Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-82-300-005 LPC Stage 2 Blade - Blend Repair, Repair-005 (VRS1376)

General

This TASK gives the instruction to remove damage on the LP Compressor Rotor Blade(s), stage 2.0 by material removal.

Price and availability - refer to IAE

The practice and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| Glass bead peening equipment | LOCAL | Glass bead peening equipment | ||

| Shot peening equipment | LOCAL | Shot peening equipment | ||

| IAE 3J13157 Shot peening fixture | 0AM53 | IAE 3J13157 | 1 | |

| IAE 3J13158 Glass peening fixture | 0AM53 | IAE 3J13158 | 1 | |

| IAE 3J13161 Glass peening fixture | 0AM53 | IAE 3J13161 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-293 GLASS BEADS | LOCAL | CoMat 01-293 | ||

| CoMat 02-003 ADHESIVE TAPE BLACK WATERPROOF | LOCAL | CoMat 02-003 | ||

| CoMat 05-006 GLASS BEADS | 0AM53 | CoMat 05-006 | ||

| CoMat 05-019 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-019 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 | ||

| CoMat 05-030 CAST STEEL SHOT DELETED | 0AM53 | CoMat 05-030 | ||

| CoMat 05-162 GLASS BEADS | LOCAL | CoMat 05-162 |

Spares

NONESafety Requirements

NONEProcedure

CAUTION

WHEELS, STONES AND ABRASIVE PAPERS USED TO DRESS, MAKE SMOOTH, OR POLISH A TITANIUM COMPONENT MUST BE OF THE SILICON CARBIDE TYPE.ALUMINUM OXIDE TYPES MUST NOT BE USED.THE MATERIAL WILL OXIDIZE AND CRACK IF MECHANICAL CUTTERS ARE USED HEAVILY. THIS HAS OCCURRED IF THE COMPONENT SHOWS DARK STRAW TO BLUE DISCOLORATION. IF AT ANY TIME THIS COLORATION OCCURS, THE BLADE MUST BE REJECTED.Scallop, make smooth and/or hand polish to remove nicks, scratches and/or damage.

Remove the minimum amount of material necessary to give the correct radius.

Refer to the SPM TASK 70-35-03-300-501.

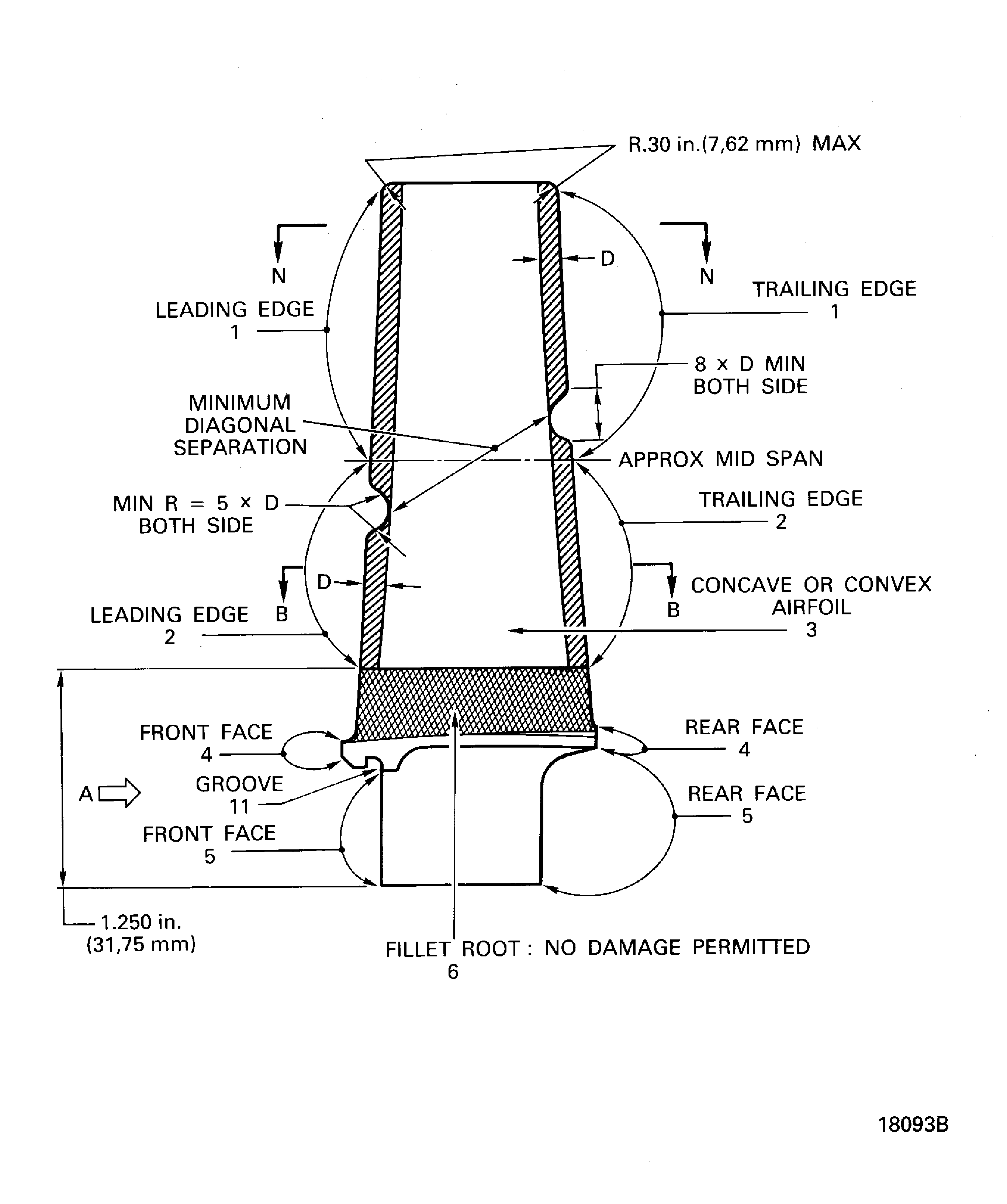

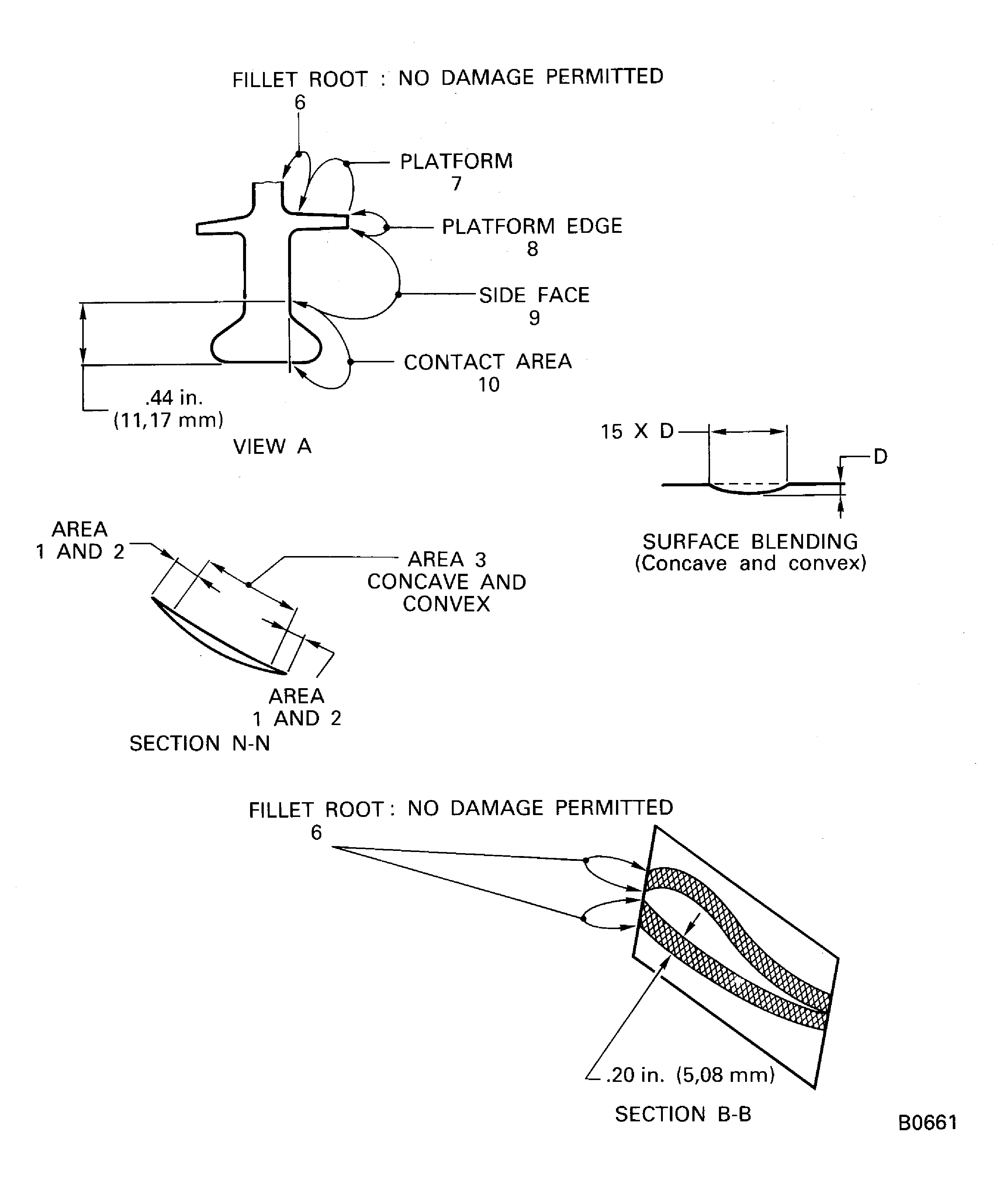

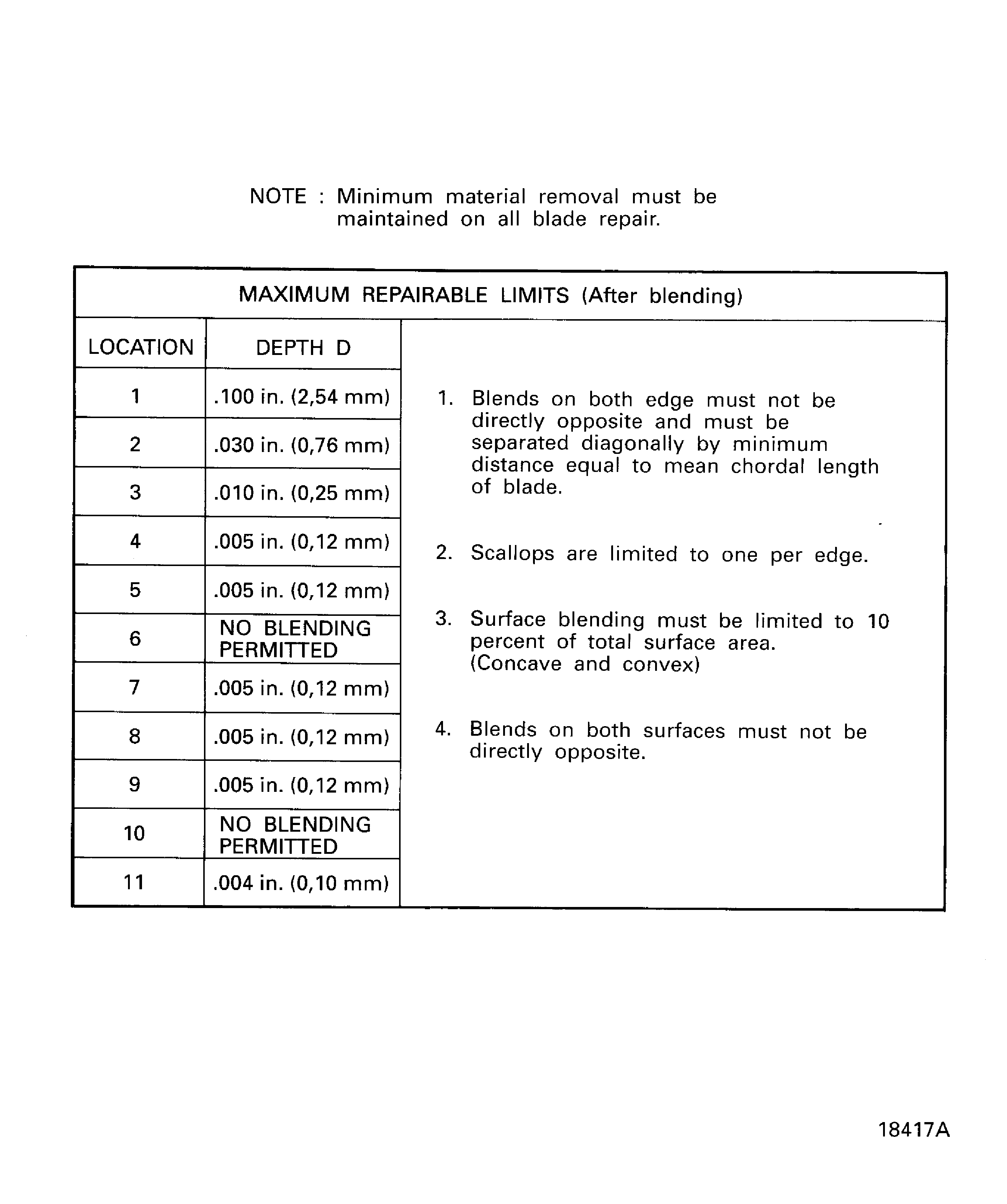

Refer to Figure.

Use CoMat 05-019 WATERPROOF SILICON CARBIDE, CoMat 05-020 WATERPROOF SILICON CARBIDE and CoMat 05-021 WATERPROOF SILICON CARBIDE.

Hand polish the blade leading and/or trailing edge radius and the vane profile to make a smooth shape.

SUBTASK 72-32-82-350-063 Remove the Damage from the LPC Stage 2.0 Blade

Make sure there are no cracks in the repaired area.

Refer to the SPM TASK 70-23-01-230-501.

Fluorescent penetrant examine the repaired area.

SUBTASK 72-32-82-230-059 Examine the LPC Stage 2.0 Blade for Cracks

Refer to Figure.

Apply CoMat 02-003 ADHESIVE TAPE BLACK WATERPROOF to the area which is not to be glass peened.

NOTE

This is an optional procedure. Do this SUBTASK if necessary after blending to remove the damage from locations 1, 2 and 3, refer to Figure.Apply the adhesive tape.

Use IAE 3J13158 Glass peening fixture 1 off.

Install the blade in to the glass bead peening fixture.

Use 0.003 to 0.012 in. (0.08 to 0.30 mm) diameter CoMat 05-006 GLASS BEADS or CoMat 05-162 GLASS BEADS or 0.0098 to 0.0165 in. (0.25 to 0.41 mm) diameter CoMat 01-293 GLASS BEADS an intensity of 10N-13N.

Use IAE 3J13161 Glass peening fixture 1 off to hold an Almen test-strip.

Refer to SPM TASK 70-38-04-300-503.

Refer to Figure.

Glass bead peen the airfoil.

Refer to the SPM TASK 70-38-04-300-503.

Visually examine the peened surface for uniform coverage and complete overlapping of the shot impressions.

Examine the blade.

SUBTASK 72-32-82-380-087 Glass Bead Peen the LPC Stage 2.0 Blade

Refer to Figure.

Apply CoMat 02-003 ADHESIVE TAPE BLACK WATERPROOF to the area which is not to be shot peened.

NOTE

This is an optional procedure. Do this SUBTASK if necessary after blending to remove the damage from locations 4, 5, 8, 9 and 11, refer to Figure.Apply the adhesive tape.

Use IAE 3J13157 Shot peening fixture 1 off.

Install the blade in to the shotpeening fixture.

Use SAE NO.110 steel shot at an intensity of 6A-8A.

Refer to the SPM TASK 70-38-04-300-503.

Refer to Figure.

Shot peen repaired area of blade shank.

Refer to the SPM TASK 70-38-04-300-503.

Visually examine the peened surface for uniform coverage and complete overlapping of the shot impressions.

Examine the blade.

SUBTASK 72-32-82-380-058 Shot Peen the LPC Stage 2.0 Blade

Figure: LP compressor stage 2.0 blades, dressing dimensions

Sheet 1

Figure: LP compressor stage 2.0 blades, dressing dimensions

Sheet 2

Figure: LP compressor stage 2.0 blades, dressing dimensions

Sheet 3

Figure: LPC stage 2.0 blade - glass bead peening area

LPC stage 2.0 blade - glass bead peening area

Figure: LP compressor stage blades - shot peening area

LP compressor stage blades - shot peening area