Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-53-300-021 No. 1 Bearing Face Seal - Weld Repair The Anti-Rotation Slots, Repair-021 (VRS3545)

General

Price and availability - none

This repair applies to parts worn beyond the limits of TASK 72-32-53-300-009 (VRS3403) (REPAIR 009), which allows chrome plate thickness of up to 0.008 in. (0.203 mm) for each side.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Machine shop equipment | LOCAL | Machine shop equipment | ||

| Welding equipment | LOCAL | Welding equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-392 WELDING WIRE | LOCAL | CoMat 03-392 |

Spares

NONESafety Requirements

NONEProcedure

SUBTASK 72-32-53-330-056 Remove the Chrome Plate by Chemical or by Machine from the Anti-Rotation Slots

NOTE

Carbon seal replacement is necessary after you complete the chrome plate repair. Masking the carbon seal is not permitted because it is possible that there will be contamination with the plating solution and the masking material.Refer to the SPM TASK 70-31-13-310-501.

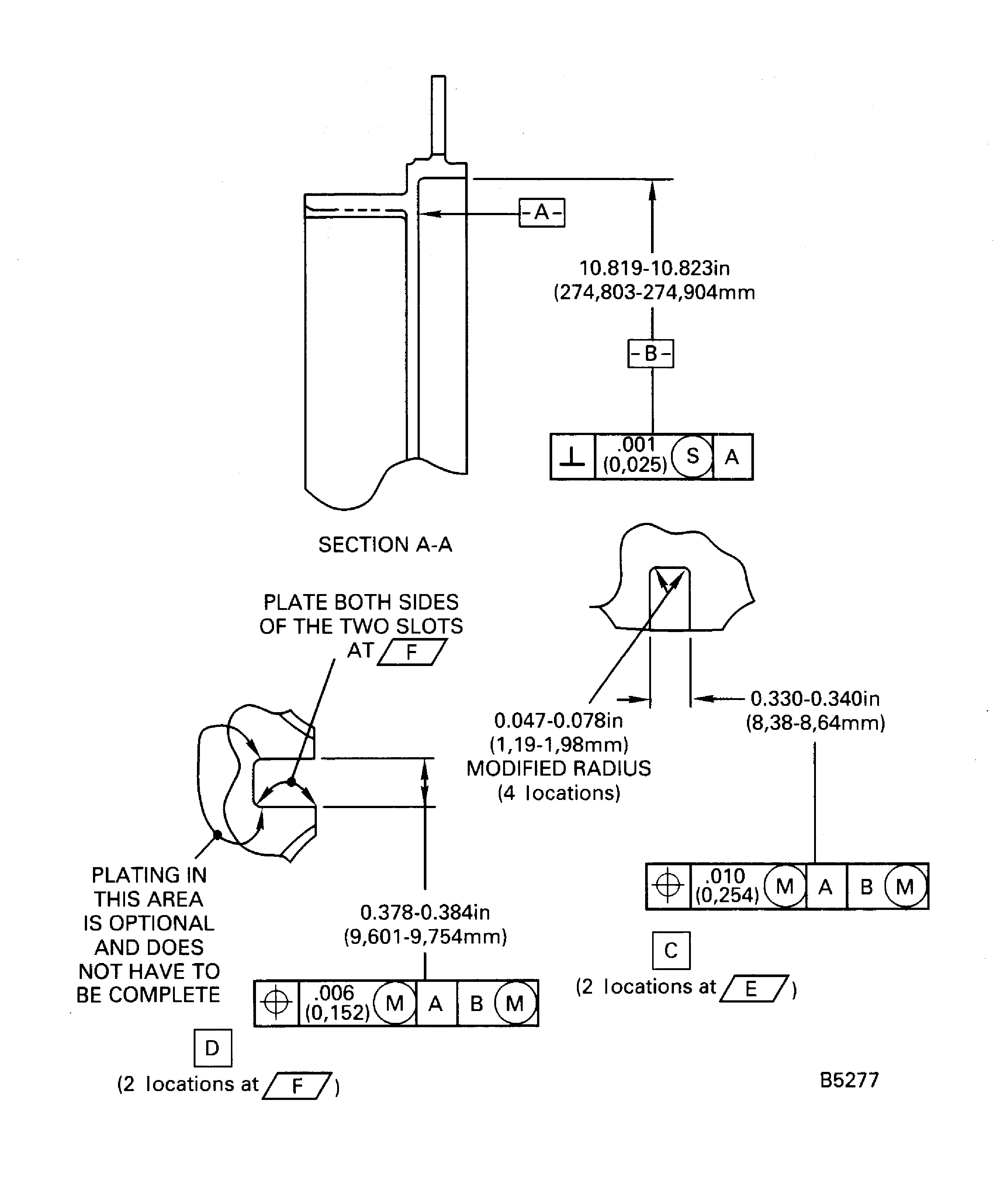

Weld buildup worn side or sides of slots sufficiently to permit machining and chrome thickness of 0.0005 to 0.0015 in. (0.013 to 0.038 mm) for each side, Figure.

Refer to the SPM TASK 70-37-07-370-501.

Stress relieve the face seal after weld repair.

SUBTASK 72-32-53-310-051 Weld Buildup Worn Side or Sides of the Anti-Rotation Slots

Refer to the SPM TASK 70-23-05-230-501.

Examine finish machined slots for cracks.

SUBTASK 72-32-53-220-098 Examine Finish Machined Areas on the Anti-Rotation Slots

Refer to the SPM TASK 70-33-02-330-501. The plating thickness must be sufficient to permit final machining with a final plate thickness of 0.0005 to 0.0015 in. (0.013 to 0.038 mm) for each side.

Apply chrome plate to the anti-rotation slots.

NOTE

No plate permitted outside of enclosed area. Dimensions are after plate.

SUBTASK 72-32-53-330-057 Chrome Plate the No. 1 Bearing Face Seal Anti-Rotation Slots

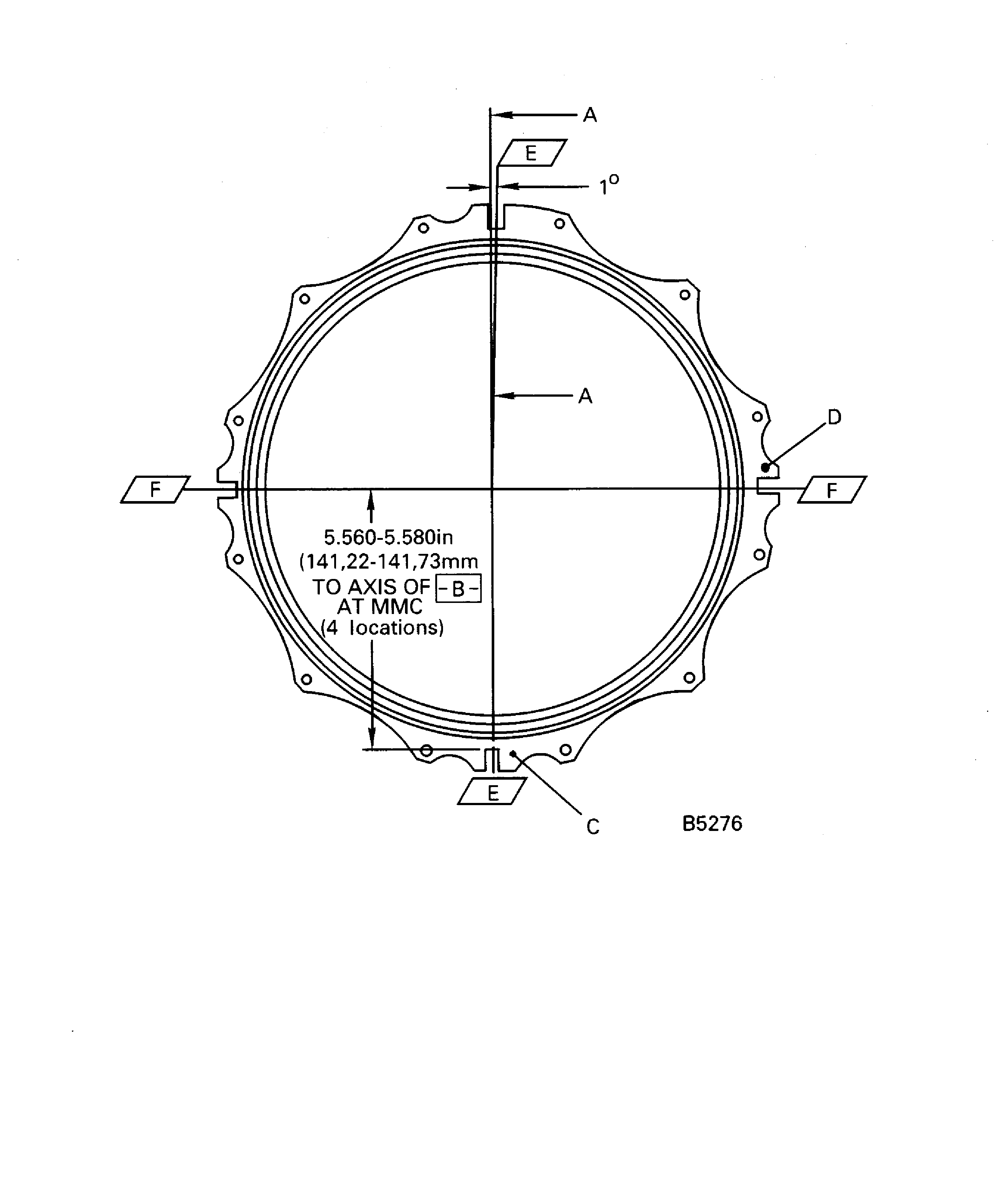

Figure: No. 1 bearing face seal anti-rotation slots repair

No. 1 bearing face seal anti-rotation slots repair

Figure: No. 1 bearing face seal anti-rotation slots repair

No. 1 bearing face seal anti-rotation slots repair