Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-31-11-300-030 LPC Fan Blade - Repair The Leading Edge Erosion By Material Removal, Repair-030 (VRS1064)

Effectivity

FIG/ITEM | PART NO. | |

|---|---|---|

01-300 | 6A3494 | Assembly A |

01-300 | 6A3971 | Assembly A |

01-300 | 6A5485 | Assembly A |

01-300 | 6A6519 | Assembly B |

01-300 | 6A4700 | Assembly C |

01-300 | 6A6521 | Assembly D |

01-300 | 6A7403 | Assembly A |

01-300 | 6A7649 | Assembly A |

01-300 | 6A7650 | Assembly A |

01-300 | 6A7651 | Assembly A |

01-300 | 6A7653 | Assembly A |

01-300 | 6A7656 | Assembly A |

01-300 | 6A7658 | Assembly A |

01-300 | 6A7613 | Assembly B |

01-300 | 6A7652 | Assembly B |

01-300 | 6A7654 | Assembly C |

01-300 | 6A7614 | Assembly D |

01-300 | 6A7655 | Assembly D |

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

LP Compressor rotor blade assembly | TFH or TJW | Titanium, Aluminum and Vanadium alloy |

General

This repair must only be done when instructed to do so is given in 72-31-11 Inspection/Check.

This repair gives the procedure to repair erosion on the leading edge only, of the LP Compressor Rotor Blade, by material removal.

The practices and processes referred to in this procedure by TASK numbers are in the SPM.

Price and availability

Refer to International Aero Engines

Related repairs

LP Compressor Rotor Blade - Repair the Airfoil Surface Finish by Glass Bead Peening (VRS1724). Refer to TASK 72-31-11-300-026, (REPAIR-026).

NOTE

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Portablegrinding equipment | LOCAL | Portable grinding equipment | ||

| Cloth | LOCAL | Cloth | ||

| Brush | LOCAL | Brush | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| IAE 3R19016 LE profile gage | 0AM53 | IAE 3R19016 | 1 | |

| IAE 3R19017 LE profile gage | 0AM53 | IAE 3R19017 | 1 | |

| IAE 3R19317 Template | 0AM53 | IAE 3R19317 | ||

| IAE 3R19320 Template | 0AM53 | IAE 3R19320 | ||

| IAE 3R19321 Mould | 0AM53 | IAE 3R19321 | ||

| IAE 3R19324 Mould | 0AM53 | IAE 3R19324 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-050 HIGH TEMPERATURE GLASS CLOTH TAPE | 76381 | CoMat 02-050 | ||

| CoMat 02-051 HIGH TEMPERATURE GLASS CLOTH TAPE | 0AM53 | CoMat 02-051 | ||

| CoMat 02-052 HIGH TEMPERATURE GLASS CLOTH TAPE | 0AM53 | CoMat 02-052 | ||

| CoMat 02-053 HIGH TEMPERATURE GLASS CLOTH TAPE | 0AM53 | CoMat 02-053 | ||

| CoMat 03-398 METAL SPRAYING STOPPING-OFFCOMPOUND | LOCAL | CoMat 03-398 | ||

| CoMat 05-019 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-019 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 | ||

| CoMat 05-064 WATERPROOF SILICON CARBIDE | K6835 | CoMat 05-064 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | LOCAL | CoMat 06-063 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 |

Spares

NONESafety Requirements

NONEProcedure

Use CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) or CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY), with penetrant crack test equipment.

Cracks are not permitted.

Refer to the SPM TASK 70-23-05-230-501.

CAUTION

ENSURE THAT THE PENETRANT FLUIDS DO NOT MAKE CONTACT WITH THE BLADE ROOT DOVETAIL FACES IF THE LP COMPRESSOR BLADE ASSEMBLY IS POST SB72-0375 OR POST SB72-0384.Do a penetrant crack test on the leading edge to find all the damage.

SUBTASK 72-31-11-230-068 Examine the LP Compressor Rotor Blade Assembly for Cracks

SUBTASK 72-31-11-350-091 Seal the LP Compressor Rotor Blade Airfoil Surfaces

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL WILL BECOME TOO HOT.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.

CAUTION

TITANIUM COMPONENT - MAXIMUM SPEED FOR MECHANICAL TOOLS MUST NOT EXCEED 1000 REVOLUTIONS PER MINUTE.

CAUTION

MAKE SURE THE LEADING EDGE PROFILE RADIUS IS POLISHED ALL ROUND THE NOSE. THE FINISHED PROFILE MUST GIVE A NOSE DOWN CONDITION Figure.Only minimum amount of material removal is required to get a satisfactory leading edge profile.

If you use mechanical tools, do not exceed 1000 rpm.

Use portable grinding equipment.

The profiling of the leading edge must be done such that excess thickness is removed only from the suction surface of the airfoil and leading edge radii is recreated/blended smoothly into the original non-eroded blade profile.

NOTE

Although erosion can be removed by full edge material removal, erosion will be more evident on the top half of the LP Compressor Rotor Blade.NOTE

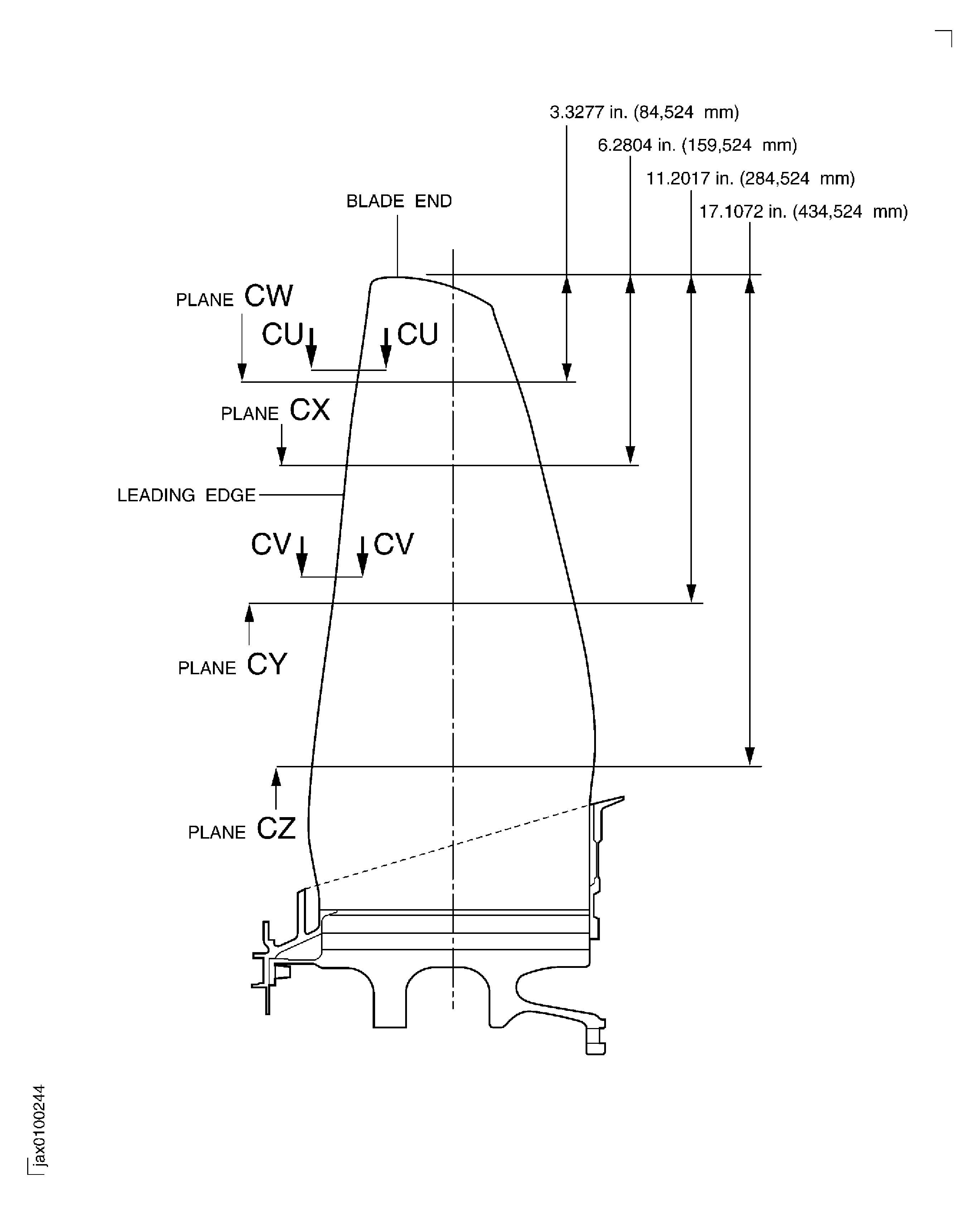

Where Profile gage IAE 3R19016 LE profile gage is marked 'USE BETWEEN TX-TT' it is equivalent to 'BLADE END - PLANE CW' on Figure.Where Profile gage IAE 3R19017 LE profile gage is marked 'USE BETWEEN TP - TJ' it is equivalent to 'PLANE CX - PLANE CY' on Figure.Re-profile the leading edge radii.

Make sure all the damage marks are completely removed and the area is made smooth into the adjacent material.

Polish repaired area(s), to remove scratches and to give a surface finish the same as the adjacent material.

Use CoMat 05-021 WATERPROOF SILICON CARBIDE, CoMat 05-020 WATERPROOF SILICON CARBIDE, CoMat 05-019 WATERPROOF SILICON CARBIDE and/or CoMat 05-064 WATERPROOF SILICON CARBIDE.

NOTE

The last polish is to be in a radial direction.Make smooth and polish the repaired area(s).

Do Step.

Remove the stopping-off compound or masking tape.

SUBTASK 72-31-11-350-092-A00 Remove Erosion from the LP Compressor Rotor Blade Assembly, Assembly A and Assembly B

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL WILL BECOME TOO HOT.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.

CAUTION

TITANIUM COMPONENT - MAXIMUM SPEED FOR MECHANICAL TOOLS MUST NOT EXCEED 1000 REVOLUTIONS PER MINUTE.

CAUTION

MAKE SURE THE LEADING EDGE PROFILE RADIUS IS POLISHED ALL ROUND THE NOSE. THE FINISHED PROFILE MUST GIVE A NOSE DOWN CONDITION Figure.Only minimum amount of material removal is required to get a satisfactory leading edge profile.

If you use mechanical tools, do not exceed 1000 rpm.

Use portable grinding equipment.

The profiling of the leading edge must be done such that excess thickness is removed only from the suction surface of the airfoil and leading edge radii is recreated/blended smoothly into the original non-eroded blade profile.

NOTE

Although erosion can be removed by full edge material removal, erosion will be more evident on the top half of the LP Compressor Rotor Blade.NOTE

Where Profile gage IAE 3R19016 LE profile gage is marked 'USE BETWEEN TX - TT' it is equivalent to 'BLADE END - PLANE CW' on Figure.Where Profile gage IAE 3R19017 LE profile gage is marked 'USE BETWEEN TP - TJ' it is equivalent to 'PLANE CX - PLANE CY' on Figure.Re-profile the leading edge radii.

Make sure all the damage marks are completely removed and the area is made smooth into the adjacent material.

Polish repaired area(s), to remove scratches and to give a surface finish the same as the adjacent material.

Use CoMat 05-021 WATERPROOF SILICON CARBIDE, CoMat 05-020 WATERPROOF SILICON CARBIDE, CoMat 05-019 WATERPROOF SILICON CARBIDEand/or CoMat 05-064 WATERPROOF SILICON CARBIDE.

NOTE

The last polish is to be in a radial direction.Make smooth and polish the repaired area(s).

Do Step.

Remove the stopping-off compound or masking tape.

SUBTASK 72-31-11-350-092-C00 Remove Erosion from the LP Compressor Rotor Blade Assembly, Assembly C and Assembly D

Refer to the SPM TASK 70-11-03-300-503, SUBTASK 70-11-03-300-002 or SUBTASK 70-11-03-300-003.

Clean the blade.

SUBTASK 72-31-11-110-075 Chemically Clean

Refer to the SPM TASK 70-11-08-300-503, SUBTASK 70-11-08-300-001 and SUBTASK 70-11-08-300-002.

Use chemical cleaning equipment.

CAUTION

ENSURE THAT THE SWAB ETCH CHEMICALS AND NEUTRALISING FLUIDS DO NOT MAKE CONTACT WITH THE BLADE ROOT DOVETAIL FACES IF THE LP COMPRESSOR BLADE ASSEMBLY IS POST SB72-0375 OR POST SB72-0384.Swab etch the repaired area(s).

SUBTASK 72-31-11-110-057 Do a Swab Etch

Refer to the SPM TASK 70-23-05-230-501.

Use CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY), with penetrant crack test equipment.

Cracks are not permitted.

CAUTION

ENSURE THAT THE PENETRANT FLUIDS DO NOT MAKE CONTACT WITH THE BLADE ROOT DOVETAIL FACES IF THE LP COMPRESSOR BLADE ASSEMBLY IS POST SB72-0375 OR POST SB72-0384.Do a local penetrant crack test on the repaired blades.

SUBTASK 72-31-11-230-060 Examine the LP Compressor Rotor Blade Assembly for Cracks

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

CAUTION

DO NOT VIBRO-ENGRAVE ON THE BLADE AIRFOIL OR LOCATION FACES.Make a mark VRS1064, adjacent to the assembly number.

SUBTASK 72-00-31-350-057 Identify the Repair

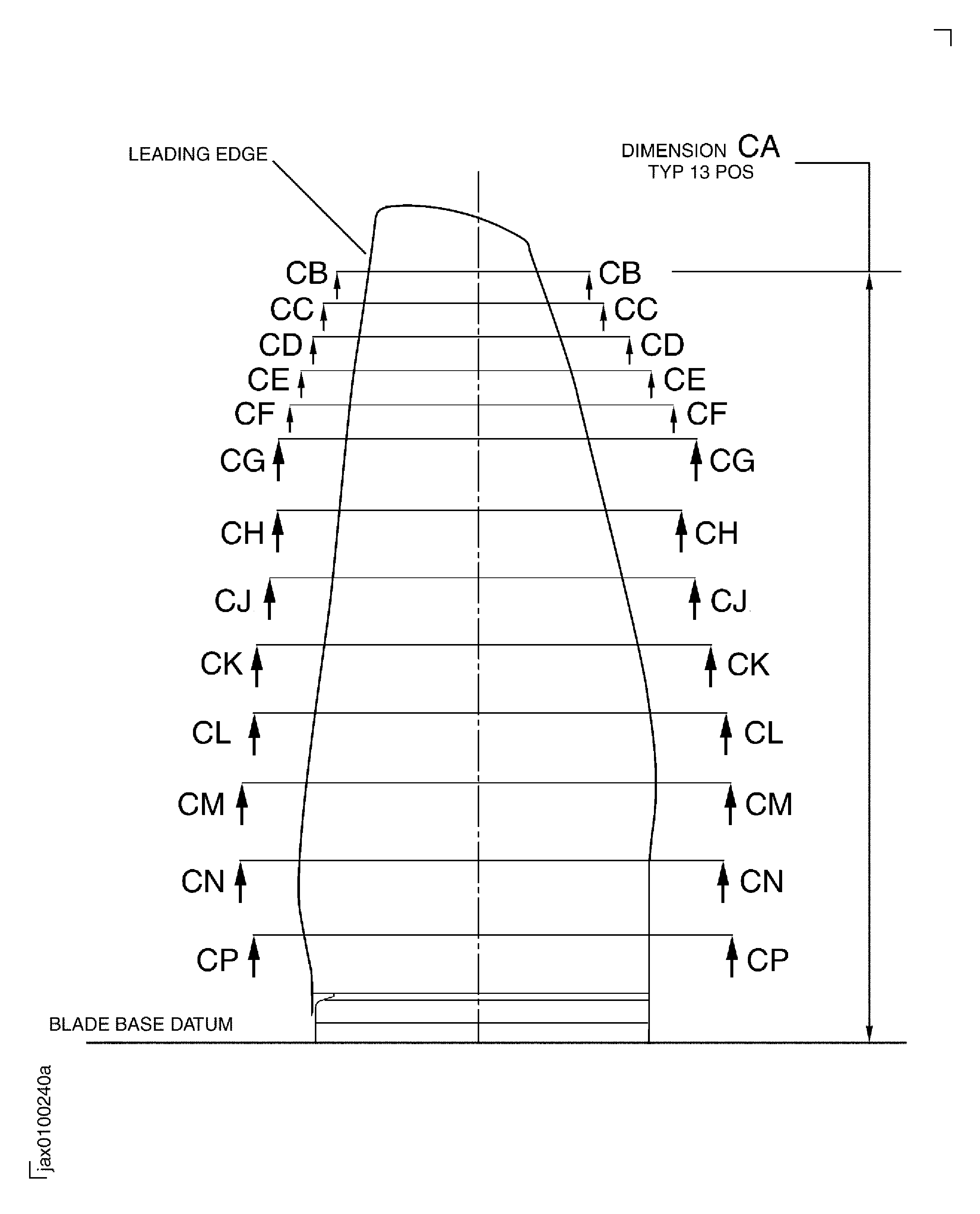

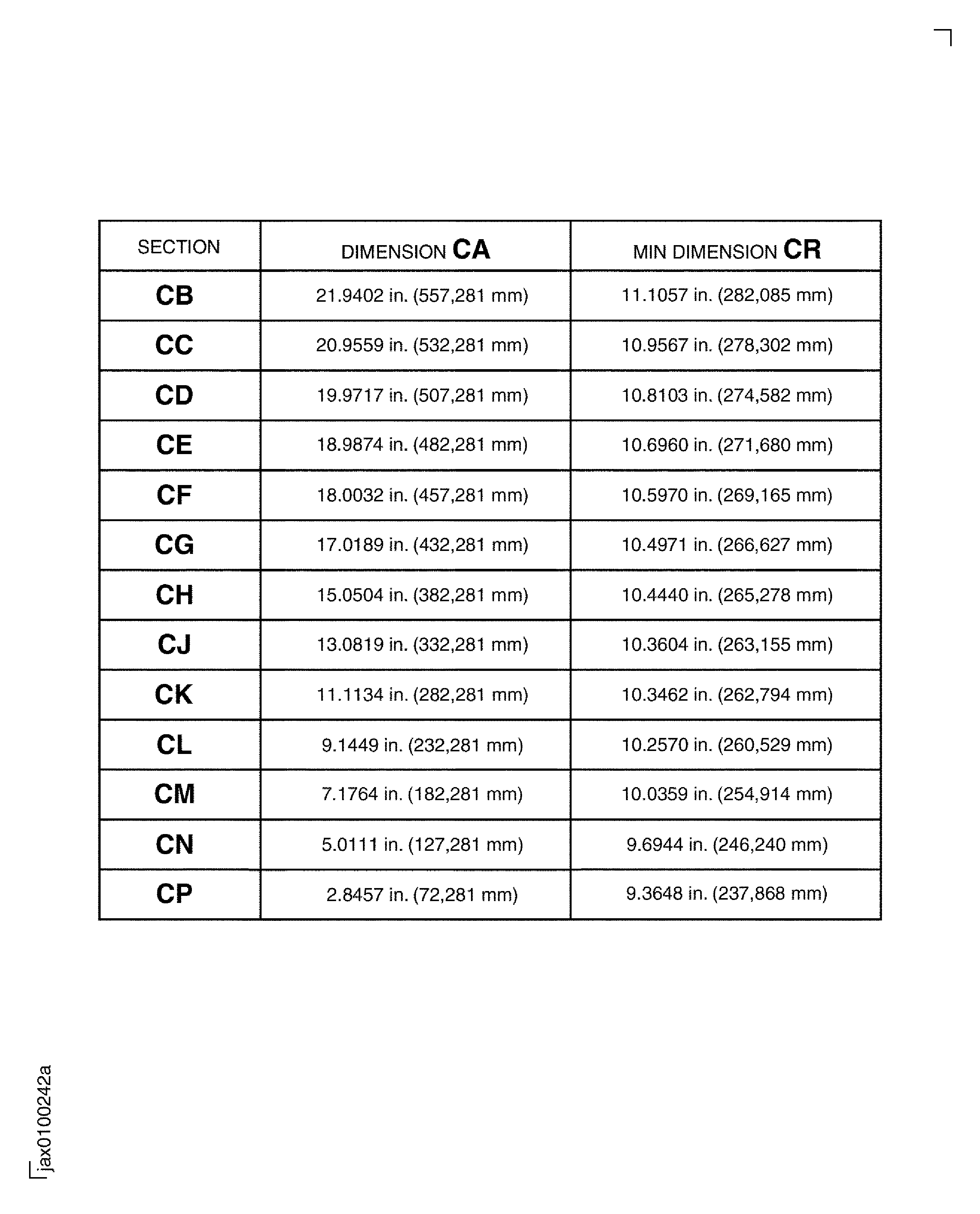

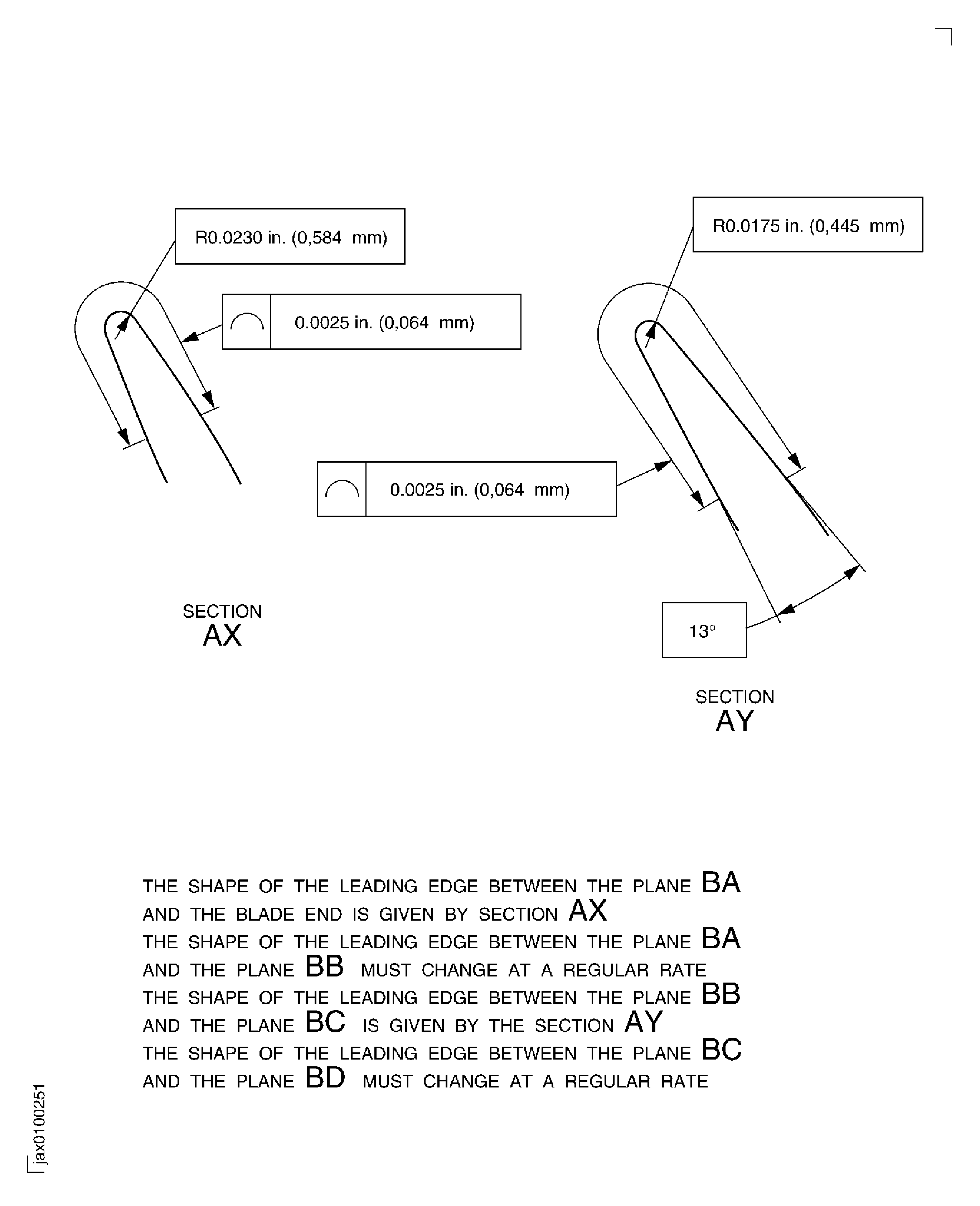

Figure: Repair Details and Dimensions, Assembly A and Assembly B

Repair Details and Dimensions, Assembly A and Assembly B

Figure: Repair Details and Dimensions, Assembly A and Assembly B

Repair Details and Dimensions, Assembly A and Assembly B

Figure: Repair Details and Dimensions, Assembly A and Assembly B

Repair Details and Dimensions, Assembly A and Assembly B

Figure: Repair Details and Dimensions, Assembly A and Assembly B

Repair Details and Dimensions, Assembly A and Assembly B

Figure: Repair Details and Dimensions, Assembly A and Assembly B

Repair Details and Dimensions, Assembly A and Assembly B

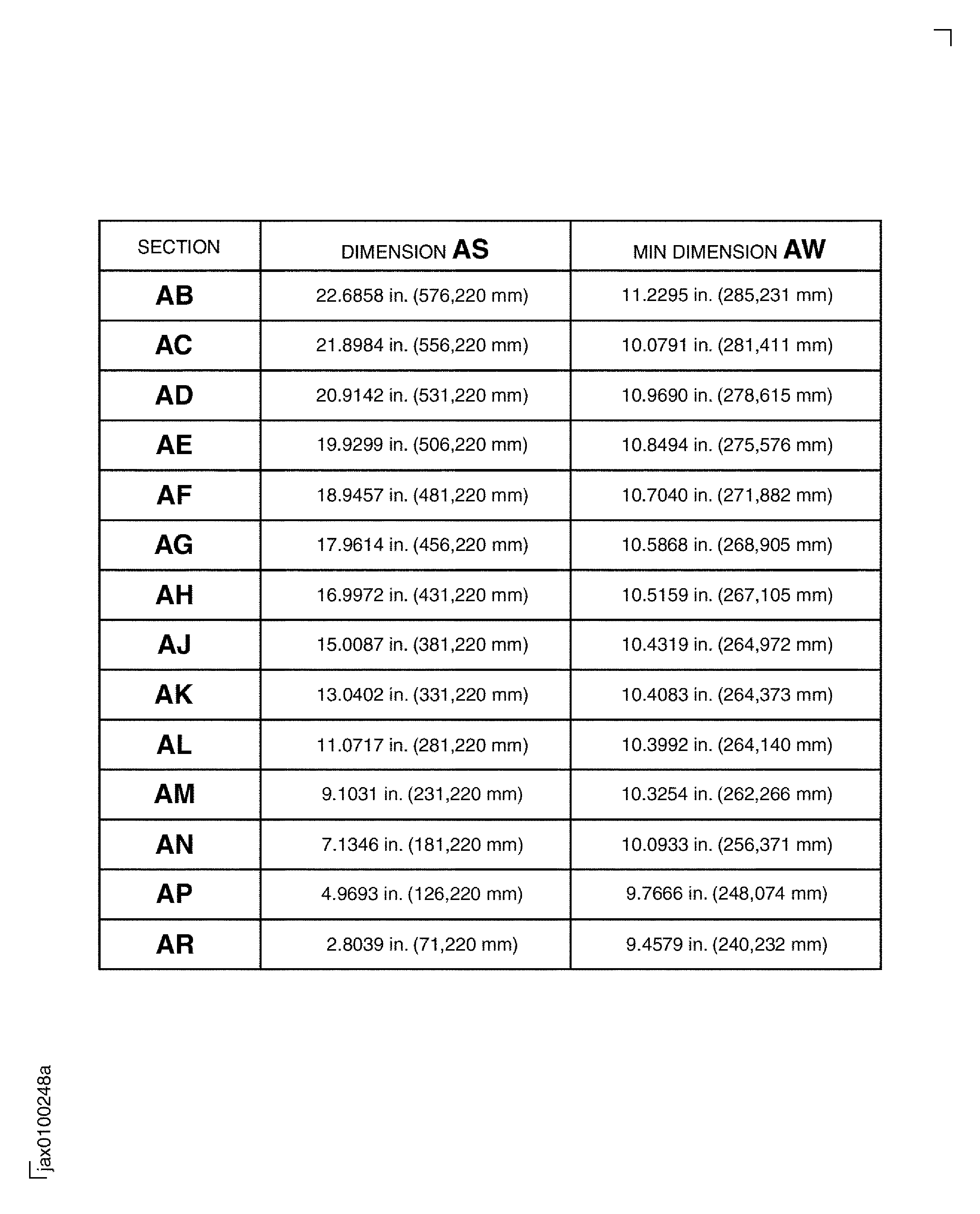

Figure: Repair Details and Dimensions, Assembly C and Assembly D

Repair Details and Dimensions, Assembly C and Assembly D

Figure: Repair Details and Dimensions, Assembly C and Assembly D

Repair Details and Dimensions, Assembly C and Assembly D

Figure: Repair Details and Dimensions, Assembly C and Assembly D

Repair Details and Dimensions, Assembly C and Assembly D

Figure: Repair Details and Dimensions, Assembly C and Assembly D

Repair Details and Dimensions, Assembly C and Assembly D

Figure: Repair Details and Dimensions, Assembly C and Assembly D

Repair Details and Dimensions, Assembly C and Assembly D

Figure: Repair Details and Dimensions

Repair Details and Dimensions