Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

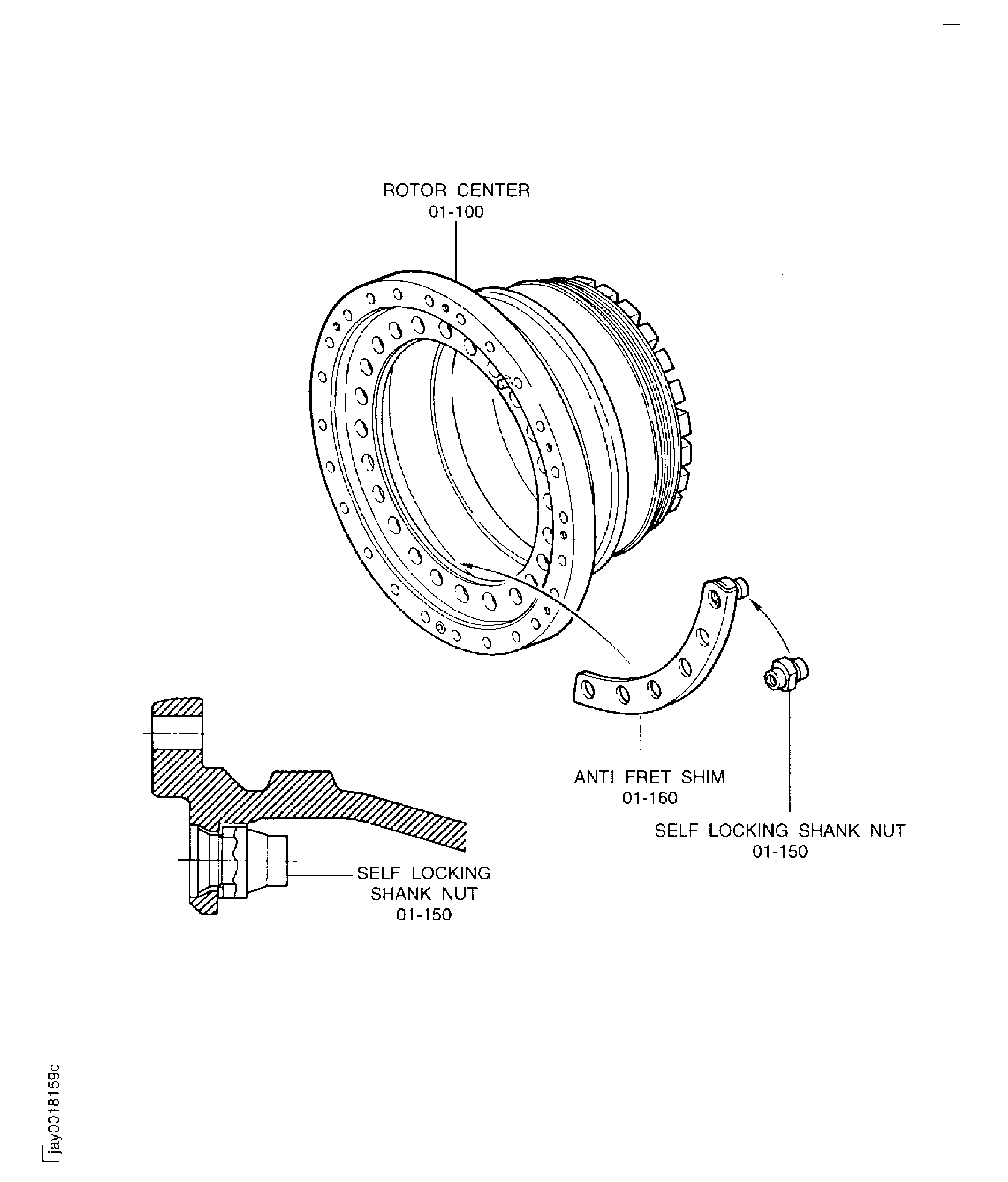

TASK 72-32-51-300-003 LP Rotor Center Shaft - Replace The Self Locking Shank Nuts, Repair-003 (VRS1277)

General

This repair TASK gives the procedure for replacing nuts.

Price and availability

Refer to IAE for any of these items.

Tools

Repair parts

Repair of spares

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Hand press | LOCAL | Hand press | ||

| IAE 3J13232 Peening fixture | 0AM53 | IAE 3J13232 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-076 METHYL ETHYL KETONE | LOCAL | CoMat 01-076 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 04-005 JOINTING COMPOUND, MEDIUM GRADE | LOCAL | CoMat 04-005 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Self locking shank nut | AS27891 | AR | ||

| Shim, anti fret | 5R0358 | AR |

Safety Requirements

NONEProcedure

Refer to Figure.

Refer to the SPM TASK 70-35-11-300-501.

Use a drillling machine with a 0.551 in. (14.0 mm) diameter drill.

Drill the flare until the nut is released.

Use CoMat 02-099 LINT-FREE CLOTH and also remove particles with air.

Clean the nut location.

SUBTASK 72-32-51-350-052 Remove the Damaged Self Locking Shank Nuts (01-150)

Refer to Figure.

SUBTASK 72-32-51-220-058 Examine the Shaft (01-100) Nut Location Holes and Anti Fret Shim (01-160)

Refer to Figure.

Refer to the SPM TASK 70-35-11-300-501.

Use IAE 3J13232 Peening fixture 1 off and hand press.

NOTE

Make sure the self locking shank nut is installed correctly.

Install the new self locking shank nut(s) and anti fret shim into the location hole(s).

Visually examine the silver coating inside of the shank for loose flakes of the silver coating. Remove any flakes using CoMat 02-099 LINT-FREE CLOTH.

SUBTASK 72-32-51-350-053 Install the New Self Locking Shank Nut(s) (01-150) and Anti Fret Shim (01-160) as necessary

Refer to TASK 72-32-51-200-000 (INSPECTION-000).

Use 10X magnifying glass. Make sure that no nicks, burrs and scores exist.

Visually examine the repaired area.

SUBTASK 72-32-51-220-059 Examine the Shaft (01-100)

Figure: Nut

Nut