Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-83-300-052 LPC Mid Case - Replace The Press Nut, Repair-052 (VRS1598)

Material of component

PART IDENT | IAE SYMBOL | MATERIAL |

|---|---|---|

LPC mid case assembly | 2.2A1-1.5Mg-1.1Ni-1.1Fe Aluminum |

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

ROSAN INC.

2901W. Coast Highway

Newport Beach, CA 92663

USA

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| Drilling machine | LOCAL | Drilling machine | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Spatula | LOCAL | Spatula | ||

| Arbor Press | LOCAL | Arbor press | ||

| Drive tool | LOCAL | RPN10DS |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 08-109 RESIN, EPOXY ADHESIVE | LOCAL | CoMat 08-109 | ||

| CoMat 08-110 HARDENER, EPOXY ADHESIVE | LOCAL | CoMat 08-110 | ||

| CoMat 05-016 GARNET PAPER, 80-GRIT | LOCAL | CoMat 05-016 | ||

| CoMat 05-017 GARNET PAPER, 60 GRIT | LOCAL | CoMat 05-017 | ||

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | LOCAL | CoMat 06-063 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Press nut | RPNF10-32SM | 6 |

Safety Requirements

NONEProcedure

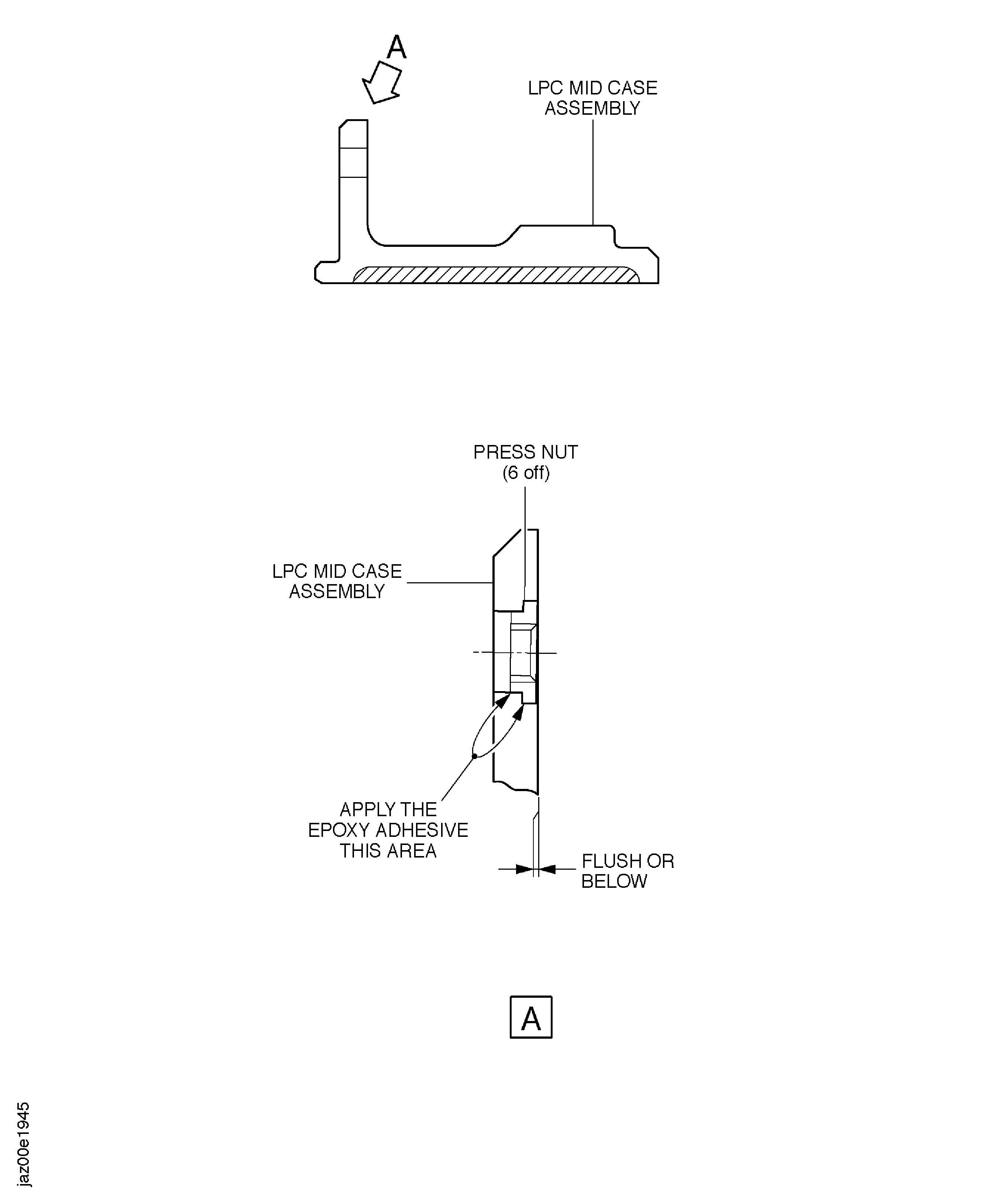

Refer to Figure.

SUBTASK 72-32-83-360-129 Remove the Damaged Press Nut from the LPC Mid Case Assembly

Refer to the SPM TASK 70-23-05-230-501.

Use penetrant crack test equipment.

Refer to TASK 72-32-83-200-000 (INSPECTION-000).

Do a penetrant crack test on the press nut location hole.

SUBTASK 72-32-83-230-096 Examine the Press Nut Hole of the LPC Mid Case Assembly for Cracks

Refer to Figure.

Use CoMat 01-124 ISOPROPYL ALCOHOL with lint free cloth.

Remove the grease from the bonding surfaces of the press nut and the LPC mid case assembly.

Repeat Step again.

SUBTASK 72-32-83-360-130 Prepare the Bonding Surfaces of the Press Nut and the LPC Mid Case Assembly

Refer to Figure.

The adhesive is made up from two parts: CoMat 08-109 RESIN, EPOXY ADHESIVE 100 parts by weight. CoMat 08-110 HARDENER, EPOXY ADHESIVE 40 parts by weight. Fully mix the two parts. The pot life of the adhesive is one hour at 68 deg F (20 deg C).

CAUTION

AFTER PREPARATION THE MATING SURFACES MUST BE FULLY CLEANED AND MUST NOT BE TOUCHED BY HAND, TO PREVENT CONTAMINATION.Make up the two part epoxy paste adhesive.

SUBTASK 72-32-83-360-131 Apply and Cure the Epoxy Paste Adhesive

Refer to Figure.

SUBTASK 72-32-83-220-219 Examine the Repaired Areas of the LPC Mid Case Assembly

Use vibrating marking pencil.

Refer to the SPM TASK 70-09-00-400-501.

Write VRS1598, adjacent to the part number on the LPC mid case assembly.

Refer to the SPM TASK 70-38-02-300-503.

Apply chromate conversion coating to the marked VRS number.

SUBTASK 72-32-83-350-118 Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions