Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-11-300-017 HPC Stage 3 - 8 Drum Disk - Restore The Stage 3 To 5 Anti-Fret Treatment, Repair-017 (VRS6487)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-200 | 6A3508 |

01-200 | 6A3648 |

01-200 | 6A3934 |

01-200 | 6A3936 |

01-200 | 6A4189 |

01-200 | 6A4900 |

01-200 | 6A5467 |

01-200 | 6A5592 |

01-200 | 6A5594 |

01-200 | 6A5659 |

01-200 | 6A6473 |

01-200 | 6A7379 |

01-200 | 6A7380 |

01-200 | 6A7382 |

01-200 | 6A7383 |

01-200 | 6A7384 |

01-200 | 6A7385 |

01-200 | 6A7401 |

01-200 | 6A7705 |

01-200 | 6A8236 |

01-200 | 6A8316 |

01-200 | 6A8318 |

01-200 | 6A8350 |

01-200 | 6B1379 |

01-200 | 6B1380 |

01-200 | 6B1381 |

01-200 | 6B1382 |

01-200 | 6B1383 |

01-200 | 6B1384 |

01-200 | 6B1385 |

01-200 | 6B1386 |

01-200 | 6B1387 |

01-200 | 6B1391 |

01-200 | 6B1392 |

01-200 | 6B1393 |

01-200 | 6B1401 |

01-200 | 6B1402 |

01-200 | 6B1403 |

01-200 | 6B1404 |

01-200 | 6B1405 |

01-200 | 6B1406 |

Material of component

PART IDENT | MATERIAL |

|---|---|

HP Compressor Stage 3 to 8 Disks Shaft Assembly | Titanium Alloy |

General

This Repair must only be done when the instruction to do so as given in the relevant inspection procedures (identified by the applicable part number) located in section 72-41-11.

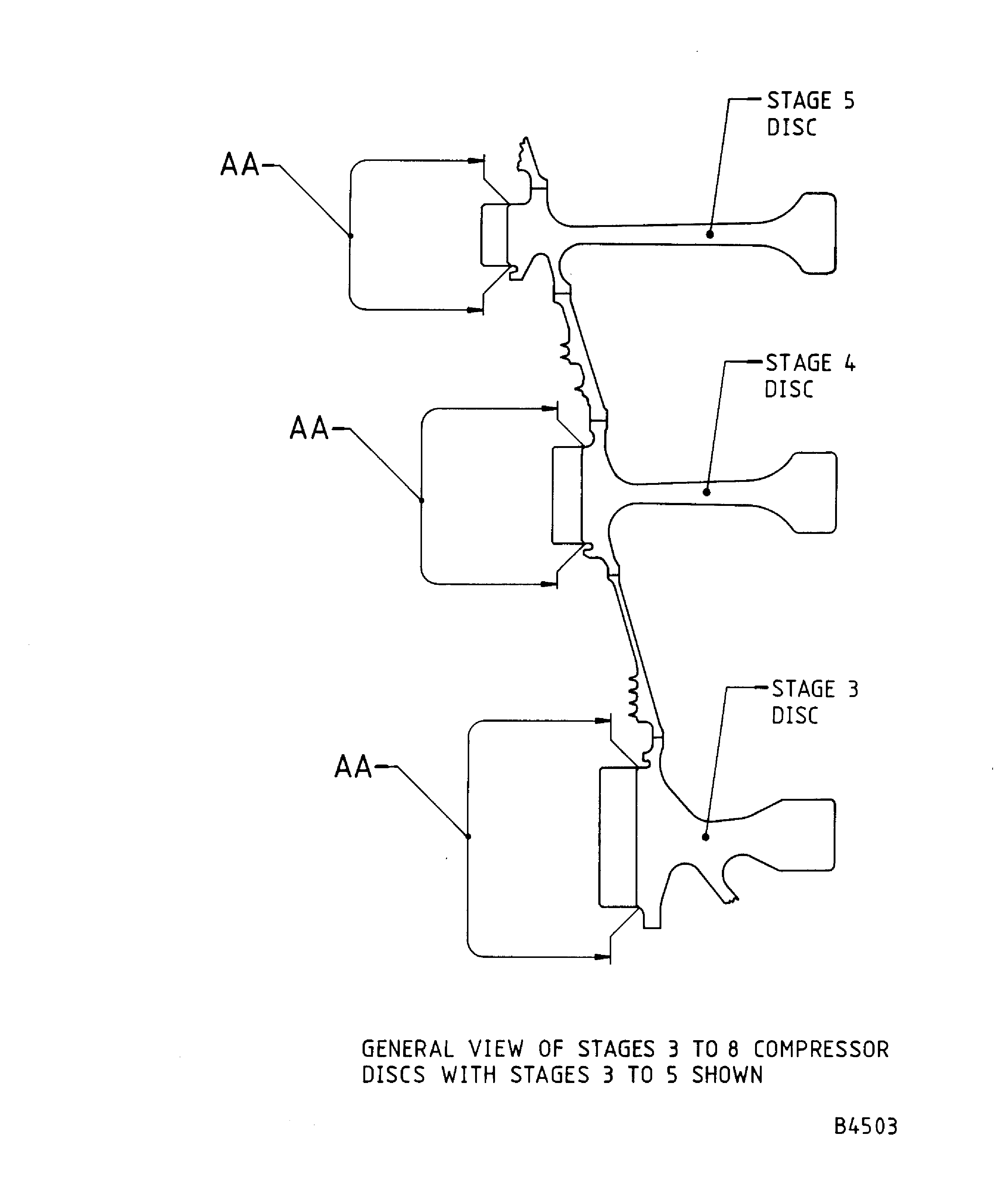

This Repair restores the dry film lubricant to the HP compressor disks, stage 3 - 8, on the stage 3 to 5 rotor blade location slots.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the Standard Practices Manual (SPM).

Price and availability

Refer to International Aero Engines

NOTE

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Spray gun | LOCAL | Spray gun | ||

| Oven | LOCAL | Oven | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-002 ADHESIVE TAPE GENERALPURPOSE PAPER | LOCAL | CoMat 02-002 | ||

| CoMat 02-019 TAPE, ADHESIVE PAPER HEAT RESISTING MASKING | 94960 | CoMat 02-019 | ||

| CoMat 07-009 THINNER | LOCAL | CoMat 07-009 | ||

| CoMat 10-002 DRY FILM LUBRICANT | LOCAL | CoMat 10-002 |

Spares

NONESafety Requirements

NONEProcedure

Refer to SPM TASK 70-11-01-300-503.

Chemically clean the disks.

SUBTASK 72-41-11-110-064 Clean the Dovetail Location Slots on the Stage 3, 4 and 5 Rotor Disks

Refer to SPM TASK 70-38-03-380-501, SUBTASK 70-38-03-380-004.

UseCoMat 10-002 DRY FILM LUBRICANT graphite with CoMat 07-009 THINNER.

Use a Spray gun.

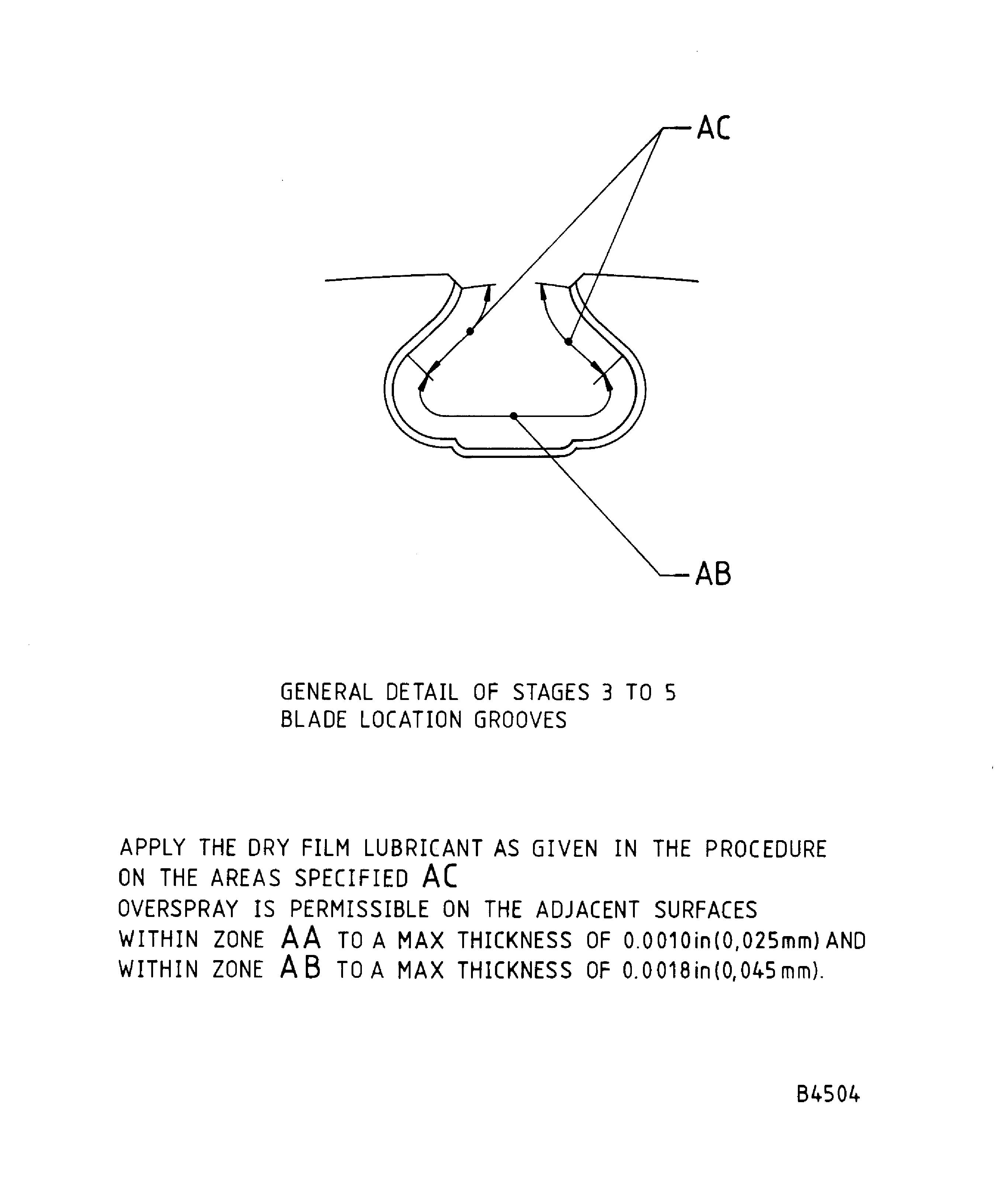

Apply the dry film lubricant, by spray to get a total thickness of 0.00012 in. to 0.00059 in. (0.003 mm to 0.014 mm) on areas identified AC.

SUBTASK 72-41-11-380-055 Apply the Dry Film Lubricant to the Dovetail Location Slots on the Stage 3, 4 and 5 Rotor Disks

Refer to SPM TASK 70-38-03-380-501, SUBTASK 70-38-03-380-005.

Use an Oven.

Stove the rotor Disks.

SUBTASK 72-41-11-380-056 Stove the Rotor Disks

Refer to SPM TASK 70-38-03-380-501, SUBTASK 70-38-03-220-001, for inspection standards.

Visually examine the dry film lubricant layer.

SUBTASK 72-41-11-220-100 Examine the Dry Film Lubricant

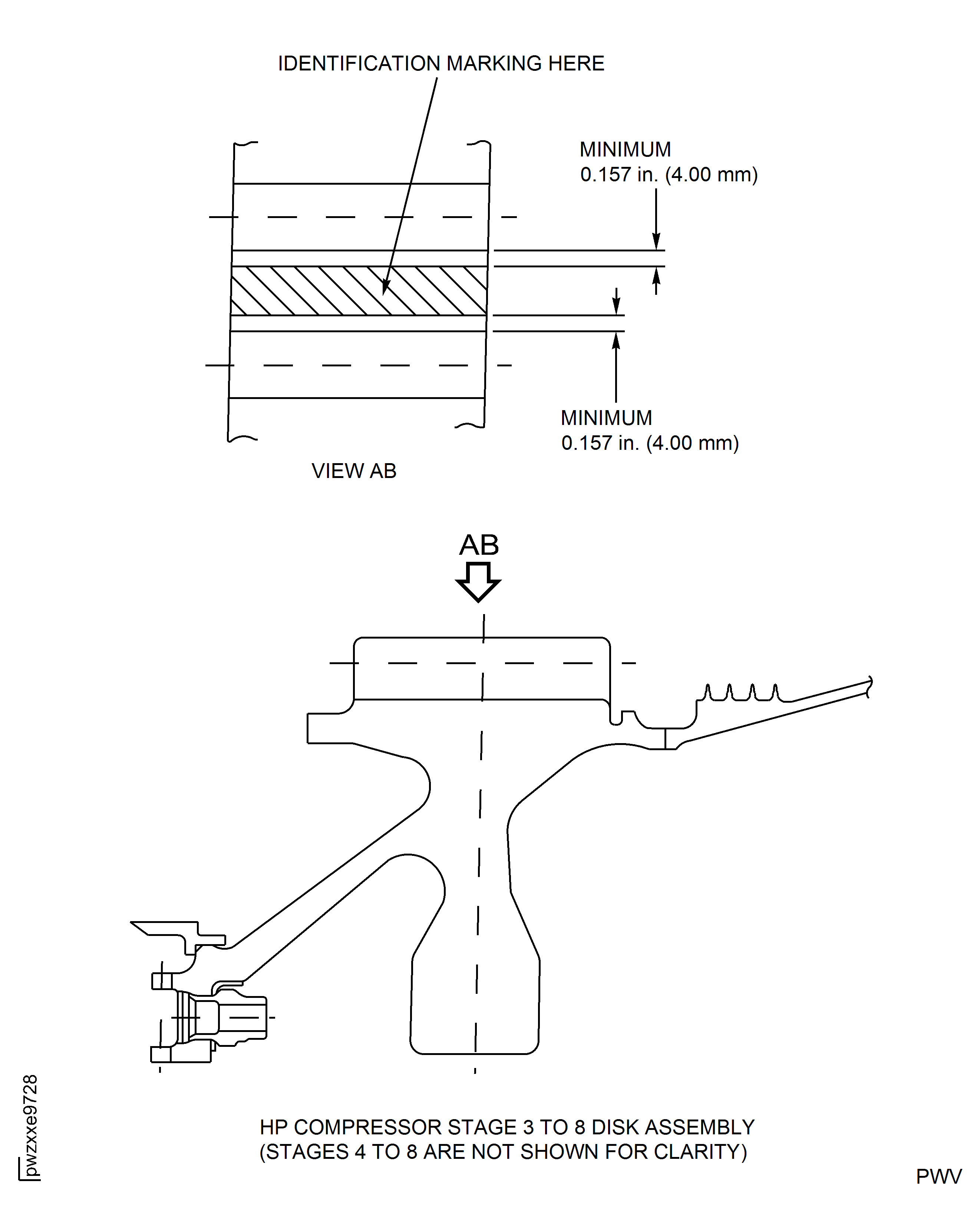

Refer to Figure.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

NOTE

If the parts are already identified with the repair scheme number "VRS6487" from a previous repair application, further identification is not necessary.

Vibro-engrave VRS6487 adjacent to the assembly number.

SUBTASK 72-41-11-350-070 Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions