Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-31-300-021 HPC Front Cases - Repair The Surface Protection, Repair-021 (VRS6501)

Effectivity

FIG/ITEM | PART NO. | |

|---|---|---|

01-400 | 6A5470 | Assembly A |

01-400 | 6A4439 | Assembly B |

01-400 | 6A3462 | Assembly C |

01-400 | 6A3675 | Assembly C |

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

HP Compressor Front Case Assembly | TEG | 6 percent Aluminum 4 percent Vanadium |

General

This repair must only be done when the instruction to do so is given 72-41-31 Inspection/Check.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and availability

Refer to International Aero Engines

Related repairs - none

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Abrasive Blast Equipment | LOCAL | Abrasive Blast Equipment | ||

| Spray gun | LOCAL | Spray gun | ||

| Oven | LOCAL | Oven | ||

| Vibrating Marking Pencil | LOCAL | Vibrating Marking Pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-002 ADHESIVE TAPE GENERALPURPOSE PAPER | LOCAL | CoMat 02-002 | ||

| CoMat 02-005 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-005 | ||

| CoMat 02-019 TAPE, ADHESIVE PAPER HEAT RESISTING MASKING | 76381 | CoMat 02-019 | ||

| CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE | X222X | CoMat 05-003 | ||

| CoMat 07-009 THINNER | K3504 | CoMat 07-009 | ||

| CoMat 10-004 DRY FILM LUBRICANT | LOCAL | CoMat 10-004 |

Spares

NONESafety Requirements

NONEProcedure

Refer to TASK 72-41-31-200-000 (INSPECTION).

Use penetrant crack test equipment.

Cracks are not permitted.

Do a penetrant crack test.

SUBTASK 72-41-31-230-085 Do a Crack Test

Refer to the SPM TASK 70-38-03-380-501 SUBTASK 70-38-03-120-001.

Use CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE, with abrasive blast equipment.

Abrasive blast the surfaces specified BA.

Refer to the SPM TASK 70-38-03-380-501, SUBTASK 70-38-03-120-001.

Clean the abrasive medium from the component.

SUBTASK 72-41-31-120-061-A00 Prepare the Surfaces for Repair, Assembly A

Refer to the SPM TASK 70-38-03-380-501 SUBTASK 70-38-03-120-001.

Use CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE with abrasive blast equipment.

Abrasive blast the surfaces specified BA.

Refer to the SPM TASK 70-38-03-380-501, SUBTASK 70-38-03-120-001.

Clean the abrasive medium from the component.

SUBTASK 72-41-31-120-061-B00 Prepare the Surfaces for Repair, Assembly B

Refer to the SPM TASK 70-38-03-380-501 SUBTASK 70-38-03-120-001.

Use CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE with abrasive blast equipment.

Abrasive blast the surfaces specified BA.

Refer to the SPM TASK 70-38-03-380-501, SUBTASK 70-38-03-120-001.

Clean the abrasive medium from the component.

SUBTASK 72-41-31-120-061-C00 Prepare the Surfaces for Repair, Assembly C

Refer to the SPM TASK 70-38-03-380-501, SUBTASK 70-38-03-380-004.

Use a spray gun and spray three coats of dry film lubricant, to give a thickness of 0.00098 to 0.0020 in. (0.025 to 0.051 mm) maximum.

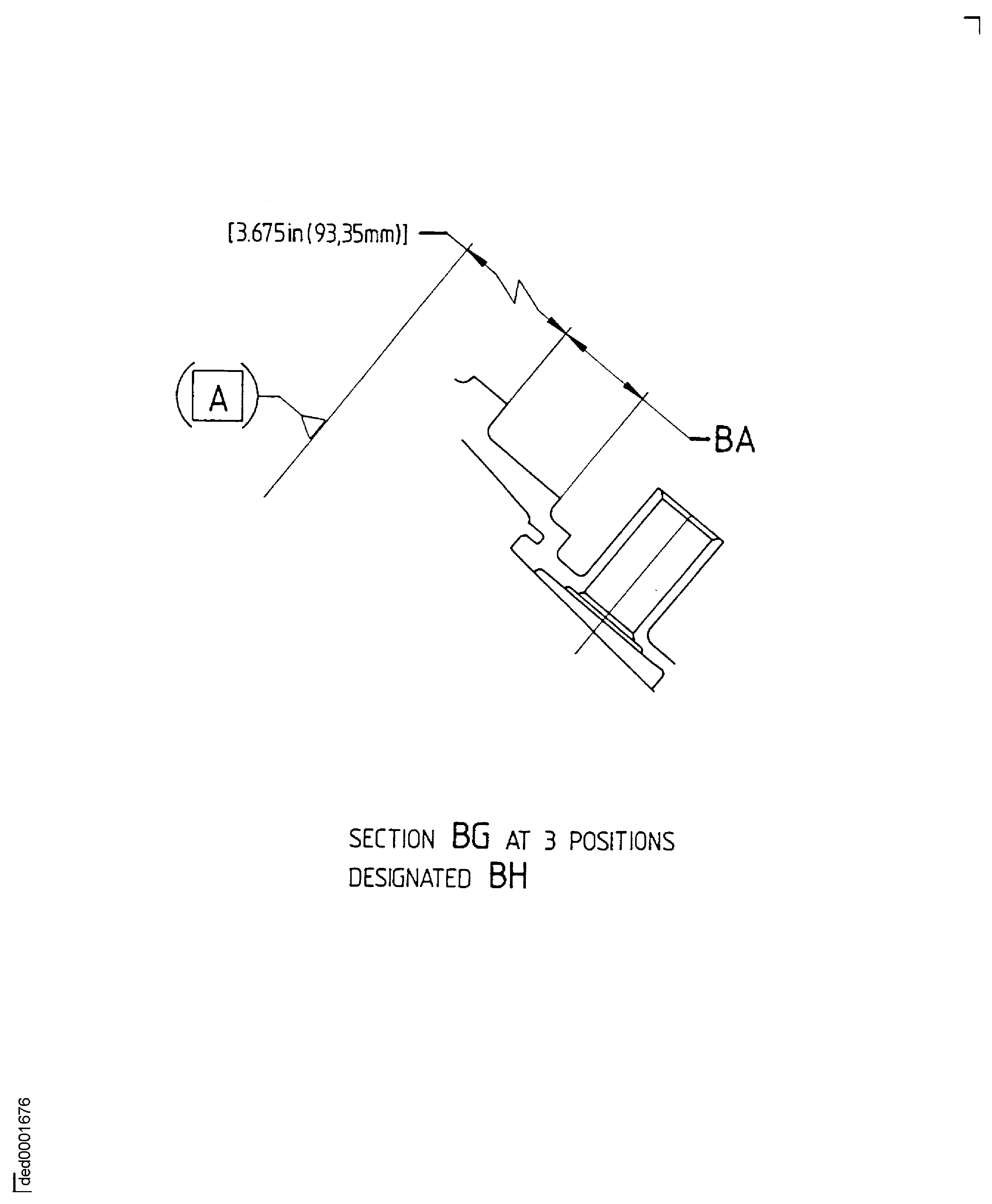

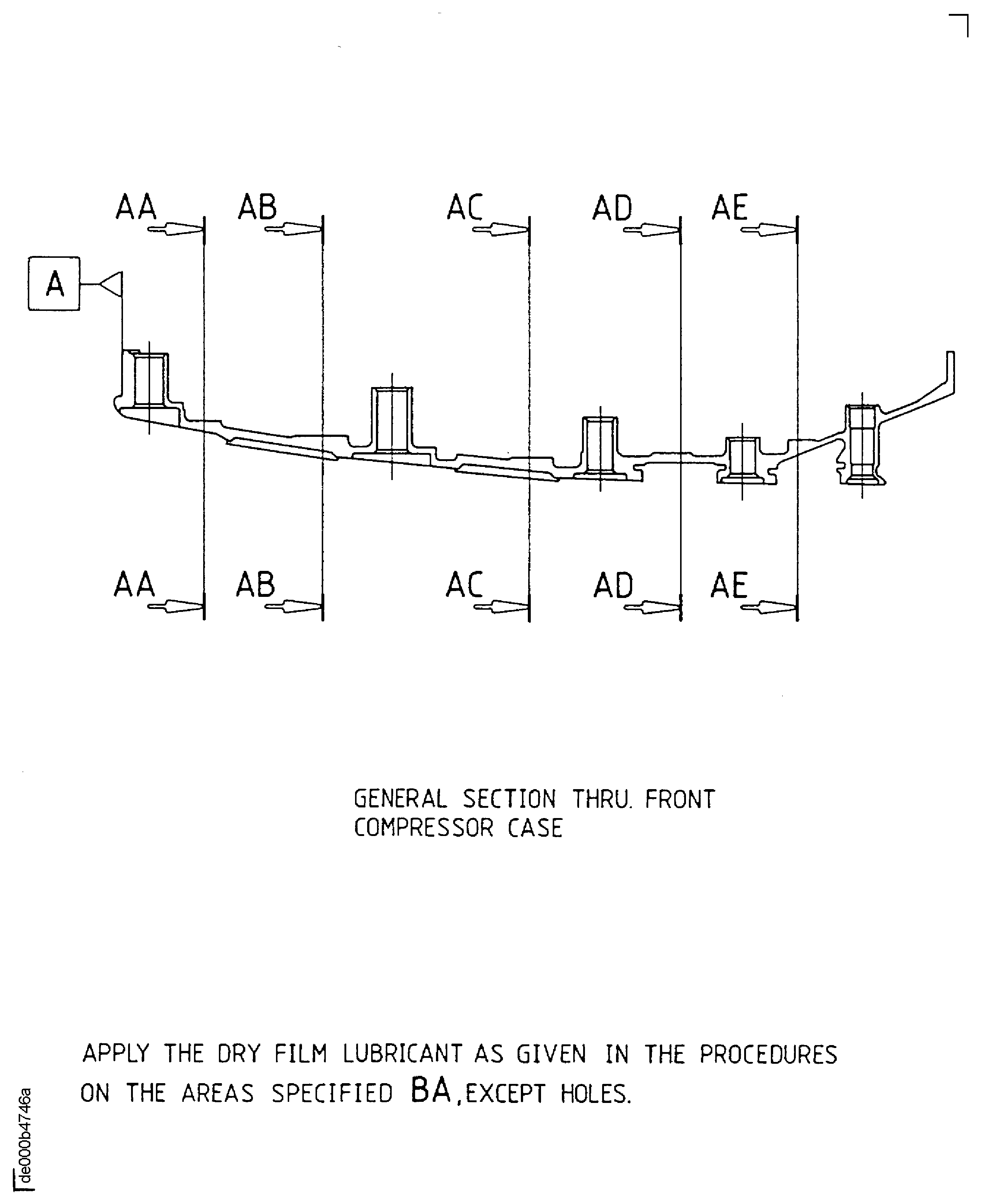

