Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-21-300-073 HPC Heatshield Retainers - Replace The HPC Stage 7 Rear Heatshield Retainer Surface Protection, Repair-073 (VRS6309)

Effectivity

FIG/ITEM | PART NO | |

03-880 | 6A3028 | Assembly A |

03-880 | 6A3993 | Assembly A |

03-880 | 6A4259 | Assembly B |

03-880 | 6A6506 | Assembly C |

Material of component

DESCRIPTION SYMBOL MATERIAL | ||

|---|---|---|

HP Compressor Stage 7 Rear | EAK, | Modified 12 percent Chromium |

Heatshield Retainer Assembly | EBL | steel |

or | ||

EAE | 11.5 percent Chromium | |

3.0 percent Nickel | ||

1.75 percent Molybdenum and | ||

1.5 percent Cobalt | ||

General

This repair must only be done when the instruction to do so is given in 72-41-21 Inspection.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are given in the SPM.

Price and Availability

Refer to International Aero Engines

Related repairs - none

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Abrasive blast equipment | LOCAL | Abrasive blast equipment | ||

| Dry blast equipment | LOCAL | Dry blast equipment | ||

| Brush | LOCAL | Brush | Vacuum assisted | |

| Paint spray equipment | LOCAL | Paint spray equipment | ||

| Conductivity meter | LOCAL | Conductivity meter |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-005 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-005 | ||

| CoMat 02-019 TAPE, ADHESIVE PAPER HEAT RESISTING MASKING | 94960 | CoMat 02-019 | ||

| CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE | LOCAL | CoMat 05-003 | ||

| CoMat 06-073 INK, METAL MARKING | 88303 | CoMat 06-073 | ||

| CoMat 07-024 AEROLAC METAL PROTECTIVE VARNISH, CLEAR | LOCAL | CoMat 07-024 | ||

| CoMat 07-036 ALUMINIUM HIGH HEAT RESISTANT PAINT | 0AM53 | CoMat 07-036 |

Spares

NONESafety Requirements

NONEProcedure

Refer to TASK 72-41-21-100-000.

Use Chemical cleaning equipment.

Chemically clean the part.

SUBTASK 72-41-21-110-201 Clean the HPC Stage 7 Rear Heatshield Retainer Assembly

Refer to the SPM TASK 70-12-02-120-501.

Use CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE with abrasive blast equipment.

Abrasive blast the areas to be repaired.

SUBTASK 72-41-21-120-061-A00 Prepare the Part for Repair, Assembly A

CAUTION

SURFACE FOR REPAIR MUST BE FULLY CLEANED AND NOT TOUCHED BY HAND.CLEAN COTTON OR POLYTHENE GLOVES MUST BE WORN.Refer to the SPM TASK 70-12-02-120-501.

Use CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE with abrasive blast equipment.

Abrasive blast the areas to be repaired.

SUBTASK 72-41-21-120-061-B00 Prepare the Part for Repair, Assembly B

CAUTION

SURFACE FOR REPAIR MUST BE FULLY CLEANED AND NOT TOUCHED BY HAND.CLEAN COTTON OR POLYTHENE GLOVES MUST BE WORN.Refer to the SPM TASK 70-12-02-120-501.

Use CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE with abrasive blast equipment.

Abrasive blast the area to be repaired.

SUBTASK 72-41-21-120-061-C00 Prepare the Part for Repair, Assembly C

CAUTION

SURFACE FOR REPAIR MUST BE FULLY CLEANED AND NOT TOUCHED BY HAND.

CAUTION

CLEAN COTTON OR POLYTHENE GLOVES MUST BE WORN.Refer to the SPM TASK 70-38-21-380-501, SUBTASK 70-38-21-380-008 (Type A coating).

NOTE

Remove masking tape, before you stove the aluminum high heat resistant paint.Use CoMat 07-036 ALUMINIUM HIGH HEAT RESISTANT PAINT with paint spray equipment.

Apply the surface protection.

SUBTASK 72-41-21-380-111-A00 Apply the Surface Protection, Assembly A

Refer to the SPM TASK 70-38-21-380-501, SUBTASK70-38-21-380-008 (Type A coating).

NOTE

Remove masking tape, before you stove the aluminum high heat resistant paint.Use CoMat 07-036 ALUMINIUM HIGH HEAT RESISTANT PAINT with paint spray equipment.

Apply the surface protection.

SUBTASK 72-41-21-380-111-B00 Apply the Surface Protection, Assembly B

Use CoMat 02-019 TAPE, ADHESIVE PAPER HEAT RESISTING MASKING paper heat resistant masking tape.

Seal the areas not to be painted.

Refer to the SPM TASK 70-38-21-380-501, SUBTASK 70-38-21-380-008 (Type A Coating).

NOTE

Remove the masking tape before you stove the aluminum high heat resistant paint.Use CoMat 07-036 ALUMINIUM HIGH HEAT RESISTANT PAINT with paint spray equipment.

Apply the surface protection.

SUBTASK 72-41-21-380-111-C00 Prepare the Part for Repair, Assembly C

Refer to the SPM TASK 70-38-21-380-501, SUBTASK 70-38-21-220-001 (Type A coating).

Examine the surface protection.

SUBTASK 72-41-21-220-452-A00 Examine the Surface Protection, Assembly A

Refer to the SPM TASK 70-38-21-380-501, SUBTASK 70-38-21-220-001 (Type A coating).

Examine the surface protection.

SUBTASK 72-41-21-220-452-C00 Examine the Surface Protection, Assembly C

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-002.

Use CoMat 06-073 INK, METAL MARKING followed by CoMat 07-024 AEROLAC METAL PROTECTIVE VARNISH, CLEAR, applied with a paint brush.

Put the part number adjacent to the existing marks which are under the surface protection.

Re-identify the part.

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-002.

Use CoMat 06-073 INK, METAL MARKING followed by CoMat 07-024 AEROLAC METAL PROTECTIVE VARNISH, CLEAR, applied with a paint brush.

Mark VRS6309 adjacent to the part number.

Make a mark VRS6309 adjacent to the part number.

SUBTASK 72-41-21-350-164 Identify the Repair

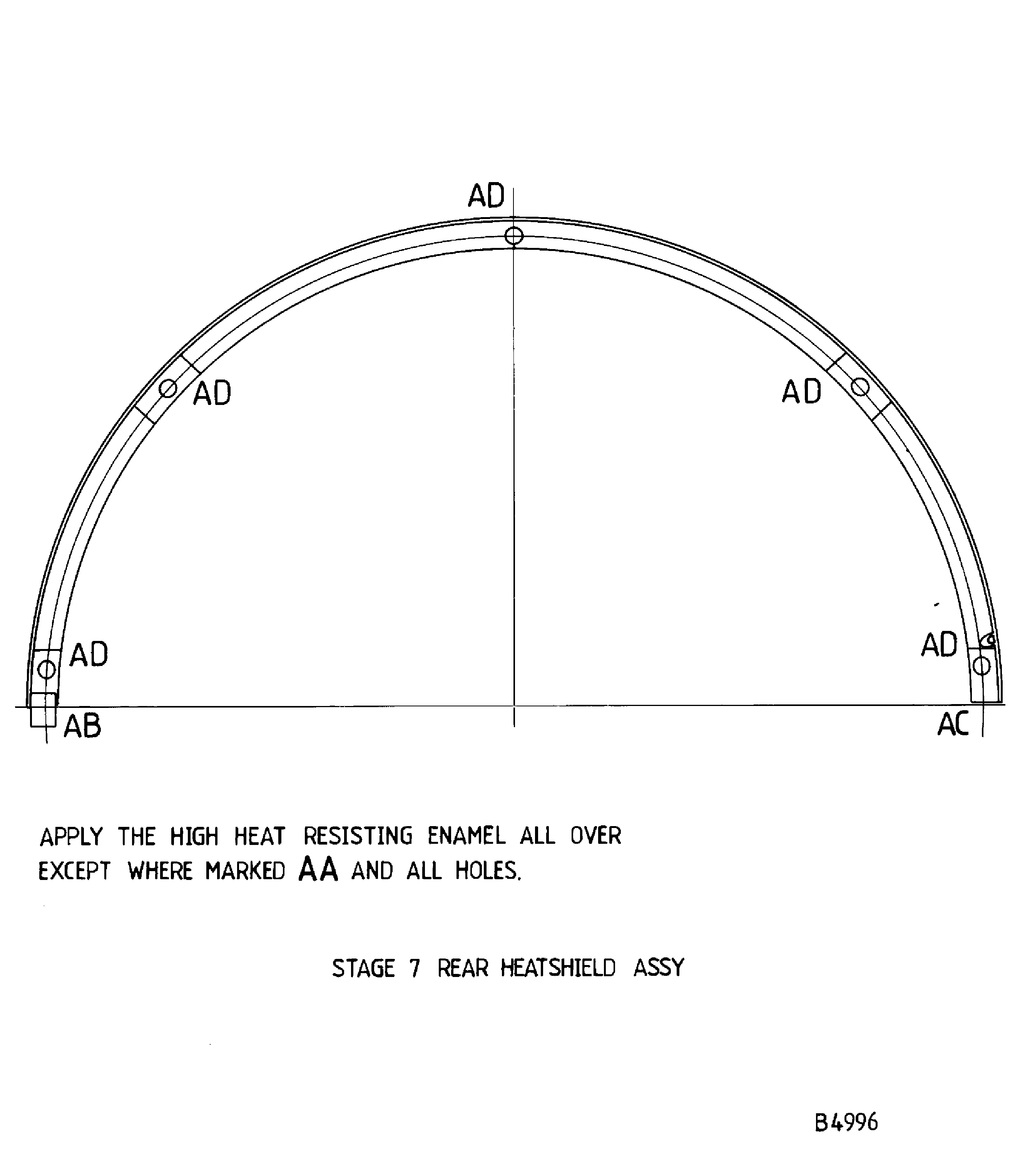

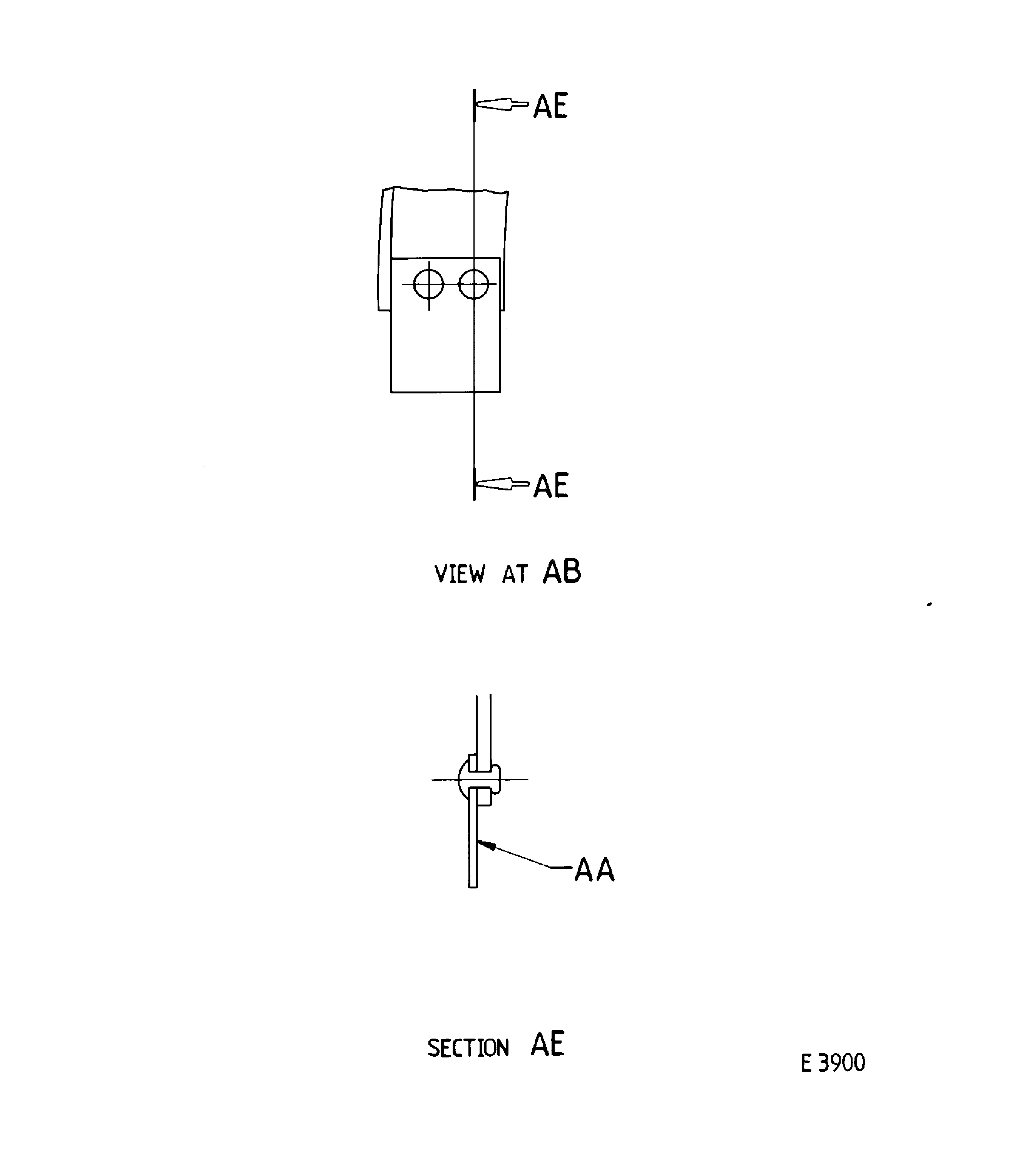

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

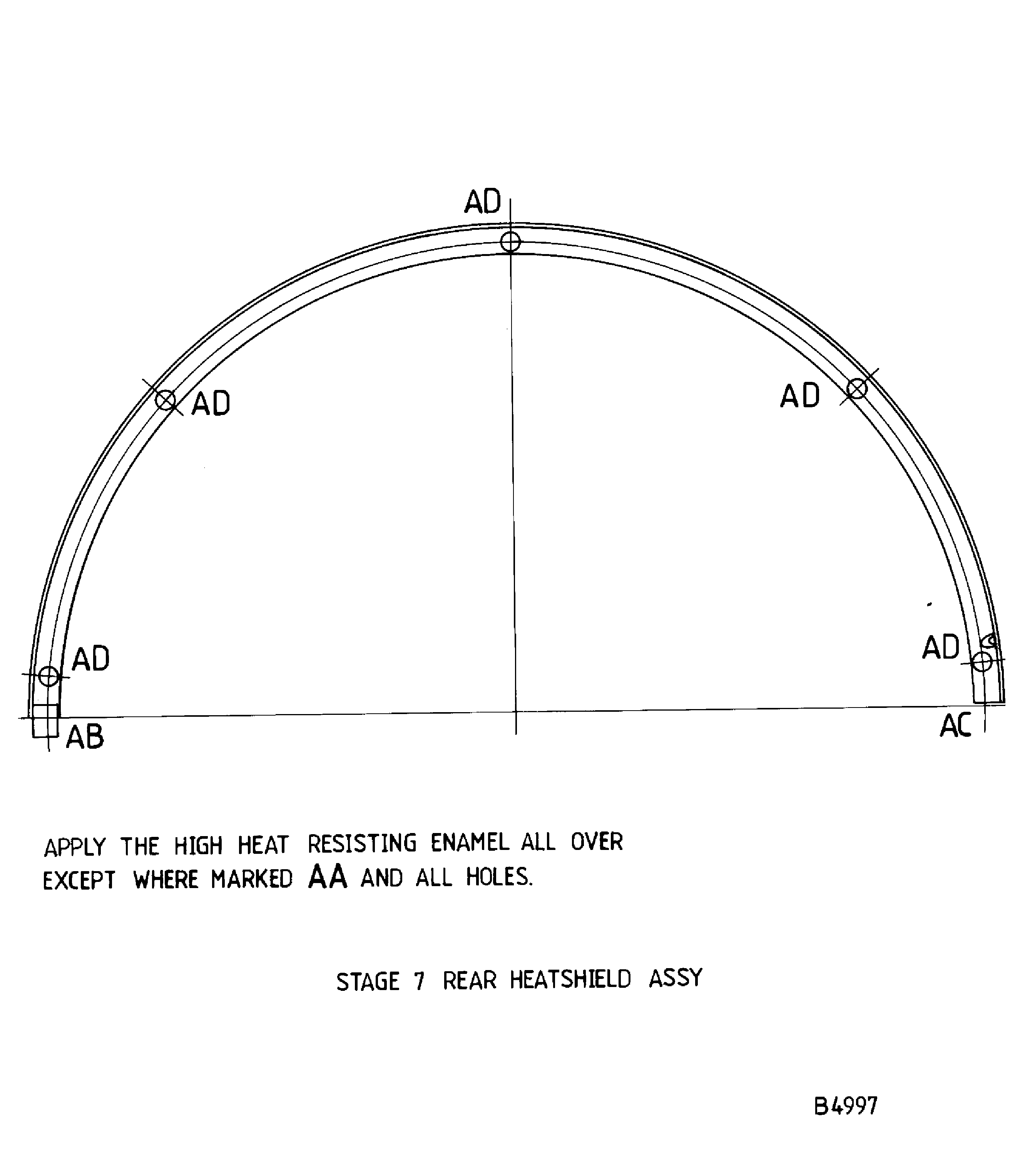

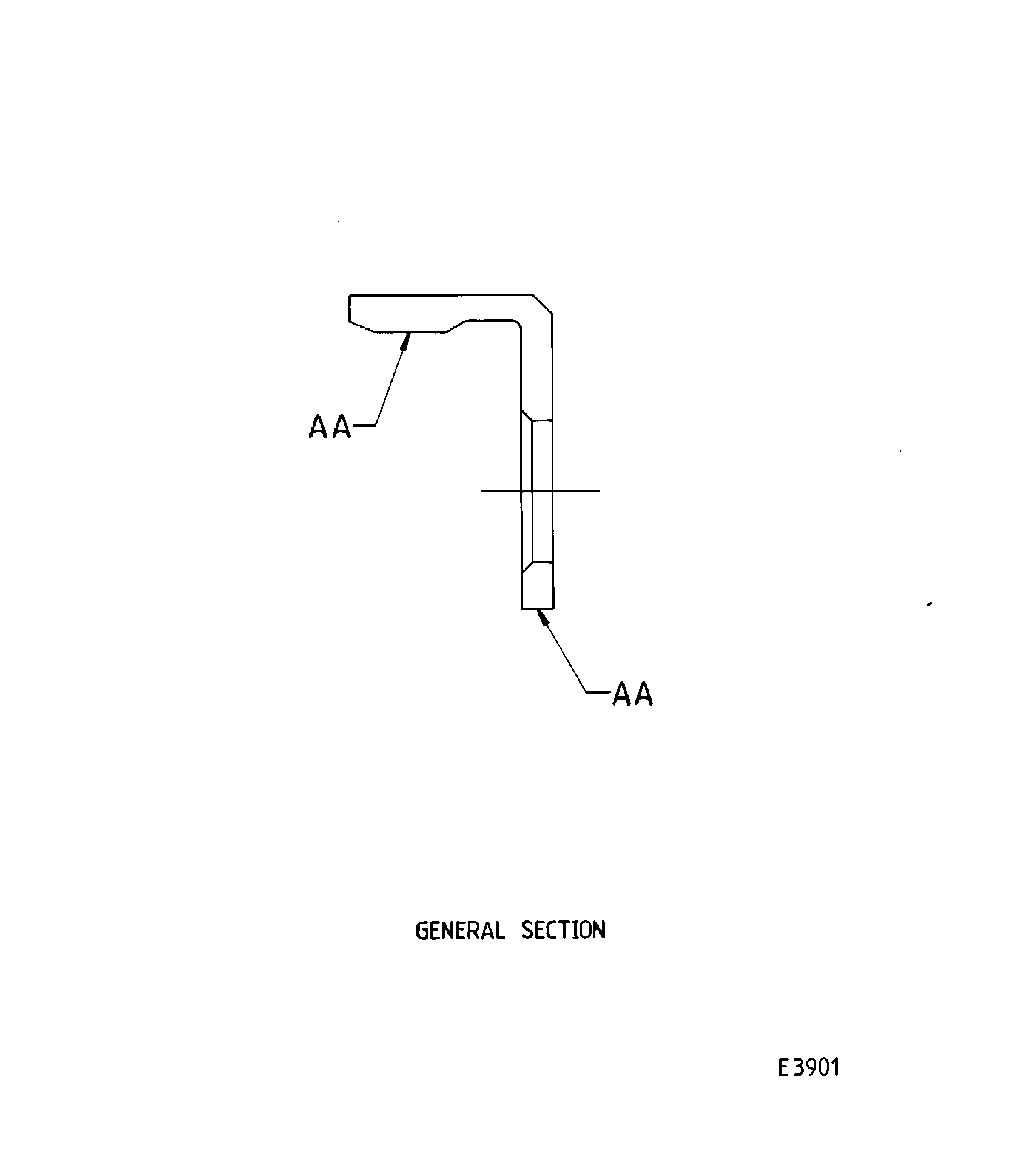

Figure: Repair details and dimensions - Assembly B and Assembly C

Repair details and dimensions - Assembly B and Assembly C

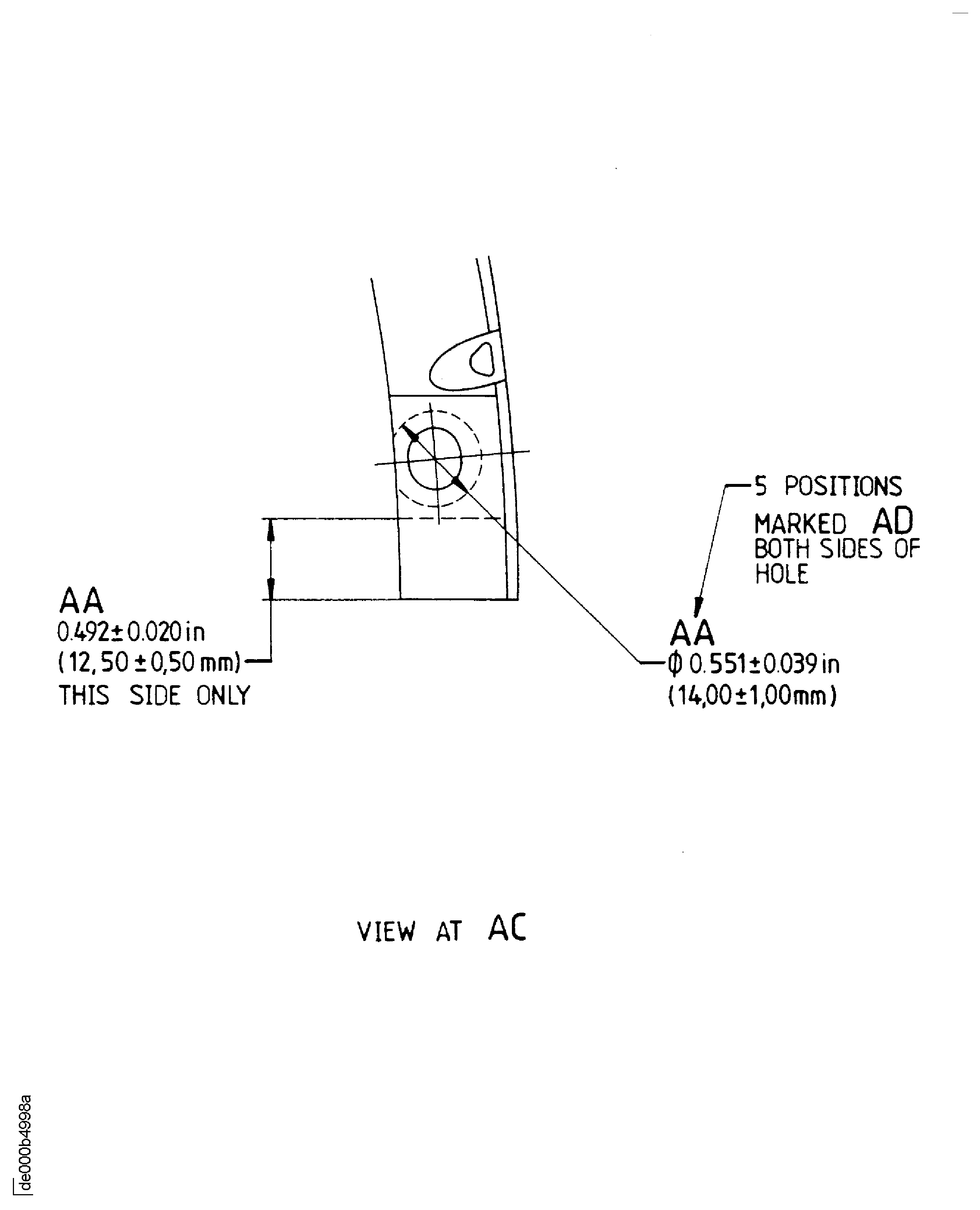

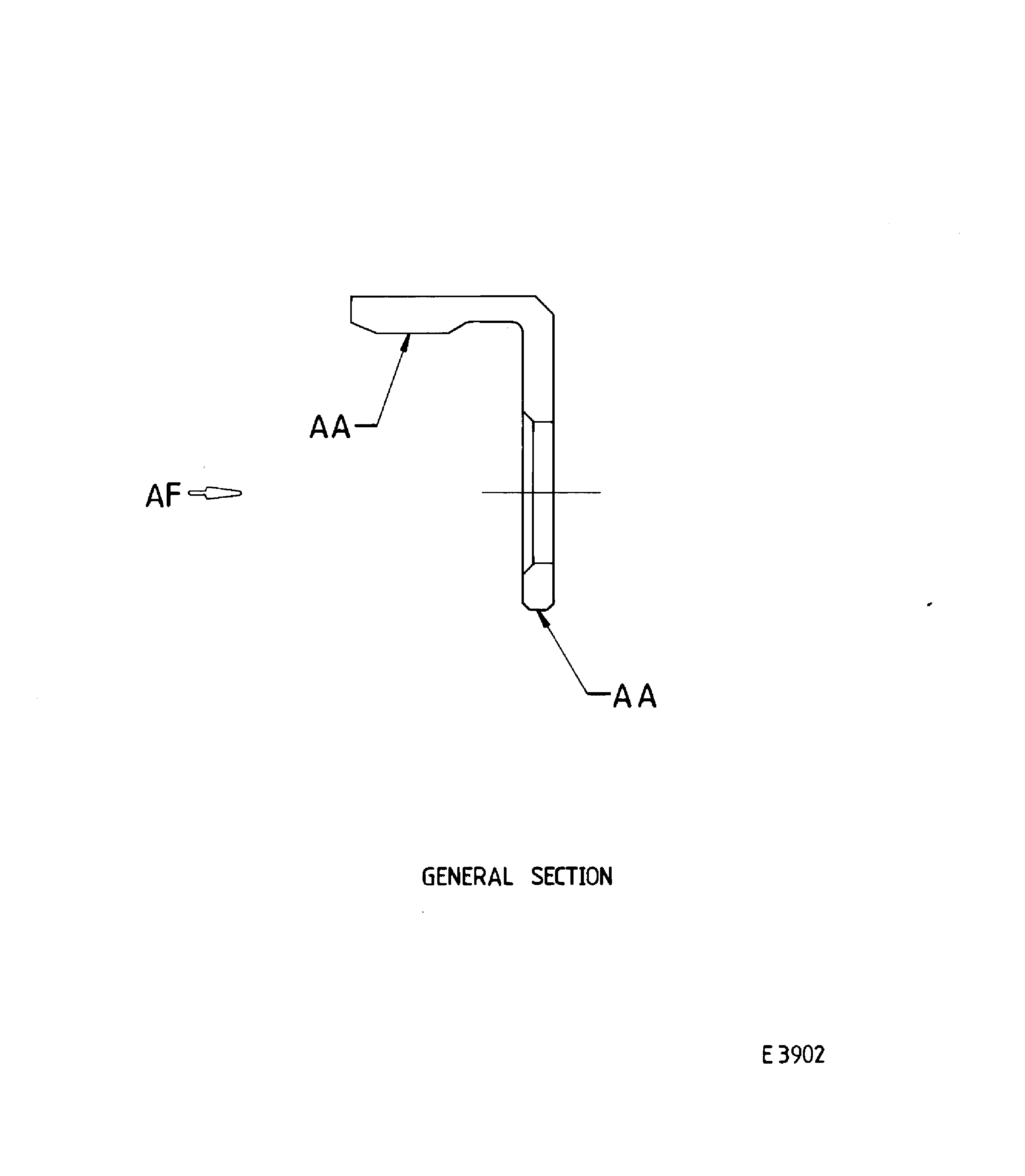

Figure: Repair details and dimensions - Assembly B and Assembly C

Repair details and dimensions - Assembly B and Assembly C

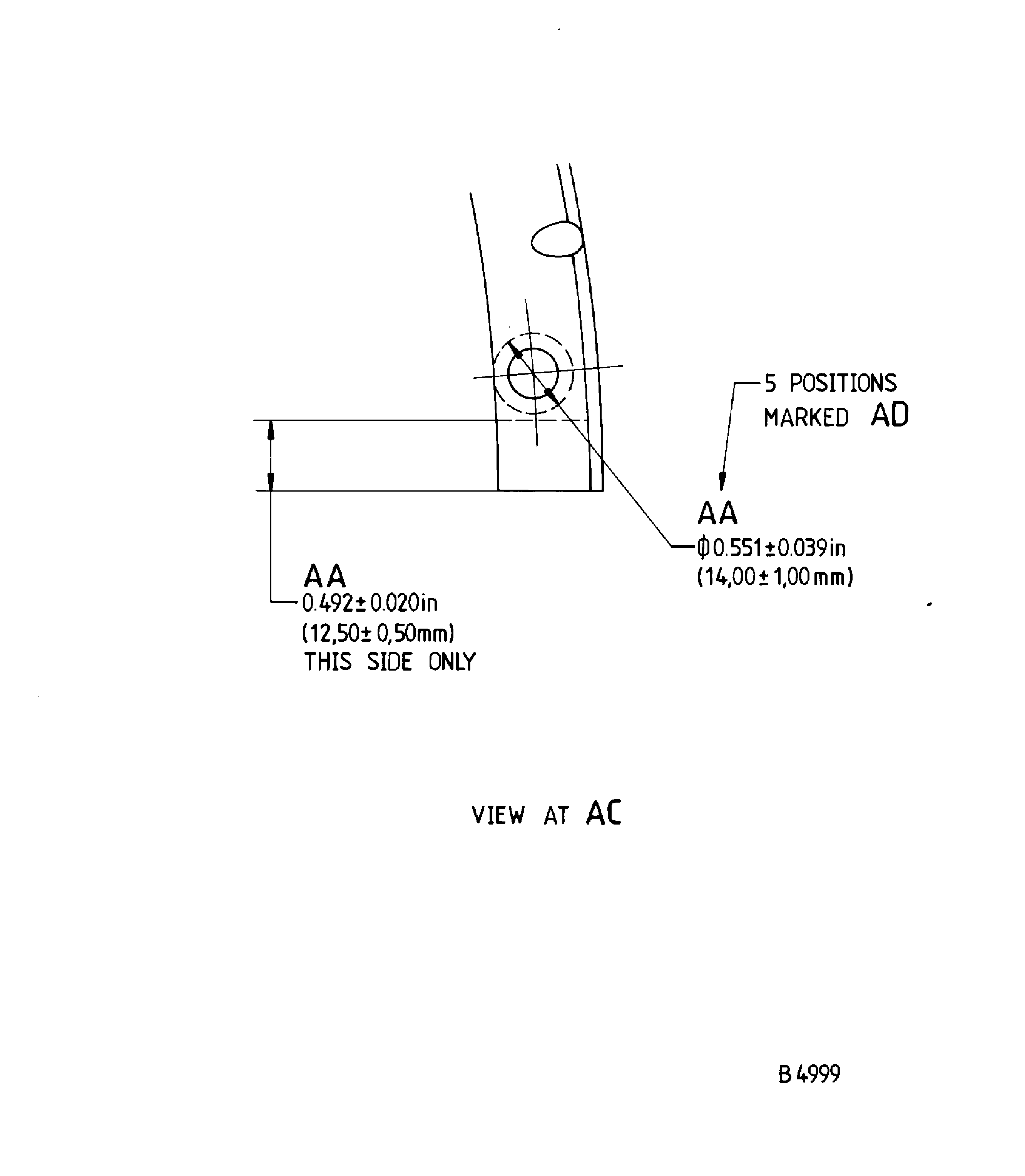

Figure: Repair details and dimensions - Assembly B

Repair details and dimensions - Assembly B

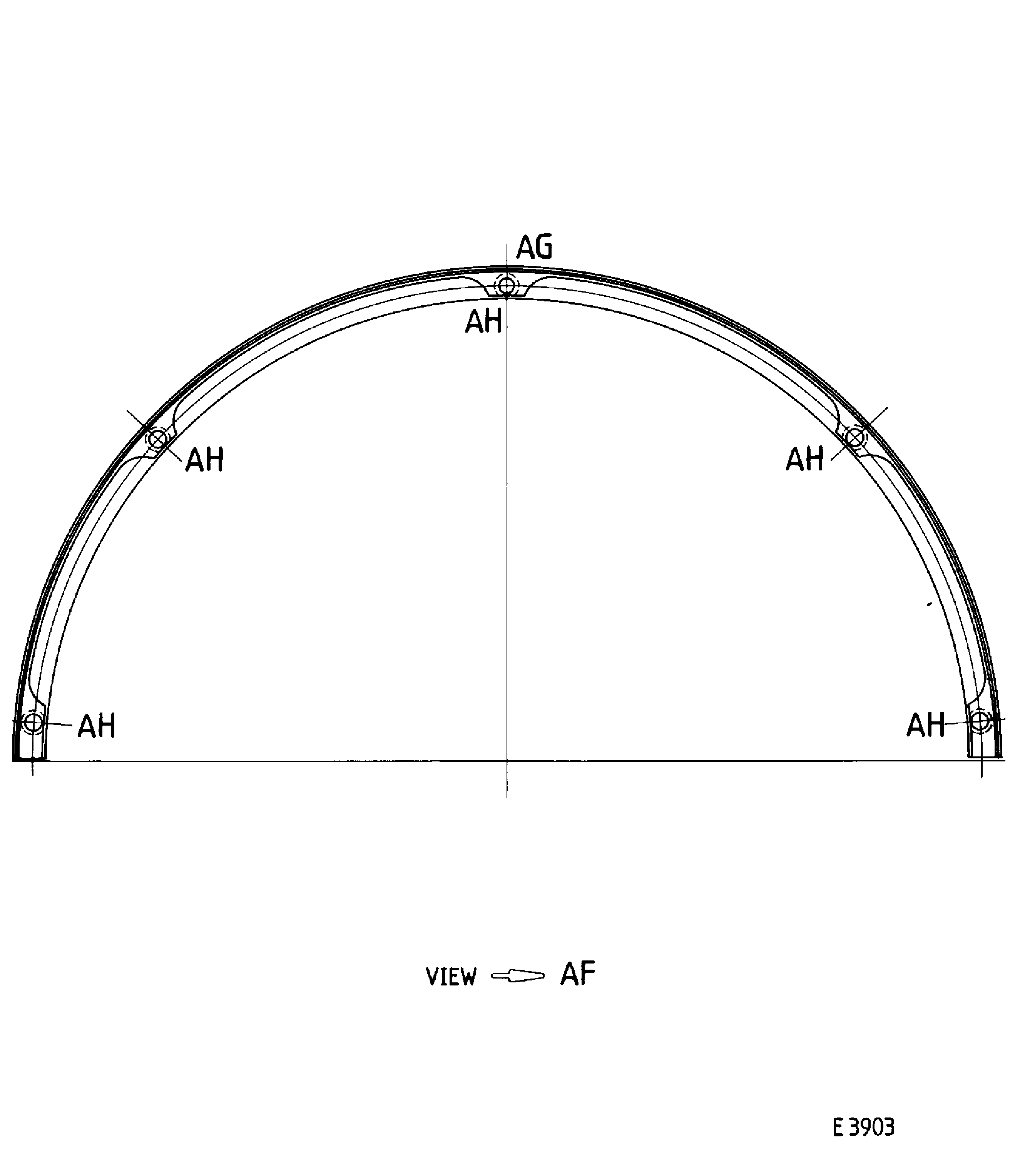

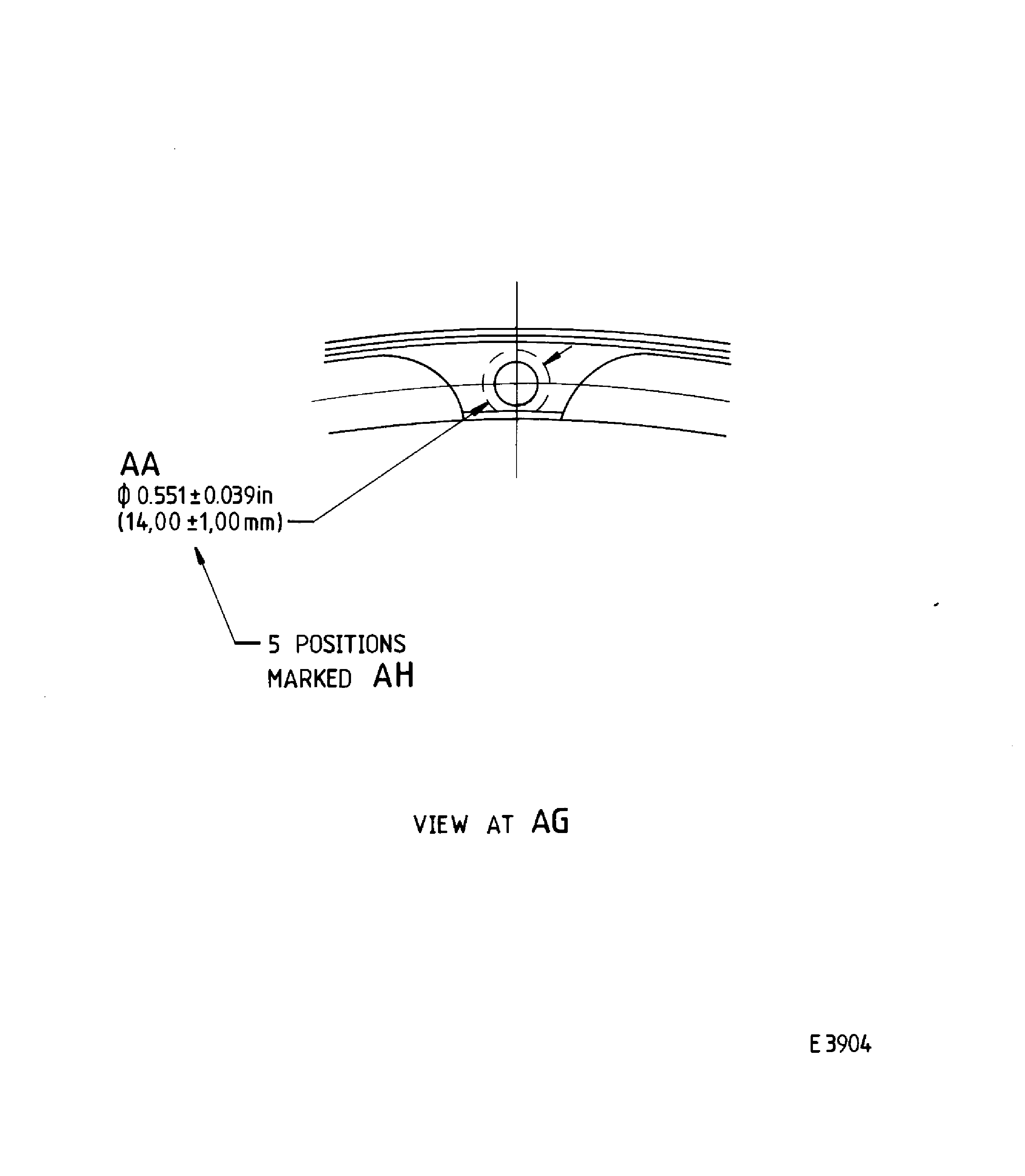

Figure: Repair details and dimensions - Assembly A, Assembly B and Assembly C

Repair details and dimensions - Assembly A, Assembly B and Assembly C

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

Figure: Repair details and dimensions - Assembly B

Repair details and dimensions - Assembly B

Figure: Repair details and dimensions - Assembly B

Repair details and dimensions - Assembly B

Figure: Repair details and dimensions - Assembly B

Repair details and dimensions - Assembly B

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C