Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-12-300-003 HPC Vortex Reducer Ring - Replace The Vortex Tube(s), Repair-003 (VRS6261)

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

Ring - vortex reducer | TAH | Titanium alloy |

Vortex tube | TBS | Titanium alloy |

General

This Repair is to replace the vortex reducer tubes which are damaged.

The vortex reducer is a balanced part and the damaged vortex tube(s) must be replaced with a tube of an identical weight.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and availability

Refer to International Aero Engines

NOTE

Equivalent materials or equipment can be used.

More equipment and materials necessary to do this Repair are in the SPM TASKS given below:

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Precision weighing scales | LOCAL | Precision weighing scales | 2500gm. capacity, with 0.01gm. graduations | |

| Drilling machine | LOCAL | Drilling machine | ||

| Marker | LOCAL | Marker | ||

| Standard workshop tools | LOCAL | Standard workshop tools | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Heat protection gloves | LOCAL | Heat protection gloves | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| IAE 3R19045 Freezing tool | 0AM53 | IAE 3R19045 | 1 | |

| IAE 3R19044 Swaging tool | 0AM53 | IAE 3R19044 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-026 LIQUID NITROGEN | LOCAL | CoMat 03-026 | ||

| CoMat 05-075 WATERPROOF SILICON CARBIDE | IE241 | CoMat 05-075 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Tube - vortex reducer | 6A3099 |

Safety Requirements

NONEProcedure

Use 2500gm. capacity scales with 0.01 gm. graduations.

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS. BLEND AND POLISH THIS COMPONENT.TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL WILL BECOME TOO HOT.TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.DO NOT DAMAGE THE VORTEX REDUCER RING MATERIAL WHEN THE VORTEX TUBE IS REMOVED.Weigh the assembly.

SUBTASK 72-41-12-350-067 Remove the Damaged Vortex Tube

Refer to the SPM TASK 70-23-05-230-501.

Use penetrant crack test equipment.

No cracks are permitted.

Locally crack test the tube location hole(s).

SUBTASK 72-41-12-230-062 Do a Crack Test

CAUTION

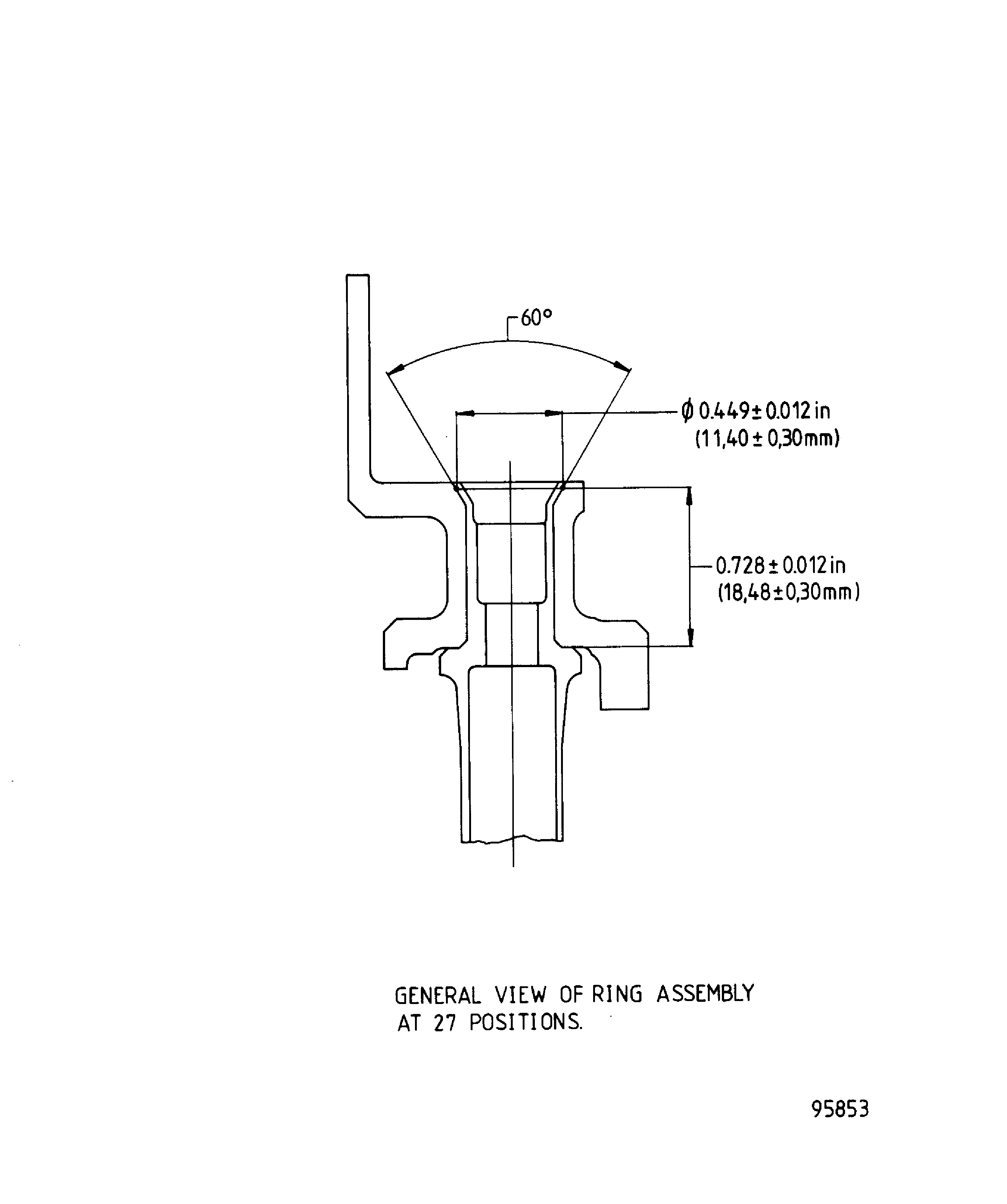

BEFORE THE TUBE LIPS ARE ROLLED, MAKE SURE THEY ARE AT ROOM TEMPERATURE TO AVOID CRACKS.Refer to Figure.

Use IAE 3R19045 Freezing tool and heat protective gloves.

Make sure the tube is pushed fully into the location hole.

Install the vortex tube.

Use IAE 3R19044 Swaging tool and standard workshop tools.

Make sure the lip is not above the surface of the vortex reducer.

Roll the tube lip to safety the tube.

SUBTASK 72-41-12-350-068 Install the Vortex Tube

Refer to the SPM TASK 70-23-05-230-501.

Use penetrant crack test equipment.

No cracks are permitted.

Locally crack test on the new tubes.

SUBTASK 72-41-12-230-063 Do a Crack Test

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions