Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-36-300-009 No. 2 and 3 Bearing Oil Distributor And Tubes - Related Parts - Replace The Insert And Lock Rings Of Main Oil Distributor Assembly, Repair-009 (VRS1932)

Price and availability

Refer to IAE for any of these items.

Tools

Repair parts

Repair of spares

Material of component

DESCRIPTION | RR SYMBOL | SYMBOL MATERIAL |

Main oil distributor | - | Aluminum alloy (AMS4215) |

General

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

NOTE

Related repairs

Main oil distributor assembly - Replace the locating pin.

Refer to VRS1933 (Repair-010) TASK 72-32-36-300-010.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Drill Machine | LOCAL | Drill Machine | ||

| Wrench (R1106-W) | LOCAL | Wrench (R1106-W) | ||

| Pusher (R106-D) | LOCAL | Pusher (R106-D) | ||

| IAE 3J12714 Special extractor - ring locked insert | 0AM53 | IAE 3J12714 | 1 |

Consumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| INSERT - LOCKED, RING | 96906 | MS51991-206L | 2 | FIG/ITEM 01-565 |

| RING - LOCKING | 96906 | MS51990-106P | 2 | FIG/ITEM 01-570 |

Safety Requirements

NONEProcedure

Use 0.3125 in. (7.9 mm) diameter Drill Machine.

Drill thru lockring and neck of insert to destroy serration interlock.

Do not drill beyond the depth of the counter-bore in the parent material.

Machine the hole in the insert.

Drive square screw extractor into insert and apply removal torque.

When insert thread flanks bear against lower surface of lockring.

Continued removal torque will cause the lockring to be jacked out.

Insert removal may thus be completed.

Remove the damaged insert and lockring.

Remove the damaged insert and lockring.

SUBTASK 72-32-36-350-056 Remove the Damage Insert and Lock Ring

Use 10X magnifying glass.

Visually examine the hole after insert removal for cracks.

SUBTASK 72-32-36-220-110 Examine the Hole after Insert Removal

Refer to Figure.

NOTE

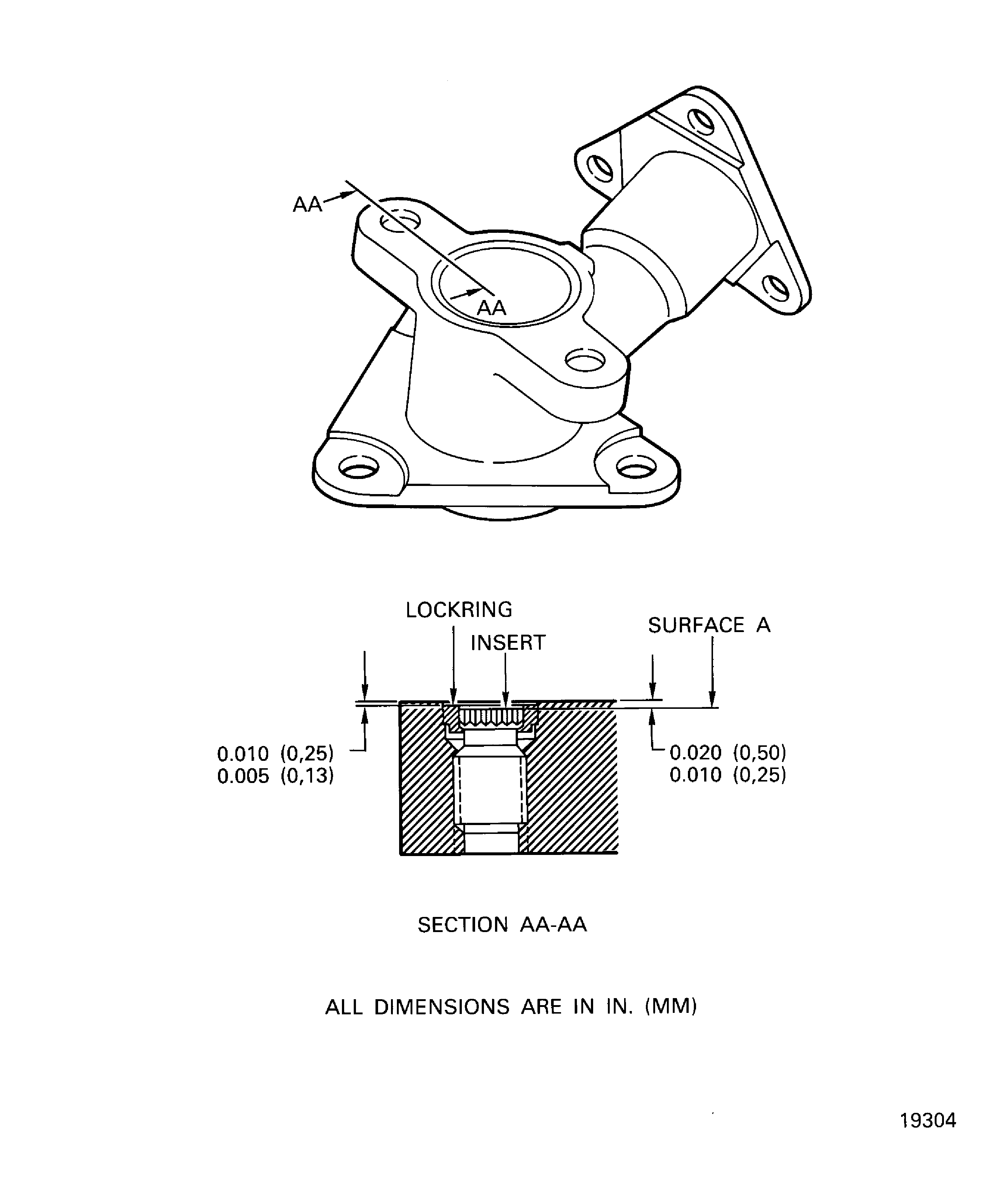

Depth of insert is important so that the lockring drive tool will not make contact with Surface A. Any impact or pressure on this surface may cause damage to threads in parent material, resulting in a loose fit.With applicable Wrench (R1106-W), install new insert to specified depth.

Insert the the new insert to specified depth.

Refer to Figure.

NOTE

Replacement of insert and lockring is made with the same size parts as those removed. Before driving new lockring, rotate the lockring external serrations to a position aligned with those in parent material. If parent material is damaged, use oversize inserts and oversize lockring.With applicable Pusher (R106-D), install new lockring to specified depth.

Drive the new lockring to specified depth.

SUBTASK 72-32-36-350-057 Install the New Insert and Lockring

Refer to Figure.

Use 10X. magnifying glass.

Refer to TASK 72-32-36-200-408**.

Visually examine and dimensional check the installed insert and lockring.

SUBTASK 72-32-36-220-111 Examine the Installed Insert and Lockring

Figure: Main Oil Distributor Assembly - Repair Limit

Main Oil Distributor Assembly - Repair Limit