Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-31-12-300-002 Fan Blade Rear Retaining Ring - Repair The Surface Damage, Repair 002(VRS1150)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Portablegrinding equipment | LOCAL | Portable grinding equipment | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

NONESafety Requirements

NONEProcedure

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT. ALUMINIUM OXIDE TYPE MUST NOT BE USED. IF MECHANICAL CUTTERS ARE USED, ONLY LIGHT CUTS MUST BE MADE TO AVOID OVERHEATING THE MATERIAL.TITANIUM COMPNENT - AVOID BUILD UP OF HEAT BY APPLYING ONLY GENTLE PRESSURE AND KEEPING THE TOOL SPEED AS LOW AS POSSIBLE. USE TECHNIQUES WHICH ALLOW FOR PROGRESSIVE WEAR OF THE DRESSING MEDIA TO PRESENT A CONTINUALLY FRESH CUTTING SURFACE TO THE WORK PIECE.DO NOT DWELL ON ONE AREA OF THE COMPONENT.DRESS, WHERE POSSIBLE, IN A CIRCULAR MOTION; TAKING LIGHT CUTS TO AVOID OVERHEATING.TITANIUM COMPONENT - YOU MUST MAKE SURE THAT WHEN YOU REMOVE MATERIAL, BLEND AND POLISH, TO MAKE SMOOTH, THAT NO SPARKS ARE PRODUCED AND THE ADJACENT AREA IS MASKED OFF.TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR DURING DRESSING, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.Use light pressure to prevent any risk of overheating material.

The width of the repaired area is to be more than 20 times the depth.

Remove the minimum quantity of material necessary to remove the damage.

Raised material and sharp edges must be removed from repaired area.

Surface finish of the repair must be the same as the adjacent area.

Refer to the SPM TASK 70-35-03-300-501.

Use portable grinding equipment, abrasive stones or papers and/or fine file.

Dress/make smooth and/or hand polish to remove nicks, dents, scratches burrs and/or galls.

SUBTASK 72-31-12-350-052 Remove the Damage from the Rear Blade Retaining Ring

Refer to the SPM TASK 70-11-08-300-503, SUBTASK 70-11-08-300-001.

Use chemical cleaning equipment.

Chemically clean.

Refer to the SPM TASK 70-11-08-300-503, SUBTASK 70-11-08-300-002.

Use chemical cleaning equipment.

Swab etch the repair area(s).

SUBTASK 72-31-12-110-064 Do a Swab Etch

Refer to the SPM TASK 70-23-05-230-501.

Fluorescent penetrant examine the repaired area.

SUBTASK 72-31-12-230-052 Examine the Rear Blade Retaining Ring for Cracks

Refer to the SPM TASK 70-09-00-400-501.

Use vibro-engraving equipment.

Mark VRS1150 adjacent to the part number.

SUBTASK 72-31-12-350-012 Identify the Repair

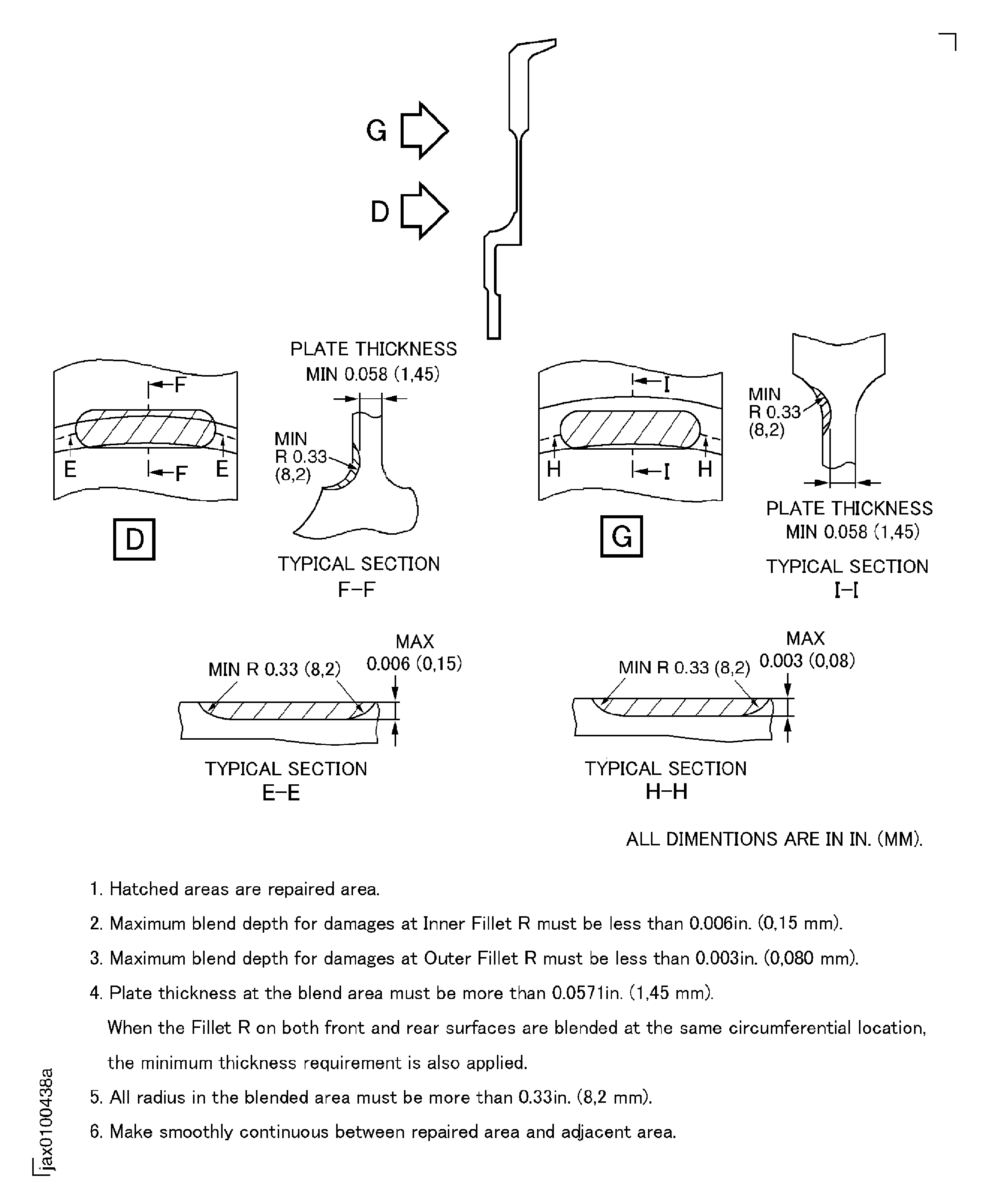

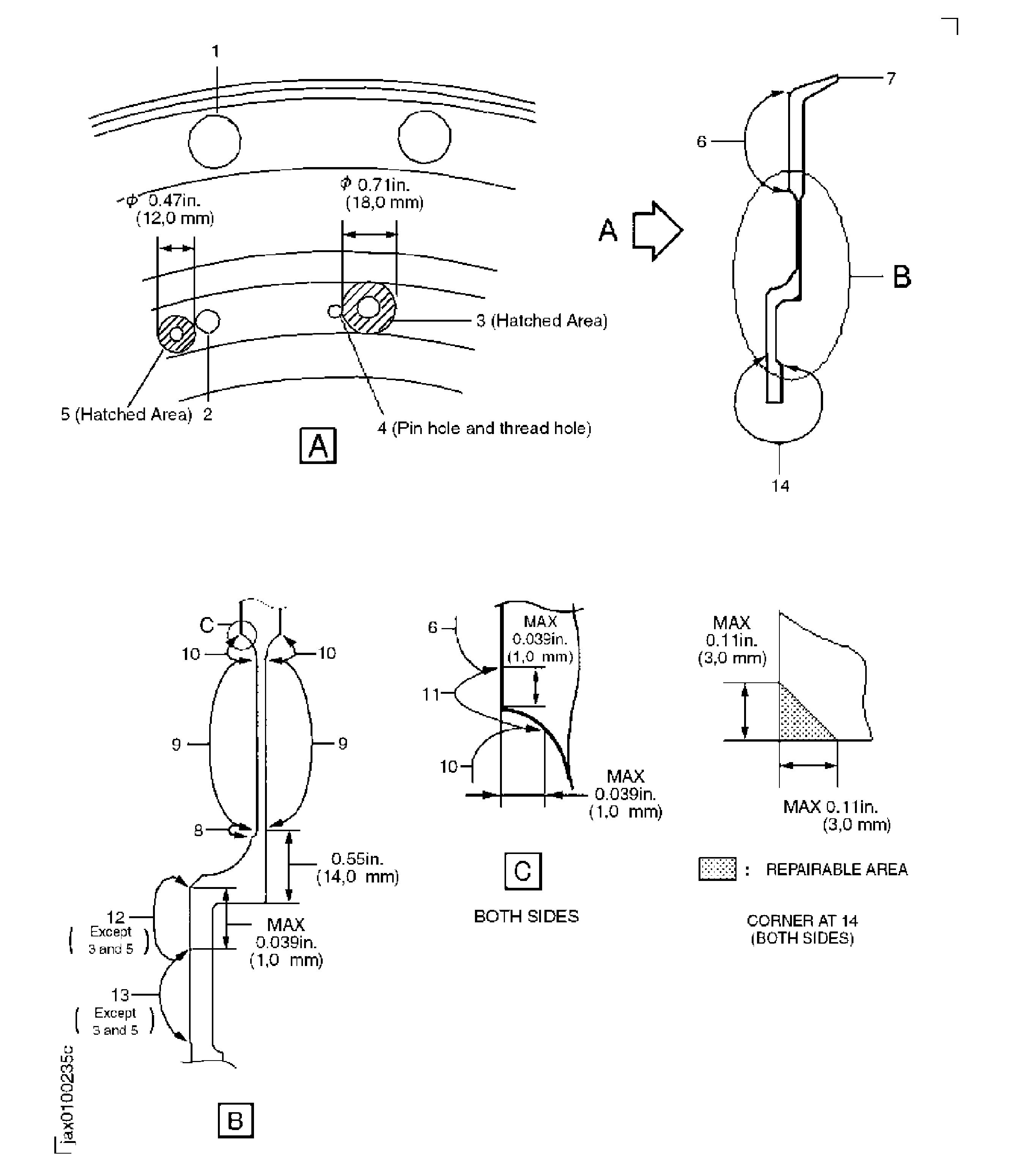

Figure: Repair Details and Dimensions for Assembly A

Sheet 1

Figure: Repair Details and Dimensions for Assembly A

Sheet 2

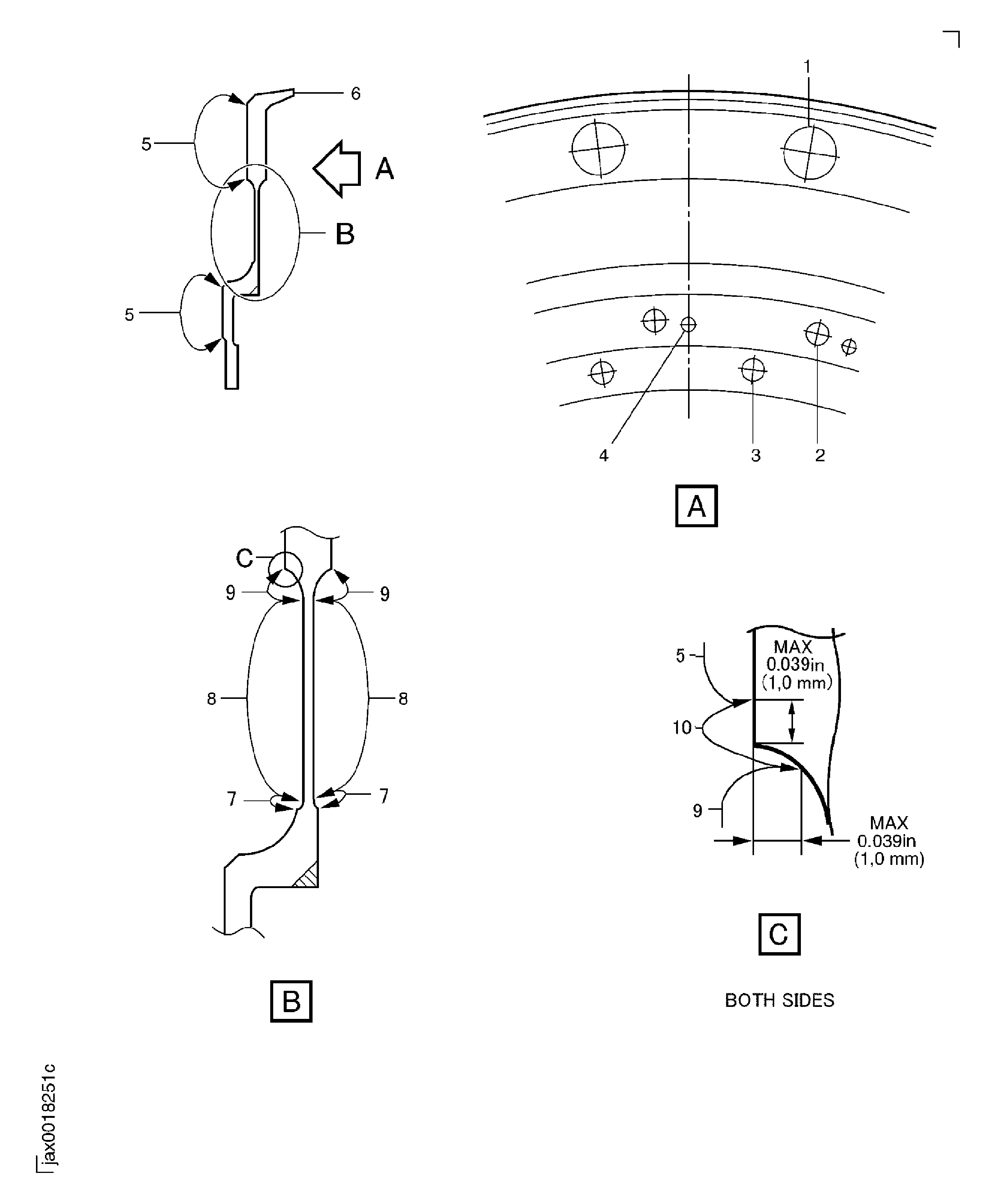

Figure: Repair Details and Dimensions for Assembly B

Sheet 1

Figure: Repair Details and Dimensions for Assembly B

Sheet 2

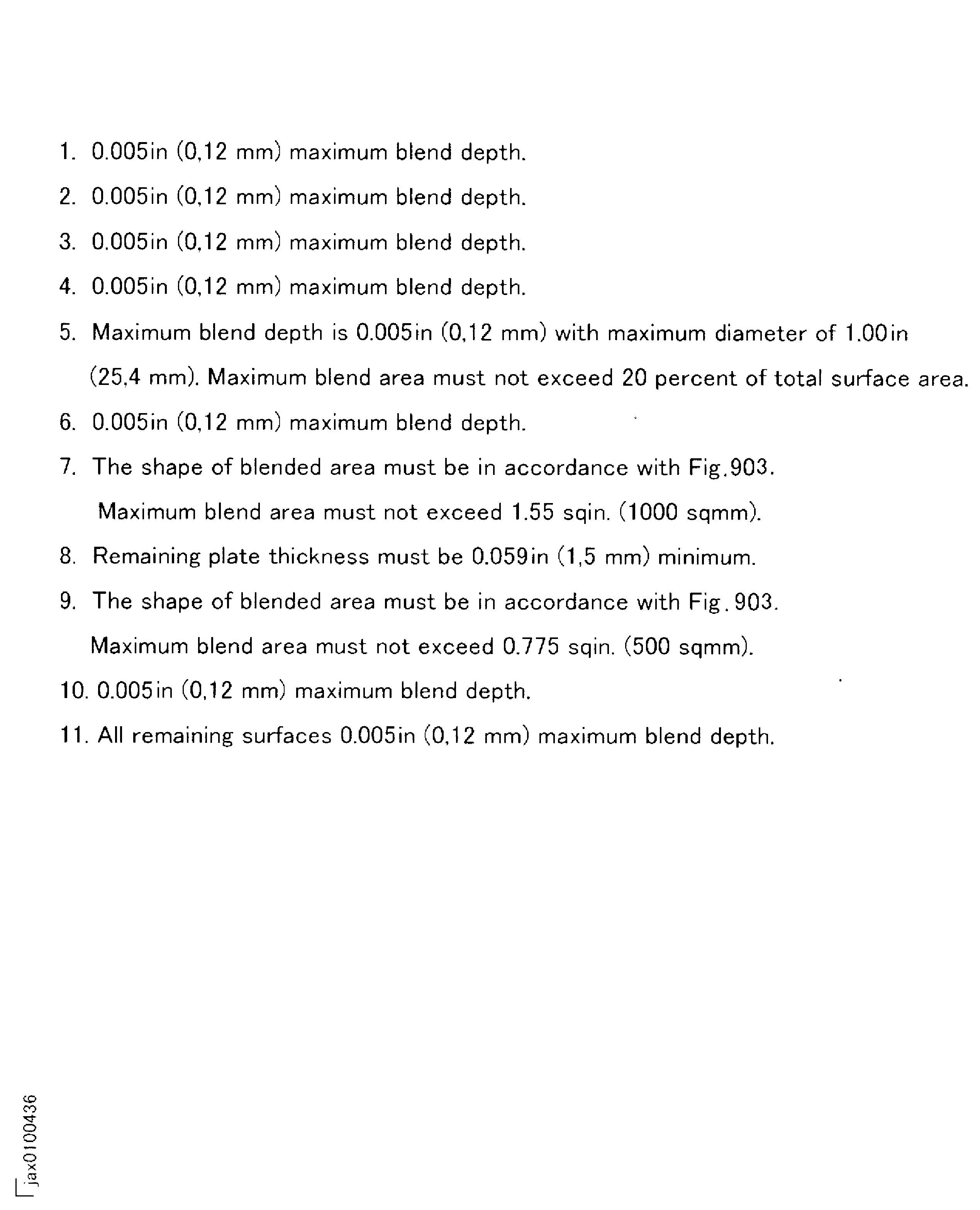

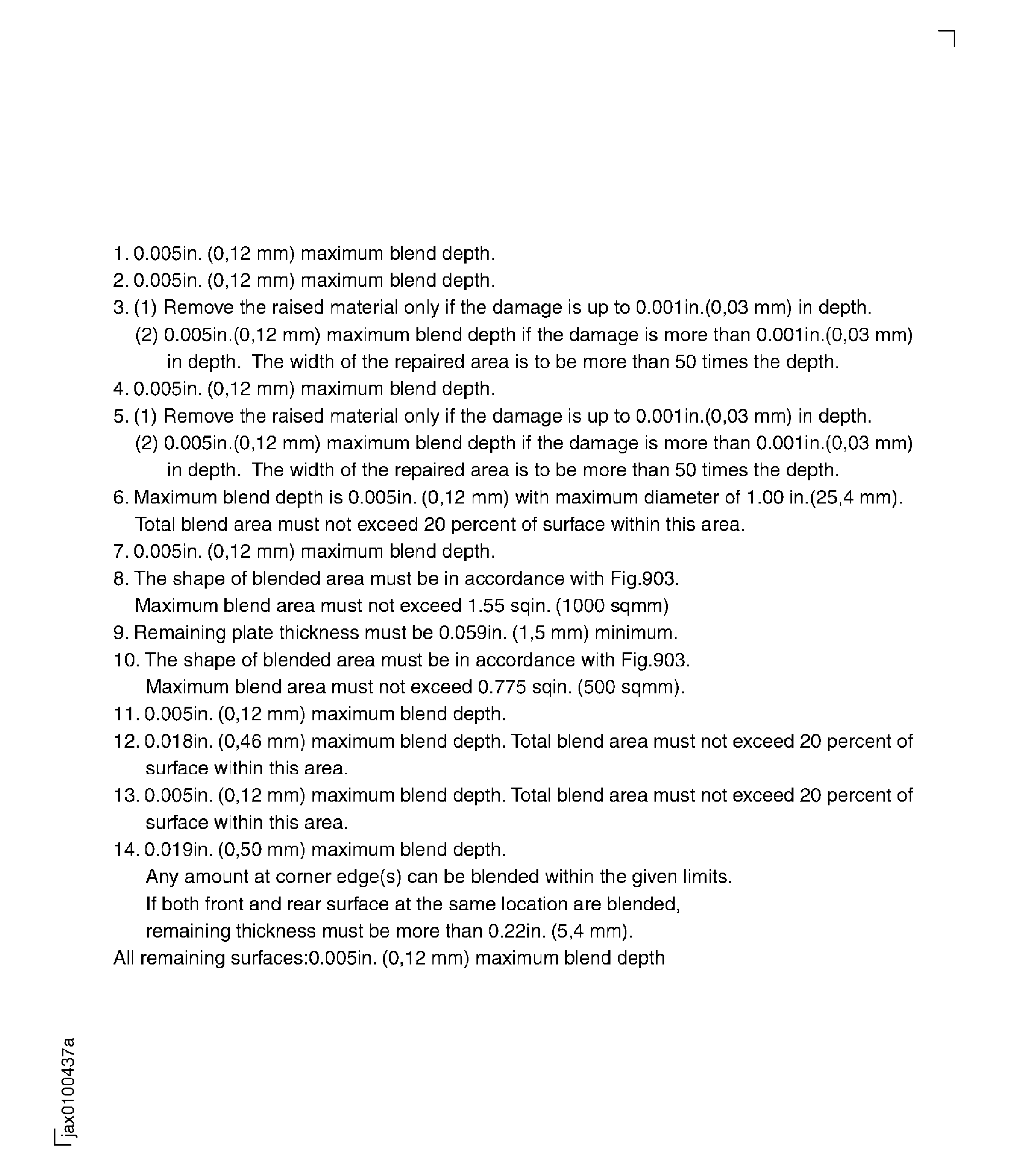

Figure: Repair Details and Dimensions

Repair Details and Dimensions