Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-15-300-004 HPC Stage 6 Rotor Blade - Repair Damage By Material Removal, Repair-004 (VRS6012)

Effectivity

FIG/ITEM | PART NO. | ASSEMBLY |

|---|---|---|

02-170 | 6A3338 | A |

02-170 | 6A7406 | B |

02-170 | 6A8322 | B |

02-170 | 6A8463 | A |

02-170 | 6A8797 | C |

02-185 | 6A3339 | A |

02-185 | 6A7407 | B |

02-185 | 6A8323 | B |

02-185 | 6A8464 | A |

02-185 | 6A8798 | C |

02-200 | 6A3340C01 | A |

02-200 | 6A7405C01 | B |

02-200 | 6A8320 | B |

02-200 | 6A8461 | A |

02-200 | 6A8732 | C |

02-215 | 6A3340C01 | A |

02-215 | 6A7405C01 | B |

02-215 | 6A8320 | B |

02-215 | 6A8461 | A |

02-215 | 6A8732 | C |

02-216 | 6B1494 | C |

02-217 | 6A3340C02 | A |

02-217 | 6A7405C02 | B |

02-217 | 6A8321 | B |

02-217 | 6A8462 | A |

02-217 | 6A8733 | C |

General Data

This repair must only be done when the instruction to do so is given in the 72-41-15 Inspection.

This repair gives the instruction to remove damage on the HP compressor rotor blade(s), stage 6 by material removal.

You can mix a scallop and/or complete edge dress to a given rotor blade, if the maximum limit for any one of these is not exceeded.

Rotor blades must be repaired as soon as damage or wear is monitored, to get back HP compressor efficiency and extend the rotor blade life.

Material removal from the HP compressor rotor blade airfoil fillet radius is not permitted.

When the depth of cut away material is more than 0.002 in. (0.05 mm), it is necessary to glass bead peen the HP compressor rotor blade(s), stage 6, to restore the airfoil surface condition, refer to Repair, VRS6150 TASK 72-41-15-300-040 (REPAIR-040).

NOTE

NOTE

It is possible that some materials in the Consumable Materials chart cannot be used for some or all of the necessary applications. Before you use the materials, make sure the types, quantities and applications of the materials necessary are legally permitted in your location. All persons must obey all applicable federal, state, local and provincial laws and regulations when it is necessary to work with these materials.

To identify the consumable materials, refer to the Overhaul Processes and Consumables Index (PCI).

Other necessary consumable materials are referred to in the SPM TASKs.

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure all the necessary cleaning and inspection procedures are done before this repair. |

Support Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to SPM TASK 70-35-03-300-501.

SUBTASK 72-41-15-350-056-A00 Remove Damage from the HP Compressor Rotor Blade(s), Stage 6, Assembly A

Refer to SPM TASK 70-35-03-300-501.

SUBTASK 72-41-15-350-056-B00 Remove Damage from the HP Compressor Rotor Blade(s), Stage 6, Assembly B

Refer to SPM TASK 70-35-03-300-501.

SUBTASK 72-41-15-350-056-C00 Remove Damage from the HP Compressor Rotor Blade(s), Stage 6, Assembly C

Refer to SPM TASK 70-11-08-300-503.

Clean and swab etch the repaired area(s).

SUBTASK 72-41-15-110-119 Do a Swab Etch

Refer to SPM TASK 70-23-05-230-501, ultra high sensitivity. Cracks are not permitted.

Refer to SPM TASK 70-23-04-230-501.

Do a penetrant crack test on the repaired area(s) by the one of the procedures that follow:

SUBTASK 72-41-15-230-064 Do a Crack Test

Refer to Repair, VRS6150 TASK 72-41-15-300-040 (REPAIR-040).

NOTE

This SUBTASK is necessary to restore the airfoil surface condition only when the depth of cut away material is more than 0.002 in. (0.05 mm).Restore the airfoil surface condition.

SUBTASK 72-41-15-380-056 Restore the Airfoil Surface Condition

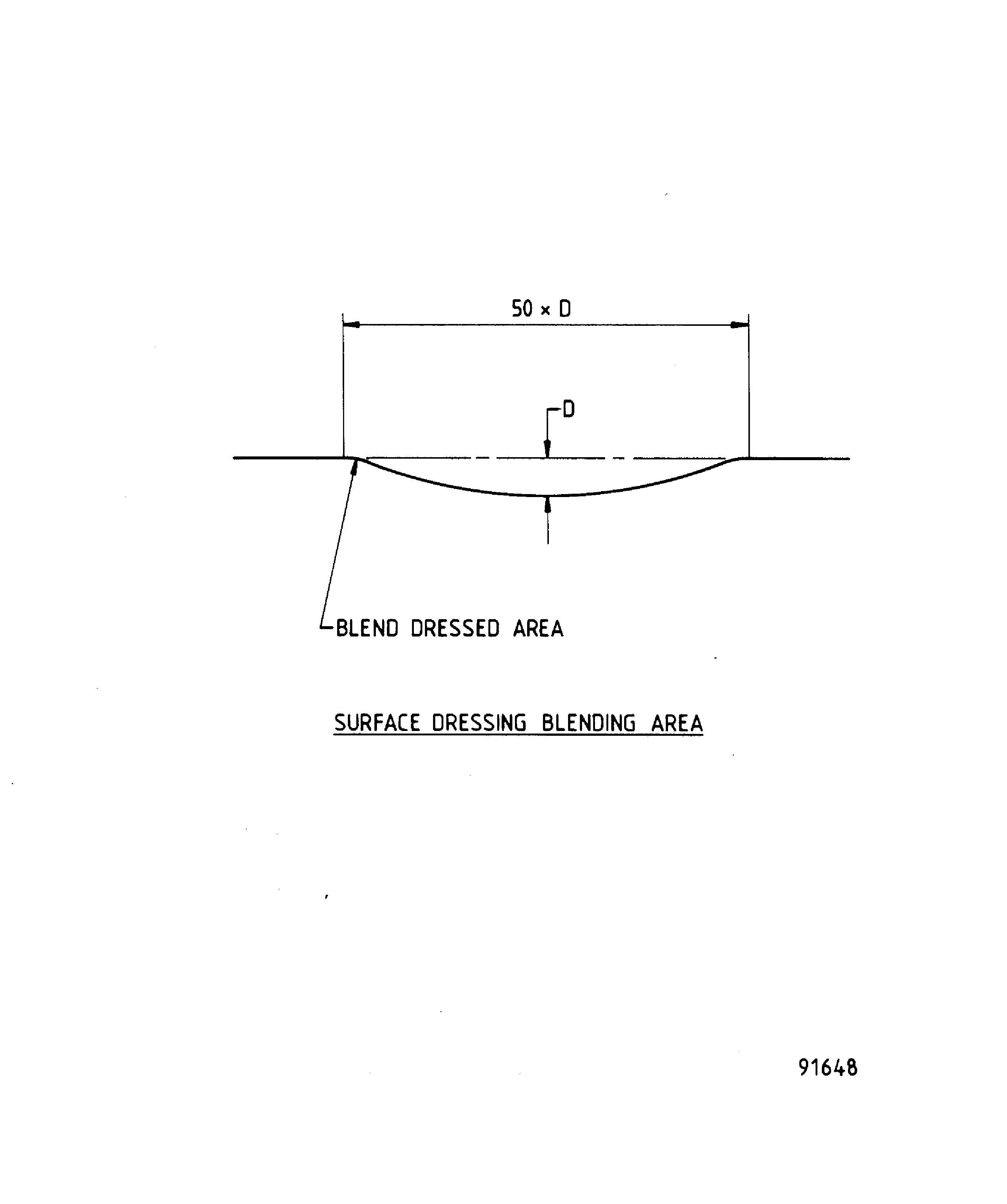

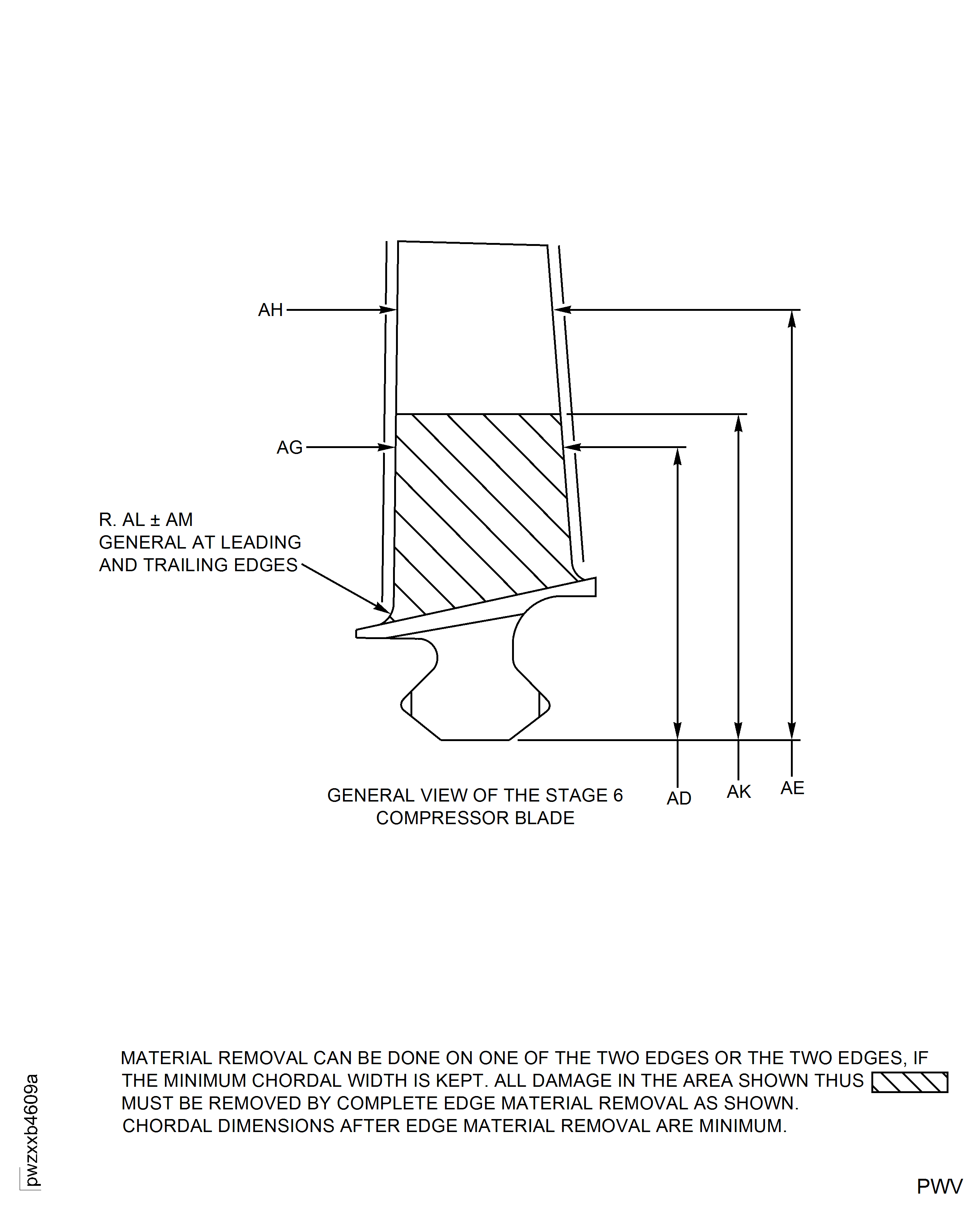

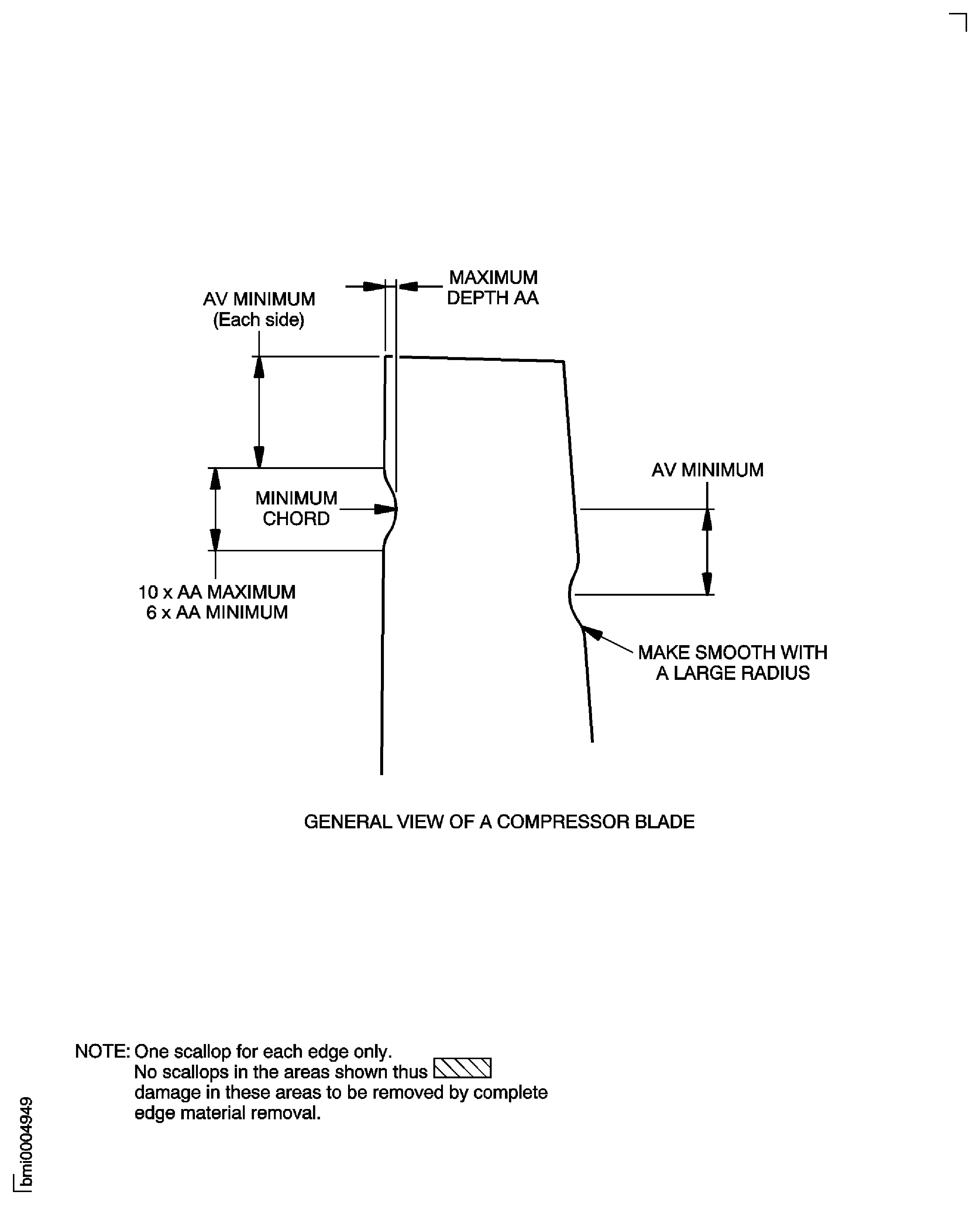

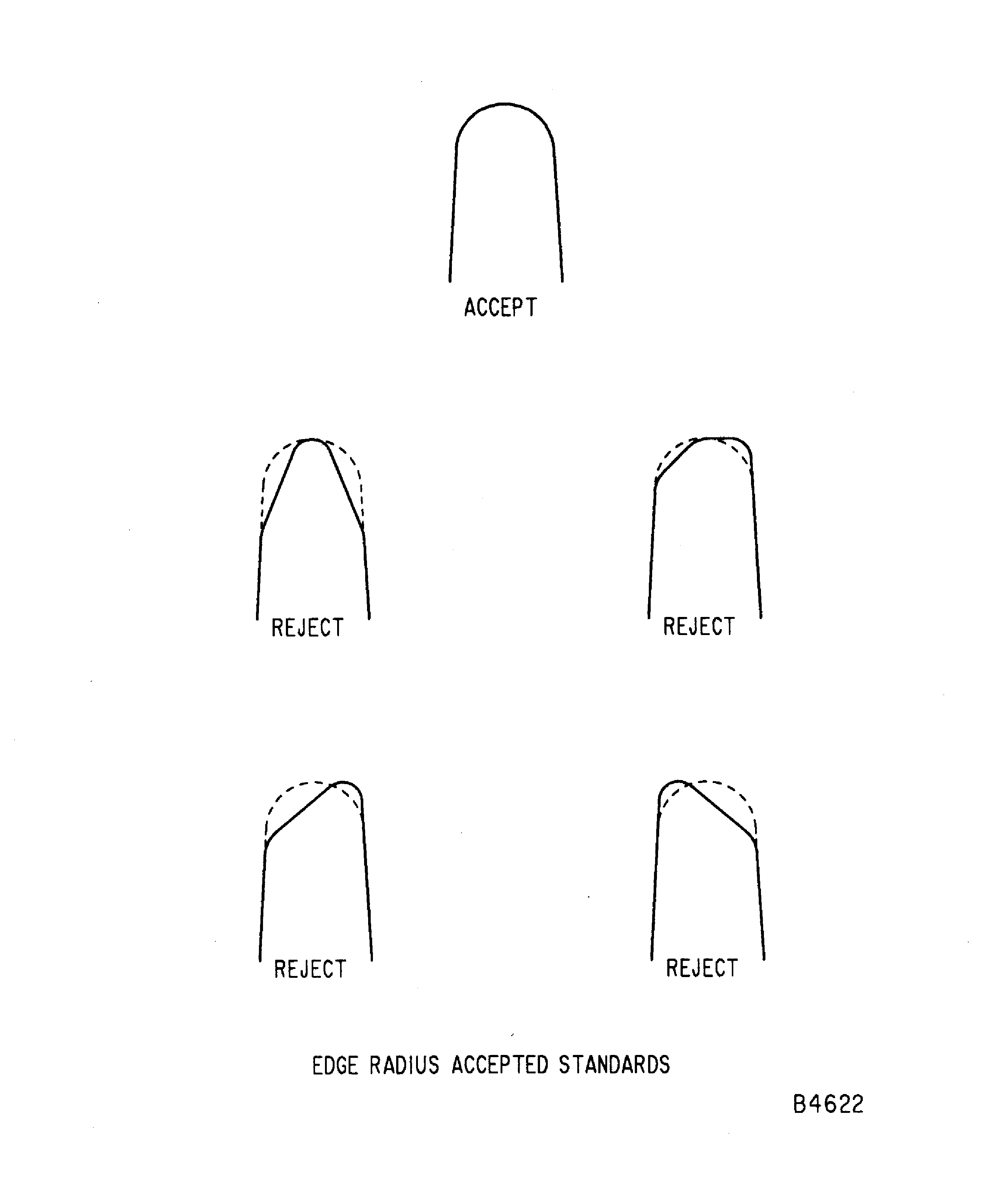

Figure: Repair Details And Dimensions - Assembly A, Assembly B, And Assembly C

Repair Details And Dimensions - Assembly A, Assembly B, And Assembly C

Figure: Repair Details And Dimensions - Assembly A, Assembly B, And Assembly C

Repair Details And Dimensions - Assembly A, Assembly B, And Assembly C

Figure: Repair Details And Dimensions - Assembly A, Assembly B, And Assembly C

Repair Details And Dimensions - Assembly A, Assembly B, And Assembly C

Figure: Repair Details And Dimensions - Assembly A, Assembly B, And Assembly C

Repair Details And Dimensions - Assembly A, Assembly B, And Assembly C