Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-83-300-007 LPC Front Case - Replace The Press Nut, Repair-007 (VRS1382)

Effectivity

FIG/ITEM | PART NO. | |

01-350 | 5A0062 | Assembly A |

01-350 | 5A0961 | Assembly A |

01-350 | 5A7399 | Assembly A |

01-350 | 5A1814 | Assembly A |

02-350 | 5A0458 | Assembly B |

02-350 | 5A1864 | Assembly B |

General

Price and availability - none

The practices and processes referred to in the procedure by TASK numbers are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| Drilling machine | LOCAL | Drilling machine | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Spatula | LOCAL | Spatula | ||

| Arbor Press | LOCAL | Arbor press | ||

| Drive tool | LOCAL | RPN250DS | 1 | |

| Drive tool | LOCAL | RPN10DS | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 08-109 RESIN, EPOXY ADHESIVE | LOCAL | CoMat 08-109 | ||

| CoMat 08-110 HARDENER, EPOXY ADHESIVE | LOCAL | CoMat 08-110 | ||

| CoMat 05-016 GARNET PAPER, 80-GRIT | LOCAL | CoMat 05-016 | ||

| CoMat 05-017 GARNET PAPER, 60 GRIT | LOCAL | CoMat 05-017 | ||

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | LOCAL | CoMat 06-063 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Nut Assembly A | RPNF250-28SM | A/R | ||

| Nut Assembly A | RPNF250-28SM | A/R | ||

| Nut Assembly B | RPNF10-32SM | A/R |

Safety Requirements

NONEProcedure

Refer to the SPM TASK 70-23-05-230-501.

Use penetrant crack test equipment.

Refer to TASK 72-32-83-200-000(INSPECTION-000).

Do a penetrant crack test on the nut location hole.

SUBTASK 72-32-83-230-083 Examine the Nut Hole of the Front Case Assembly for Cracks

Use CoMat 01-124 ISOPROPYL ALCOHOL with lint free cheese cloth.

Remove the grease from bonding surfaces of the nut and front case.

Do Step again.

SUBTASK 72-32-83-360-120 Prepare the Bonding Surfaces of the Nut and the LPC Case Assembly

The pot life of the adhesive is one hour at 68 deg F (20 deg C).

The adhesive is made up from two parts: CoMat 08-109 RESIN, EPOXY ADHESIVE 100 parts by weight. CoMat 08-110 HARDENER, EPOXY ADHESIVE 40 parts by weight. Fully mix the two parts.

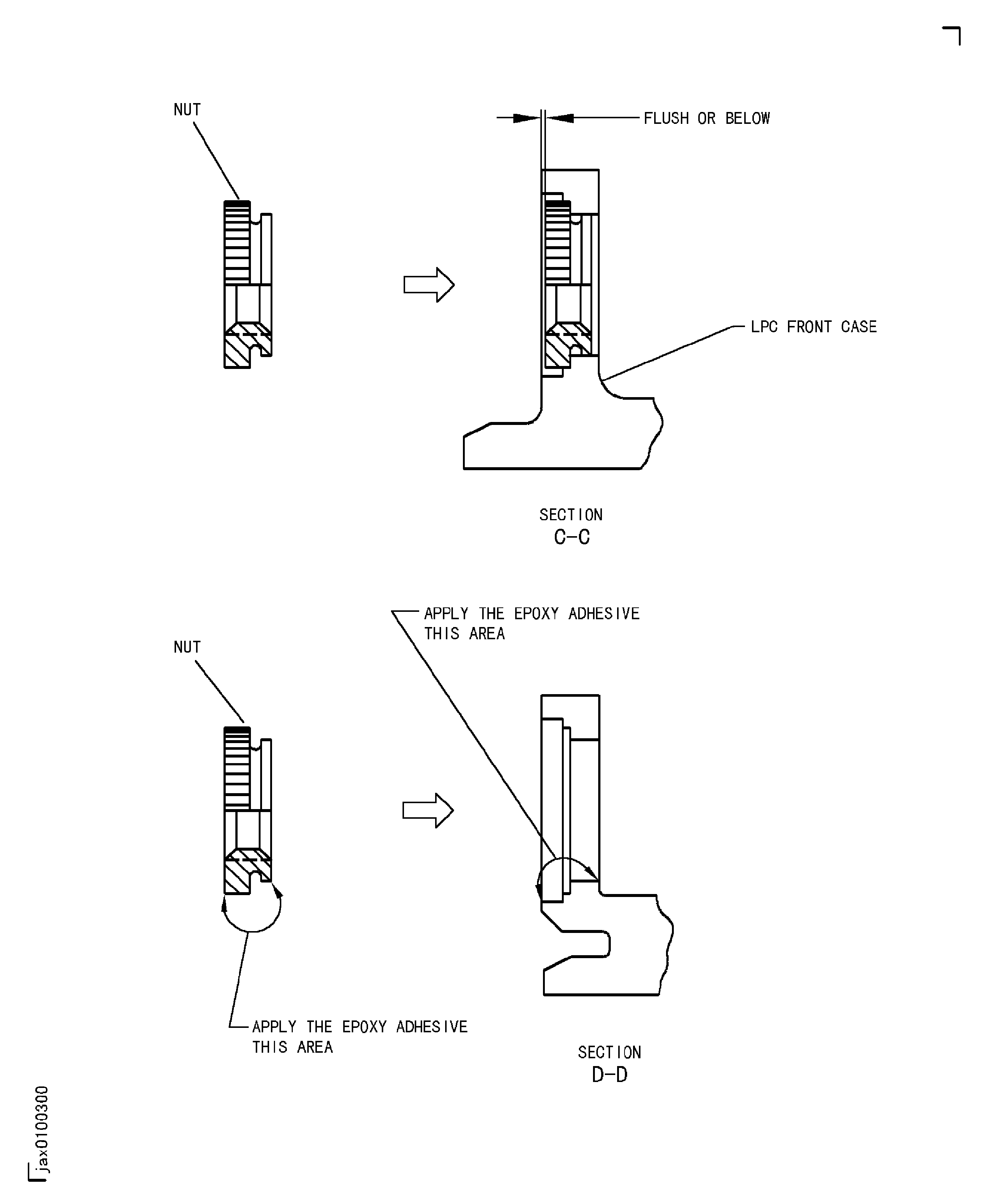

SUBTASK 72-32-83-360-121 Apply and Cure the Epoxy Paste Adhesive

Refer to the SPM TASK 70-09-00-400-501.

Use vibrating marking pencil.

Write VRS1382, adjacent to the part number on front case assembly.

Refer to the SPM TASK 70-38-02-300-503.

Apply chromate conversion coating to the marked repair number.

SUBTASK 72-32-83-350-095 Mark Repair Number on the LPC Front Case Assembly

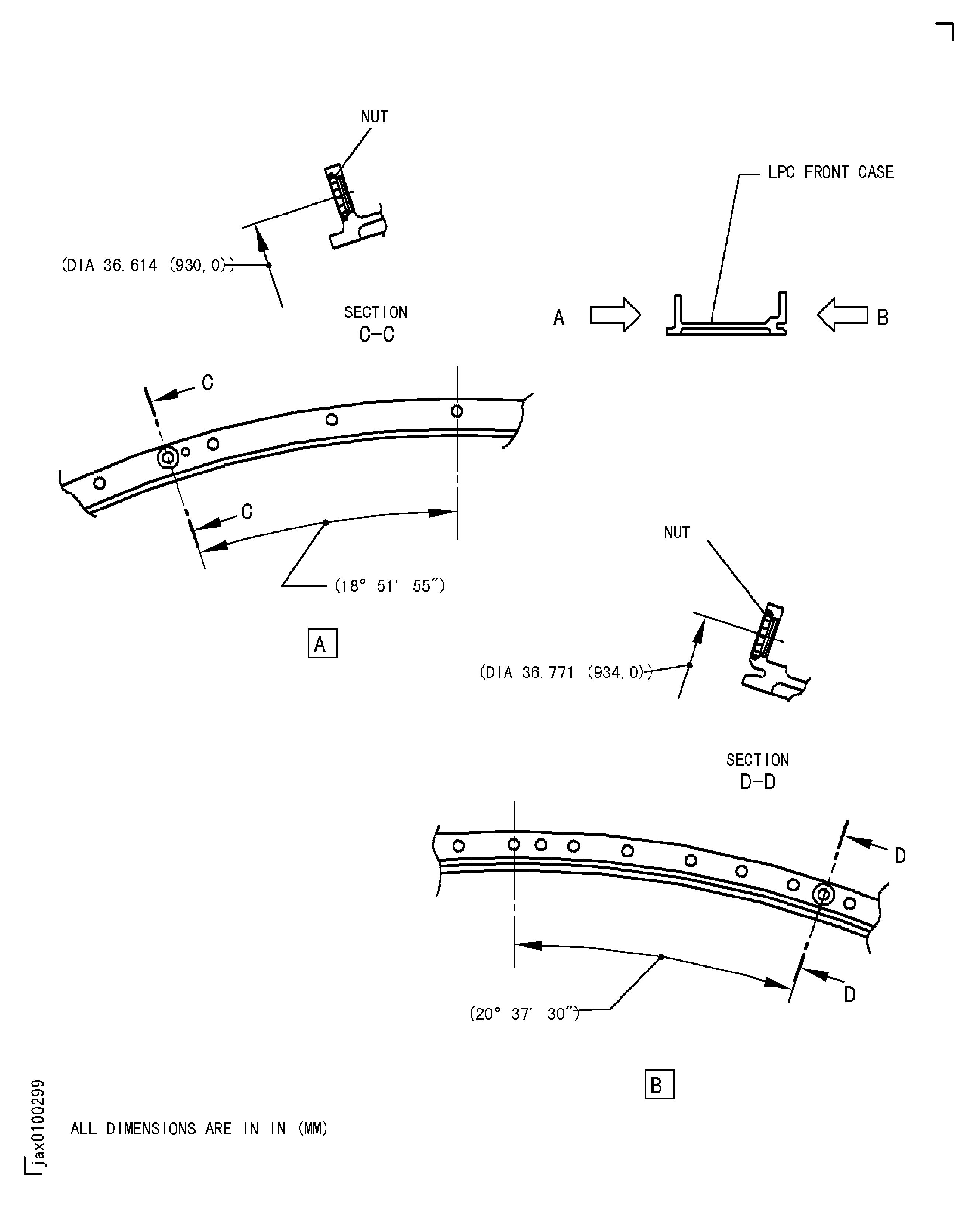

Figure: Repair details and dimensions - Assembly A

Sheet 1

Figure: Repair details and dimensions - Assembly B

Sheet 2

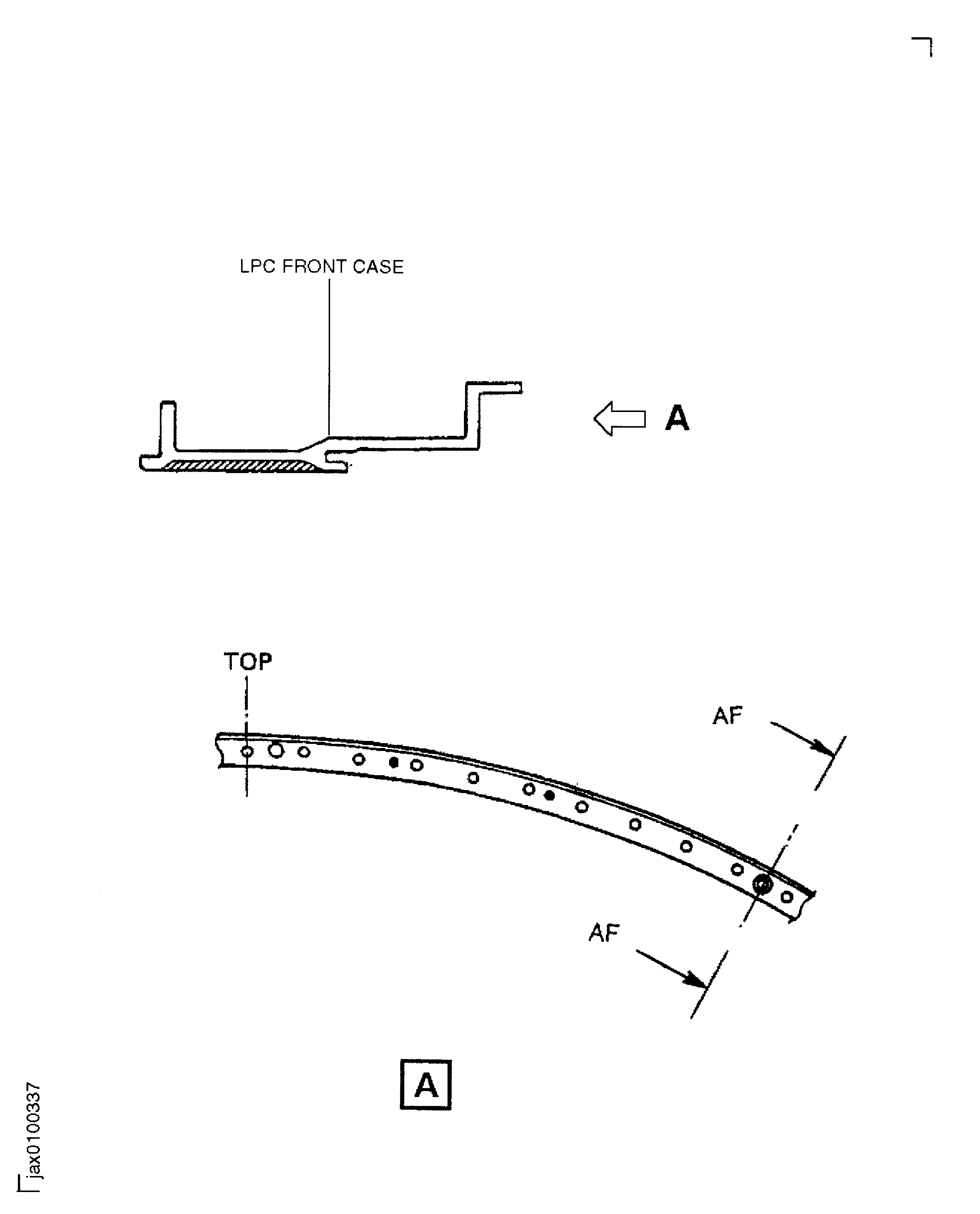

Figure: Repair details and dimensions - Assembly B

Sheet 3

Figure: Repair details and dimensions - Assembly B

Sheet 4