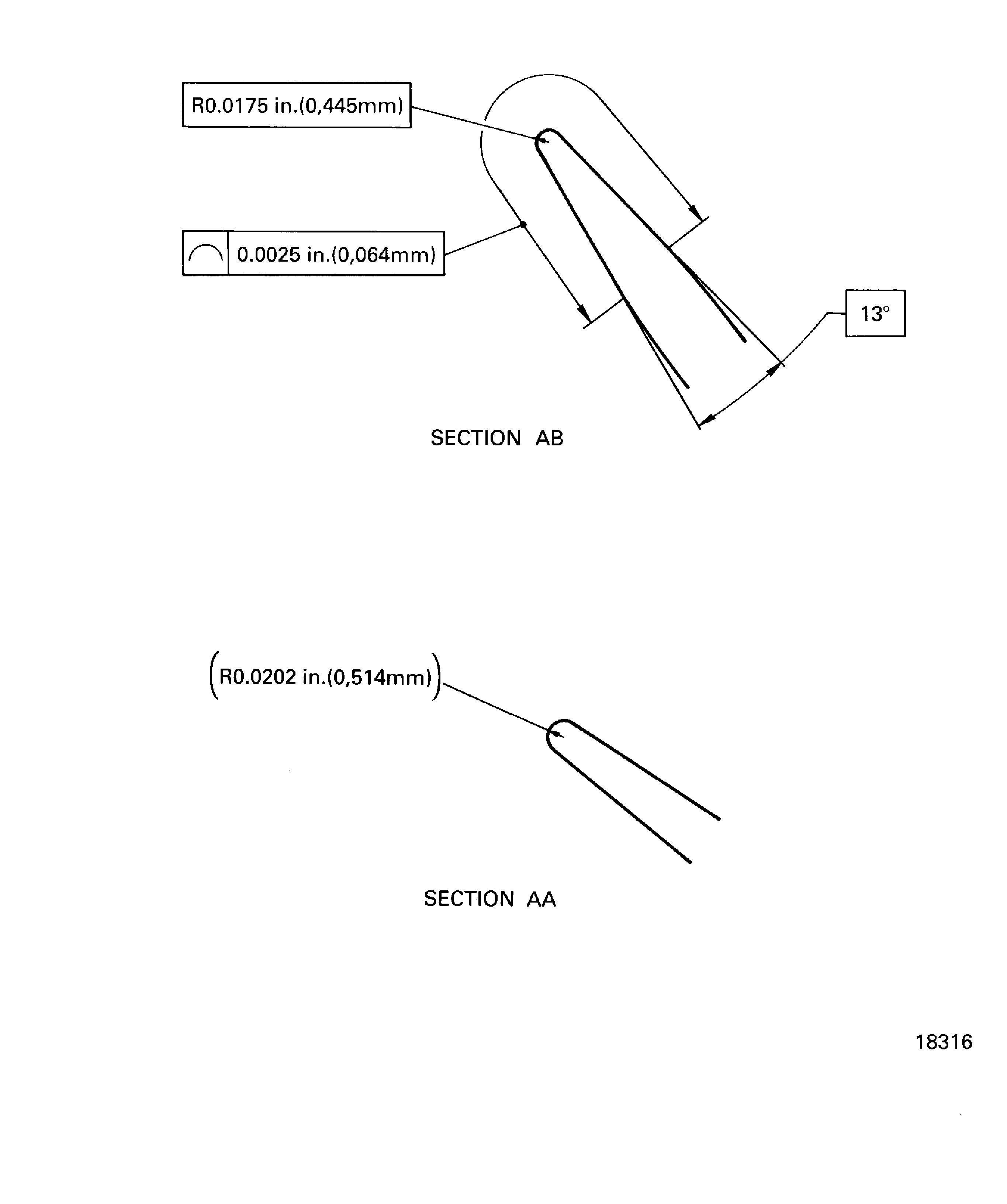

Figure: Section AA-AA and section AB-AB

Section AA-AA and section AB-AB

Figure: Section AC-AC

Section AC-AC