Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-05-300-003 PTO Center Bearing Housing - Repair The Bearing Bore By Plasma Spray, Repair-003 (VRS1186)

General

Price and availability - not applicable

The practice and processes referred to in the procedure by the TASK number are in the SPP.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Abrasive blasting facility | LOCAL | Abrasive blasting facility | ||

| Plasma spray facility | LOCAL | Plasma spray facility | ||

| Grinding machine | LOCAL | Grinding machine | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| IAE 3J12723 Machining fixture | 0AM53 | IAE 3J12723 | 1 | |

| IAE 3J12724 Diamond wheel | 0AM53 | IAE 3J12724 | 1 | |

| IAE 3J12725 Coating fixture | 0AM53 | IAE 3J12725 | 1 | |

| IAE 3J12726 TBD | 0AM53 | IAE 3J12726 | 1 | |

| IAE 3J12820 Masking fixture | 0AM53 | IAE 3J12820 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 03-302 METAL SPRAYING POWDER,WC/Co | LOCAL | CoMat 03-302 | ||

| CoMat 03-320 METAL SPRAYING POWDER,WC/Co | LOCAL | CoMat 03-320 | ||

| CoMat 03-321 METAL SPRAYING POWDER,WC/Co | LOCAL | CoMat 03-321 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 |

Spares

NONESafety Requirements

NONEProcedure

Use IAE IAE 3J12723 Machining fixture 1 off and IAE IAE 3J12724 Diamond wheel 1 off.

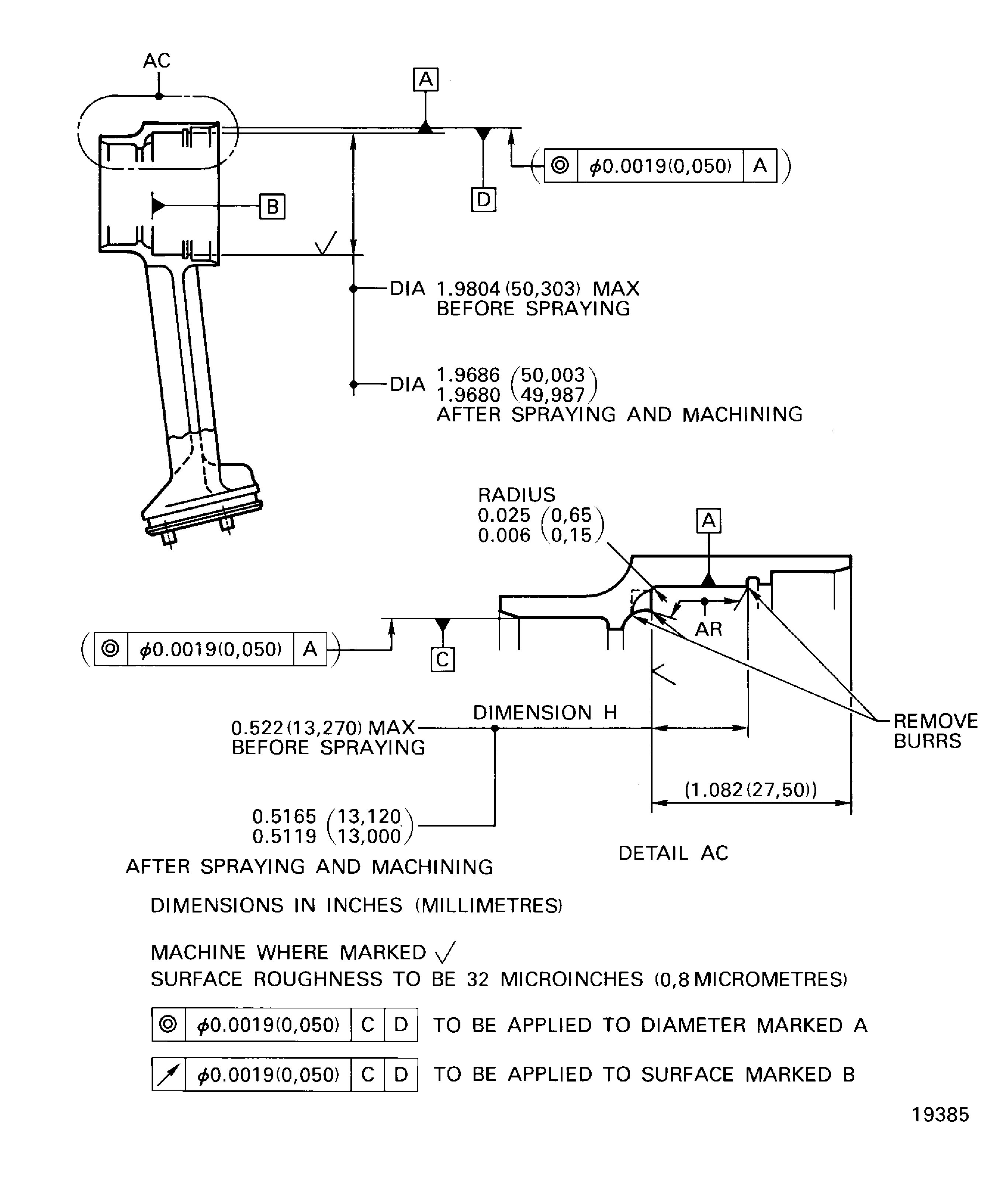

Machine the diameter A and face B.

SUBTASK 72-32-05-320-051 Machine the Bearing Bore of the Center Bearing Housing Assembly

Refer to the SPM TASK 70-23-05-230-501.

Fluorescent penetrant examine machined area.

SUBTASK 72-32-05-230-055 Examine the Center Bearing Housing Assembly for Cracks

Use IAE 3J12725 Coating fixture 1 off and IAE 3J12726 TBD 1 off or IAE 3J12820 Masking fixture 1 off.

Apply masking tape to the areas which are not to be given plasma spray.

Refer to the SPM TASK 70-34-01-340-501.

Abrasive blast the bearing bore (Area AR).

Refer to the SPM TASK 70-34-01-340-501.

Plasma spray parameters

SPRAY GUN

Type:

Metco 7MB

Nozzle:

704

Powder Port:

No.5

Uni-Jet Ring:

N/A

Insulator:

7M 50

GAS

Pressure - Primary, psi:

100

bars:

6.89

Secondary, psi:

-

bars:

-

Flow - Primary:

200

Secondary

0

POWER

Unit:

6MR, 7MR

Aro Amps:

1.000

Arc Volts:

45-55

POWDER FEED

Unit: 3MP or 3MP-DUAL

Meter wheel:

S

PRM:

15

Carrier Gas Flow

50

SPRAYING

Spray Distance, inches:

2.5

mm.

64

Spray rate, lb/hr:

6

kg/hr:

2.72

Plasma spray area AR of the bearing bore.

SUBTASK 72-32-05-340-051 Plasma Spray the Bearing Bore of the Center Bearing Housing Assembly

Refer to the SPM TASK 70-34-01-340-501.

Examine the bearing bore for adhesion, chipping and separation.

SUBTASK 72-32-05-220-068 Examine the Bearing Bore of the Center Bearing Housing Assembly

Use IAE 3J12723 Machining fixture 1 off and IAE IAE 3J12724 Diamond wheel 1 off.

Locate the center bearing housing assembly on fixture, set fixture to run true.

SUBTASK 72-32-05-340-052 Machine the Bearing Bore of the Center Bearing Housing Assembly

Refer to the SPM TASK 70-34-01-340-501.

Visually and dimensionally examine the repaired areas.

SUBTASK 72-32-05-220-069Examine the Center Bearing Housing Assembly

Figure: Repair details and dimensions (Assembly A)

Sheet 1

Figure: Repair details and dimensions (Assembly B)

Sheet 2