Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-38-11-300-005 Inlet Cone Assembly - Replace The Balance Weight, Repair-005 (VRS1464)

General

Price and availability - not applicable

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Mass weighing scale | LOCAL | Mass weighing scale | (Accuracy 3.5 x 0.0001 oz (0.01 g)) | |

| Balancing machine | LOCAL | Balancing machine | ||

| IAE 3J12736 Hydraulic mandrel | 0AM53 | IAE 3J12736 | 1 | |

| IAE 3J12737 Balance adapter | 0AM53 | IAE 3J12737 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-149 DRY ICE | LOCAL | CoMat 02-149 | ||

| CoMat 02-181 MODELLING CLAY | LOCAL | CoMat 02-181 | ||

| CoMat 05-016 GARNET PAPER, 80-GRIT | LOCAL | CoMat 05-016 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 08-047 HARDENER | 0LCV8 | CoMat 08-047 | ||

| CoMat 08-048 RESIN | LOCAL | CoMat 08-048 | ||

| CoMat 08-049 FIBREGLASS CLOTH | K6835 | CoMat 08-049 | ||

| CoMat 08-070 STAINLESS STEEL POWDER 200-MESH | K6835 | CoMat 08-070 |

Spares

NONESafety Requirements

NONEProcedure

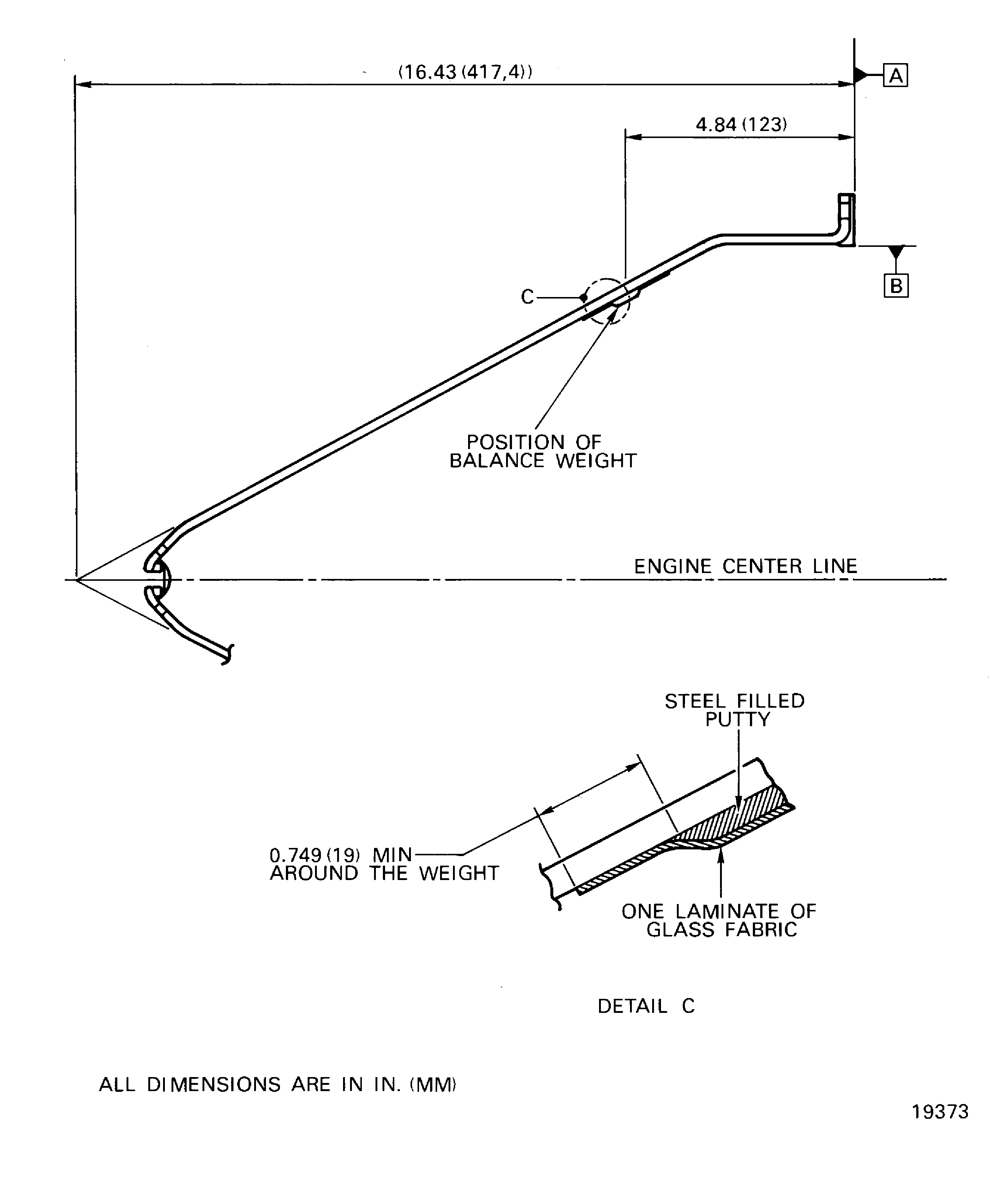

Refer to Figure.

Inspect and identify the damaged balance weights.

Use a cutter knife, a scraper and CoMat 05-020 WATERPROOF SILICON CARBIDE.

Refer to Figure.

Remove the disengaged balance weight and laminate glass fabric without any damage to the parent material, and remove the remaining resin.

SUBTASK 72-38-11-330-054 Remove the Damaged Balance Weights from the Inlet Cone Assembly

Use CoMat 02-149 DRY ICE.

Make cool the IAE 3J12737 Balance adapter 1 off by dry ice at 04 deg F (-20 deg C) for 15 to 20 minutes.

Use IAE 3J12737 Balance adapter 1 off.

Refer to Figure.

Attach the inlet cone assembly on the balance adapter and the tighten the bolts in a diagonal sequence.

Use IAE 3J12736 Hydraulic mandrel 1 off and a balancing machine ZE40 or VE4L.

Install the hydraulic mandrel on the balancing machine.

SUBTASK 72-38-11-290-051 Do the Static Balance for the Inlet Cone Assembly

Refer to Figure.

Hand clean the surface of the removed balance weights and the area around.

SUBTASK 72-38-11-360-054 Prepare the Surfaces for the Steel Filled Putty

CoMat 08-047 HARDENER must be mixed into CoMat 08-070 STAINLESS STEEL POWDER 200-MESH, CoMat 08-048 RESIN added and mixed until it becomes smooth.

The steel filled putty is made-up from three parts: CoMat 08-048 RESIN 60 parts by weight, CoMat 08-070 STAINLESS STEEL POWDER 200-MESH 330 parts by weight and CoMat 08-047 HARDENER 6.6 parts by weight.

SUBTASK 72-38-11-360-055 Make-up of the Steel Filled Putty

Use a mass weighing scale.

Accuracy: 3.5 x 0.0001 oz (0.01 g).

Weigh the steel filled putty which is mixed by Step.

Refer to Figure.

Apply the putty circumferentially.

Apply the steel filled putty to the prepared surface within 15 minutes after mixing.

SUBTASK 72-38-11-360-056 Apply and Cure the Steel Filled Putty

NOTE

Do not mix this material in amounts greater than 3.52 oz (100 g).The resin mixture is made-up from two parts: CoMat 08-047 HARDENER 10 to 12 parts by weight and CoMat 08-048 RESIN 100 parts by weight.

SUBTASK 72-38-11-360-057 Make-up of the Resin Mixture

Apply it circumferentially.

Refer to Figure.

CAUTION

AFTER PREPARATION, THE MATING SURFACES MUST BE FULLY CLEANED AND MUST NOT BE TOUCHED BY HAND, TO PREVENT CONTAMINATION.After applying the putty, cover the putty with one laminate of fiberglass cloth which overlaps the edge of the putty by 0.748 in. (19 mm).

Coat the resin mixture which is made-up as specified in Step.

SUBTASK 72-38-11-360-058 Apply and Cure the Resin/Fibre Reinforcements by the Wet Lay-up

Refer to the SPM TASK 70-09-00-400-501.

Mark VRS1464 adjacent to the part number.

SUBTASK 72-38-11-350-053 Identify the Repair

Figure: Replace the Balance Weight

Replace the Balance Weight

Figure: Balance Check of the Inlet Cone Assembly

Balance Check of the Inlet Cone Assembly