Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-12-300-026 HPC Vortex Reducer Ring - Repair The Oversized Location Diameter 1006 By Material Removal, Repair-026 (VRS6529)

General

This Repair must only be done when the instruction to do so is given in the relevant Inspection.

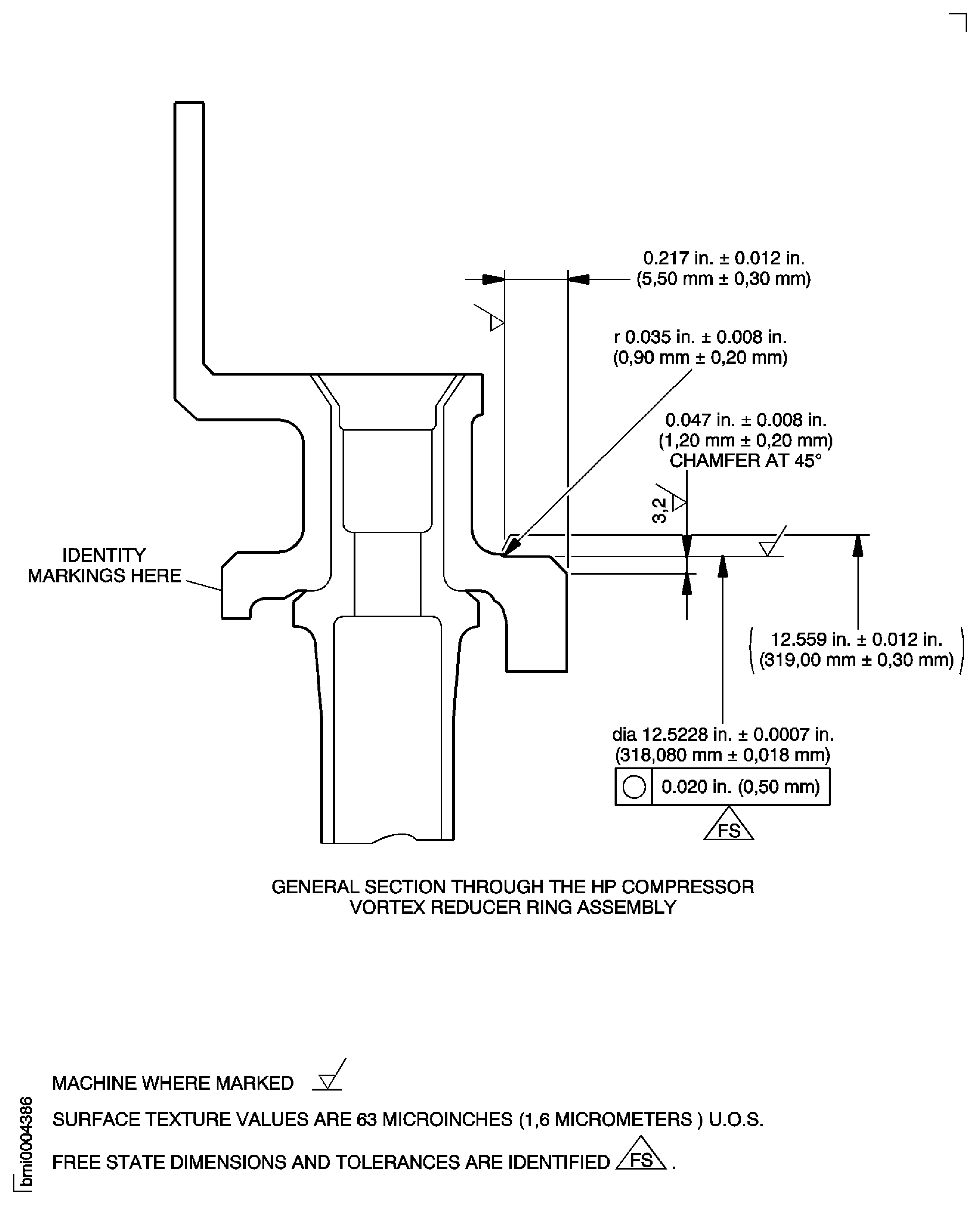

The TASK gives the procedure to repair the oversized location diameter 1006 on the HP compressor vortex reducer ring assembly by machining.

TASKs identified by SPM TASK are in the Standard Practices and Processes Manual (SPM).

Price and availability

Refer to International Aero Engines

Related repairs - none

NOTE

NOTE

It is possible that some materials in the Consumable Materials chart cannot be used for some or all of the necessary applications. Before you use the materials, make sure the types, quantities and applications of the materials necessary are legally permitted in your location. All persons must obey all applicable federal, state, local and provincial laws and regulations when it is necessary to work with these materials.

To identify the consumable materials, refer to the Overhaul Processes and Consumables Index (PCI).

Other necessary consumable materials are referred to in the SPM TASKs.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Binoculars | LOCAL | Binoculars | 20x | |

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Lathe | LOCAL | Lathe | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 | ||

| CoMat 05-106 ABRASIVE STONE | K6835 | CoMat 05-106 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 |

Spares

NONESafety Requirements

NONEProcedure

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS, BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - MAXIMUM SPEED FOR MECHANICAL TOOLS MUST NOT EXCEED 1000 REVOLUTIONS PER MINUTE.

CAUTION

TITANIUM COMPONENT - YOU MUST MAKE SURE THAT WHEN YOU REMOVE MATERIAL, BLEND AND POLISH, TO MAKE SMOOTH, THAT NO SPARKS ARE PRODUCED.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO A DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.

CAUTION

TITANIUM COMPONENT - AVOID BUILD UP OF HEAT BY APPLYING ONLY GENTLE PRESSURE AND KEEPING THE TOOL SPEED AS LOW AS POSSIBLE. USE TECHNIQUES WHICH ALLOW FOR PROGRESSIVE WEAR OF THE DRESSING MEDIA TO PRESENT A CONTINUALLY FRESH CUTTING SURFACE TO THE WORK PIECE.

CAUTION

DO NOT DWELL ON ONE AREA OF THE COMPONENT.

CAUTION

DRESS, WHERE POSSIBLE, IN A CIRCULAR MOTION, TAKING LIGHT CUTS TO AVOID OVERHEATING.Refer to Figure.

Refer to the SPM TASK 70-35-03-300-501.

Use standard workshop equipment.

Remove burrs and sharp edges.

SUBTASK 72-41-12-320-058 Machine the HP Compressor Vortex Reducer Ring Assembly Location Diameter 1006

Refer to the SPM TASK 70-11-08-300-503, SUBTASK 70-11-08-300-001.

Use chemical cleaning equipment.

Chemically clean the area(s) of material removal.

Refer to the SPM TASK 70-11-08-300-503, SUBTASK 70-11-08-300-002.

Use chemical cleaning equipment.

Swab etch the area(s) of material removal.

SUBTASK 72-41-12-110-086 Do a Swab Etch

Refer to the SPM TASK 70-23-05-230-501.

Use penetrant crack test equipment.

Cracks are not permitted.

Do a local penetrant crack test on the repair area.

SUBTASK 72-41-12-230-083 Do a Crack Test

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO A DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.Refer to Figure.

SUBTASK 72-41-12-220-121 Examine the Repair Area

Refer to Figure.

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Make a mark VRS6529 adjacent to the part number.

SUBTASK 72-41-12-350-087 Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions