Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

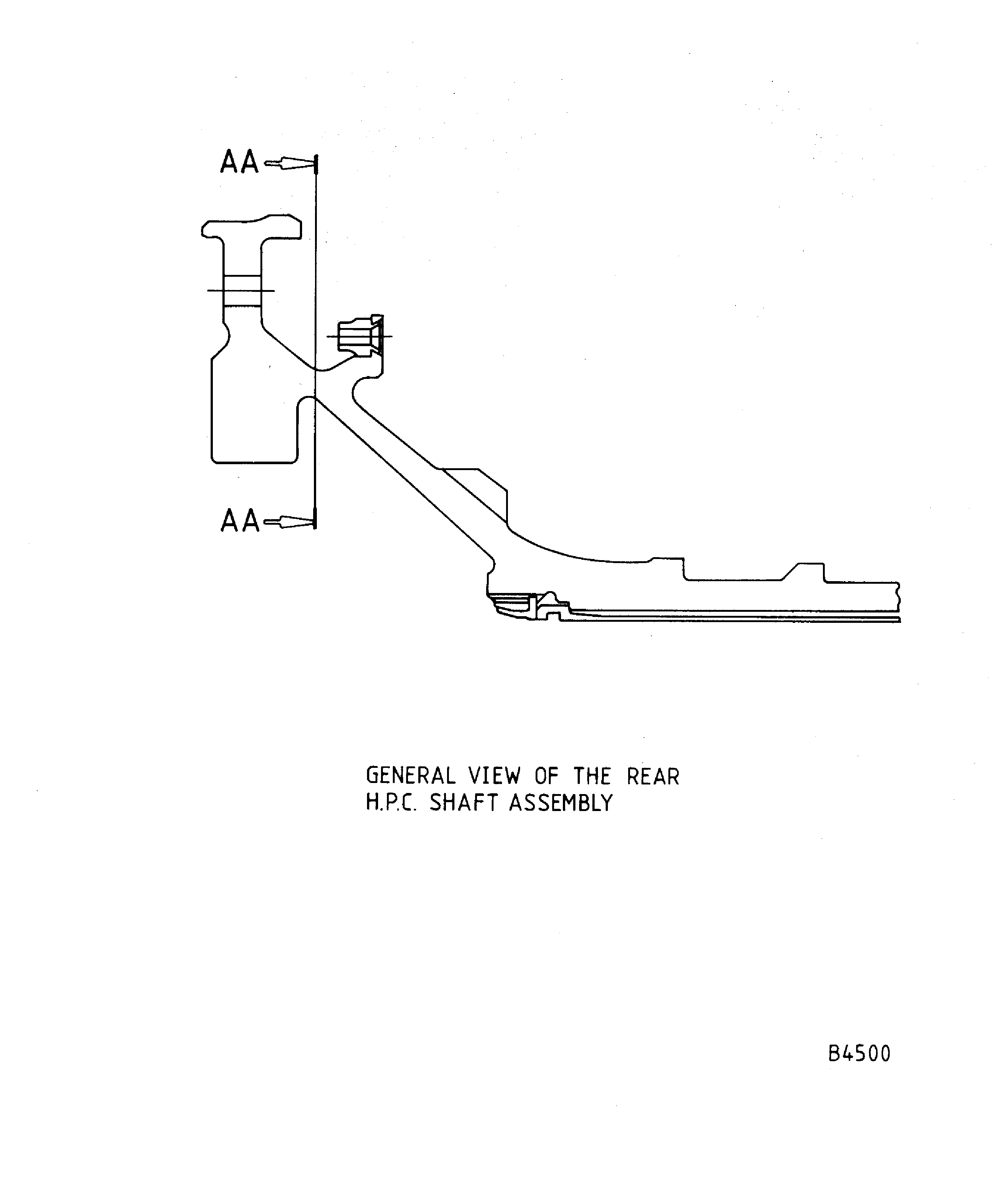

TASK 72-41-13-300-016 HPC Rear Shaft - Replace The Damaged Shank Nuts, Repair-016 (VRS6123)

Material of component

RR | ||

|---|---|---|

DESCRIPTION | SYMBOL | MATERIAL |

H.P. compressor - Rear shaft | QYX | Inconel 718 |

assembly | ||

Nut, self-locking shank | EAR | Austenitic heat resisting |

steel - Vacuum melted | ||

General

This Repair must only be done when the instruction to do so is given in 72-41-13 Inspection.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Drilling equipment | LOCAL | Drilling equipment | ||

| Drill | LOCAL | Drill | 0.220 in. (5.60 mm) diameter | |

| Drill | LOCAL | Drill | 0.315 in. (8.00 mm) diameter | |

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| IAE 3R19066 Tool bolt | 0AM53 | IAE 3R19066 | 1 | |

| IAE 3R19067 Swage bush | 0AM53 | IAE 3R19067 | 1 | |

| IAE 3R18718 Tool bolt | 0AM53 | IAE 3R18718 | 1 | |

| IAE 3R18737 Swage bush | 0AM53 | IAE 3R18737 | 1 |

Consumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Nut, self-locking shank | AS27853 | 18 | ||

| Nut, self-locking shank | AS27857 | 18 |

Safety Requirements

NONEProcedure

Refer to the SPM TASK 70-35-11-300-501.

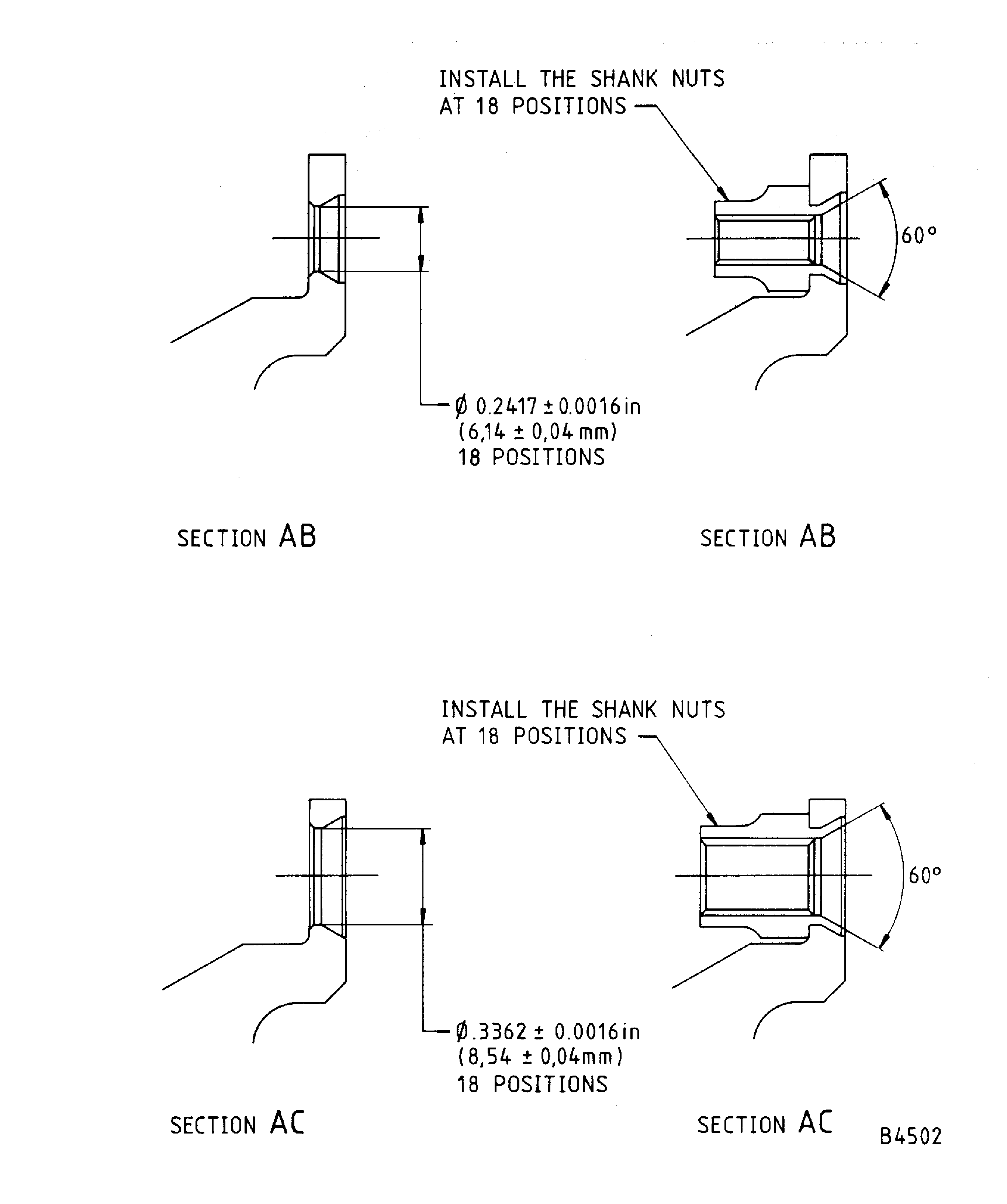

Use a drilling machine with an 0.220 in. (5.60 mm) diameter drill.

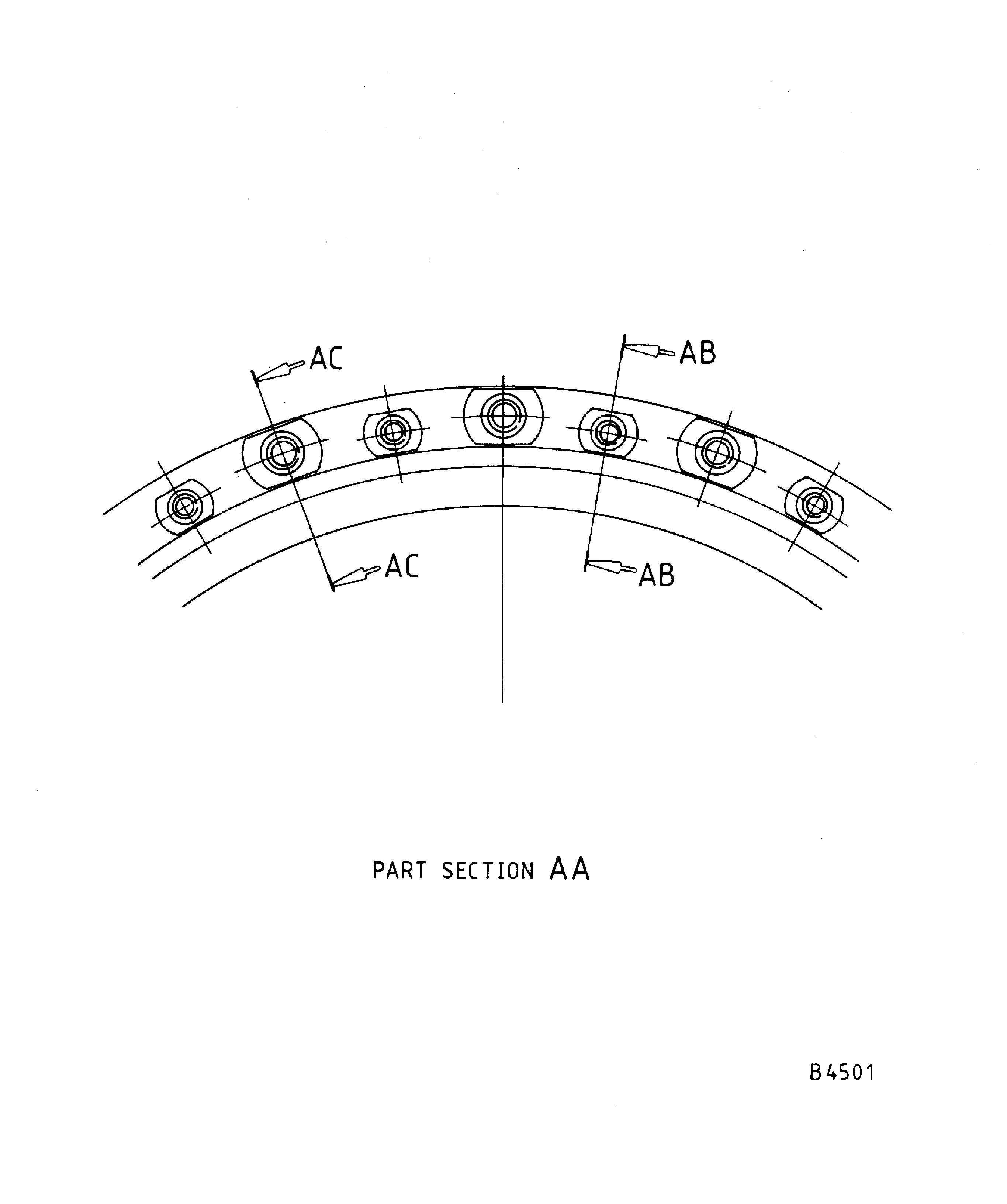

Refer to Figure.

Drill the flare section AB, until the nut is released.

Refer to the SPM TASK 70-35-11-300-501.

Use a drilling machine with an 0.315 in. (8.00 mm) diameter drill.

Refer to Figure.

Drill the flare section AC, until the nut is released.

SUBTASK 72-41-13-323-051 Remove the Shank Nuts

Use penetrant crack test equipment.

Cracks are not permitted.

Refer to the SPM TASK 70-23-01-230-501.

Do a penetrant crack test, in the area of repair.

SUBTASK 72-41-13-230-061 Do a Crack Test

Use IAE 3R19066 Tool bolt 1 off, with IAE 3R19067 Swage bush 1 off and/or IAE 3R18718 Tool bolt 1 off with IAE 3R18737 Swage bush 1 off.

Hold the nut and swage the flare.

SUBTASK 72-41-13-350-061 Install the New Shank Nuts

Refer to Figure.

SUBTASK 72-41-13-220-099 Examine the Nut

Use penetrant crack test equipment.

Cracks are not permitted.

Refer to the SPM TASK 70-23-01-230-501.

Do a penetrant crack test, in the area of repair.

SUBTASK 72-41-13-230-062 Do a Crack Test

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions