Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-72-300-008 LPC Bleed Valve Ring - Repair The Worn Pin Holes By Bush, Repair-008 (VRS1360)

General

Price and availability - none

The practice and processes referred to in the procedure by TASK/SUBTASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Horizontal boring mill | LOCAL | Horizontal boring mill | ||

| Rotary table | LOCAL | Rotary table | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Dial bore gage | LOCAL | Dial bore gage | ||

| Oven | LOCAL | Oven | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| Dial set indicator | LOCAL | Dial set indicator | ||

| External micrometer | LOCAL | External micrometer | ||

| IAE 3J12852 Machining fixture | 0AM53 | IAE 3J12852 | 1 | |

| IAE 3J12853 Pin hole location gage | 0AM53 | IAE 3J12853 | 1 |

Consumables, Materials and Expendables

NONESafety Requirements

NONEProcedure

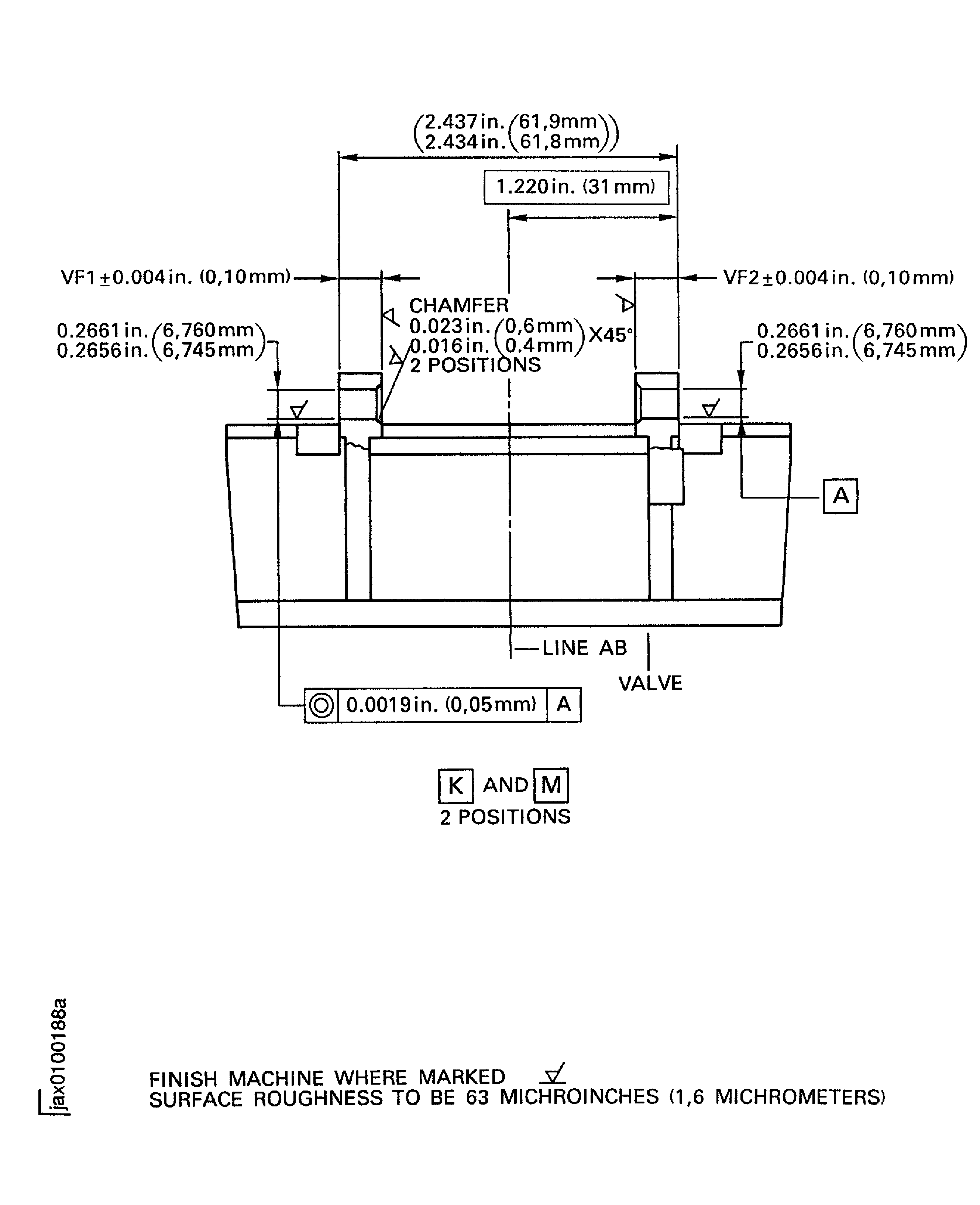

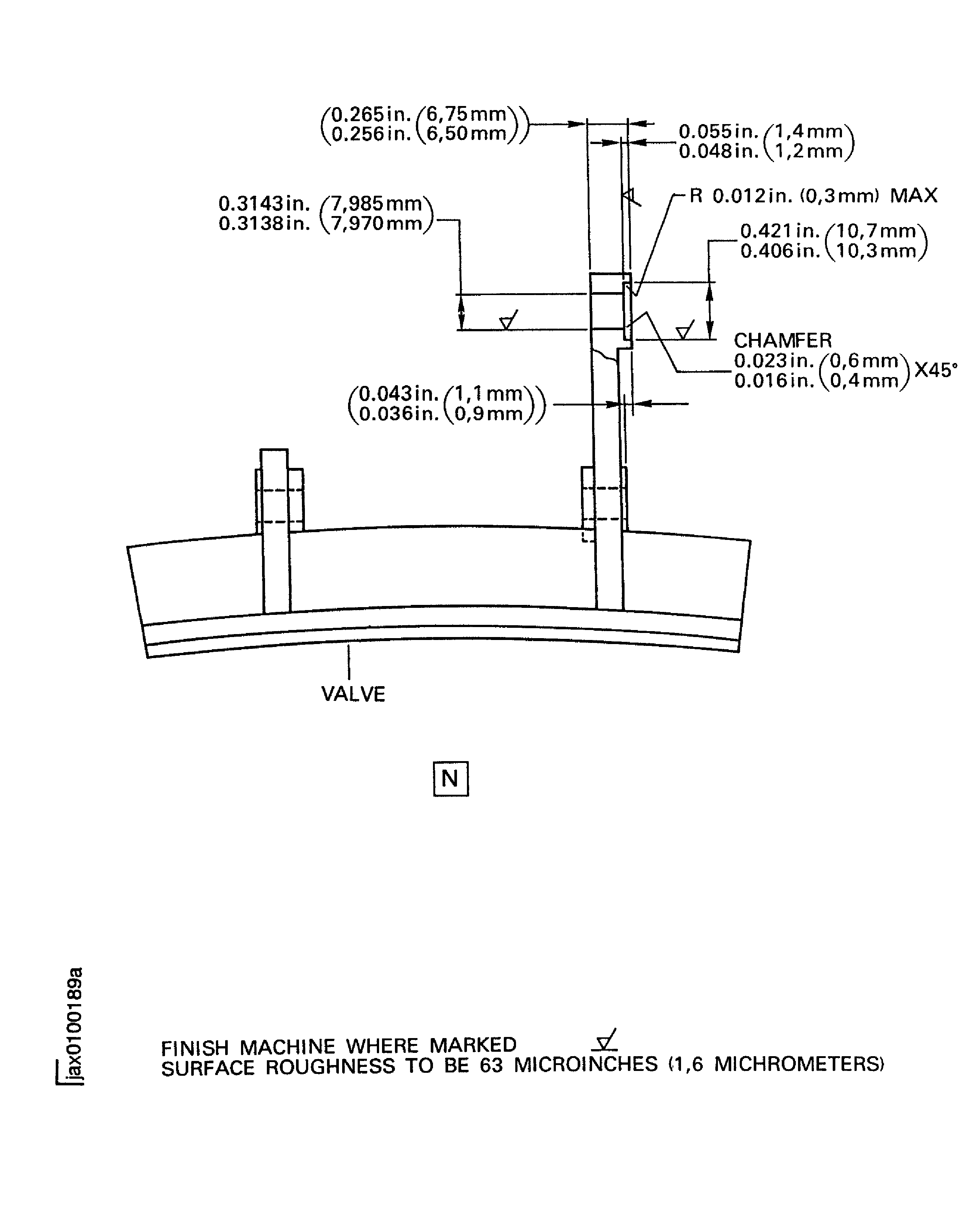

Refer to Figure.

SUBTASK 72-32-72-220-088 Examine the Valve Pin Hole Bush

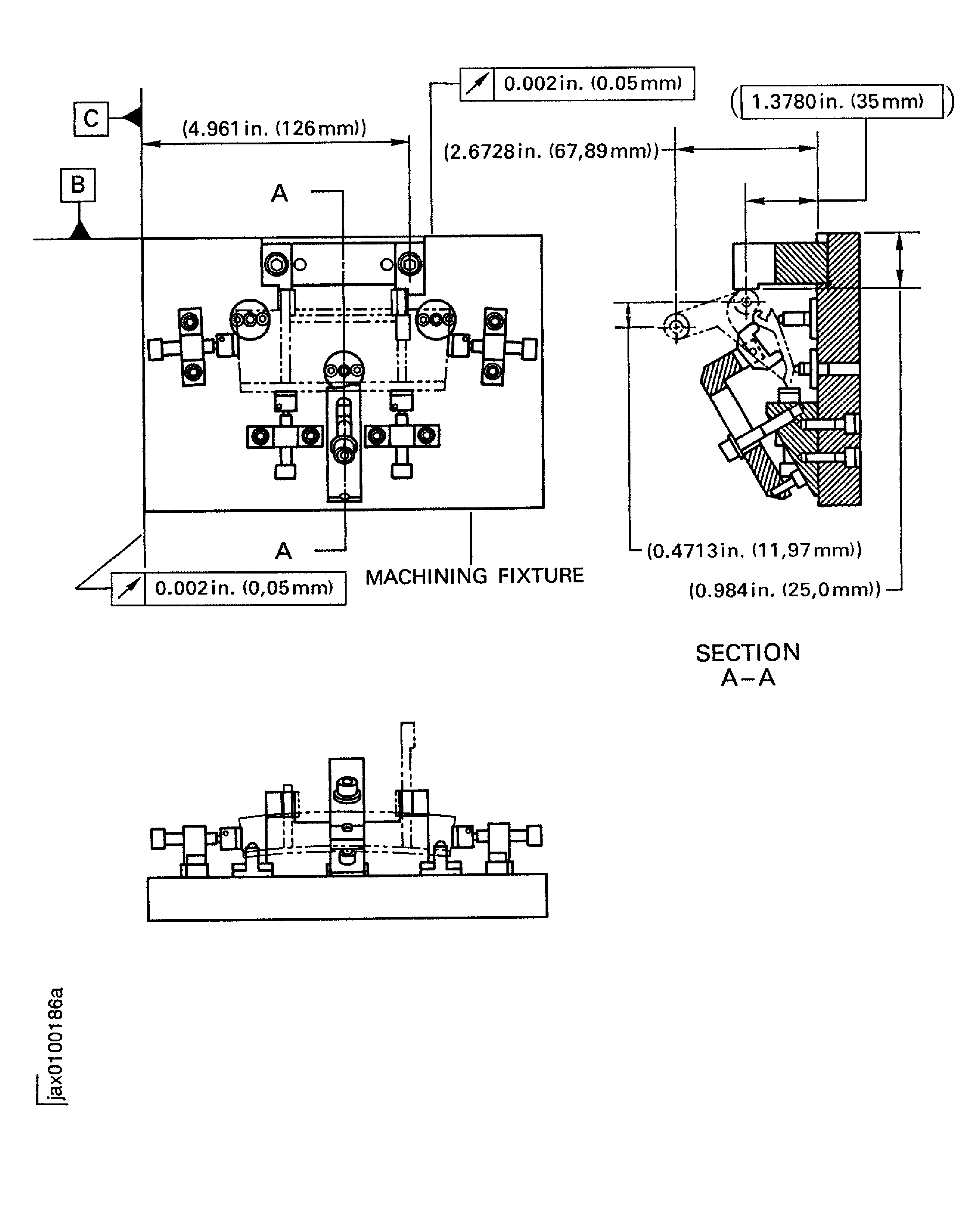

Use Rotary table and Horizontal boring mill.

Set a rotary table on to the horizontal boring machine.

Use IAE 3J12852 Machining fixture 1 off.

Put machining fixture on to the boring machine.

Use Dial set indicator.

Set machining fixture by surface B and C given in the figure.

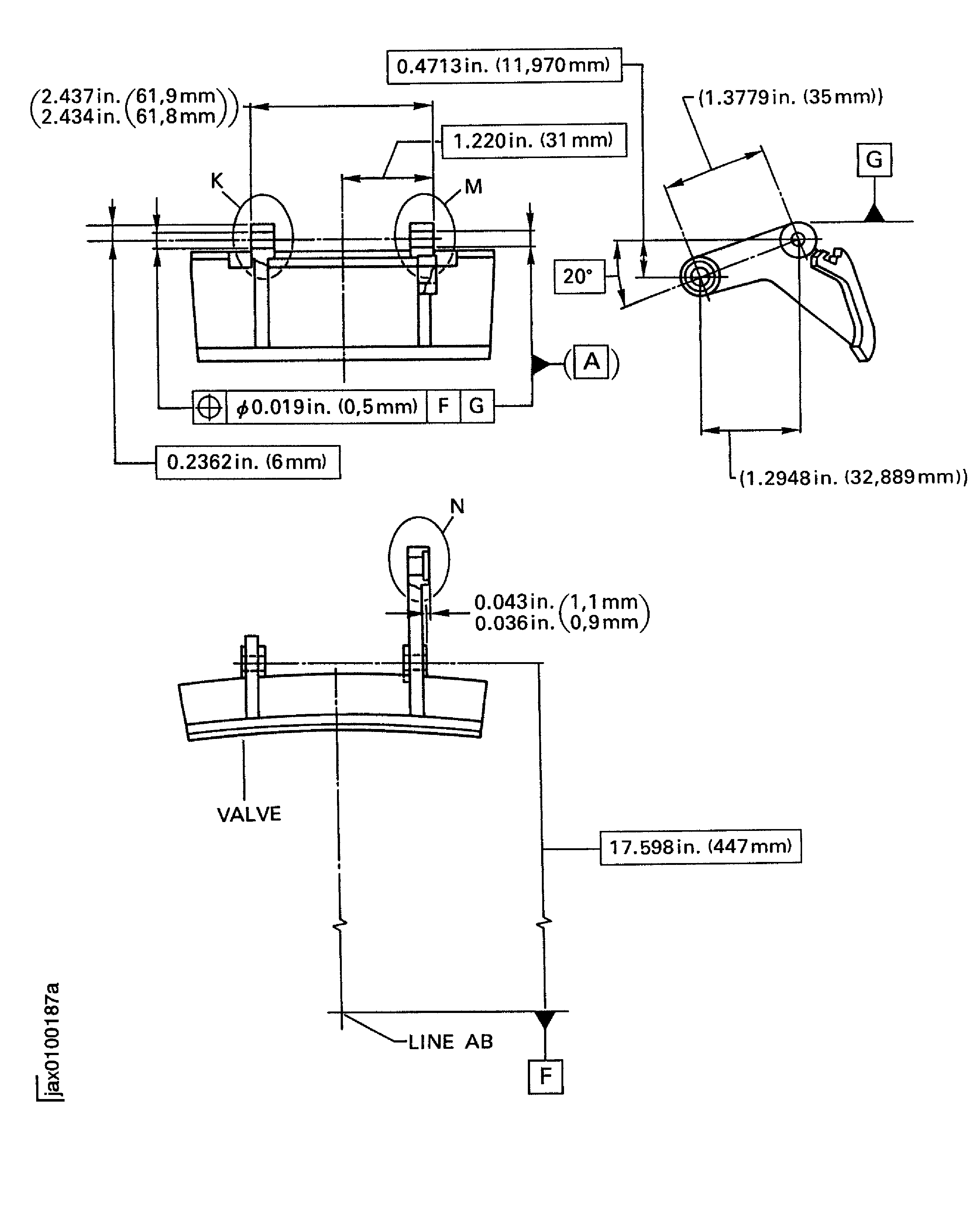

SUBTASK 72-32-72-320-051 Machine the Worn Pin Hole(s) on the Valve

Use External micrometer.

Use dial bore gage.

Measure the dimensions of the pin hole and thickness on the valve.

SUBTASK 72-32-72-220-089 Examine the Machined Valve

Refer to the SPM TASK 70-23-02-230-501.

No cracks are permitted.

Do a penetrant crack test on the machined area.

SUBTASK 72-32-72-230-060 Examine the Machined Pin Hole and Face of the Valve for Cracks

Refer to the SPM TASK 70-38-02-300-503, SUBTASK 70-38-02-300-002.

Apply the chromate conversion coating to the machined pin hole and face of the valve.

SUBTASK 72-32-72-380-057 Apply the Chromate Conversion Coating to the Valve

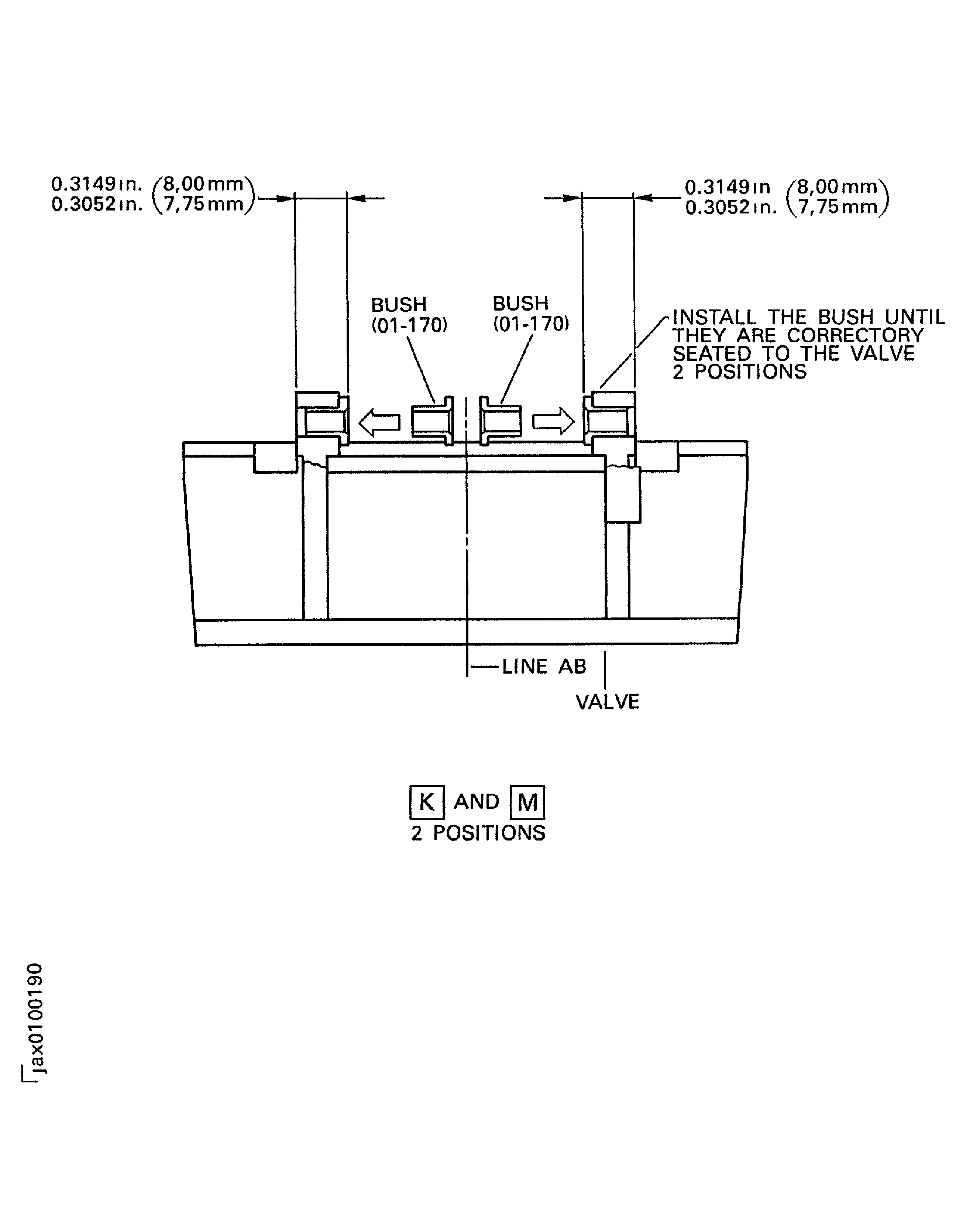

Use an Oven.

Heat the valve at 320 to 392 deg F (160 to 200 deg C) for 30 minutes.

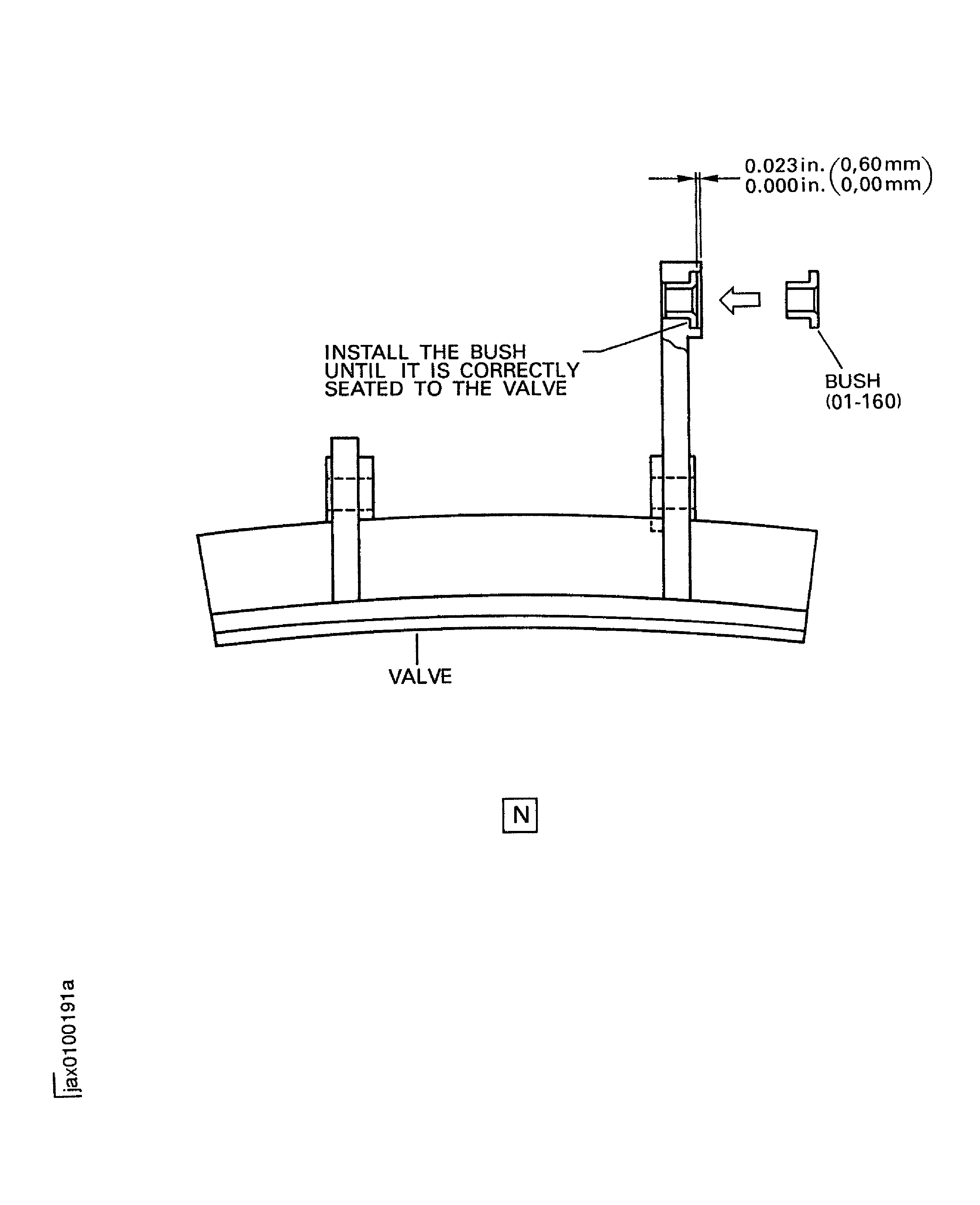

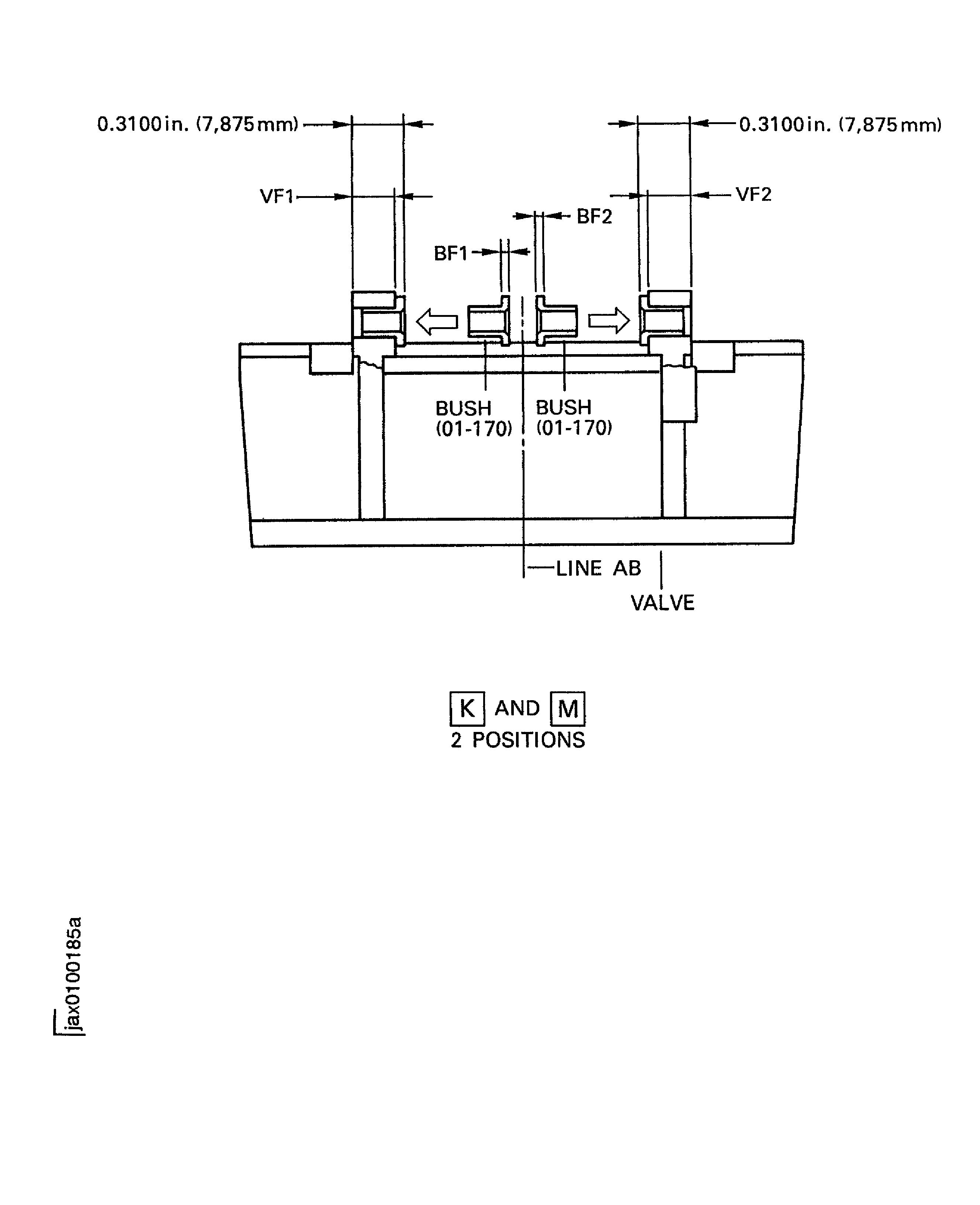

Use 5A1799 (01-160) bush and/or 5A1800 (01-170) bush.

Use Standard workshop equipment with heat protective grooves.

Install the bush(es) to the valve.

SUBTASK 72-32-72-350-059 Install the Bush(es) (01-160 and/or 01-170) to the Valve

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Make a mark VRS1360 adjacent to the part number.

Refer to the SPM TASK 70-38-02-300-503.

Apply the chromate conversion coating to the marked letter.

SUBTASK 72-32-72-350-060 Identify the Repair

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions (Machining fixture)

Repair details and dimensions (Machining fixture)

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions