Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-31-12-300-007 LPC Fan Disk - Replace The Shank Nuts, Repair-007 (VRS1157)

Material of component

DESCRIPTION | SYMBOL | MATERIAL |

|---|---|---|

Stage 1 fan disk | - | Titanium alloy |

Shank nut | - | Corrosion resistant steel |

General

The practices and processes referred to in the procedure by the TASK number are in the SPM.

Price and availability - not applicable

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Drilling machine | LOCAL | Drilling machine | Radial | |

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| IAE 3J12712 Peening tools | 0AM53 | IAE 3J12712 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Self locking shank nut | AS27870 | A/R | (For Assembly A,B) | |

| Self locking shank nut | AS27870 | A/R | (For Assembly A,B) | |

| Self locking shank nut | AS55202-2 | A/R | (For Assembly B) | |

| Self locking shank nut | AS55202-5 | A/R | (For Assembly B) | |

| Self locking shank nut | AS55202-8 | A/R | (For Assembly B) | |

| Self locking shank nut | AS55202-2 | A/R | (For Assembly B) | |

| Self locking shank nut | AS55202-5 | A/R | (For Assembly B) | |

| Self locking shank nut | AS55202-8 | A/R | (For Assembly B) |

Safety Requirements

NONEProcedure

CAUTION

WHEELS, STONES AND ABRASIVE PAPERS USED TO DRESS, MAKE SMOOTH OR POLISH A TITANIUM COMPONENT MUST BE OF THE SILICON CARBIDE TYPE. ALUMINUM OXIDE TYPES MUST NOT BE USED.

CAUTION

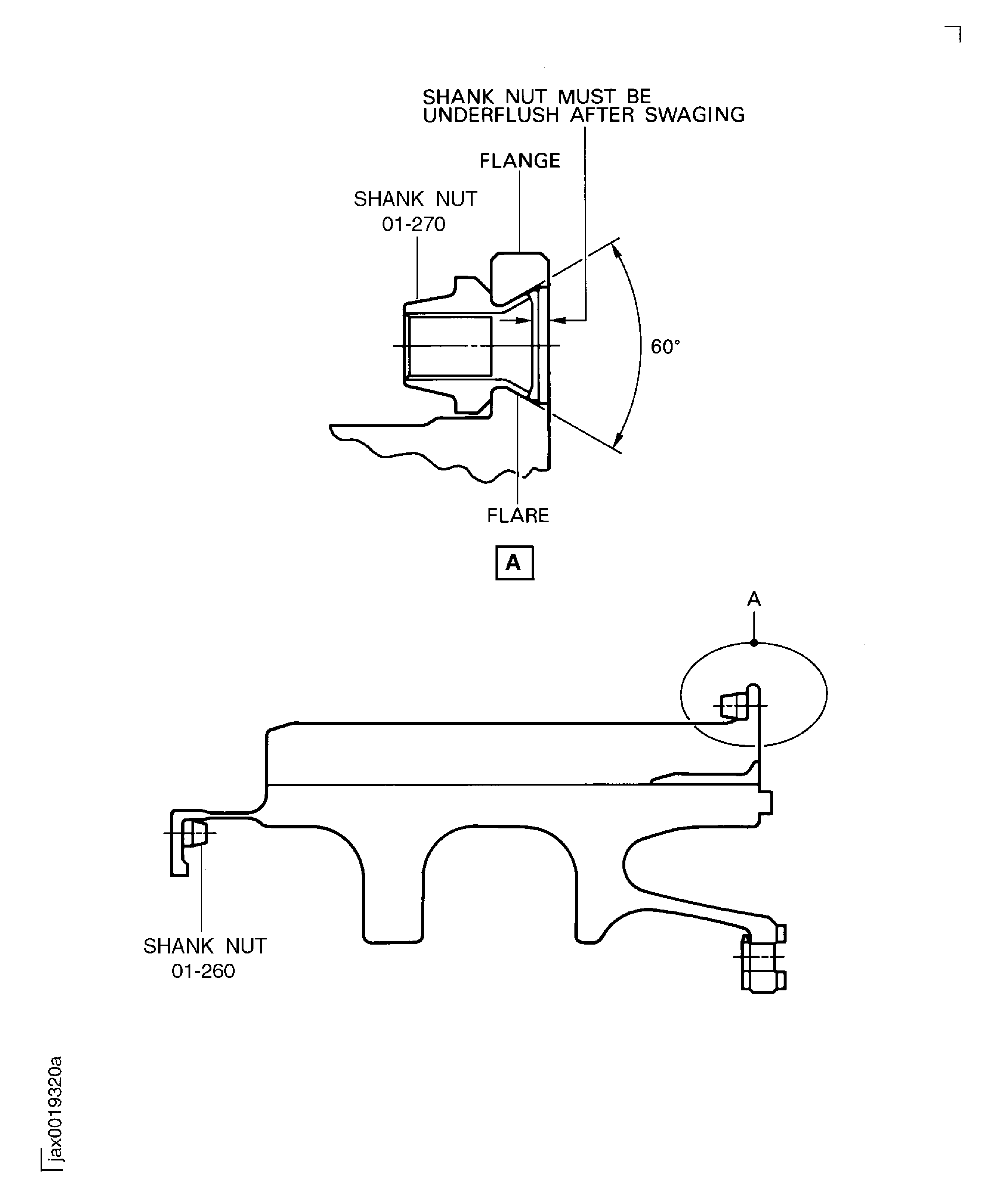

IF MECHANICAL CUTTERS ARE USED, ONLY SMALL CUTS MUST BE MADE TO PREVENT TOO MUCH HEAT.Refer to Figure.

Use a 0.378 in. (9.60 mm) drill.

Take care not to damage the flange bore or face.

Refer to the SPM TASK 70-35-11-300-501.

With the use of a radial Drilling machine, drill the flare of the shank nut until the flare twists.

Remove the damaged shank nut.

SUBTASK 72-31-12-350-056 Remove the Damaged Shank Nuts of the Stage 1 Fan Disk Assembly

Cracks are not permitted.

Refer to the SPM TASK 70-23-05-230-501.

Do a penetrant crack test.

SUBTASK 72-31-12-230-056 Examine the Flange Nut Location Hole of the Stage 1 Fan Disk Assembly

Refer to Figure

Prepare the new shank nut which has same part number as identified for each location hole in Step, step 4 (A), (B).

Shank nut must be firmly held against the flange before the start of swaging.

Care must be taken that the flange does not become damaged.

During swaging, the tool may damage the silver coating inside the shank.

This is permitted and it is not necessary to touch up if coating is damaged. Any loose flakes of silver coating are to be removed.

Refer to the SPM TASK 70-35-11-300-501.

Use IAE 3J12712 Peening tools 1 off.

Hold the shank nut in position and make a flare.

SUBTASK 72-31-12-350-057 Fit a New Shank Nut to the Stage 1 Fan Disk Assembly

Refer to Figure

SUBTASK 72-31-12-220-072 Examine the Shank Nut of the Stage 1 Fan Disk Assembly

Figure: Replace the shank nut of the stage 1 fan disk - Assembly A

Replace the shank nut of the stage 1 fan disk - Assembly A

Figure: Replace the shank nut of the stage 1 fan disk - Assembly B

Replace the shank nut of the stage 1 fan disk - Assembly B