Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

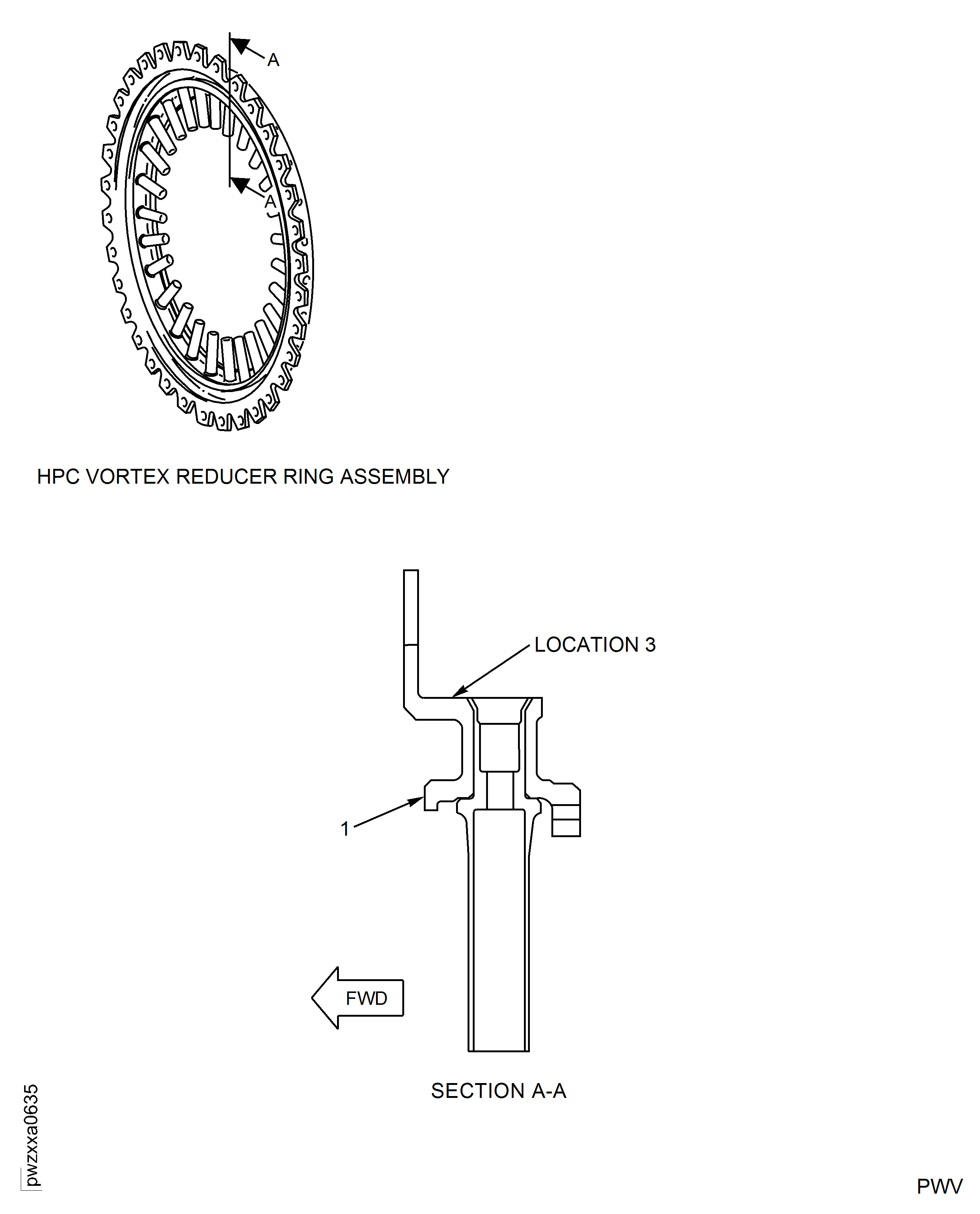

TASK 72-41-12-300-006 HPC Vortex Reducer Ring Assembly - Surface At Location 3, Blend Repair, Repair- 006 (VRS9531)

General

This Repair must only be done when the instruction to do so is given in the relevant Inspection.

The TASK gives the procedure to repair the damage(s) on surface at Location 3 of the HP Compressor Vortex Reducer Ring Assembly.

NOTE

TASKs identified by SPM TASK are in the V2500 Standard Practices and Processes Manual (SPM) PN 24414 applicable sections.

Price and availability - Refer to International Aero Engines

Related repair - none

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that the cleaning and inspection procedures are done before this repair. |

Support Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Blend the damage to maximum depth of 0.005 in. (0.127 mm).

Total depth of material removed includes the depth of any material removed in previous blend application and current application of this repair.

The minimum blend length to depth ratio is 50 to 1 circumferentially and 15 to 1 axially.

Blend must be smooth and continuous with adjacent surfaces.

Remove the minimum amount of parent material necessary to accomplish the repair.

Blends must not encroach into the adjacent fillet radius.

Blends are permissible to extend up to AVT hole edge but must not enter onto the AVT hole diameter.

Blend to remove scoring from the HPC Vortex Reducer Ring Surface Assembly, surface at Location 3 by SPM TASK 70-35-03-300-501.

SUBTASK 72-41-12-350-179 Blend to Remove Scoring

Refer to Figure.

Swab etch the repaired area(s) of HPC Vortex Reducing Ring by SPM TASK 70-11-08-300-503.

SUBTASK 72-41-12-110-172 Swab Etch the Repaired Area(s)

Refer to Figure.

Use 3 - 10X binoculars.

Make sure that there are no indications of defects on the repaired surfaces.

Make sure there is no raised metal remaining.

Do a binocular inspection of the repaired area(s).

SUBTASK 72-41-12-220-211 Do a Binocular Inspection

Refer to Figure.

Cracks are not permitted.

Do a fluorescent penetrant inspection of the repaired area(s) by SPM TASK 70-23-05-230-501.

SUBTASK 72-41-12-230-150 Do a Fluorescent Penetrant Inspection

Refer to Figure.

Polish the swab etch area(s) by SPM TASK 70-35-03-300-501.

SUBTASK 72-41-12-350-180 Polish the Swab Etch Area(s)

Refer to Figure.

Make sure that post blend depth is not more than 0.005 in. (0.127 mm).

Do a dimensional inspection of the part.

SUBTASK 72-41-12-220-212 Do a Dimensional Inspection

Make a permanent mark by the procedure given in the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001. Use vibro-engraving equipment.

Mark VRS9531 adjacent to the part number. See Figure for marking location.

SUBTASK 72-41-12-350-181 Mark the Part

Figure: HPC Vortex Reducer Ring Assembly - Surface at Location 3, Blend Repair, Repair-006 (VRS9531)

Marking Location