Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-23-300-015 HPC Front Shaft Assembly - Repair Damaged Threads By Material Removal, Repair-015 (VRS1991)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-745 | 6A2914 |

01-745 | 6A2940 |

01-745 | 6A3888 |

01-745 | 6A3899 |

01-745 | 6A4147 |

01-745 | 6A8083 |

01-745 | 6A8094 |

Material of component

PART IDENT | IAE SYMBOL | MATERIAL |

|---|---|---|

HP Compressor Front Stubshaft | TEG | Titanium aluminum vanadium alloy |

General

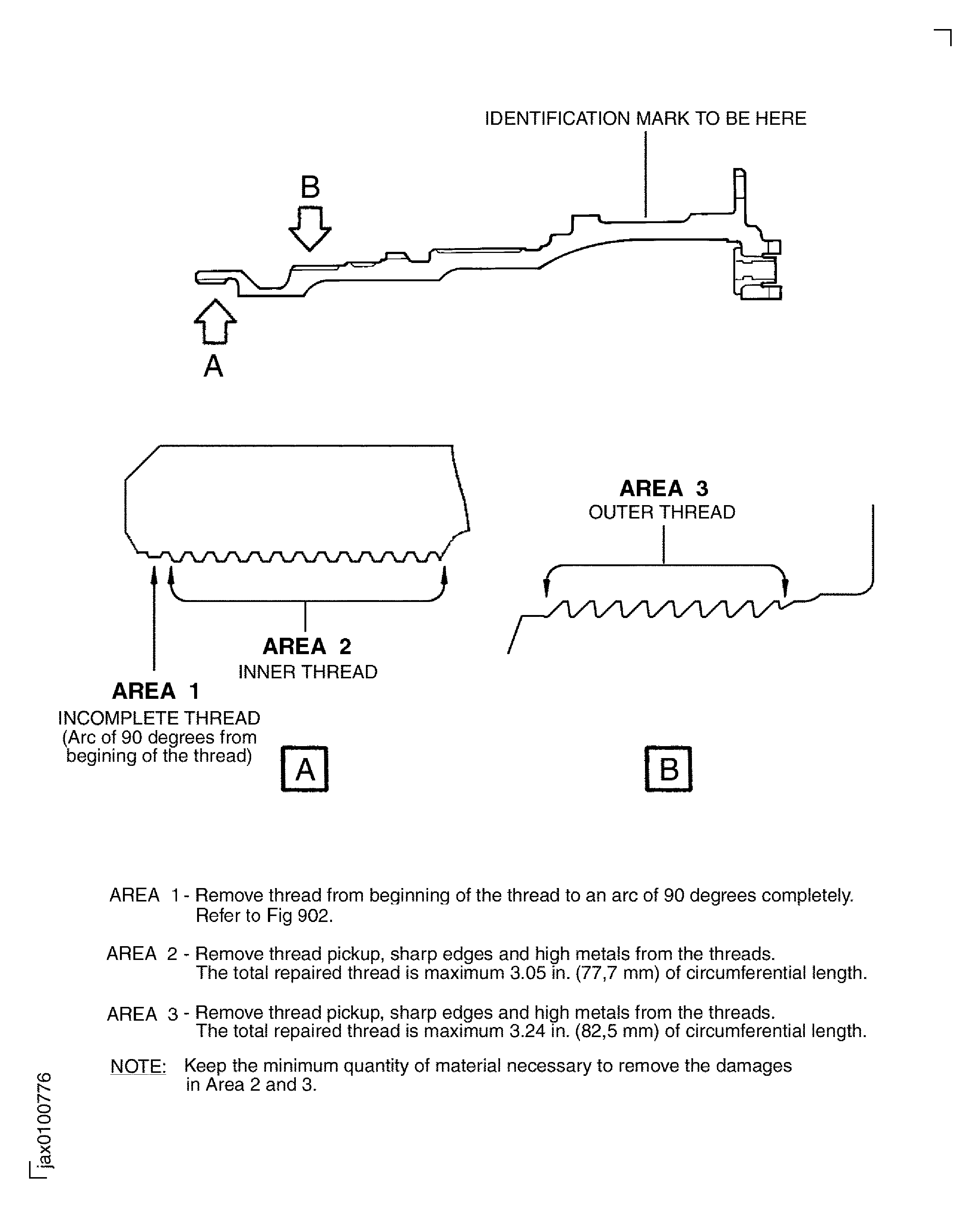

This repair can only be done one time on incomplete thread of inner thread (Area 1). Refer to Figure. When incomplete thread is removed to this repair, a code letter A is put following the repair identification mark.

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPP.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Portablegrinding equipment | LOCAL | Portable grinding equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-019 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-019 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

NONESafety Requirements

NONEProcedure

If the mark with "VRS1991 A" is found, Step must not be applied to the shaft.

Area 1 cannot be repaired again.

Use Portablegrinding equipment or abrasive stone.

The end of the repaired area must be smoothly continuous.

Refer to the SPM TASK 70-35-03-300-501.

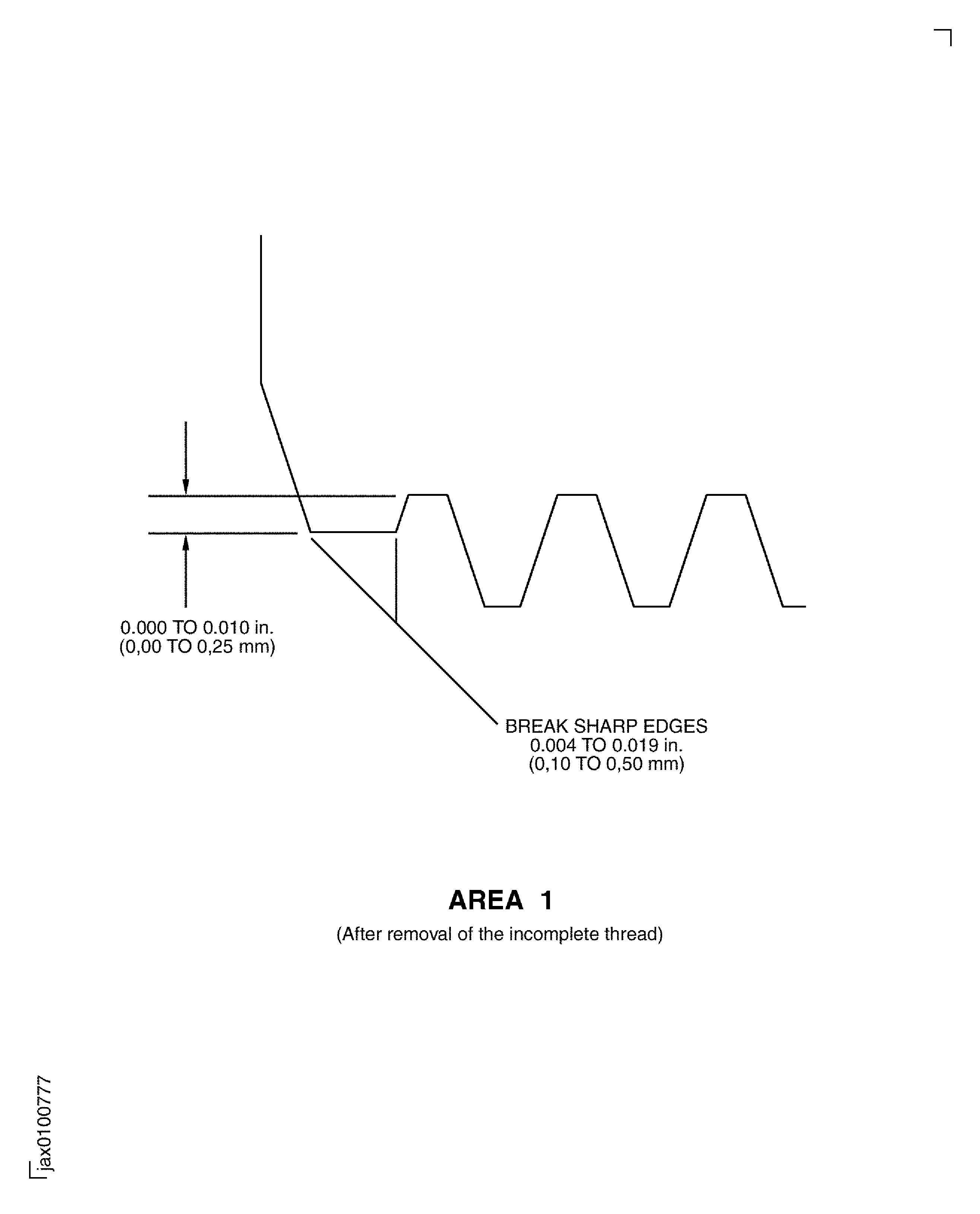

Remove thread over an arc of 90 degrees from beginning of the thread completely.

Make smooth and/or hand polish to remove thread pick up, sharp edges and high metals on threads.

Use honing stone or CoMat 05-019 WATERPROOF SILICON CARBIDE, CoMat 05-020 WATERPROOF SILICON CARBIDE and CoMat 05-021 WATERPROOF SILICON CARBIDE and/or fine file.

SUBTASK 72-32-23-350-013 Remove the Damage from the Thread

CAUTION

1. TITANIUM COMPONENT - SILICON CARBIDE TYPE WHEELS, STONES AND ABRASIVE PAPERS ARE TO BE USED FOR THIS REPAIR.

CAUTION

2. TITANIUM COMPONENT - ALUMINUM OXIDE MUST NOT BE USED.

CAUTION

3. TITANIUM COMPONENT - THE MATERIAL WILL OXIDIZE AND CRACK IF MECHANICAL CUTTERS ARE USED HEAVILY. IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.Surface finish of the repair must be the same as the adjacent area.

Refer to the SPM TASK 70-35-03-300-501.

Use CoMat 05-019 WATERPROOF SILICON CARBIDE, CoMat 05-020 WATERPROOF SILICON CARBIDE and CoMat 05-021 WATERPROOF SILICON CARBIDE.

SUBTASK 72-32-23-350-014 Polish the Repaired Area

CAUTION

1. TITANIUM COMPONENT - SILICON CARBIDE TYPE WHEELS, STONES AND ABRASIVE PAPERS ARE TO BE USED FOR THIS REPAIR.

CAUTION

2. TITANIUM COMPONENT - ALUMINUM OXIDE MUST NOT BE USED.

CAUTION

3. TITANIUM COMPONENT - THE MATERIAL WILL OXIDIZE AND CRACK IF MECHANICAL CUTTERS ARE USED HEAVILY. IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.Refer to TASK 72-32-23-200-000.

Visually examine the repaired area.

SUBTASK 72-32-23-220-119 Examine the Repair

Refer to the SPM TASK 70-23-05-230-501.

Cracks are not permitted.

Do a local penetrant crack test.

SUBTASK 72-32-23-230-082 Do a Crack Test

Refer to Figure.

Refer to the SPM TASK 70-09-00-400-501.

If incomplete thread is removed in Step put a code letter A following the mark VRS1991.

SUBTASK 72-32-23-350-015 Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions