Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-40-00-530-001 HP System Module - Pack The HP System Module

General

Fig/item numbers in parentheses in the procedure agree with those used in the EIPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the EIPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures refer to the SPM TASK 70-41-00-400-501, SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-410-501.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS unless other lubricants are referred to in the procedure.

Refer to the V2500 Illustrated Tool and Equipment Manual (ITEM) Pub.ref. ITE-V2500-1IA, for the illustrations of the special tools given in this procedure.

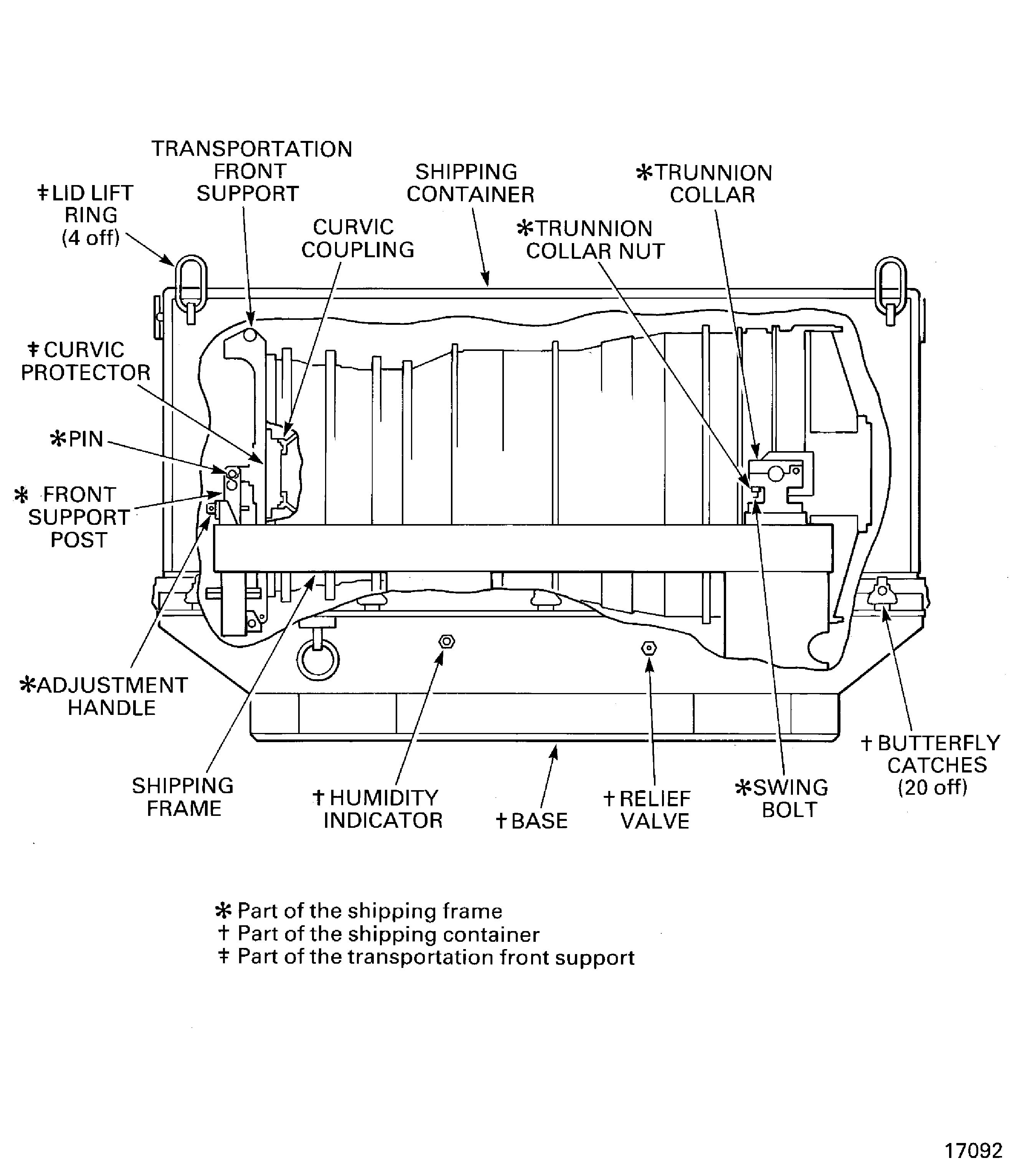

The shipping equipment includes IAE 1P16046 Removal/Installation fixture or IAE 1P16543 Removal/Installation fixture 1 off, IAE 5F10206 HP system shipping frame 1 off, IAE 5R18235 Transportation front support 1 off and IAE 5R18288 Shipping container 1 off.

Make sure that all flange faces and tool faces that touch are very clean.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Four legged sling | LOCAL | Four legged sling | ||

| IAE 1F10262 Lift sling | 0AM53 | IAE 1F10262 | 1 | |

| IAE 1P16046 Removal/Installation fixture | 0AM53 | IAE 1P16046 | ||

| IAE 1P16543 Removal/Installation fixture | 0AM53 | IAE 1P16543 | ||

| IAE 5F10124 Shipping equipment | 0AM53 | IAE 5F10124 | 1 | |

| IAE 5F10206 HP system shipping frame | 0AM53 | IAE 5F10206 | ||

| IAE 5R18235 Transportation front support | 0AM53 | IAE 5R18235 | ||

| IAE 5R18288 Shipping container | 0AM53 | IAE 5R18288 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 | ||

| CoMat 12-013 PRINTED, WAXED, VCI COATED PAPER | LOCAL | CoMat 12-013 | ||

| CoMat 12-022 DESICCANT SELF INDICATING | LOCAL | CoMat 12-022 | ||

| CoMat 04-005 JOINTING COMPOUND, MEDIUM GRADE | LOCAL | CoMat 04-005 | ||

| CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON | K6835 | CoMat 02-122 |

Spares

NONESafety Requirements

NONEProcedure

Move the hoist over IAE 5F10124 Shipping equipment 1 off and attach the four legged sling to the four lid lift rings.

SUBTASK 72-40-00-530-051 Remove the HP System Shipping Container Lid

If you do TASK 72-00-40-560-004 use the remove and install fixture in the shipping container. To remove the remove/install fixture from the module refer to Step.

Make sure that the HP system module is in the horizontal position. If it is not, refer to TASK 72-00-40-560-004. It is not necessary to remove the remove/install fixture, but it is necessary to remove the tie-rod adaptor, in this TASK.

Use the bolt, the washer and the nut removed in Step to hold the support bracket in position. Tighten the nut.

Remove the support bracket from the remove/install fixture.

Remove the remove/install fixture from the shipping frame.

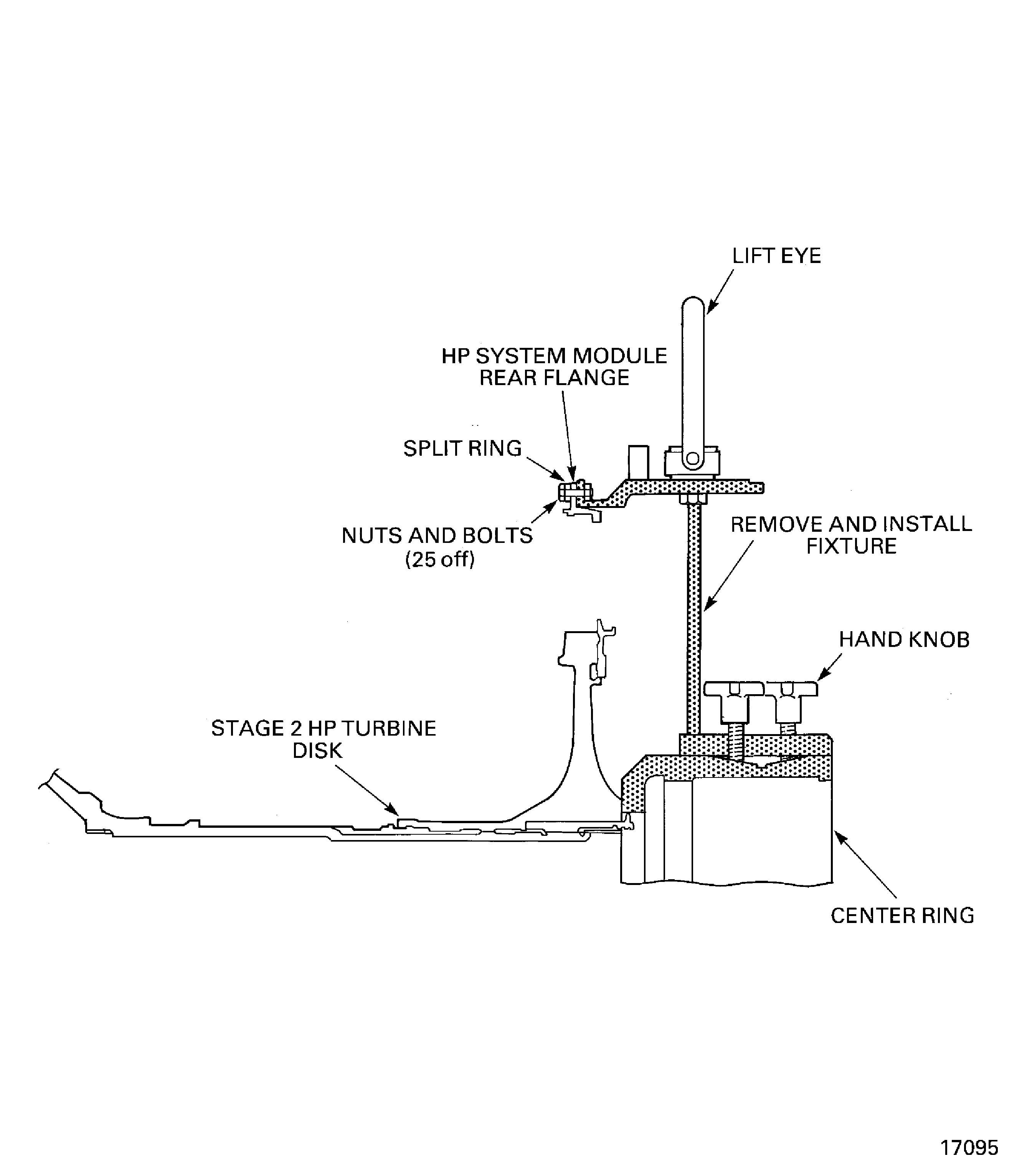

SUBTASK 72-40-00-530-052 Install the Remove/Install Fixture on to the HP System Module Rear Flange

NOTE

The HP system module front flange bolt holes must be kept clear.Put a cover on the HP system module front flange. Use CoMat 12-013 PRINTED, WAXED, VCI COATED PAPER to make the cover.

SUBTASK 72-40-00-530-053 Install the Transportation Front Support on to the HP System Module Front Flange

Refer to Figure.

Put a thin layer of CoMat 04-005 JOINTING COMPOUND, MEDIUM GRADE on to the bracket where it touches the blank.

Install one of the blanks HP COMPRESSOR SPLIT CASE (72-41-31, 01-120), the bracket HP COMPRESSOR SPLIT CASE (72-41-31, 01-118) and two of the bolts HP COMPRESSOR SPLIT CASE (72-41-31, 01-122) in to the HP compressor at location A.

Put a thin layer of CoMat 04-005 JOINTING COMPOUND, MEDIUM GRADE on the bracket where it touches the blank.

Install one of the blanks HP COMPRESSOR SPLIT CASE (72-41-31, 01-120), the bracket HP COMPRESSOR SPLIT CASE (72-41-31, 01-115) and two of the bolts HP COMPRESSOR SPLIT CASE (72-41-31, 01-122) in the HP compressor at location C.

Install the other blank HP COMPRESSOR SPLIT CASE (72-41-31, 01-120) and the other bolts HP COMPRESSOR SPLIT CASE (72-41-31, 01-122) in to the HP compressor at location B. Torque the bolts to 85 to 105 lbfin (10 to 12 Nm).

SUBTASK 72-40-00-530-054 Remove the HP Compressor Support Rods

Put a cover on to, and seal, all the openings on the HP system module and the tools. Use CoMat 12-013 PRINTED, WAXED, VCI COATED PAPER to make the covers.

SUBTASK 72-40-00-530-055 Prepare the HP System Module for Storage

Refer to Figure.

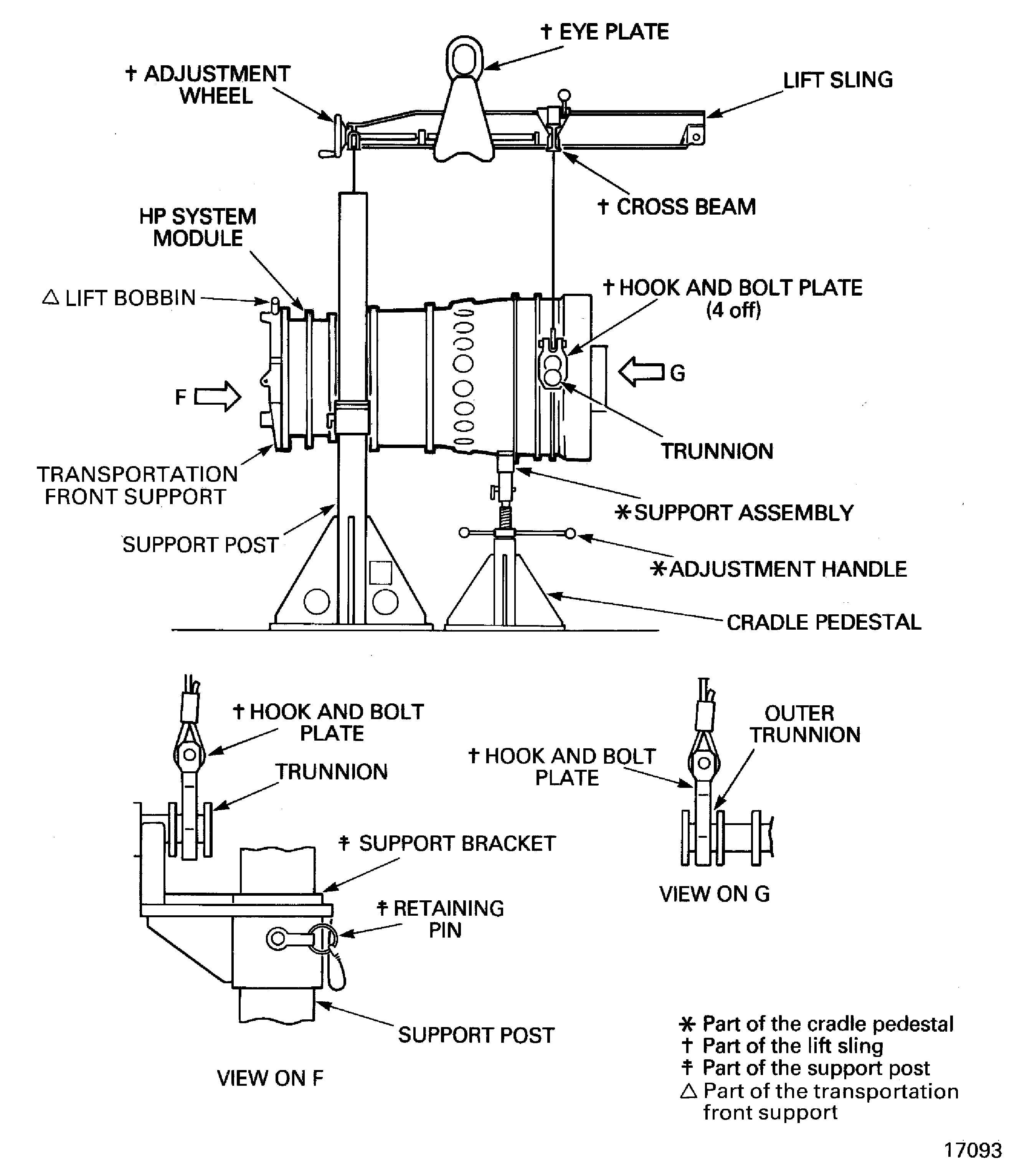

Attach IAE 1F10262 Lift sling 1 off to the HP system module.

SUBTASK 72-40-00-530-056 Install the HP System Module in to the HP System Shipping Frame

Refer to Figure.

Install the five bolts HPC Assembly (72-41-00, 01-308) and the five nuts removed in Step Torque the nuts to 180 to 220 lbfin (20 to 25 Nm).

Install the five bolts HPC Assembly (72-41-00, 01-308) and the five nuts removed in Step. Torque the nuts to 180 to 220 lbfin (20 to 25 Nm).

SUBTASK 72-40-00-530-057 Remove the Trunnion Assemblies from the HP System Module

Refer to Figure.

SUBTASK 72-40-00-530-058 Seal the Shipping Container

Refer to Figure.

Put the correct amount of desiccant in to the desiccant receptacle. Follow the instructions given on the shipping container lid adjacent to the desiccant receptacle. Use CoMat 12-022 DESICCANT SELF INDICATING. Replace the desiccant receptacle cover.

SUBTASK 72-40-00-530-059 Put the Desiccant and the Records in to the Shipping Container

Remove the desiccant from the desiccant receptacle and replace it with new desiccant. Follow the instructions given on the shipping container lid, adjacent to the desiccant receptacle for the correct amount. Use CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON. Replace the desiccant receptacle cover.

Do Step again.

If the humidity indicator changes color from blue, do the subsequent steps.

SUBTASK 72-40-00-530-060 Do the Subsequent Checks after the Shipping Container is Sealed

Figure: Install the remove/install fixture on to the HP system module

Install the remove/install fixture on to the HP system module

Figure: HP system module shipping equipment

HP system module shipping equipment

Figure: Install the transportation front support on to the HP system module

Install the transportation front support on to the HP system module

Figure: Install the HP compressor support rods

Install the HP compressor support rods

Figure: Install the HP compressor support rods

Install the HP compressor support rods

Figure: Install the HP system module in to the shipping frame

Install the HP system module in to the shipping frame

Figure: Install the HP system module in to the shipping frame

Install the HP system module in to the shipping frame

Figure: Remove the HP compressor trunnions

Remove the HP compressor trunnions