Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-23-300-013 HPC Front Shaft Assembly - Repair The Spacers, Repair-013 (VRS6488)

Material of component

RR | ||

|---|---|---|

DESCRIPTION | SYMBOL | MATERIAL |

HP Compressor front stub | TEG | Titanium aluminum vanadium |

shaft assembly | alloy | |

Spacer | EAK | Modified 12 percent Chromium |

steel |

General

This repair must only be done when the instruction to do so is given in 72-32-23 Inspection/Check.

This repair lets you replace damaged and/or loose spacers, in the HP. Compressor, Front Stub Shaft.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are given in the SPM.

Price and availability

Refer to International Aero Engines

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| IAE 3R19048 Holding fixture | 0AM53 | IAE 3R19048 | 1 | |

| IAE 3R19049 Punch | 0AM53 | IAE 3R19049 | 1 | |

| IAE 3R19050 Special reamer, 1st oversize | 0AM53 | IAE 3R19050 | 1 | |

| IAE 3R19051 Special reamer, 2nd oversize | 0AM53 | IAE 3R19051 | 1 | |

| IAE 3R19052 Freezing plug | 0AM53 | IAE 3R19052 | 1 | |

| IAE 3R19053 Protective ring | 0AM53 | IAE 3R19053 | 1 | |

| IAE 3R19116 Location pin (standard) | 0AM53 | IAE 3R19116 | 1 | |

| IAE 3R19117 Location pin (oversize) | 0AM53 | IAE 3R19117 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-026 LIQUID NITROGEN | LOCAL | CoMat 03-026 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Spacer | UP11051 | 20 AR | ||

| Spacer | 6A4372 | 20 AR | ||

| Spacer | 6A4373 | 20 AR |

Safety Requirements

NONEProcedure

Refer to TASK 72-32-23-200-000 (INSPECTION-000).

Do a penetrant crack test.

SUBTASK 72-32-23-230-070 Do a Crack Test

Use IAE 3R19053 Protective ring 1 off.

Place the protective ring over the curvic coupling of the HP Compressor Front Stub Shaft Assembly.

Use IAE 3R19049 Punch 1 off, with standard workshop equipment.

Remove loose or damaged spacer(s).

SUBTASK 72-32-23-350-086 Remove Loose or Damaged Spacer(s), from the HP Compressor Front Stub Shaft Assembly

Refer to the SPM TASK 70-11-03-300-503.

Chemically clean the repaired area(s).

SUBTASK 72-32-23-110-078 Chemically Clean

Refer to the SPM TASK 70-23-05-230-501.

Cracks are not permitted.

Do a local penetrant crack test.

SUBTASK 72-32-23-230-071 Do a Crack Test

Do Step.

If there is an interference fit of 0.0003 to 0.0013 in. (0.008 to 0.032 mm), on the location diameter.

SUBTASK 72-32-23-220-103 Examine the HP Compressor Front Stub Shaft Assembly

Use IAE 3R19048 Holding fixture 1 off, with a drilling ,machine and Standard workshop equipment.

Install the holding fixture into the machine.

Use IAE 3R19116 Location pin (standard) 1 off or IAE 3R19117 Location pin (oversize) 1 off, as necessary.

Locate the holding fixture over the spacer location to be machined and secure in position.

Use IAE 3R19050 Special reamer, 1st oversize 1 off or IAE 3R19051 Special reamer, 2nd oversize 1 off, as necessary.

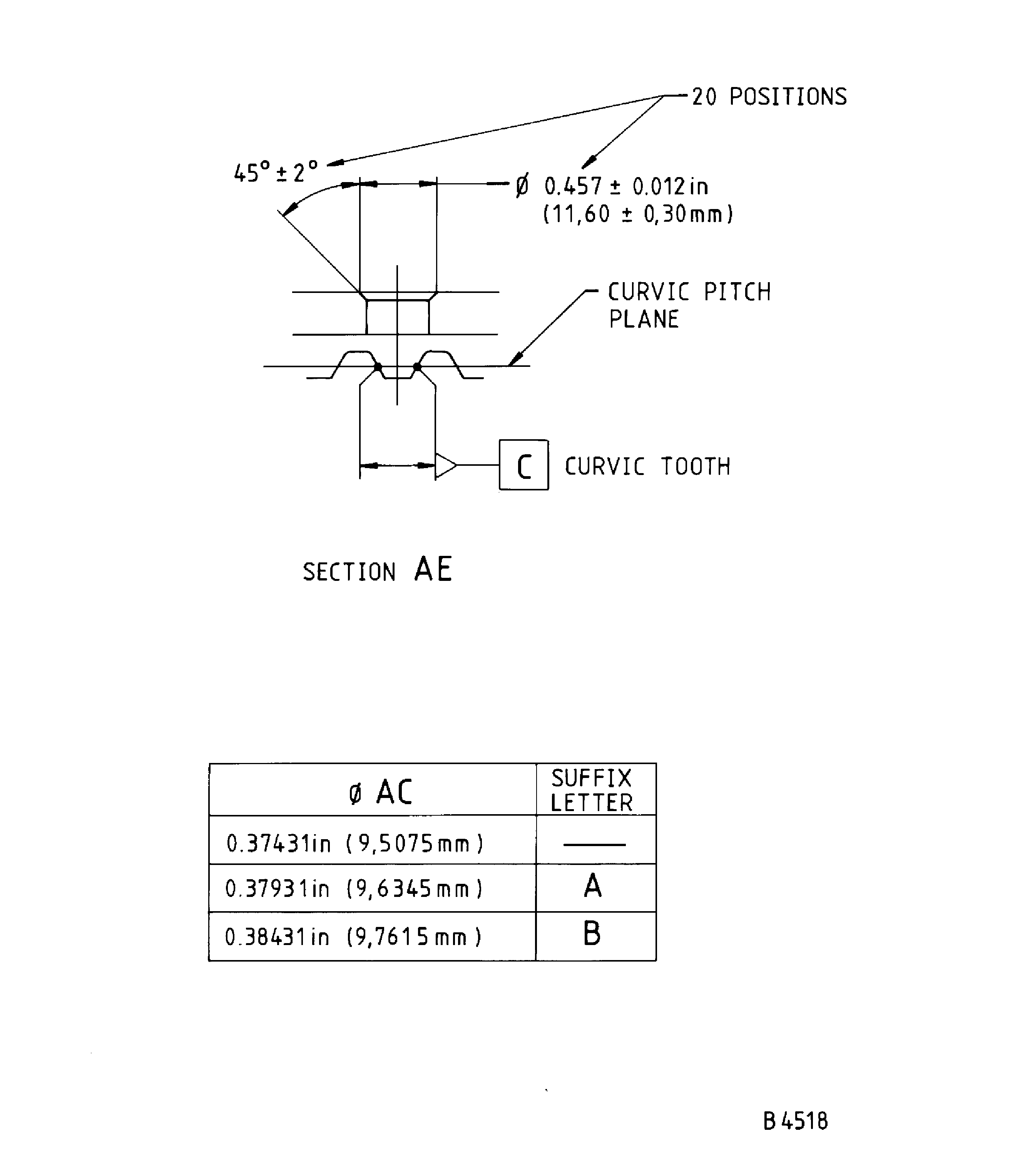

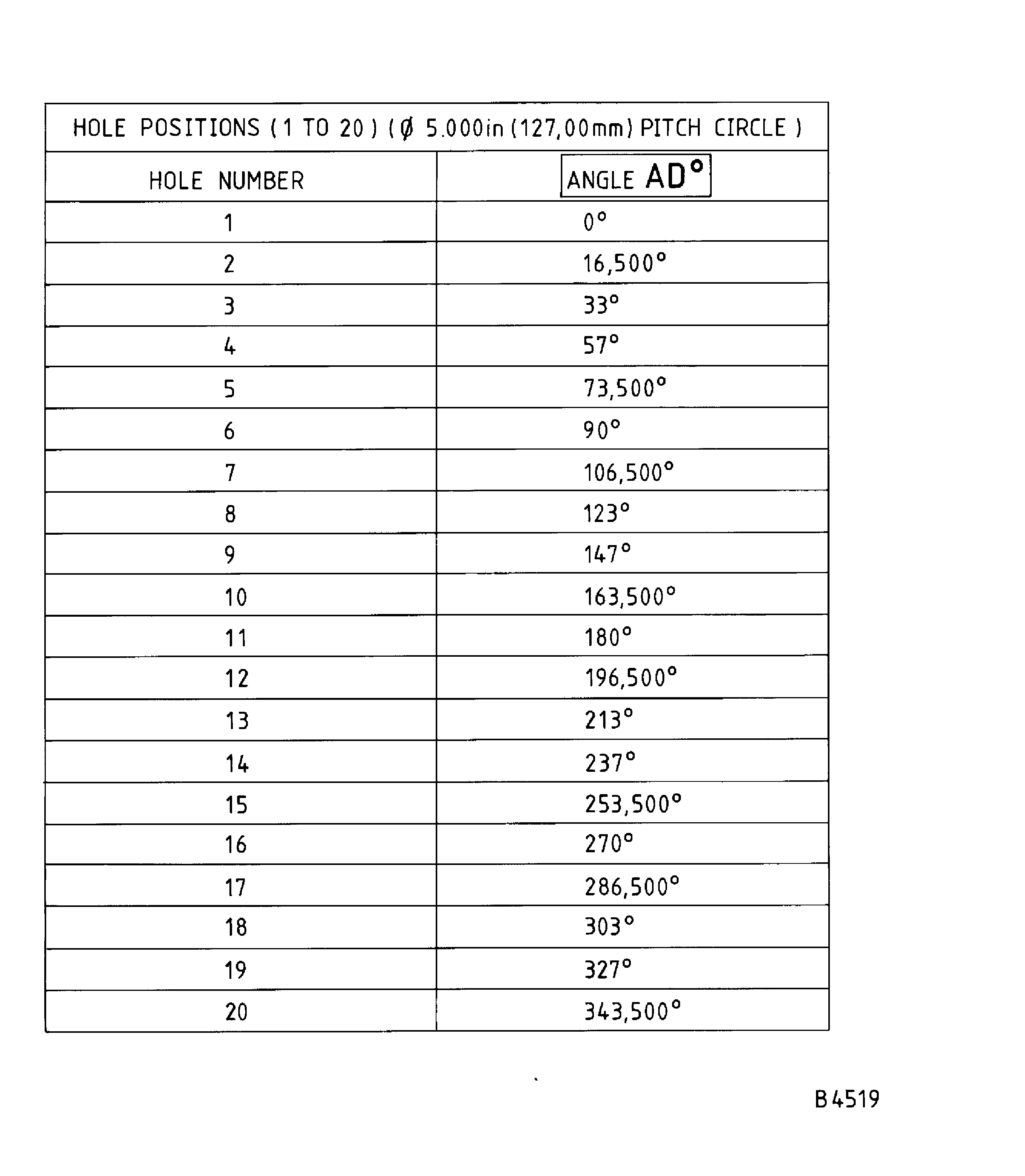

Machine the spacer location(s) diameter AC, to the minimum oversize as necessary.

SUBTASK 72-32-23-323-051 Machine the Spacer Location(s), as necessary

Refer to the SPM TASK 70-11-08-300-503, SUBTASK 70-11-08-300-001.

Chemically clean.

Refer to the SPM TASK 70-11-08-300-503, SUBTASK 70-11-08-300-002.

Swab etch the repaired area.

SUBTASK 72-32-23-110-079 Do a Swab Etch

Refer to the SPM TASK 70-23-05-230-501.

Cracks are not permitted.

Do a local penetrant crack test.

SUBTASK 72-32-23-230-072 Do a Crack Test

Use UP11051 spacer, 01-760, 1 off, 6A4372 spacer, 01-762, 1 off and/or 6A4373 spacer, 01-763, 1 off, as necessary, with IAE 3R19052 Freezing plug 1 off, with standard workshop equipment.

Install the new spacer on to the freezing plug.

SUBTASK 72-32-23-350-087 Install New Spacer(s) into the HP Compressor Front Stub Shaft Assembly

Refer to the SPM TASK 70-23-05-230-501.

Cracks are not permitted.

Do a local penetrant crack test.

SUBTASK 72-32-23-230-073 Do a Crack Test

Refer to the SPM TASK 70-11-03-300-503.

Chemically clean the repaired area(s).

SUBTASK 72-32-23-110-080 Chemically Clean

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

NOTE

For example, mark VRS6488/3/A, adjacent to the part number.

Make a mark VRS6488, followed by the hole position(s), adjacent to the part number.

SUBTASK 72-32-23-350-088 Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions