Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-31-11-300-003 Annulus Filler - Replace The Seals And Bumper, Repair-003 (VRS1007)

General

The practices and processes referred to in the procedure by the TASK number are in the SPM.

Price and availability - none

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Vibration peen | LOCAL | Vibration peen |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 01-275 CHROMATE CONVERSION COATING FOR ALUMINIUM | LOCAL | CoMat 01-275 | ||

| CoMat 05-016 GARNET PAPER, 80-GRIT | LOCAL | CoMat 05-016 | ||

| CoMat 05-017 GARNET PAPER, 60 GRIT | LOCAL | CoMat 05-017 | ||

| CoMat 05-019 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-019 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 08-013 COLD CURING SILICONE COMPOUND | LOCAL | CoMat 08-013 | ||

| CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT | 0AM53 | CoMat 08-014 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Suction side seal | 5A1112 | 1 | ||

| Pressure side seal | 5A1113 | 1 | ||

| Pad bumper | 5A1114 | 1 |

Safety Requirements

NONEProcedure

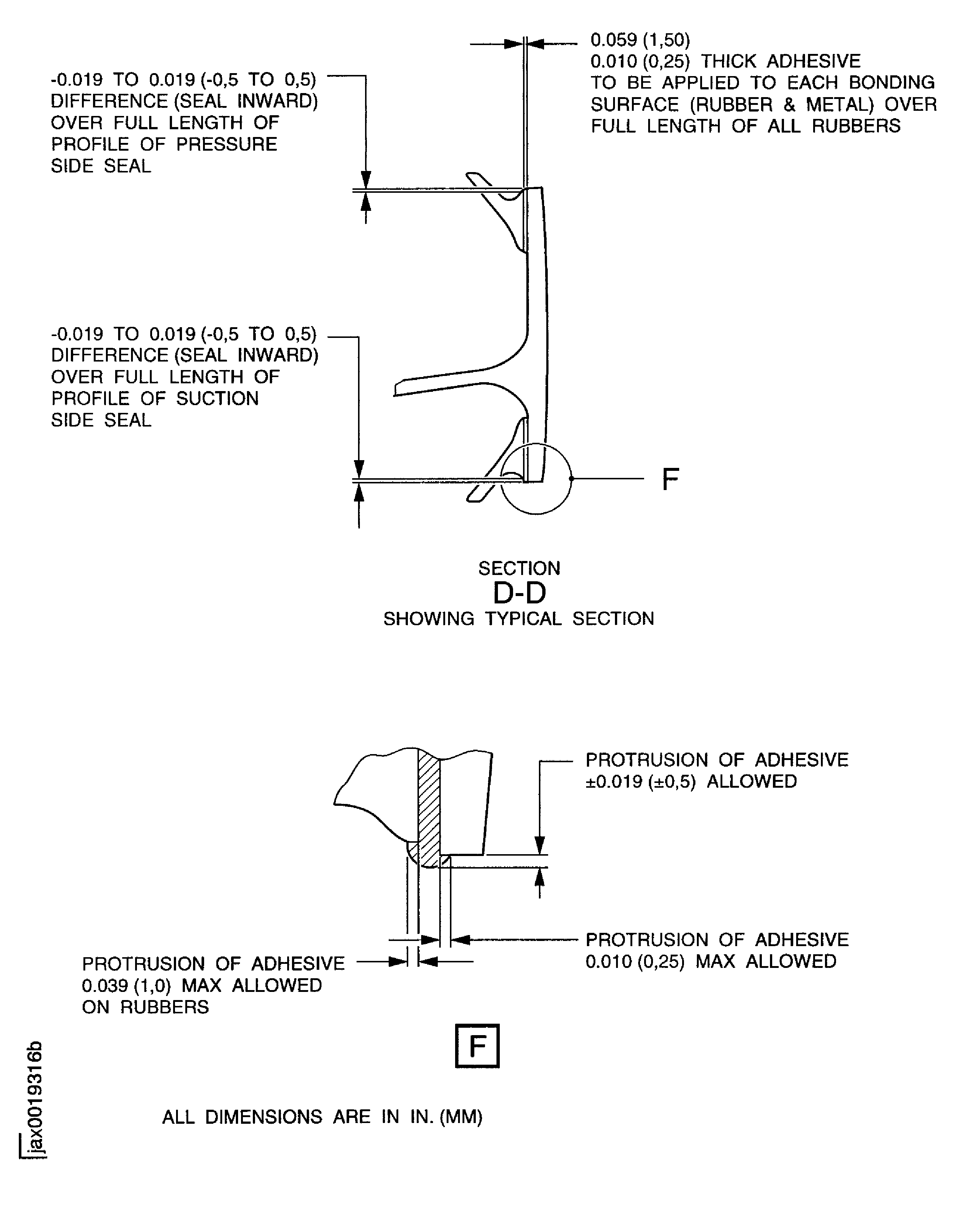

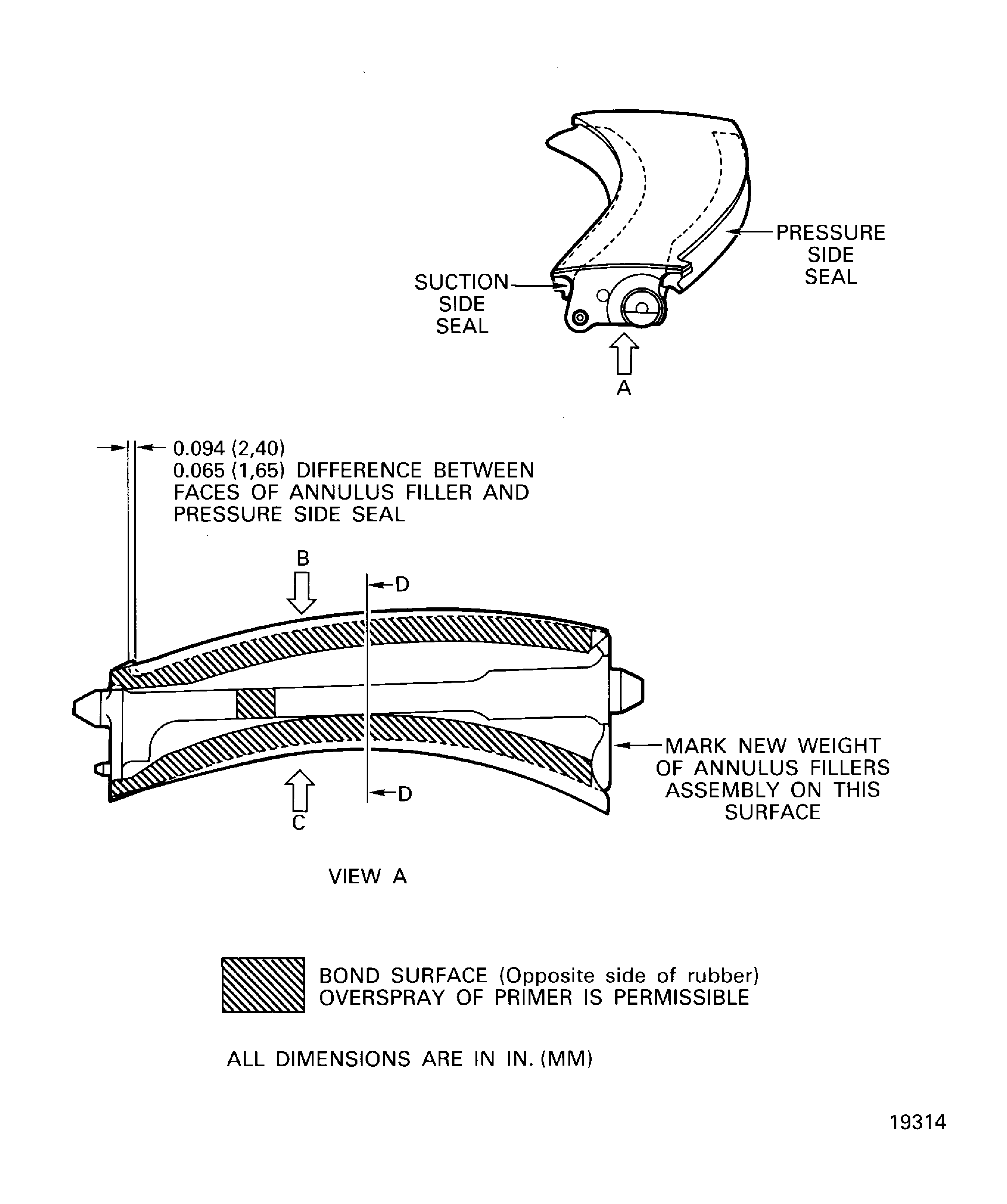

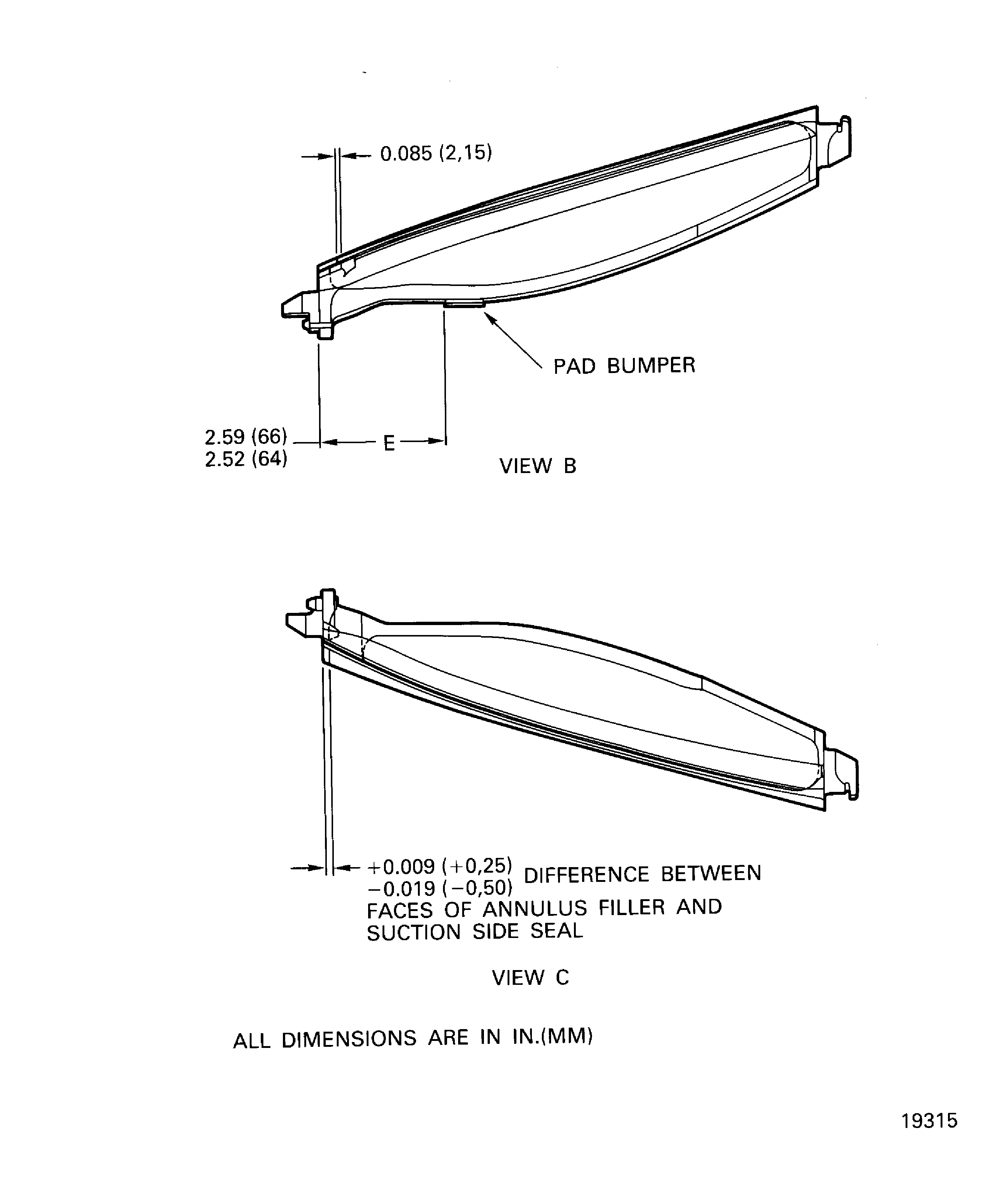

Refer to Figure.

Use cutter knife or scraper. Use CoMat 05-019 WATERPROOF SILICON CARBIDE and CoMat 05-020 WATERPROOF SILICON CARBIDE.

Remove the damaged seals and bumper without any damage to the parent material, and remove the remaining compound.

SUBTASK 72-31-11-350-065 Remove the Damaged Seal and Bumper from the Annulus Filler Assembly

Refer to Figure.

Refer to the SPM TASK 70-36-02-360-501.

Cold liquid degrease the mating surfaces of the annulus filler, the seals and pad bumper.

Refer to the SPM TASK 70-36-02-360-501.

Hand clean the mating surfaces.

SUBTASK 72-31-11-360-054 Prepare the Mating Surface for the Cold Curing Silicone Rubber Compound

Refer to: Figure

Refer to the SPM TASK 70-38-02-300-503.

Apply chromate conversion coating to the repair surfaces if necessary.

SUBTASK 72-31-11-350-066 Apply the Surface Protection to the Annulus Filler Assembly

CAUTION

DO NOT EAT ANYTHING OR SMOKE AT LOCATIONS WHERE THESE MATERIALS ARE USED.AFTER PREPARATION THE MATING SURFACES MUST BE FULLY CLEANED AND MUST NOT BE TOUCHED BY HAND, TO PREVENT CONTAMINATION.DO NOT APPLY THE PRIMER TO THE MATING SURFACE OF THE SEALS AND BUMPER BECAUSE THE SILICONE RUBBER IS WEAK IN THE BOND STRENGTH IF YOU APPLY THE PRIMER.APPLY THE PRIMER WITHIN EIGHT HOURS OF ANODIZING.NOTE

The primer must be applied immediately after the mating surfaces are prepared. It is cured at room temperature by the moisture in the air.Refer to Figure.

Use CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT for silcoset 151, 152, 153 and an applicable oven.

Apply a very thin layer of primer only to the prepared mating surface of the annulus filler. Dry in room temperature for 30 minutes minimum.

Use a spatula and CoMat 08-013 COLD CURING SILICONE COMPOUND.

Refer to the SPM TASK 70-36-02-360-501.

Apply the cold curing silicone rubber compound to each of the mating surfaces.

Make sure that the compound can be seen around the sealed surfaces.

Refer to the SPM TASK 70-36-02-360-501.

Install the seals and the pad bumper to the annulus filler within three minutes after the compound is applied.

Refer to the SPM TASK 70-36-02-360-501.

NOTE

The parts can be handled carefully after 2 hours at room temperature.Cure the compound at 68 deg F (20 deg C) for 48 hours.

Use a Vibration peen.

Vibro-peen VRS1007 adjacent to the part number.

SUBTASK 72-31-11-360-055 Apply and Cure the Cold Curing Silicone Rubber Compound

Refer to Figure.

SUBTASK 72-31-11-220-075 Examine the Repaired Areas of the Annulus Filler Assembly

Figure: Bond the seal and bumper

Sheet 1

Figure: Bond the seal and bumper

Sheet 2

Figure: Bond the seal and bumper

Sheet 3