Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-76-300-007 LPC Stage 2.5 Stator - Replace The Abradable Rubber Of The Outer Shroud Ring, Repair-007 (VRS1354)

General

Price and availability - Refer to IAE

This Repair scheme gives the procedure for replacing of abradable rubber.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Hand Tools | LOCAL | Tools, Hand | ||

| Knife | LOCAL | Knife | Sharp | |

| Oven | LOCAL | Oven | ||

| Precision weighing scales | LOCAL | Precision weighing scales | ||

| Hardness tester (Durometer) | LOCAL | Hardness tester (Durometer) | ||

| Bond test tool | LOCAL | Bond test tool | ||

| Probe pressure tool | LOCAL | Probe pressure tool | ||

| IAE 3J12775 Bond test fixture | 0AM53 | IAE 3J12775 | 1 | |

| IAE 3J12785 Inspection stand | 0AM53 | IAE 3J12785 | 1 | |

| IAE 3J13154 Molding support | 0AM53 | IAE 3J13154 | 1 | |

| IAE 3J13155 Filler injector | 0AM53 | IAE 3J13155 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-076 METHYL ETHYL KETONE | LOCAL | CoMat 01-076 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 02-217 MOLD RELEASE AGENTS | 18598 | CoMat 02-217 | ||

| CoMat 02-218 MOLD RELEASE AGENTS | 18598 | CoMat 02-218 | ||

| CoMat 08-032 PRIMER | LOCAL | CoMat 08-032 | ||

| CoMat 08-037 DELETED | LOCAL | CoMat 08-037 | ||

| CoMat 08-038 SILICONE RUBBER COMPOUND | 64101 | CoMat 08-038 |

Spares

NONESafety Requirements

NONEProcedure

Apply very thin coat of CoMat 08-032 PRIMER with CoMat 02-099 LINT-FREE CLOTH.

CAUTION

THICK PRIMER WILL CAUSE BOND FAILURE OF SILICONE RUBBER.NOTE

Permit primer to dry at room temperature for 2 hours minimum, 24 hours maximum at moisture level equivalent to 50 percent minimum relative humidity at 77 deg F (25 deg C).NOTE

Parts shall have CoMat 08-037 DELETED or CoMat 08-038 SILICONE RUBBER COMPOUND applied within 24 hours of completion of primer application.Apply primer to bond surface.

SUBTASK 72-32-76-380-054 Apply Primer

The working life of the mixed silicone rubber is maximum 6 hours at room temperature.

Refer to the SPM TASK 70-36-06-360-501.

Measure out materials by weight as follows: 10 parts rubber 1 part curing agent.

SUBTASK 72-32-76-360-055 Mixing Instruction

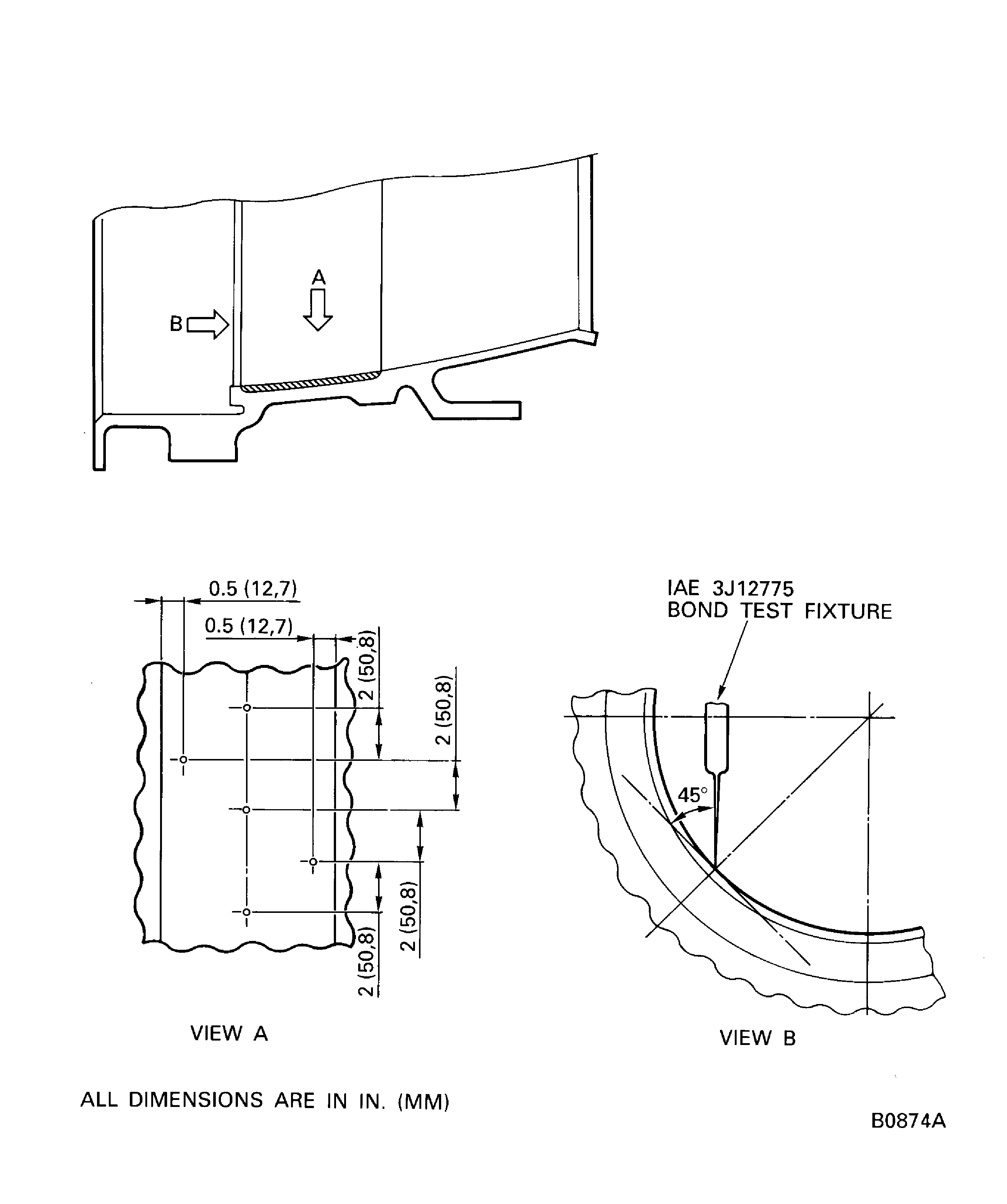

Refer to Figure.

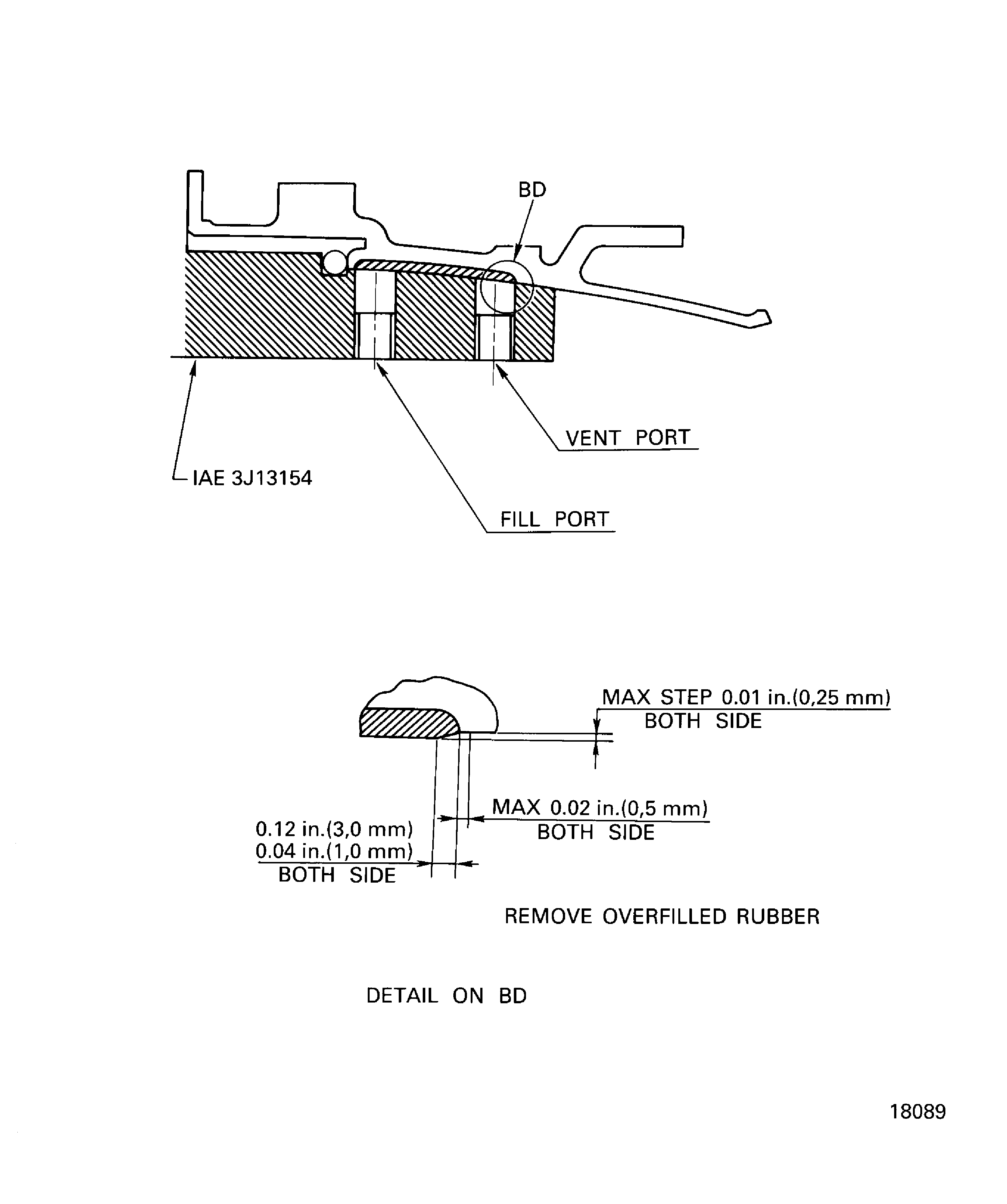

Use tools IAE 3J13154 Molding support 1 off and IAE 3J13155 Filler injector 1 off.

Set the tools to repair part.

SUBTASK 72-32-76-360-056 Fill with Mixed Silicone Rubber

Refer to the SPM TASK 70-36-06-360-501.

Cure at 290 to 310 deg F (143 to 155 deg C) for one hour with molding fixture.

Refer to the SPM TASK 70-36-06-360-501.

Cure the component removed at 390 to 410 deg F (199 to 210 deg C) for one hour out of molding fixture.

SUBTASK 72-32-76-360-057 Cure the Silicone Rubber Compound

Refer to Figure.

SUBTASK 72-32-76-350-058 Remove Overfilled Silicone Rubber

Refer to Figure.

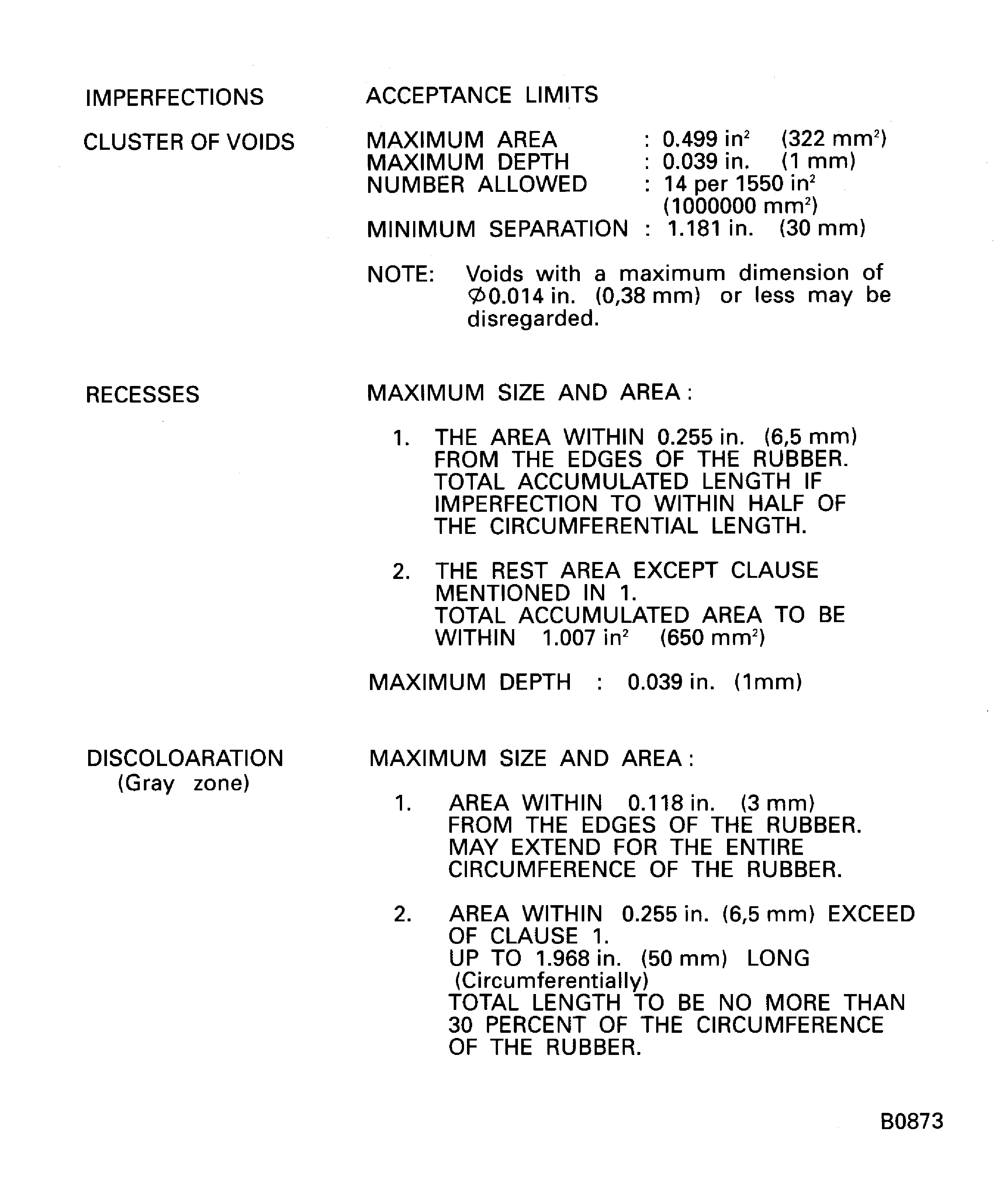

No bubbles are permitted.

No foreign inclusions are permitted.

No peelings are permitted.

Refer to Figure.

Refer to the SPM TASK 70-36-06-360-501.

If necessary, do this TASK again.

No cracks are permitted.

Visually examine the repaired area.

SUBTASK 72-32-76-220-057 Visually Examine the Repair Area

Refer to Figure.

Inspection gas: Air or nitrogen gas.

Gas pressure: 400 psi (28.1 kg/sqcm).

Inspection position: Refer to Figure.

Vary the pattern as necessary to inspect partial repaired areas.

Probe angle: Approximately 45 degrees.

Holes created by bond test to be permitted.

No signs of bulging or air leakage are permitted.

Refer to Figure.

Use the IAE 3J12775 Bond test fixture 1 off and the IAE 3J12785 Inspection stand 1 off.

NOTE

Bond test shall be done after curing (bake) of rubber on the following conditions.Do a bond test on the repaired area.

SUBTASK 72-32-76-220-076 Do a Bond Test on the Repaired Area

Figure: Silicone rubber application area

Silicone rubber application area

Figure: Replacement of the abradable rubber

Replacement of the abradable rubber

Figure: Bond test of the abradable rubber

Bond test of the abradable rubber