Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-83-300-037 LPC Front Case - Repair Surface Damage By Blending And Surface Protection, Repair-037 (VRS1759)

General

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Price and availability - none

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| Magnifying glass, 10x | LOCAL | Magnifying glass, 10x |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-275 CHROMATE CONVERSION COATING FOR ALUMINIUM | LOCAL | CoMat 01-275 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 |

Spares

NONESafety Requirements

NONEProcedure

The surface finish of the repair must be the same as the adjacent area.

Refer to the SPM TASK 70-35-03-300-501.

Make smooth and/or hand polish to remove corrosion, galls, nicks, pits, scratches and burrs.

SUBTASK 72-32-83-350-067 Remove the Damage from the LPC Front Case Assembly, Except at Location 3, 4 and 8

The surface finish of this repair must be the same as the adjacent area.

Refer to the SPM TASK 70-35-03-300-501.

Make smooth and/or hand polish to remove corrosion, galls, nicks, pits, scratches and burrs.

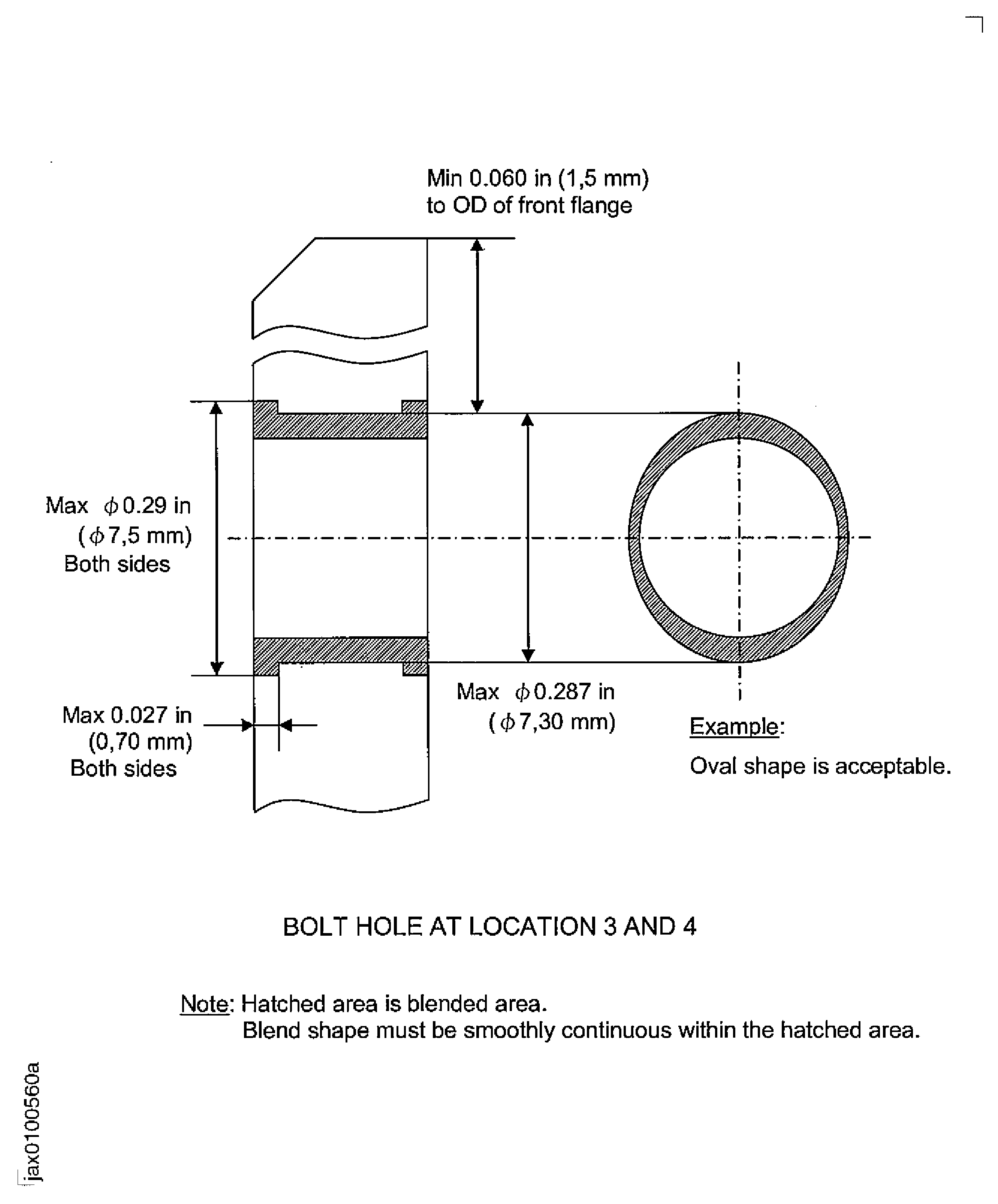

SUBTASK 72-32-83-350-100 Remove the Damage from Bolt Holes at Location 3 and 4

The surface finish of the repair must be the same as the adjacent area.

The width of the repaired area is to be 8 times the depth.

Refer to the SPM TASK 70-35-03-300-501.

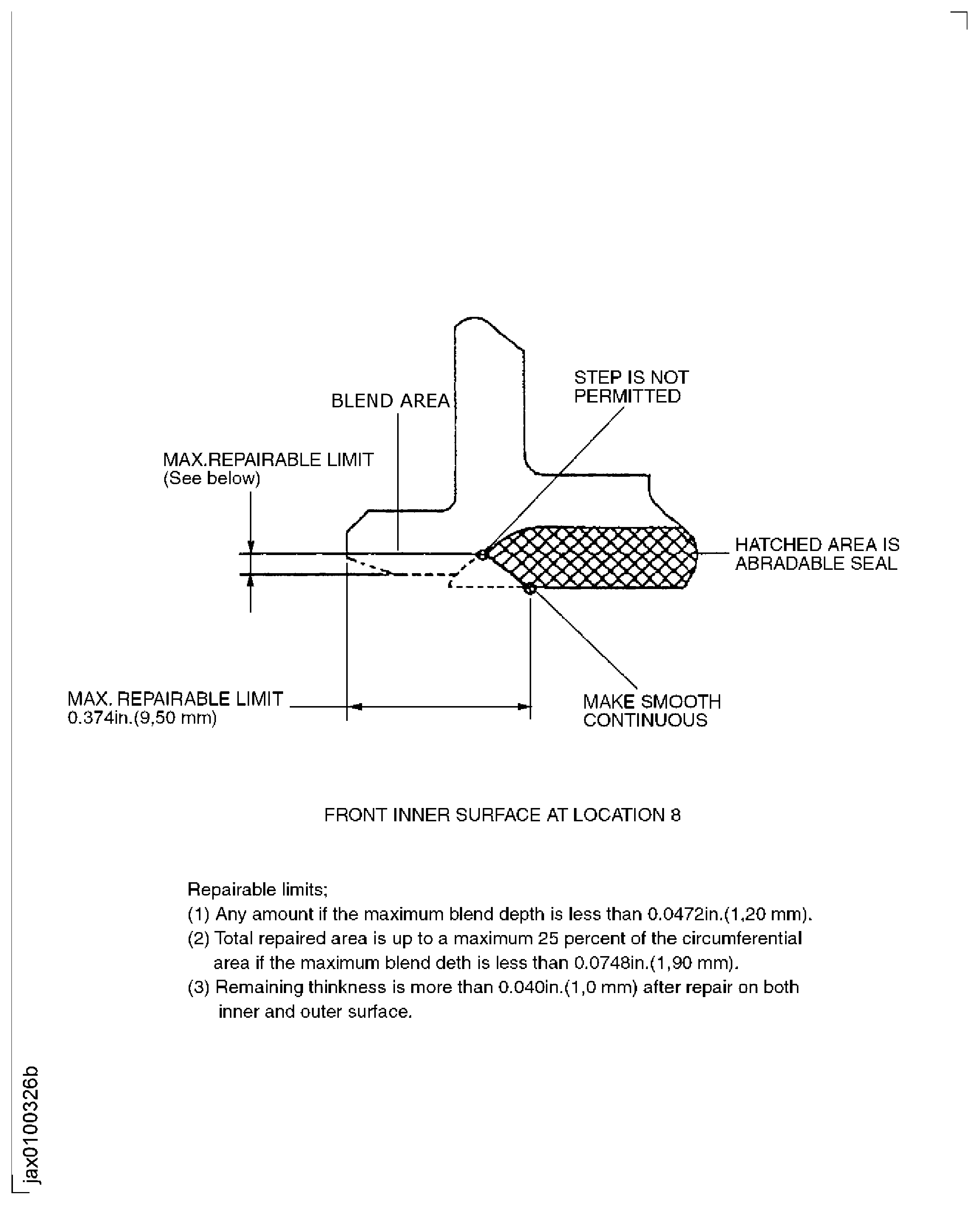

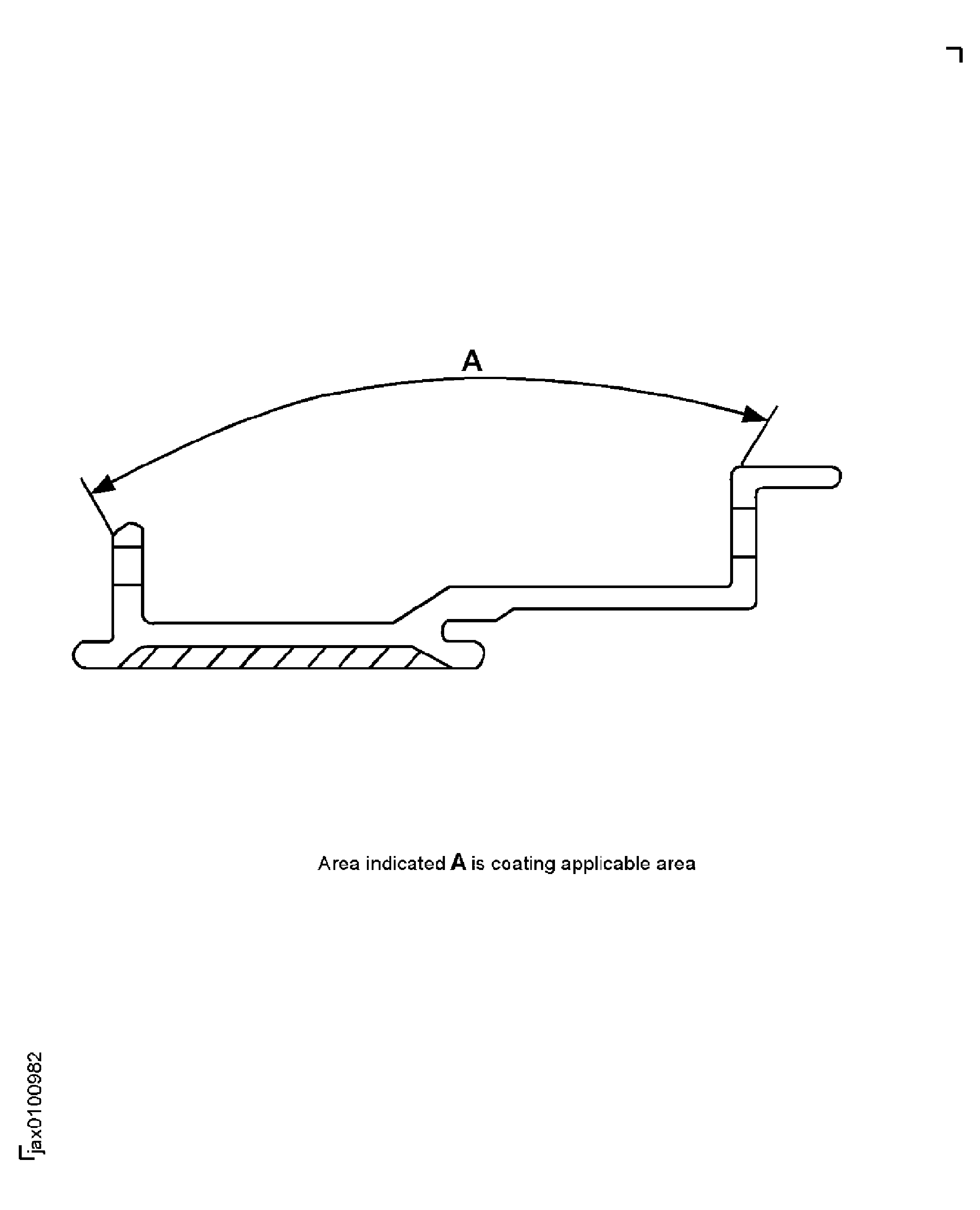

If abradable seal is removed with parent material for smooth blending, blend the abradable seal in accordance with Figure.

Make smooth and/or polish to remove corrosion, galls, nicks, pits, scratches and burrs.

SUBTASK 72-32-83-350-096 Remove the Damage from Front Inner Surface at Location 8

Use a 10X magnifying glass.

Refer to TASK 72-32-83-200-000 (INSPECTION-000).

Visually examine the repaired area.

SUBTASK 72-32-83-220-155 Examine the LPC Front Case Assembly

Refer to the SPM TASK 70-23-05-230-501.

Make sure that there are no cracks in the repaired area.

Fluorescent penetrant examine the repaired area.

SUBTASK 72-32-83-230-069 Examine the LPC Front Case Assembly for Cracks

Refer to the SPM TASK 70-11-26-300-503.

SUBTASK 72-32-83-110-062 Remove the Grease from the LPC Front Case Assembly

Refer to the SPM TASK 70-38-02-300-503.

Apply the chromate conversion coating for aluminum with a brush to the repaired area.

SUBTASK 72-32-83-380-057 Apply Surface Protection to the LPC Front Case Assembly

Refer to Figure.

Refer to the SPM TASK 70-38-20-380-501, SUBTASK 70-38-20-380-002.

Apply the primer to the repaired area.

Use coating of white.

Refer to the SPM TASK 70-38-20-380-501, SUBTASK 70-38-20-380-002.

Apply the heat resisting E.S. coating to the repaired area.

SUBTASK 72-32-83-380-075 Apply the Heat Resisting E.S. Coating to the Repaired Area

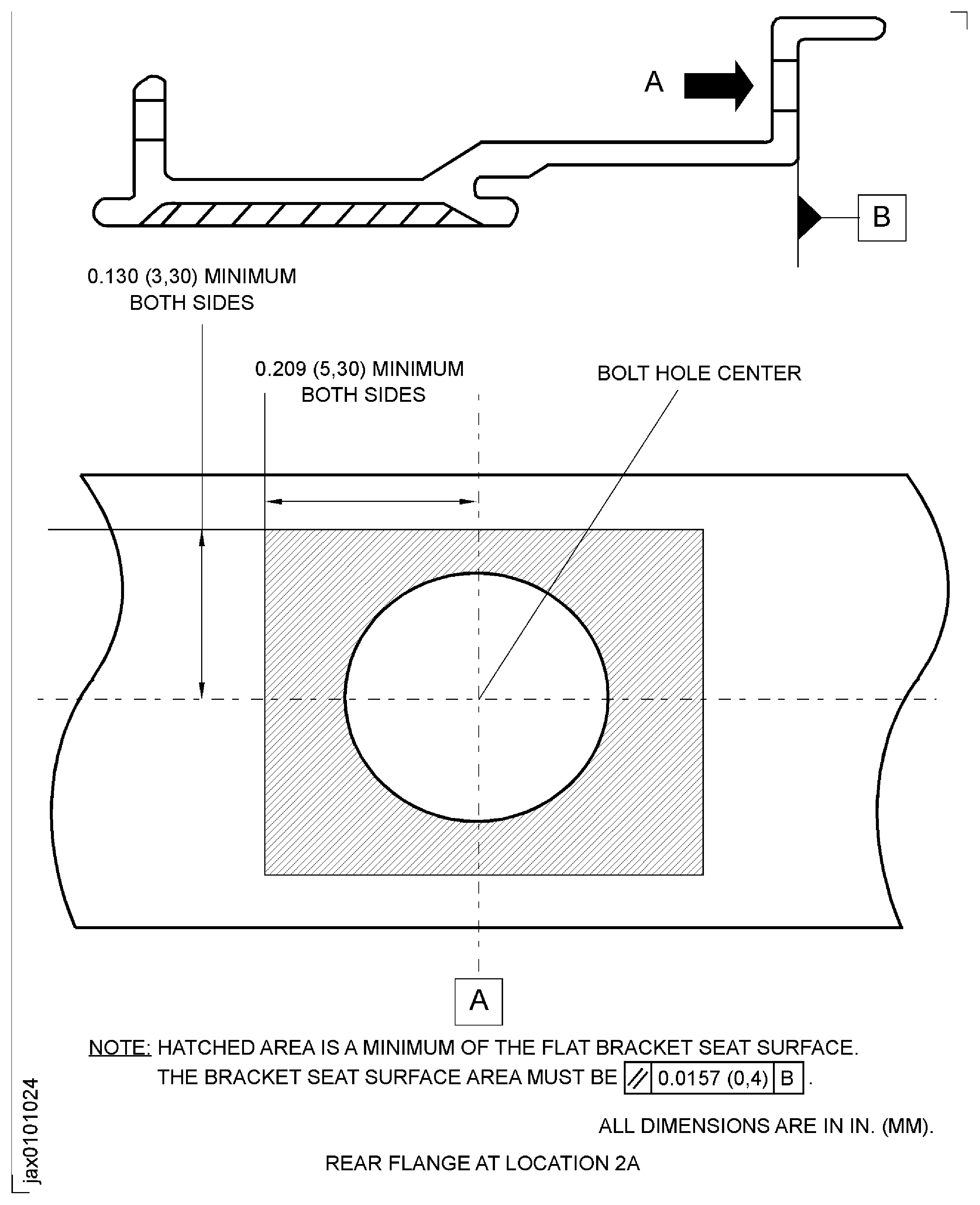

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

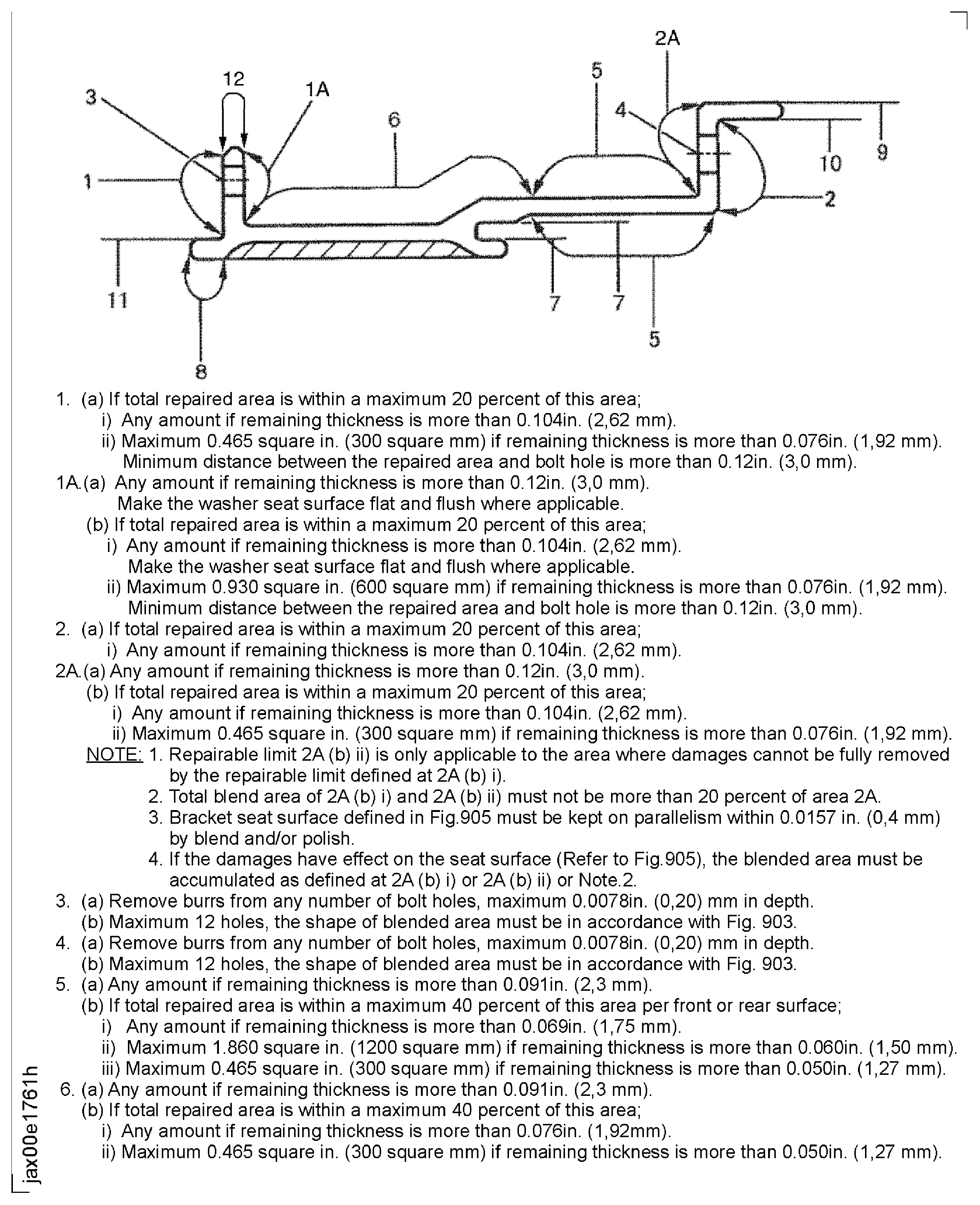

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair details and dimensions

Repair details and dimensions