Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-37-300-004 Fan Speed/Trim Balance Probes Electrical Harness - Replace The Sleeves, Repair-004 (VRS1263)

Material of component

PART IDENT | IAE SYMBOL | MATERIAL |

|---|---|---|

Terminal | Copper alloy | |

Sleeve marker | Viton | |

Sleeve | Fluorethylenepropylene (FEP) (inner) Tetrafluoroethylene (TFE) (outer) |

General

Price and availability - none.

Repair Parts

FIG/ITEM | PART NO. | PART IDENT | QTY |

|---|---|---|---|

01-105 | 20-32492-6 | Sleeve | 1 |

01-145 | 20-32492-6 | Sleeve | 1 |

01-185 | 20-32492-6 | Sleeve | 1 |

01-225 | 20-32492-6 | Sleeve | 1 |

01-115 | 5A9536 | Sleeve marker 1 | 1 |

01-120 | 5A9537 | Sleeve marker 2 | 1 |

01-155 | 5A9538 | Sleeve marker 3 | 1 |

01-160 | 5A9539 | Sleeve marker 4 | 1 |

01-195 | 5A9540 | Sleeve marker 5 | 1 |

01-200 | 5A9541 | Sleeve marker 6 | 1 |

01-235 | 5A9542 | Sleeve marker 7 | 1 |

01-240 | 5A9543 | Sleeve marker 8 | 1 |

01-110 | 5A1239 | Sleeve marker A | A/R |

01-150 | 5A1256 | Sleeve marker B | A/R |

01-190 | 5A1257 | Sleeve marker C | A/R |

01-230 | 5A1258 | Sleeve marker D | A/R |

01-125 | 20-32492-5 | Sleeve | A/R |

01-130 | 150457 | Terminal | A/R |

01-165 | 20-32492-5 | Sleeve | A/R |

01-170 | 150457 | Terminal | A/R |

01-205 | 20-32492-5 | Sleeve | A/R |

01-210 | 150457 | Terminal | A/R |

01-245 | 20-32492-5 | Sleeve | A/R |

01-250 | 150457 | Terminal | A/R |

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Hot air gun | LOCAL | Hot air gun |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure.

NOTE

Harnesses are of sufficient length to allow the removal and renewal of the terminal three times only.Examine and identify the damaged sleeves.

Remove the damaged sleeve without any damage to the insulations.

Cut the two terminals and move the sleeve markers carefully if the distance between the sleeve on the terminal and the sleeve marker can not be kept within 0.95 in and 1.02 in. (24 mm to 26 mm).

SUBTASK 72-32-37-350-051 Remove the Sleeves (01-105, 01-145, 01-185 and 01-225) from the NF Electrical Harness

Use a Hot air gun. Refer to Figure, Figure and Figure.

CAUTION

DO NOT APPLY HOT AIR FOR MORE THAN 50 SECONDS.Heat shrink the sleeve with a hot air gun, at air temperature 770 deg F to 860 deg F (410 deg C to 460 deg C) after five minutes warm up period. Apply heat until the sleeve becomes transparent, continue heating for a further 10 to 15 seconds to ensure that the inner sleeve has fully heated and a plastic state is got. As soon as you have the above condition, stop hot air.

SUBTASK 72-32-37-350-052 Fit the Sleeves (01-105, 01-145, 01-185 and 01-225) to the NF Electrical Harness

Refer to VRS1261 TASK 72-32-37-300-002 (REPAIR-002).

Fit the terminals and the sleeve markers.

SUBTASK 72-32-37-350-053 Fit the Terminals and the Sleeve Markers (If removed) (01-115, 01-120, 01-155, 01-160, 01-195, 01-200, 01-235 and 01-240)

Remove the damaged sleeve marker without any damage to the insulation.

Cut the terminals.

SUBTASK 72-32-37-350-054 Remove the Sleeve Markers 1 through 8 (01-115, 01-120, 01-155, 01-160, 01-195, 01-200, 01-235 and 01-240) from the NF Electrical Harness

Refer to Repair, VRS1261 TASK 72-32-37-300-002(REPAIR-002).

Fit the terminals and the sleeve markers.

SUBTASK 72-32-37-350-055 Fit the Terminals and the Sleeve Markers (01-115, 01-120, 01-155, 01-160, 01-195, 01-200, 01-235 and 01-240) to the NF Electrical Harness

Put the sleeve marker onto its position as specified.

NOTE

You can put the two insulations into the sleeve without cutting the terminals.Use a Hot air gun.

Heat shrink the sleeve until the sleeve is fully shrunk.

SUBTASK 72-32-37-350-057 Fit the Sleeve Markers (01-110, 01-150, 01-190 and 01-230) to the NF Electrical Harness

Refer to TASK 72-32-37-700-301 (TESTING-001).

Do the test for continuity and insulation resistance.

SUBTASK 72-32-37-750-057 Do the Test for Continuity and Insulation Resistance

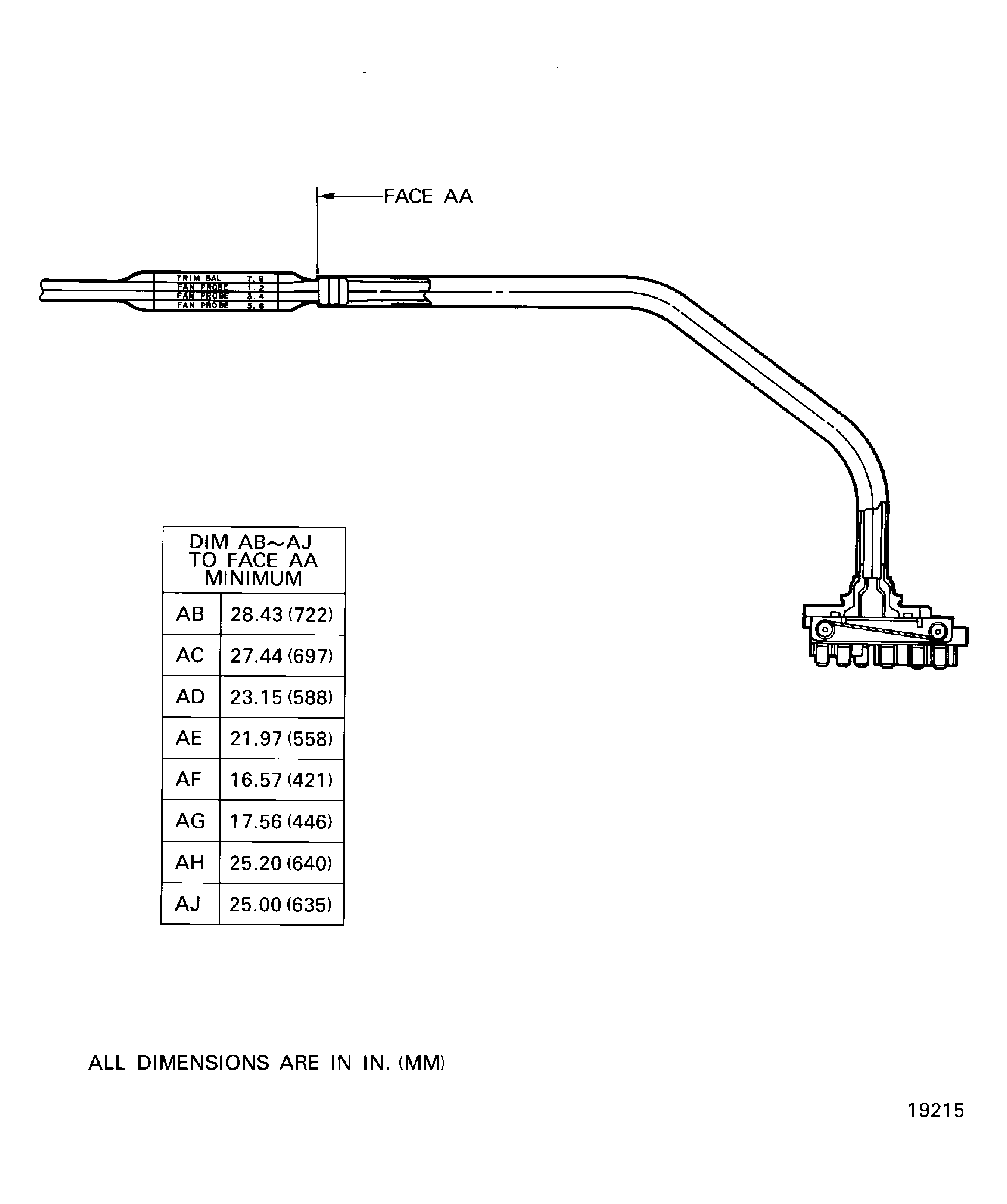

Figure: Replace the Sleeves

Replace the Sleeves

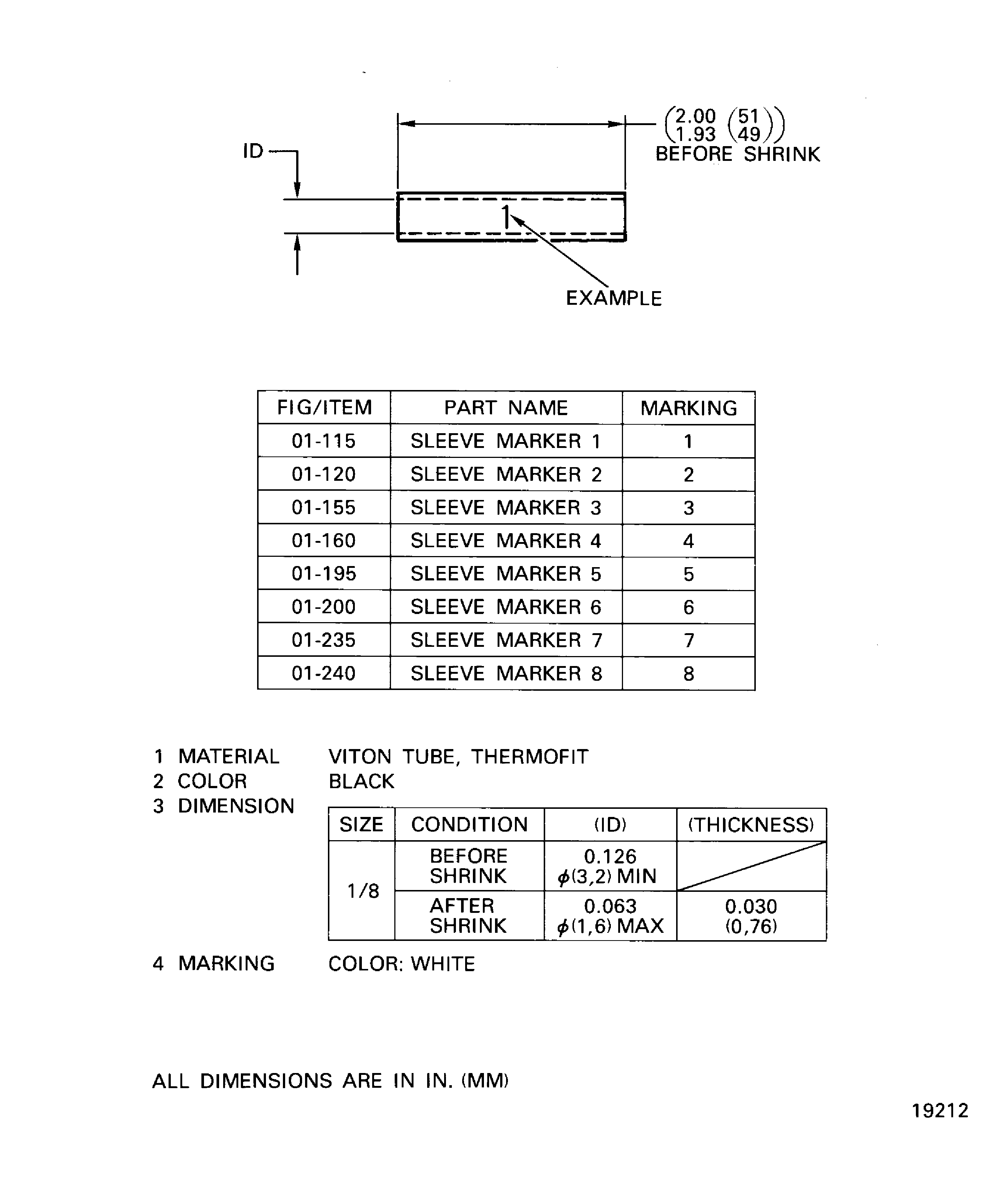

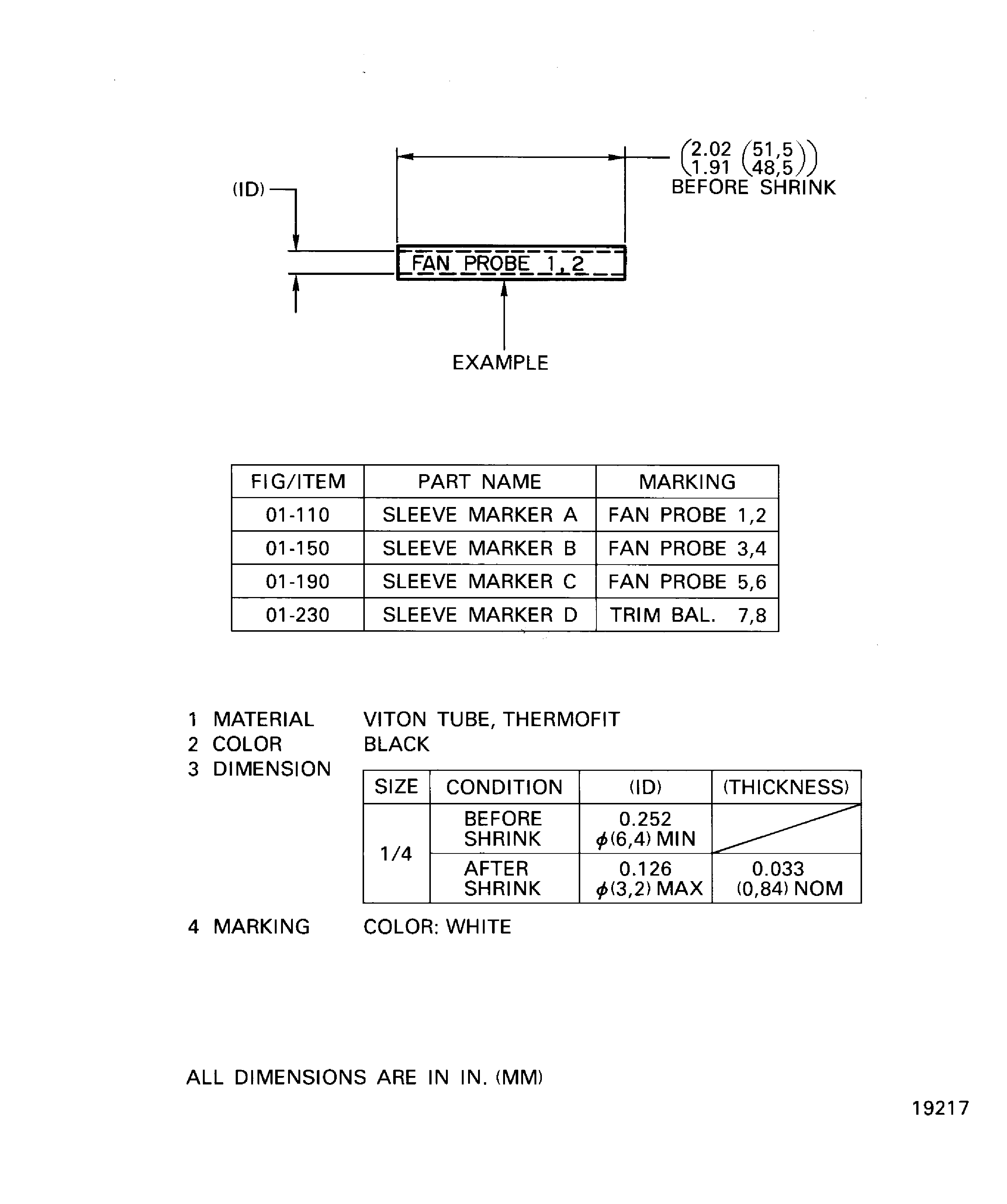

Figure: Basic Dimensions - Sleeve Markers

Basic Dimensions - Sleeve Markers

Figure: Basic Data - Sleeve Markers

Basic Data - Sleeve Markers

Figure: Replace the Terminals

Replace the Terminals

Figure: Basic Dimensions - NF Electrical Harness

Basic Dimensions - NF Electrical Harness

Figure: Basic Dimensions - NF Electrical Harness

Basic Dimensions - NF Electrical Harness