Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-12-300-001 HPC Vortex Reducer Ring - Repair, Repair-001 (VRS6086)

Material of component

PART IDENT | MATERIAL |

|---|---|

HP Compressor Vortex Reducer Ring Assembly | Titanium Alloy (TAH) |

General

This TASK gives the procedure to Repair Defects on the HP Compressor Vortex Reducer Ring Lugs by hand dressing.

This repair must only be done when the instruction to do so is given in inspection procedures (identified by the applicable part number) located in TASK 72-41-12-200-001.

This repair scheme is written in 3 parts.

PART 1: Dress to X1 Depth.

Hand dress the HP Compressor Vortex Reducer Ring Lugs to remove material to the depth of the defect only.

PART 2: Dress to X2 Depth.

Hand dress the HP Compressor Vortex Reducer Ring Lugs to remove material to twice the depth of the defect.

PART 3 - Dress to Remove Burrs, Raised Material and Sharp Edges.

Hand dress the HP Compressor Vortex Reducer Ring Lugs to remove burrs, raised material and sharp edges.

The depth of the applied dressing must be in accordance with the instructions in the Inspection/Check, refer to TASK 72-41-12-200-001.

Power tools or hand held power tools are not to be used to repair the component.

TASKS identified by SPM TASK are in the Standard Practices and Processes Manual (SPM).

Price and availability

Refer to International Aero Engines

Related repair - none

NOTE

NOTE

It is possible that some materials in the consumable materials chart cannot be used for some or all of the necessary applications. Before you use the materials, make sure the types, quantities and applications of the materials necessary are legally permitted in your location. All persons must obey all applicable federal, state, local and provincial laws and regulations when it is necessary to work with these materials.

To identify the consumable materials, refer to the overhaul Processes and Consumables Index (PCI).

Other necessary consumable materials are referred to in SPM TASKs.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Dimensional inspection equipment | LOCAL | Dimensional inspection equipment | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| Vibro-peen equipment | LOCAL | Vibro-peen equipment | ||

| Binocular inspection equipment | LOCAL | Binocular inspection equipment | 10X |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-096 MARKER PEN | LOCAL | CoMat 02-096 | ||

| CoMat 02-124C MARKING INK | K6858 | CoMat 02-124C | ||

| CoMat 05-080 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-080 | ||

| CoMat 05-106 ABRASIVE STONE | K6835 | CoMat 05-106 | ||

| CoMat 05-111 EMERY POLISHING PAPER | 06565 | CoMat 05-111 | ||

| CoMat 05-141 ABRASIVE STONE SILICON CARBIDE | LOCAL | CoMat 05-141 | ||

| CoMat 06-065 FLUORESCENT PENETRANT (WATER WASHABLE HIGH SENSITIVITY) | K6858 | CoMat 06-065 |

Spares

NONESafety Requirements

NONEProcedure

NOTE

The number(s) of the lug(s) which has been dressed previously were recorded upon successful completion of VRS6086 to make it easier to identify the repair locations.NOTE

The repaired location(s) on the individual lug(s) and the depth of the dressing were not recorded. Care must be taken during inspection to identify previously repaired locations as a second repair of the same lug is not permitted.Reject.

If the component has had VRS6086 applied previously and the lug with the defect(s) was repaired during the previous application.

Bedding check the proposed repair area to determine if the lug has been repaired before.

Reject.

If the bedding check of the repair area shows less than 90% bedding.

Continue with the repair.

If the bedding check shows greater than 90% bedding.

If the component has been repaired in accordance with VRS6086 previously and the previous repair location cannot be determined.

Continue with the repair.

If the component has not been repaired in accordance with VRS6086 previously.

Examine the HP Compressor Vortex Reducer Ring for previous applications of VRS6086.

NOTE

A combination of repairs at corresponding locations on Surface 1 and Surface 2 is not permitted.Reject.

If the repair will exceed the maximum permitted depth.

Reject.

NOTE

A combination of repairs at corresponding locations on Surface 1 and Surface 2 is not permitted.

If the repair area will remove material over more than 25% of the contact surface of the lug(s).

Mark the location(s) that are to be repaired and continue with the repair.

If the lug(s) has not been repaired previously and the repair area will not remove more than 25% of the contact face of the lug.

Refer to TASK 72-41-12-200-001.

Examine the defect(s) on the HP Compressor Vortex Reducer Ring.

Continue the repair from Step.

If there is no x mark on the identity marking surface adjacent to one of the lugs.

Continue the repair from Step, Step or Step, as specified in TASK 72-41-12-200-001.

If there is an x mark on the identity marking surface adjacent to one of the lugs.

Examine the identity marking location for a x mark adjacent to one of the lugs from a previous repair.

NOTE

The x mark will only exist if VRS6086 has been applied previously.

SUBTASK 72-41-12-210-001 Examine the HP Compressor Vortex Reducer Ring

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use Vibro-peen equipment.

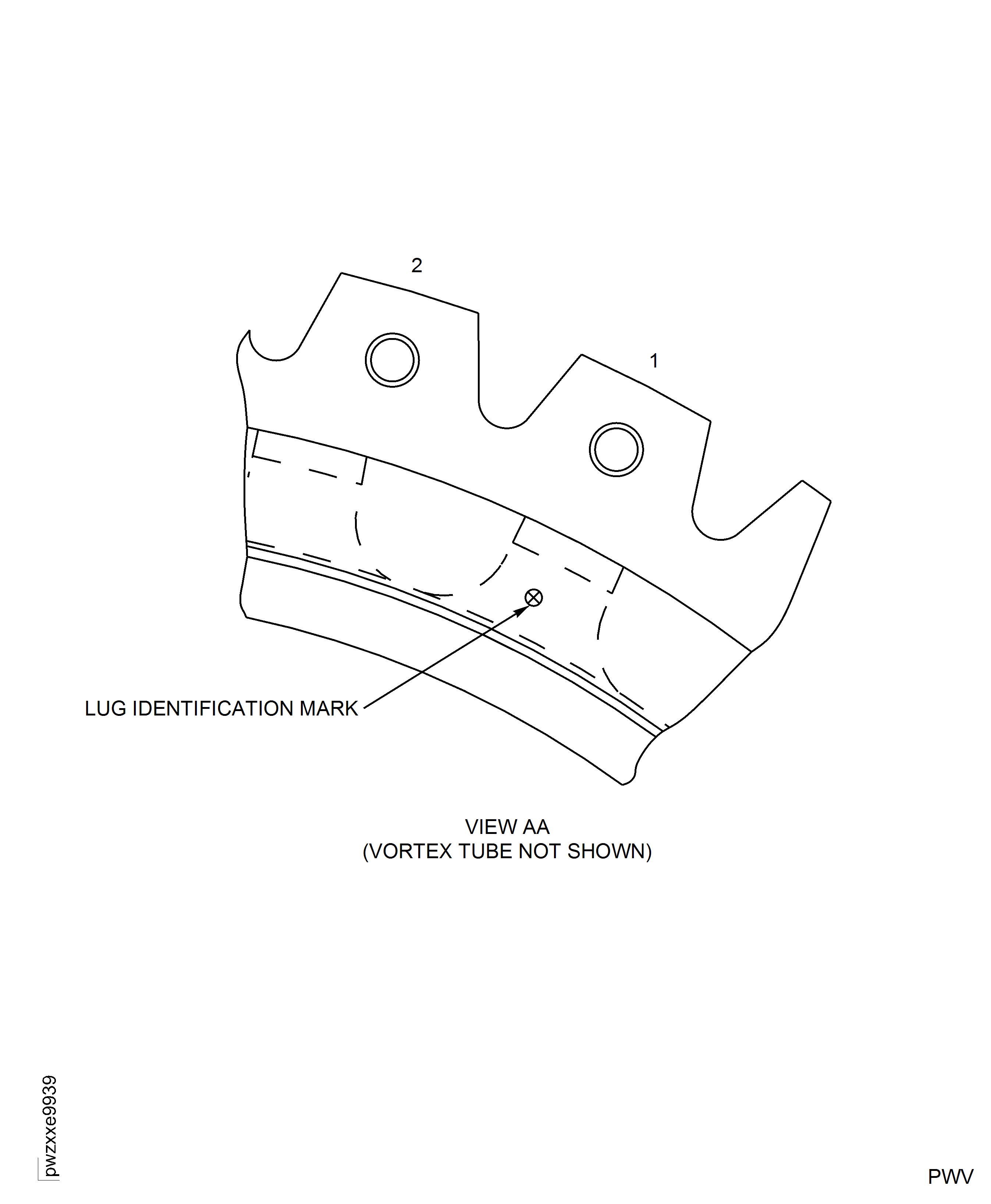

If this is the first application of VRS6086 vibro-peen a circle with an X in it, x, at the identity marking location adjacent to the HP Compressor Vortex Reducer Ring Lugs to act as a reference.

NOTE

To determine the number of the Lug being repaired, use the lug with the vibro-peened x mark as the number 1 lug and count counter-clockwise, viewed from the front, to the repaired Lug.

SUBTASK 72-41-12-350-001 Identify a Reference Lug (If Required)

CAUTION

DRESSING IN ACCORDANCE WITH PART 1 OF VRS6086 MUST ONLY BE DONE WHEN THE INSTRUCTION TO DO SO IS GIVEN IN THE INSPECTION/CHECK, REFER TO TASK 72-41-12-200-001.PART 1 - DRESS TO THE DEPTH OF THE DEFECT (X1 TIMES THE DEPTH)

Hand dress the HP Compressor Vortex Reducer Ring Lug(s) to remove material to the depth of the defect(s) only.

Refer to TASK 72-41-12-200-001.

Dress to X1 times the depth of the defect only.

Use non-powered hand tools and/or CoMat 05-141 ABRASIVE STONE SILICON CARBIDE and CoMat 05-080 WATERPROOF SILICON CARBIDE.

Remove the minimum amount of material necessary to remove the defect(s).

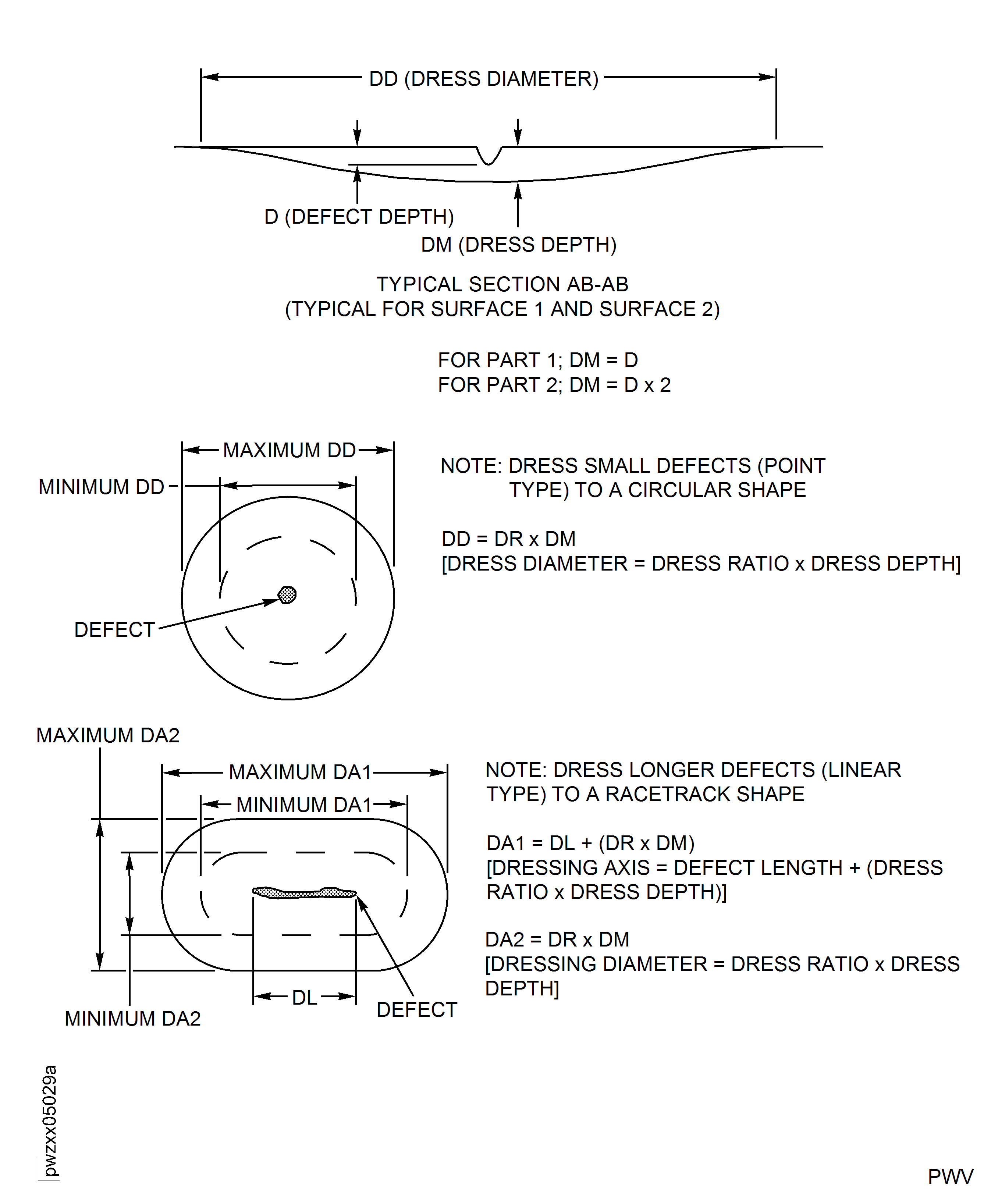

The minimum dress ratio is 50 to 1. The maximum recommended dress ratio is 100 to 1, however, larger dress ratios are acceptable. Larger dress ratios may lead to an unacceptable reduction (greater than 25 percent) of the contact area of the lug.

Make sure that radii or chamfers affected by the repair do not decrease in size due to the repair.

Hand dress to remove defect(s) from the HP Compressor Vortex Reducer Ring Lug(s).

NOTE

Defects positioned next to each other can be treated as a single defect providing the maximum length-depth ratio is maintained. In case of a combination of defects next to each other which must be dressed to Part 1 and Part 2 where the dressed areas will overlap, the repair must be accomplished in accordance with Part 2. Dressing to Part 2 at any location is only acceptable if specifically instructed in TASK 72-41-12-200-001.

SUBTASK 72-41-12-350-002 Hand Dress the Identified Defect(s)

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - AVOID BUILD UP OF HEAT BY APPLYING ONLY GENTLE PRESSURE AND KEEPING THE DRESSING SPEED AS LOW AS POSSIBLE. USE TECHNIQUES WHICH ALLOW FOR PROGRESSIVE WEAR OF THE DRESSING MEDIA TO PRESENT A CONTINUALLY FRESH CUTTING SURFACE TO THE WORK PIECE.

CAUTION

DRESS, WHERE POSSIBLE, IN A CIRCULAR MOTION.

CAUTION

TITANIUM COMPONENT - YOU MUST MAKE SURE THAT WHEN YOU DRESS AND POLISH TO MAKE THE SURFACE SMOOTH, THAT NO SPARKS ARE PRODUCED.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOUR DURING DRESSING, TO DARKER THAN A LIGHT STRAW COLOUR, THE COMPONENT MUST BE REJECTED.

CAUTION

DO NOT USE POWER TOOLS OR HAND HELD POWER TOOLS TO REPAIR THE HP COMPRESSOR VORTEX REDUCER RING LUGS.

CAUTION

MAKE SURE THAT ALL BURRS CREATED BY THE DRESSING PROCESS ARE REMOVED.Refer to TASK 72-41-12-200-001.

Reject.

If the dressed areas are in excess of the limits.

Reject.

If the dressed area is greater than 25% of the contact surface of the Lug(s).

Repeat the repair from Step.

If there are any defect indications remaining.

Continue with the repair.

If all of the defect indications have been removed and the repair(s) are within the limits.

Dimensionally inspect the repaired area(s) of the HP Compressor Vortex Reducer Ring Lug(s).

SUBTASK 72-41-12-220-001 Dimensionally Inspect the Repaired Areas

Refer to SPM TASK 70-11-08-300-503, SUBTASK 70-11-08-300-002.

Hydrofluoric/Nitric Acid swab etch the repair areas on the HP Compressor Vortex Reducer Ring Lug(s).

SUBTASK 72-41-12-110-001 Swab Etch the Repair Area(s)

Refer to SPM TASK 70-23-05-230-501, SUBTASK 70-23-05-230-002.

Reject.

If cracking is detected.

Continue with the repair.

If no cracking is detected.

Inspect for cracking at the repair area on the HP Compressor Vortex Reducer Ring Lug(s) using fluorescent penetrant inspection.

SUBTASK 72-41-12-230-001 Fluorescent Penetrant Inspect

Hand polish the repair areas.

The surface texture of the repair area(s) on Surface 1 and Surface 2 must be 63 micro-inches (1.6 micro-metres) or better.

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - AVOID BUILD UP OF HEAT BY APPLYING ONLY GENTLE PRESSURE AND KEEPING THE DRESSING SPEED AS LOW AS POSSIBLE. USE TECHNIQUES WHICH ALLOW FOR PROGRESSIVE WEAR OF THE DRESSING MEDIA TO PRESENT A CONTINUALLY FRESH CUTTING SURFACE TO THE WORK PIECE.

CAUTION

DRESS, WHERE POSSIBLE, IN A CIRCULAR MOTION.

CAUTION

TITANIUM COMPONENT - YOU MUST MAKE SURE THAT WHEN YOU DRESS AND POLISH TO MAKE THE SURFACE SMOOTH, THAT NO SPARKS ARE PRODUCED.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOUR DURING DRESSING, TO DARKER THAN A LIGHT STRAW COLOUR, THE COMPONENT MUST BE REJECTED.

CAUTION

DO NOT USE POWER TOOLS OR HAND HELD POWER TOOLS TO REPAIR THE HP COMPRESSOR VORTEX REDUCER RING.Polish the repair area(s) on the HP Compressor Vortex Reducer Ring Lugs.

SUBTASK 72-41-12-350-003 Polish the Repair Area

Refer to Figure.

NOTE

If the HP Compressor Vortex Reducer Ring is already identified with the repair scheme number VRS6086 from a previous repair application, only the number of the repaired lug(s) needs to be added.Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use Vibro-peen equipment.

Vibro-peen VRS6086 at the indicated location(s) on the HP Compressor Vortex Reducer Ring.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

To determine the lug number, use the lug with the vibro-peened x mark as number 1 and count counter-clockwise, viewed from the front, to the repaired lug(s).

Use Vibro-peen equipment.

Vibro-peen the number of the repaired lug(s) adjacent to the repair scheme number at the indicated location.

Remove raised material, burrs and/or sharp edges at the vibro-peen marking area and x the mark location.

NOTE

It will only be required to remove raised material, burrs and/or sharp edges from the x mark location if this is the first application of VRS6086.

SUBTASK 72-41-12-350-004 Identify the Repair

CAUTION

DRESSING IN ACCORDANCE WITH PART 2 OF VRS6086 MUST ONLY BE DONE WHEN THE INSTRUCTION TO DO SO IS GIVEN IN THE INSPECTION/CHECK, REFER TO TASK 72-41-12-200-001.PART 2 - DRESS TO TWICE THE DEPTH OF THE DEFECT(S) (X2 TIMES THE DEPTH)

Hand dress the HP Compressor Vortex Reducer Ring Lugs to remove material to twice the depth of the defect(s).

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - AVOID BUILD UP OF HEAT BY APPLYING ONLY GENTLE PRESSURE AND KEEPING THE DRESSING SPEED AS LOW AS POSSIBLE. USE TECHNIQUES WHICH ALLOW FOR PROGRESSIVE WEAR OF THE DRESSING MEDIA TO PRESENT A CONTINUALLY FRESH CUTTING SURFACE TO THE WORK PIECE.

CAUTION

DRESS, WHERE POSSIBLE, IN A CIRCULAR MOTION.

CAUTION

TITANIUM COMPONENT - YOU MUST MAKE SURE THAT WHEN YOU DRESS AND POLISH TO MAKE THE SURFACE SMOOTH, THAT NO SPARKS ARE PRODUCED.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOUR DURING DRESSING, TO DARKER THAN A LIGHT STRAW COLOUR, THE COMPONENT MUST BE REJECTED.

CAUTION

DO NOT USE POWER TOOLS OR HAND HELD POWER TOOLS TO REPAIR THE HP COMPRESSOR VORTEX REDUCER RING LUGS.

CAUTION

MAKE SURE THAT ALL BURRS CREATED BY THE DRESSING PROCESS ARE REMOVED.Refer to TASK 72-41-12-200-001.

Dress to X2 times the depth of the defect only.

Use non-powered hand tools and/or CoMat 05-141 ABRASIVE STONE SILICON CARBIDE and CoMat 05-080 WATERPROOF SILICON CARBIDE.

The minimum dress ratio is 50 to 1. The maximum recommended dress ratio is 100 to 1, however, larger dress ratios are acceptable. Larger dress ratios may lead to an unacceptable reduction (greater than 25 percent) of the contact area of the lug.

Make sure that radii or chamfers affected by the repair do not decrease in size due to the repair.

Hand dress to remove defect(s) from the HP Compressor Vortex Reducer Ring Lug(s).

NOTE

Defects positioned next to each other can be treated as a single defect providing the maximum length-depth ratio is maintained. In case of a combination of defects next to each other which must be dressed to Part 1 and Part 2 where the dressed areas will overlap, the repair must be accomplished in accordance with Part 2. Dressing to Part 2 at any location is only acceptable if specifically instructed in TASK 72-41-12-200-001.

SUBTASK 72-41-12-350-005 Hand Dress the Identified Defect(s)

Refer to TASK 72-41-12-200-001.

Reject.

If the dressed areas are in excess of the limits.

Reject.

If the dressed area is greater than 25% of the contact surface of the Lug(s).

Repeat the repair from Step.

If there are any defect indications remaining.

Continue with the repair.

If all of the defect indications have been removed and the repair(s) are within the limits.

Dimensionally inspect the repaired area(s) of the HP Compressor Vortex Reducer Ring Lug(s).

SUBTASK 72-41-12-220-002 Dimensionally Inspect the Repaired Areas

Refer to SPM TASK 70-11-08-300-503, SUBTASK 70-11-08-300-002.

Hydrofluoric/Nitric Acid swab etch the repair areas on the HP Compressor Vortex Reducer Ring Lug(s).

SUBTASK 72-41-12-110-002 Swab Etch the Repair Area(s)

Refer to SPM TASK 70-23-05-230-501, SUBTASK 70-23-05-230-002.

Reject.

If cracking is detected.

Continue with the repair.

If no cracking is detected.

Inspect for cracking at the repair area on the HP Compressor Vortex Reducer Ring Lug(s) using fluorescent penetrant inspection.

SUBTASK 72-41-12-230-002 Fluorescent Penetrant Inspect

Hand polish the repair areas.

The surface texture of the repair area(s) on Surface 1 and Surface 2 must be 63 micro-inches (1.6 micrometres) or better.

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - AVOID BUILD UP OF HEAT BY APPLYING ONLY GENTLE PRESSURE AND KEEPING THE DRESSING SPEED AS LOW AS POSSIBLE. USE TECHNIQUES WHICH ALLOW FOR PROGRESSIVE WEAR OF THE DRESSING MEDIA TO PRESENT A CONTINUALLY FRESH CUTTING SURFACE TO THE WORK PIECE.

CAUTION

DRESS, WHERE POSSIBLE, IN A CIRCULAR MOTION.

CAUTION

TITANIUM COMPONENT - YOU MUST MAKE SURE THAT WHEN YOU DRESS AND POLISH TO MAKE THE SURFACE SMOOTH, THAT NO SPARKS ARE PRODUCED.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOUR DURING DRESSING, TO DARKER THAN A LIGHT STRAW COLOUR, THE COMPONENT MUST BE REJECTED.

CAUTION

DO NOT USE POWER TOOLS OR HAND HELD POWER TOOLS TO REPAIR THE HP COMPRESSOR VORTEX REDUCER RING.Polish the repair area(s) of the HP Compressor Vortex Reducer Ring Lug(s).

SUBTASK 72-41-12-350-006 Polish the Repair Area(s)

Refer to Figure.

NOTE

If the HP Compressor Vortex Reducer Ring is already identified with the repair scheme number VRS6086 from a previous repair application, only the number of the repaired lug(s) needs to be added.Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use Vibro-peen equipment.

Vibro-peen VRS6086 at the indicated location(s) on the HP Compressor Vortex Reducer Ring.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

To determine the lug number, use the lug with the vibro-peened x mark as number 1 and count counter-clockwise, viewed from the front, to the repaired lug.

Use Vibro-peen equipment.

Vibro-peen the number of the repaired lug(s) adjacent to the repair scheme number at the indicated location.

Remove raised material, burrs and/or sharp edges at the vibro-peen marking area and x the mark.

NOTE

It will only be required to remove raised material, burrs and/or sharp edges from the x mark location if this is the first application of VRS6086.

SUBTASK 72-41-12-350-007 Identify the Repair

CAUTION

DRESSING IN ACCORDANCE WITH PART 3 OF VRS6086 MUST ONLY BE DONE WHEN THE INSTRUCTION TO DO SO IS GIVEN IN THE INSPECTION/CHECK, REFER TO TASK 72-41-12-200-001.PART 3 - DRESS TO REMOVE BURRS, RAISED MATERIAL AND SHARP EDGES.

Hand dress the HP Compressor Vortex Reducer Ring Lug(s) to remove burrs, raised material and sharp edges.

Dress to remove burrs, raised material and sharp edges from the defect/repair area only.

If the dressed area overlaps a corner or chamfer make the edges of the polished area smooth.

Make sure that radii or chamfers affected by the repair do not decrease in size due to the repair.

Use non-powered hand tools and/or CoMat 05-141 ABRASIVE STONE SILICON CARBIDE and CoMat 05-080 WATERPROOF SILICON CARBIDE.

Hand dress to remove burrs, raised material and/or sharp edges from the HP Compressor Vortex Reducer Ring Lug(s).

SUBTASK 72-41-12-350-008 Dress the Burrs, Raised Material and/or Sharp Edges at the Repair Area

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - AVOID BUILD UP OF HEAT BY APPLYING ONLY GENTLE PRESSURE AND KEEPING THE DRESSING SPEED AS LOW AS POSSIBLE. USE TECHNIQUES WHICH ALLOW FOR PROGRESSIVE WEAR OF THE DRESSING MEDIA TO PRESENT A CONTINUALLY FRESH CUTTING SURFACE TO THE WORK PIECE.

CAUTION

DRESS, WHERE POSSIBLE, IN A CIRCULAR MOTION.

CAUTION

TITANIUM COMPONENT - YOU MUST MAKE SURE THAT WHEN YOU DRESS AND POLISH TO MAKE THE SURFACE SMOOTH, THAT NO SPARKS ARE PRODUCED AND THE ADJACENT AREA IS MASKED OFF.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOUR DURING DRESSING, TO DARKER THAN A LIGHT STRAW COLOUR, THE COMPONENT MUST BE REJECTED.

CAUTION

DO NOT USE POWER TOOLS OR HAND HELD POWER TOOLS TO REPAIR THE HP COMPRESSOR VORTEX REDUCER RING LUGS.

CAUTION

MAKE SURE THAT ALL BURRS CREATED BY THE DRESSING PROCESS ARE REMOVED.

CAUTION

DO NOT REMOVE ANY PARENT MATERIAL WHICH WAS NOT DEFORMED WHILE DRESSING IN ACCORDANCE WITH PART 3.Repeat the repair from Step.

If all of the burrs, raised material and sharp edges have not been removed or if the repair area(s) does not have a smooth profile.

Continue with the repair.

If all of the burrs, raised material and sharp edges have been removed and the repair area(s) has a smooth profile.

Make sure that all of the burrs, raised material and sharp edges have been removed and that the repair area(s) has a smooth profile.

Examine the repaired area(s) of the HP Compressor Vortex Reducer Ring Lug(s).

SUBTASK 72-41-12-220-003 Examine the Dressed Areas

Refer to SPM TASK 70-11-08-300-503, SUBTASK 70-11-08-300-002.

Hydrofluoric/Nitric Acid swab etch the repair areas on the HP Compressor Vortex Reducer Ring Lug(s).

SUBTASK 72-41-12-110-003 Swab Etch the Repair Area(s)

Refer to SPM TASK 70-23-05-230-501, SUBTASK 70-23-05-230-002.

Reject.

If cracking is detected.

Continue with the repair.

If no cracking is detected.

Inspect for cracking at the repair area on the HP Compressor Vortex Reducer Ring Lug(s) using fluorescent penetrant inspection.

SUBTASK 72-41-12-230-003 Fluorescent Penetrant Inspect

Hand polish to achieve the required surface texture.

The surface texture of the repair area(s) on Surface 1 and Surface 2 must be 63 micro-inches (1.6 micrometres) or better.

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - AVOID BUILD UP OF HEAT BY APPLYING ONLY GENTLE PRESSURE AND KEEPING THE DRESSING SPEED AS LOW AS POSSIBLE. USE TECHNIQUES WHICH ALLOW FOR PROGRESSIVE WEAR OF THE DRESSING MEDIA TO PRESENT A CONTINUALLY FRESH CUTTING SURFACE TO THE WORK PIECE.

CAUTION

DRESS, WHERE POSSIBLE, IN A CIRCULAR MOTION.

CAUTION

TITANIUM COMPONENT - YOU MUST MAKE SURE THAT WHEN YOU DRESS AND POLISH TO MAKE THE SURFACE SMOOTH, THAT NO SPARKS ARE PRODUCED.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOUR DURING DRESSING, TO DARKER THAN A LIGHT STRAW COLOUR, THE COMPONENT MUST BE REJECTED.

CAUTION

DO NOT USE POWER TOOLS OR HAND HELD POWER TOOLS TO REPAIR THE HP COMPRESSOR VORTEX REDUCER RING.

CAUTION

MAKE SURE THAT ALL OF THE BURRS CREATED BY THE REPAIR PROCESS ARE REMOVED.Hand polish the repair areas.

SUBTASK 72-41-12-350-009 Polish the Repair Area

Make sure that all of the burrs, raised material and sharp edges have been removed and that the repair area(s) has a smooth profile and that the required surface finish has been achieved.

Repeat the repair from Step.

If all of the burrs, raised material and sharp edges have not been removed, or.

Repeat the repair from Step.

If the repair area(s) does not have a smooth profile.

Repeat the repair from Step.

If the required surface finish has not been achieved.

Continue with the repair.

If all of the burrs, raised material and sharp edges have been removed, the repair area(s) has a smooth profile and if the required surface finish has been achieved.

Use 10X Binocular inspection equipment.

Examine the polished area(s) of the HP Compressor Vortex Reducer Ring Lug(s).

SUBTASK 72-41-12-220-004 Examine the Polished Areas

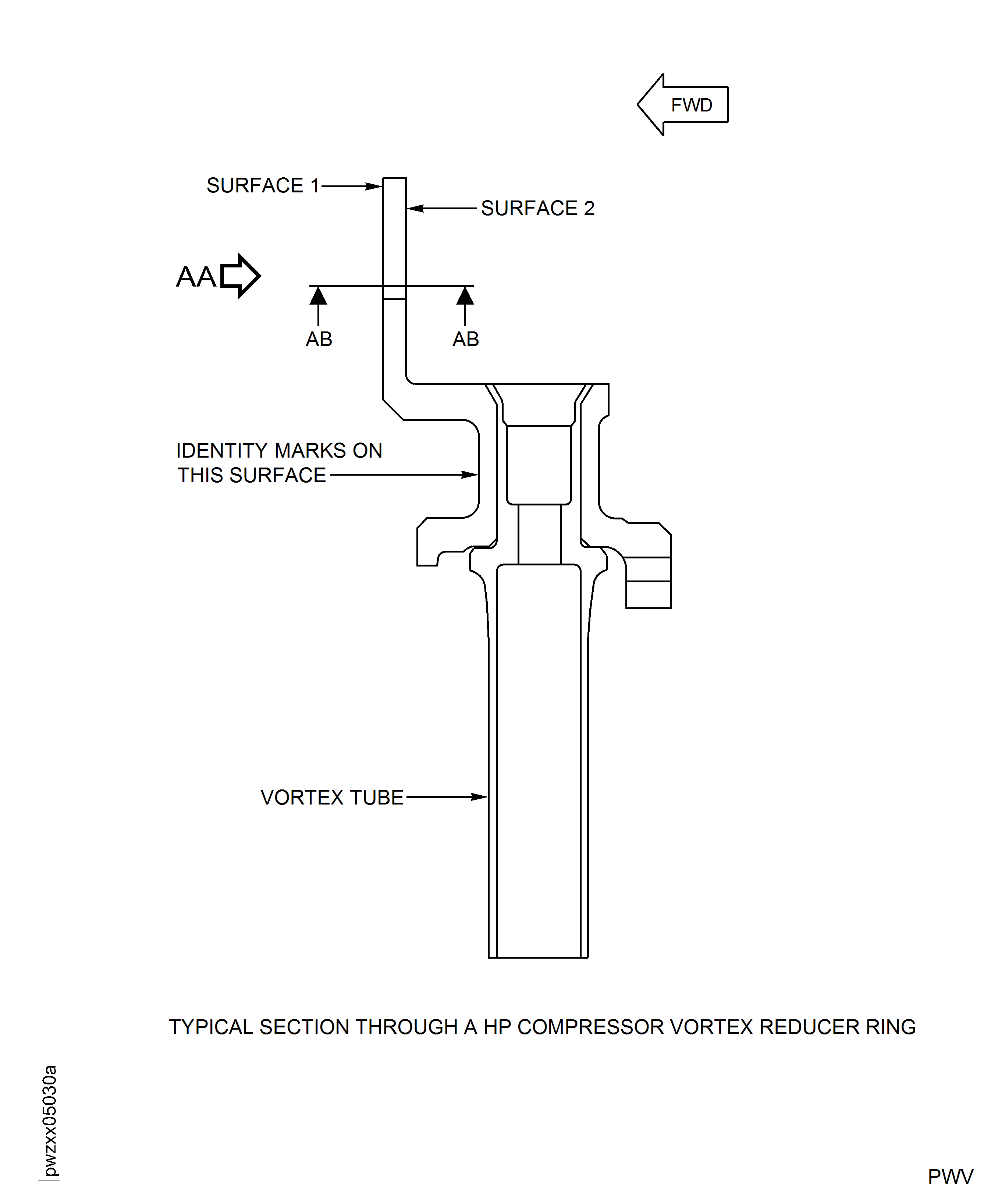

Figure: HP Compressor Vortex Reducer Ring Lug - Areas and Locations

HP Compressor Vortex Reducer Ring Lug - Areas and Locations

Figure: HP Compressor Vortex Reducer Ring Lugs - Lug Identification Information

HP Compressor Vortex Reducer Ring Lugs - Lug Identification Information

Figure: HP Compressor Vortex Reducer Ring Lugs - Dressing Ratios and Shapes

HP Compressor Vortex Reducer Ring Lugs - Dressing Ratios and Shapes