Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-13-300-018 HPC Rear Shaft - Blend Repair On The Splines, Repair-018 (VRS3518)

General

This blend repair uses the rotary or manual type of consumable materials. Use only the consumable materials specified for each type of repair.

The maximum rotary equipment is 18,000 RPM.

Use the rotary consumable material only in the sequence given below or damage to the part will result. It is not necessary to use all of the rotary equipment for each repair. When you start with a rotary consumable material, you must use all the subsequent materials through D. For example, if you use the material in B. you must also use all the materials in C. and D.:

The practices and processes referred to in the procedure by TASK number are in the SPM.

Price and availability - not applicable

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Portablegrinding equipment | LOCAL | Portable grinding equipment | ||

| Shot peening equipment | LOCAL | Shot peening equipment | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| Standard inspection equipment | LOCAL | Standard inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-143 STONE, BROWN INDIA (MEDIUM) | 9K848 | CoMat 05-143 | ||

| CoMat 05-144 WHEEL, BEAR-TEX UNIFIED DEBURRING | 9K848 | CoMat 05-144 | ||

| CoMat 05-145 WHEEL, CLOTH BUFF | IAE65 | CoMat 05-145 | ||

| CoMat 05-146 WHEEL, SILICON CARBIDE ABRASIVE COAT DELETED | 0AM53 | CoMat 05-146 | ||

| CoMat 05-147 WHEEL, RUBBER BONDED GRINDING | LOCAL | CoMat 05-147 | ||

| CoMat 05-148 STONE, WHITE ARKANSAS (HARD) | 06565 | CoMat 05-148 | ||

| CoMat 05-149 COMPOUND, BUFFING AND POLISHING | IAE65 | CoMat 05-149 |

Spares

NONESafety Requirements

CAUTION

Procedure

Refer to Figure requirements.

Use the rotary consumable materials given in the general section.

Make the abrasive coat become soft on the CoMat 05-146 WHEEL, SILICON CARBIDE ABRASIVE COAT DELETED.

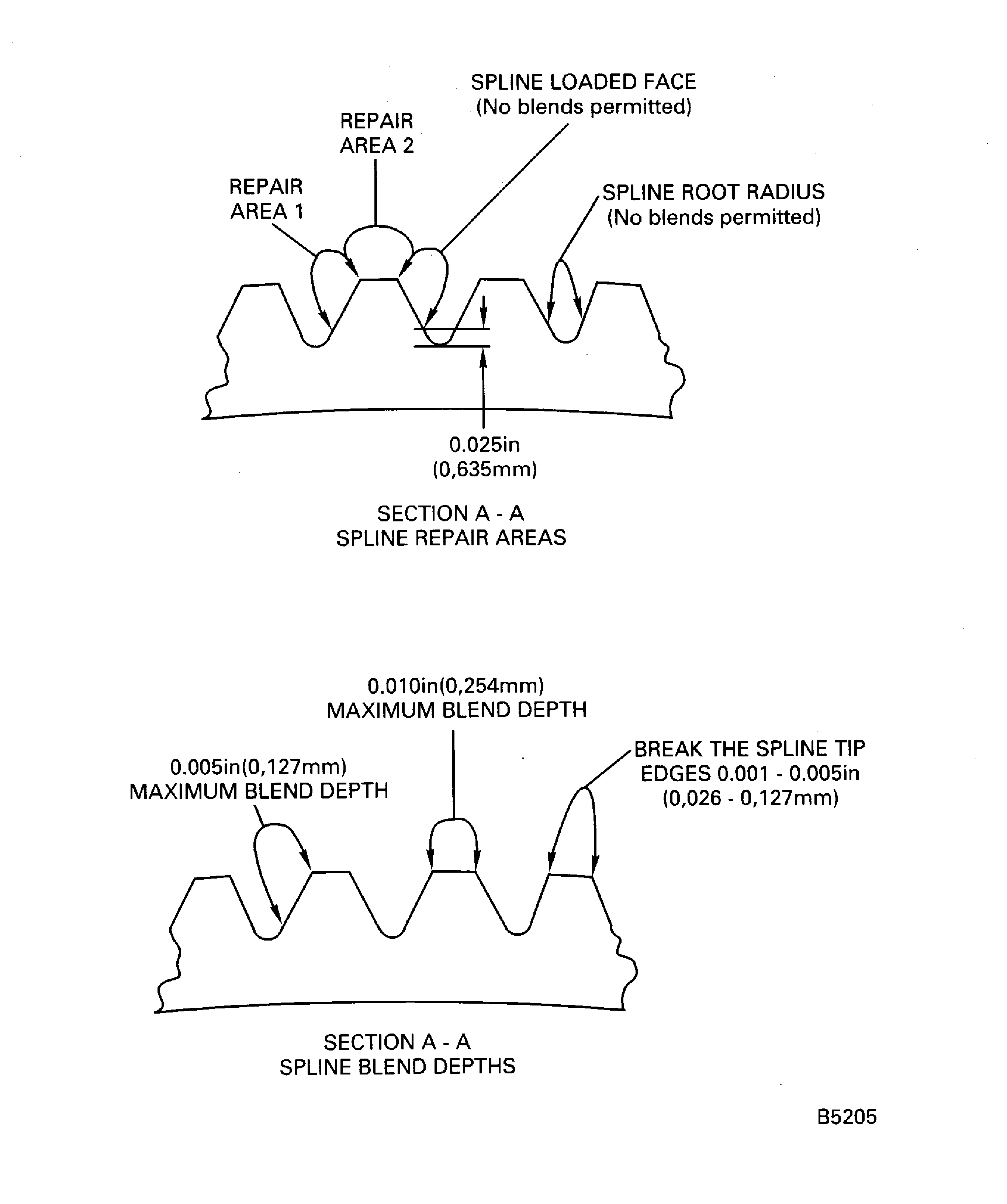

Do not blend the spline root radius and the spline loaded face area.

The surface texture must be 80 AA (2.0 micro m) or smoother.

The finish marks must follow the lay of the original tool marks.

All blends must be smooth and continuous.

The minimum blend length to depth ratio is 100 to 1.

Remove the rough and unwanted grit until the wheel surface is smooth before you do the blend repair.

Remove all the lifted material.

A maximum of ten splines can be repaired with a maximum blended length of 0.500in. (12.7 mm) or less on each spline.

A maximum of five splines can be repaired if the blended length is more than 0.500in. (12.7 mm) on each spline.

The maximum spline blend depth requirements in the repair areas are given in the figure.

All the blend finish marks must follow the lay of the original machining marks.

Remove only the minimum quantity of material that is necessary to do the repair.

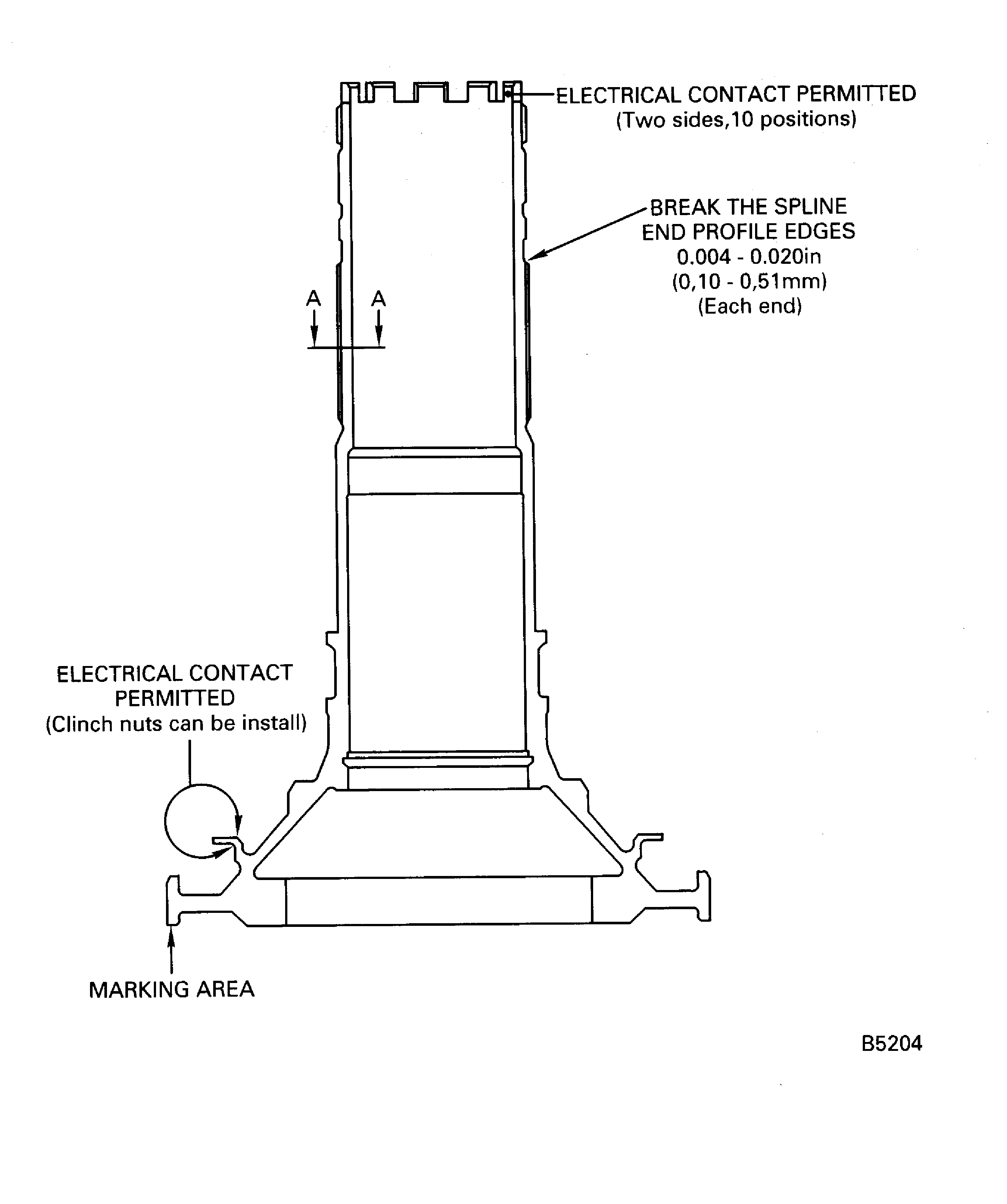

Break the spline tip edges and end profile edges to the requirements given in the figure.

Blend the surface damage such as dents, nicks, scratches and corrosion pits on the splines.

SUBTASK 72-41-13-350-057-001 Blend the Shaft Assembly Splines (Rotary Method)

WARNING

WEAR EYE PROTECTION WHEN YOU OPERATE THE ROTARY EQUIPMENT. DISCHARGE AIR WILL BLOW LOOSE GRIT AND MATERIALS WHICH CAN CAUSE INJURY TO A PERSON.Refer to Figure requirements.

Do not blend the spline root radius and the spline loaded face area.

The surface texture must be 80 AA (2.0 micro m) or smoother.

The finish marks must follow the lay of the original tool marks.

All blends must be smooth and continuous.

The minimum blend length to depth ratio is 100 to 1.

Remove all the lifted material.

A maximum of ten splines can be repaired with a maximum blended length of 0.500in. (12.7 mm) or less on each spline.

A maximum of five splines can be repaired if the blended length is more than 0.500in. (12.7 mm) on each spline.

The maximum spline blend depth requirements in the repair areas are given in the figure.

All the blend finish marks must follow the lay of the original machining marks.

Remove only the minimum quantity of material that is necessary to do the repair.

Break the spline tip edges and end profile edges to the requirements given in the figure.

Blend the surface damage such as dents, nicks, scratches and corrosion pits on the splines.

SUBTASK 72-41-13-350-057-002 Blend the Shaft Assembly Splines (Manual Method)

Refer to Figure requirements.

Do the procedure given in the SPM TASK 70-23-03-230-501 or SPM TASK 70-23-08-230-501.

No cracks permitted.

Fluorescent penetrant inspect all of the repaired surfaces for cracks.

SUBTASK 72-41-13-230-057 Fluorescent Penetrant the Repair Areas

Refer to Figure requirements.

Visually examine the repaired splines.

SUBTASK 72-41-13-220-095 Examine the Repair

Refer to Figure requirements.

Make a permanent mark by the procedures given in the SPM TASK 70-09-00-400-501.

See figure for the electrical contact area.

No burning, pitting or selective attack is permitted from the electrical contact.

Use the deep electrolytic etch method.

Mark VRS3518 adjacent to the part number.

SUBTASK 72-41-13-350-058 Identify the Repair

Figure: HPC shaft assembly spline blend repair areas

HPC shaft assembly spline blend repair areas

Figure: HPC shaft assembly spline blend repair areas

HPC shaft assembly spline blend repair areas