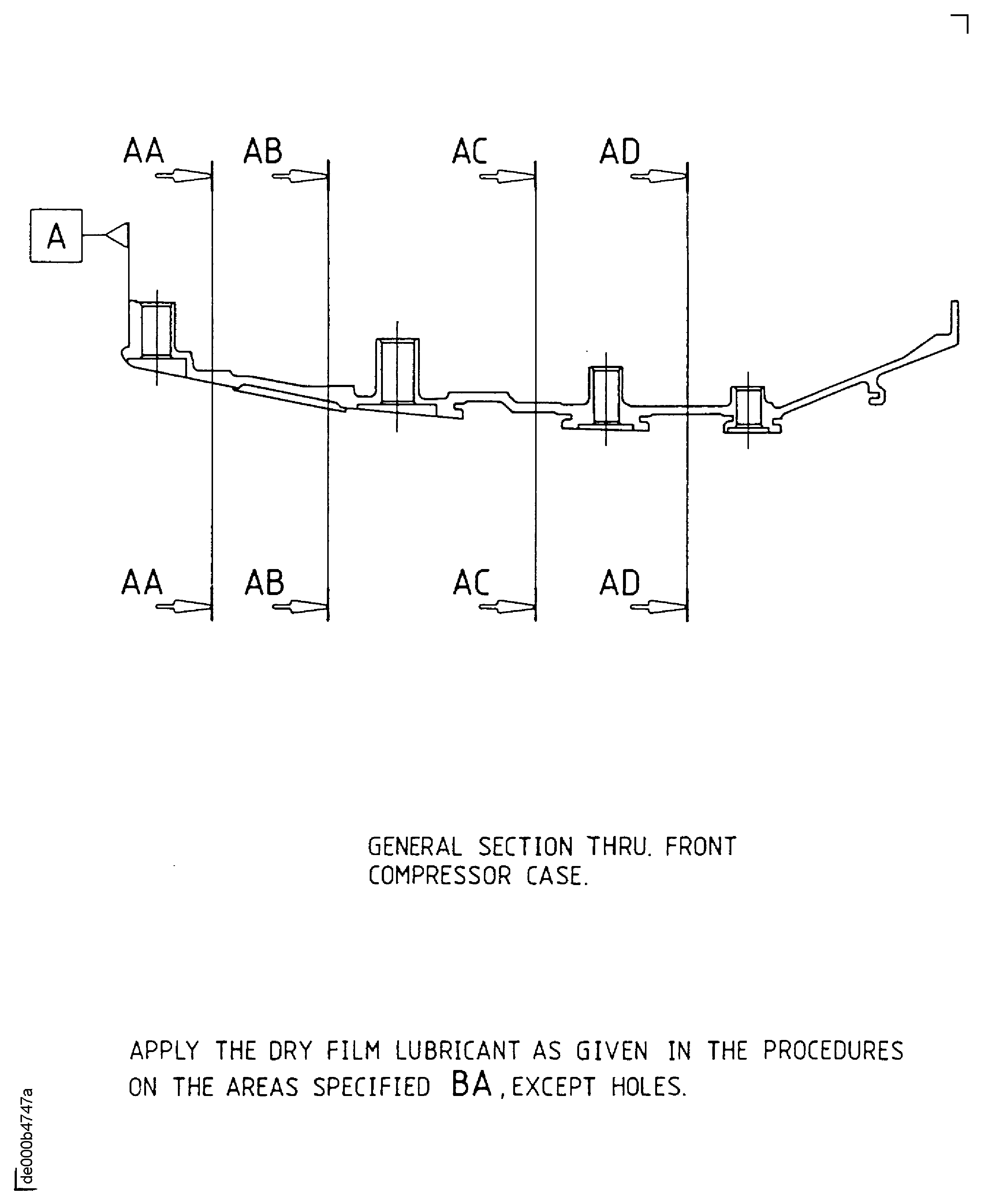

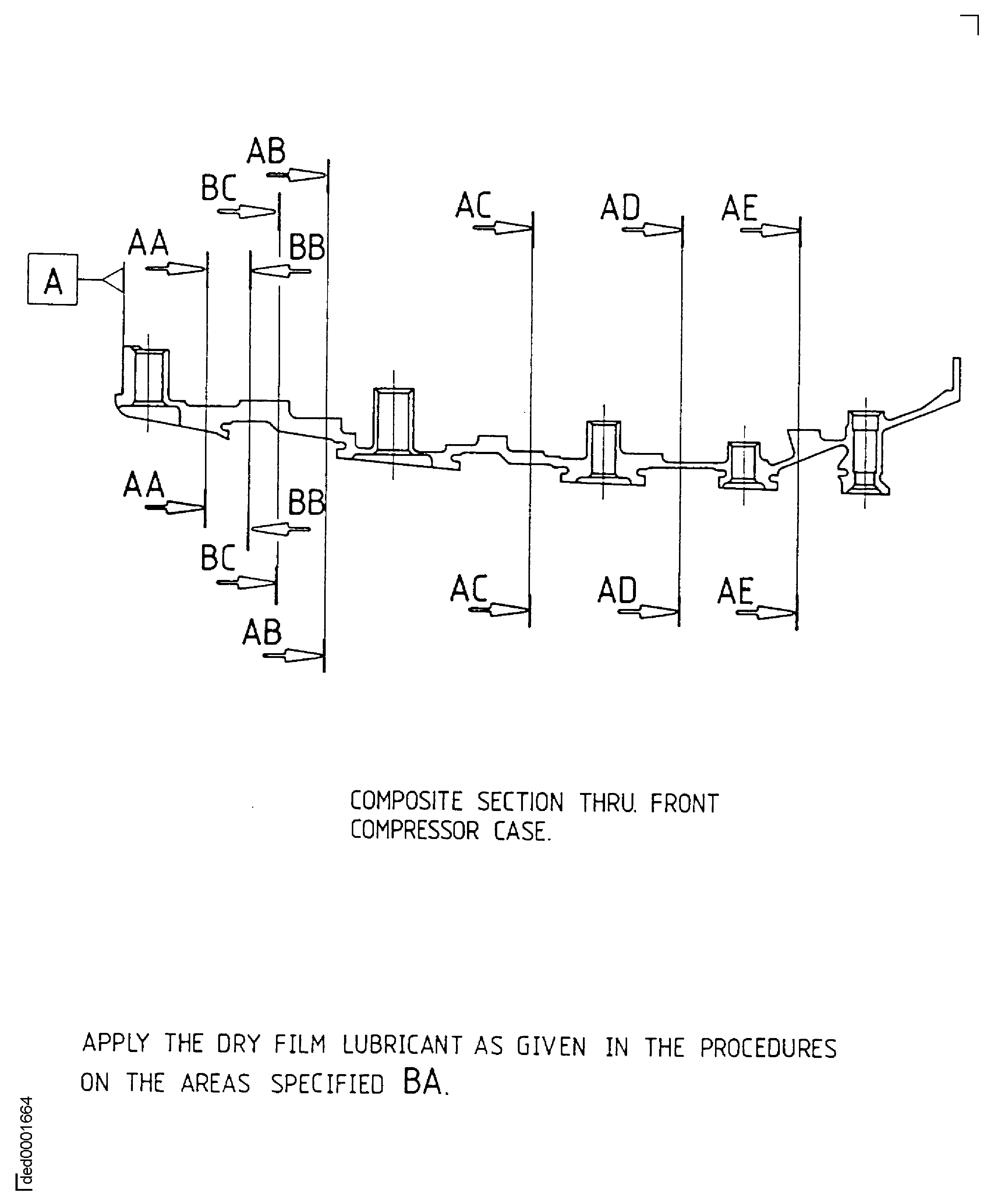

Apply the dry film lubricant, to the areas specified BA.

SUBTASK 72-41-31-380-051-A00 Apply the Dry Film Lubricant to the HP Compressor Front Case Assembly, Assembly A

Refer to the SPM TASK 70-38-03-380-501, SUBTASK 70-38-03-380-004.

Use a spray gun and spray three coats of dry film lubricant, to give a thickness of 0.00098 to 0.0020 in. (0.025 to 0.051 mm) maximum.

Apply the dry film lubricant, to the areas specified BA.

SUBTASK 72-41-31-380-051-B00 Apply the Dry Film Lubricant to the HP Compressor Front Case Assembly, Assembly B

Refer to the SPM TASK 70-38-03-380-501, SUBTASK 70-38-03-380-004.

Use a spray gun and spray three coats of dry film lubricant, to give a thickness of 0.00098 to 0.0020 in. (0.025 to 0.051 mm) maximum.

Apply the dry film lubricant, to the areas specified BA.

SUBTASK 72-41-31-380-051-C00 Apply the Dry Film Lubricant to the HP Compressor Front Case Assembly, Assembly C

Refer to the SPM TASK 70-38-03-380-501, SUBTASK 70-38-03-220-001, for inspection standards.

Make sure you have a thickness of 0.00098 to 0.0020 in. (0.025 to 0.051 mm) maximum.

Visually examine the dry film lubricant.

SUBTASK 72-41-31-220-208-A00 Examine the Dry Film Lubricant, Assembly A

Make sure you have a thickness of 0.00098 to 0.0020 in. (0.025 to 0.051 mm) maximum.

Refer to SPM TASK 70-38-03-380-501, SUBTASK 70-38-03-220-001, for inspection standards.

Visually examine the dry film lubricant.

SUBTASK 72-41-31-200-208-B00 Examine the Dry Film Lubricant, Assembly B

Make sure you have a thickness of 0.00098 to 0.0020 in. (0.025 to 0.051 mm) maximum.

Refer to SPM TASK 70-38-03-380-501, SUBTASK 70-38-03-220-001, for inspection standards.

Visually examine the dry film lubricant.

SUBTASK 72-41-31-200-208-C00 Examine the Dry Film Lubricant, Assembly C

Use vibro-engraving equipment.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Make a mark VRS6501 adjacent to the part number.

SUBTASK 72-41-31-350-085 Identify the Repair

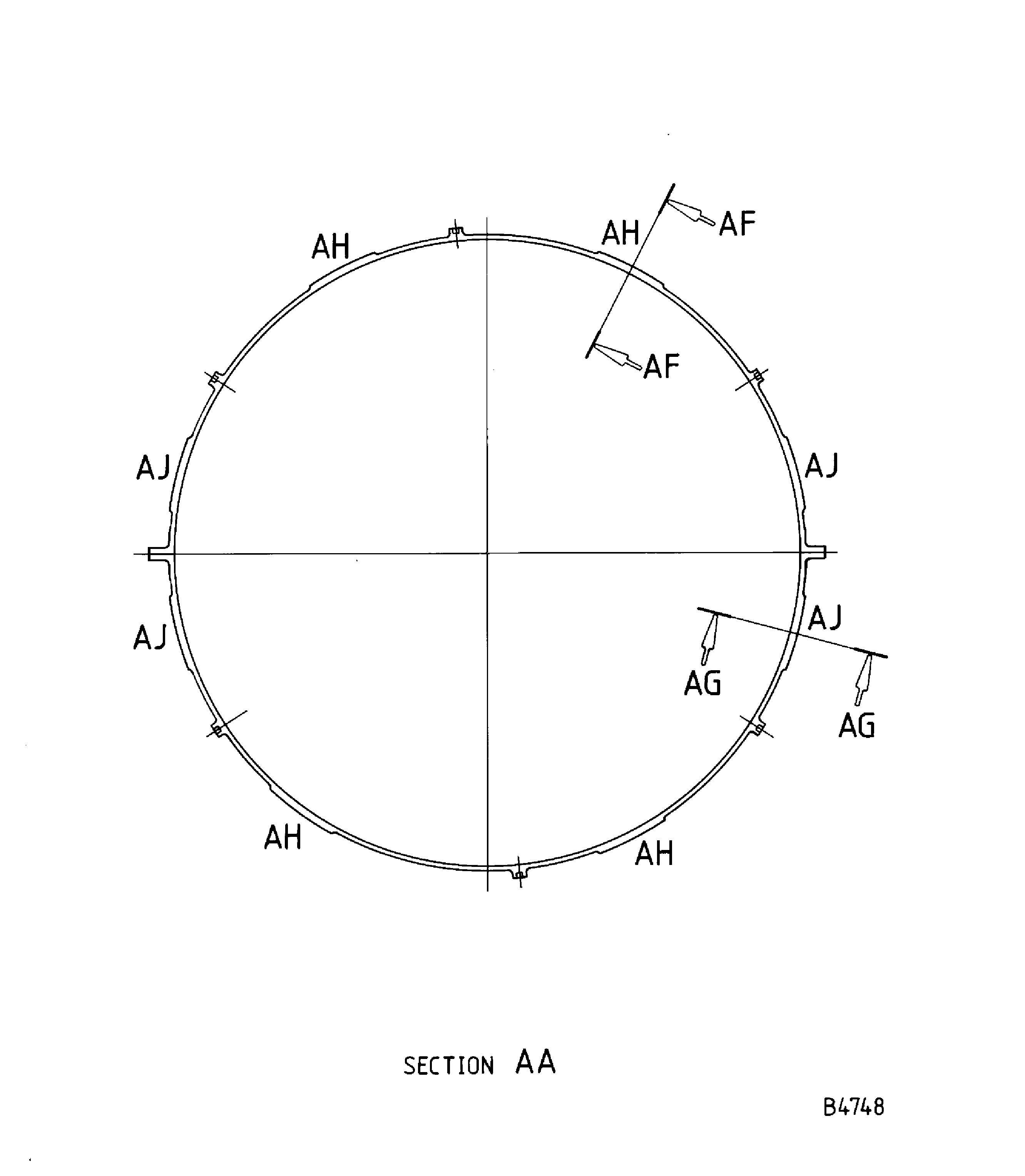

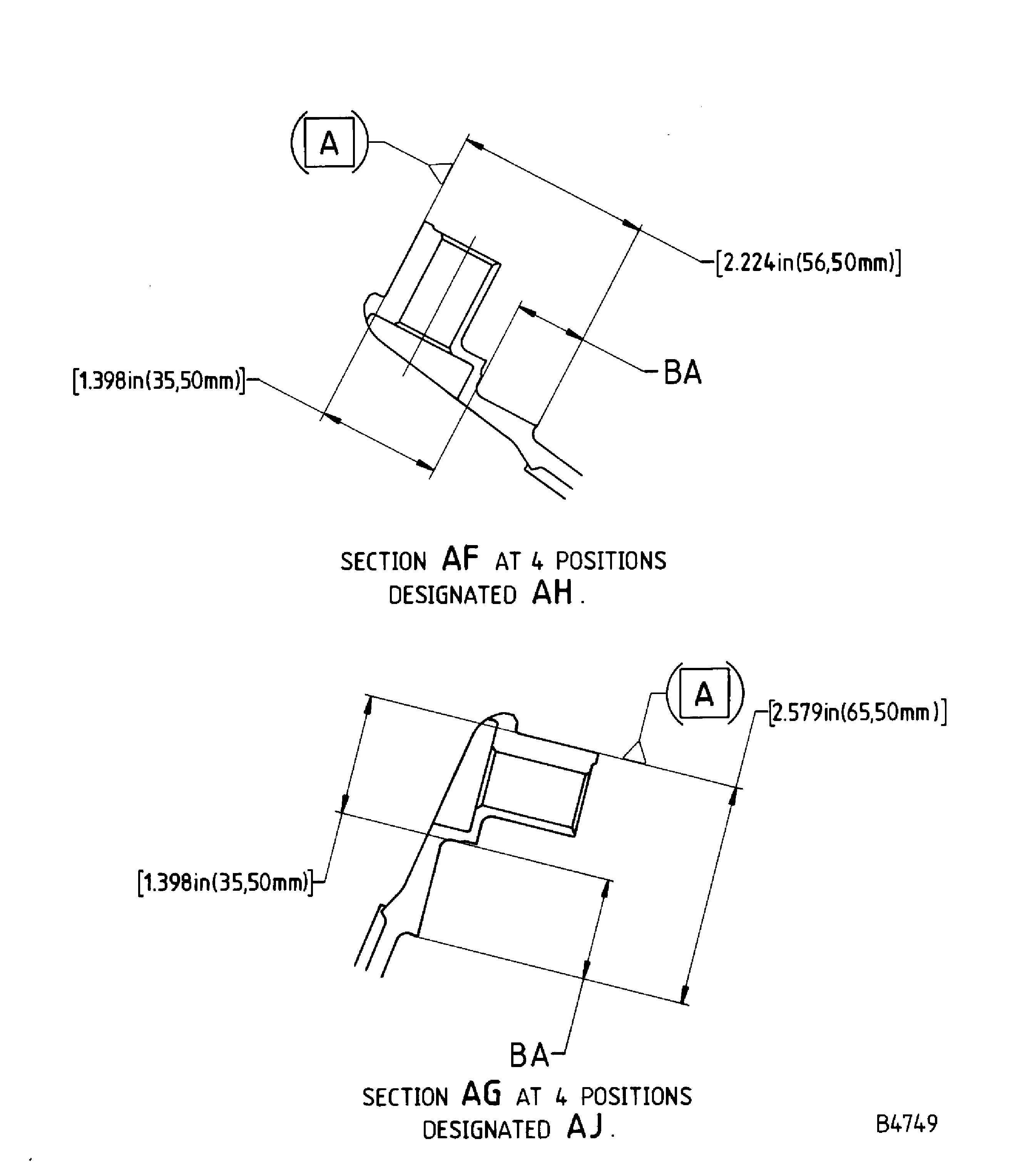

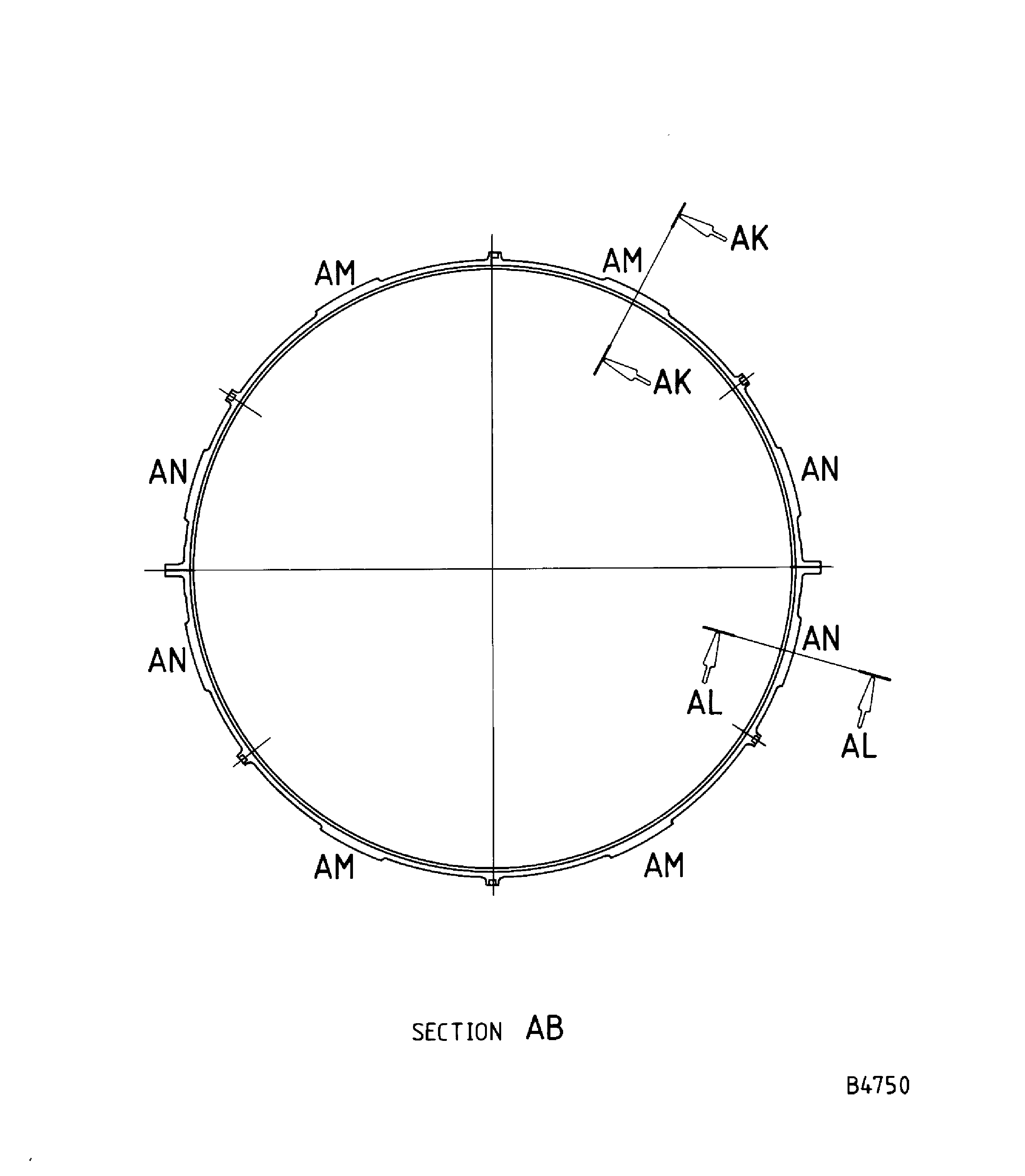

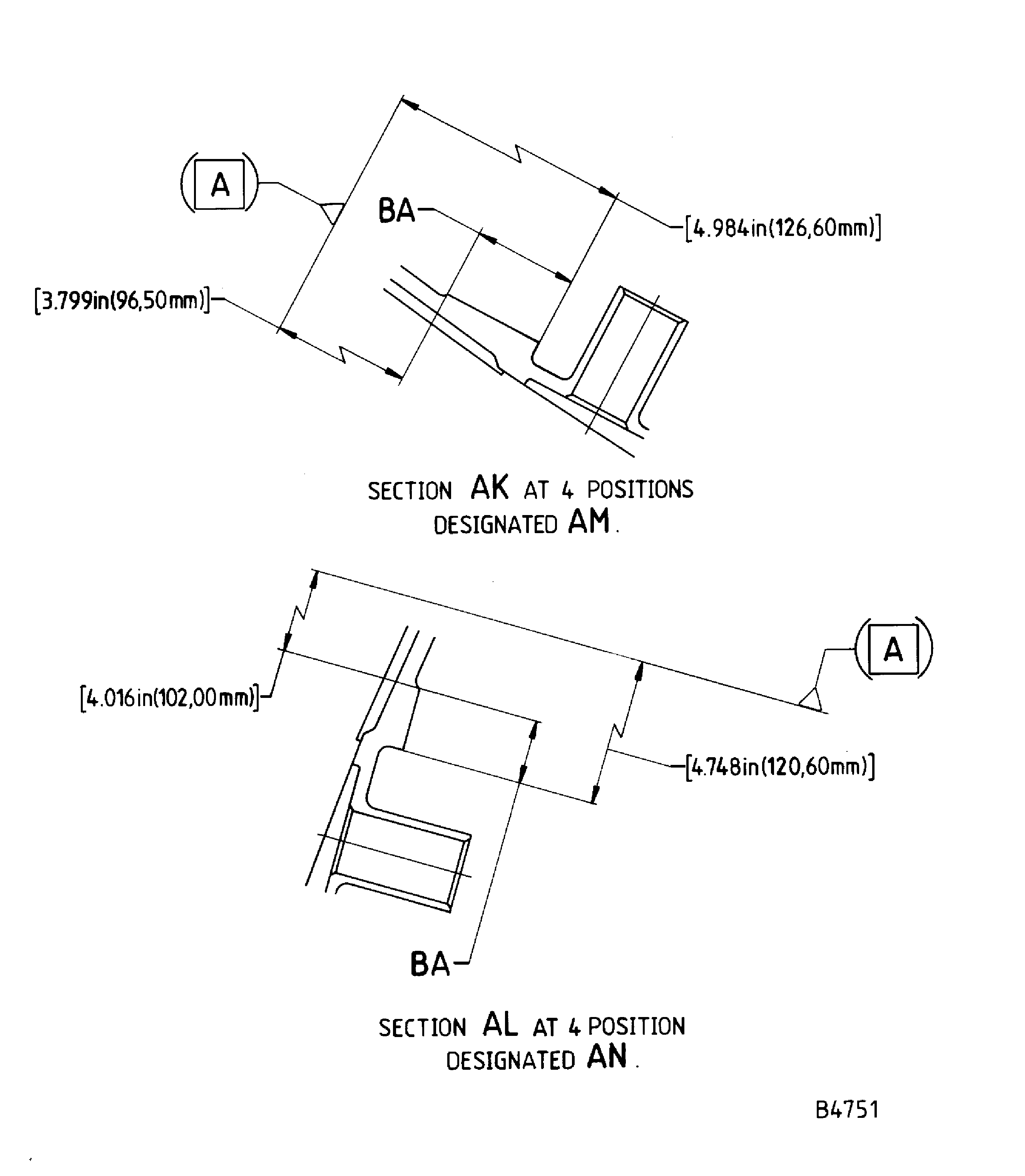

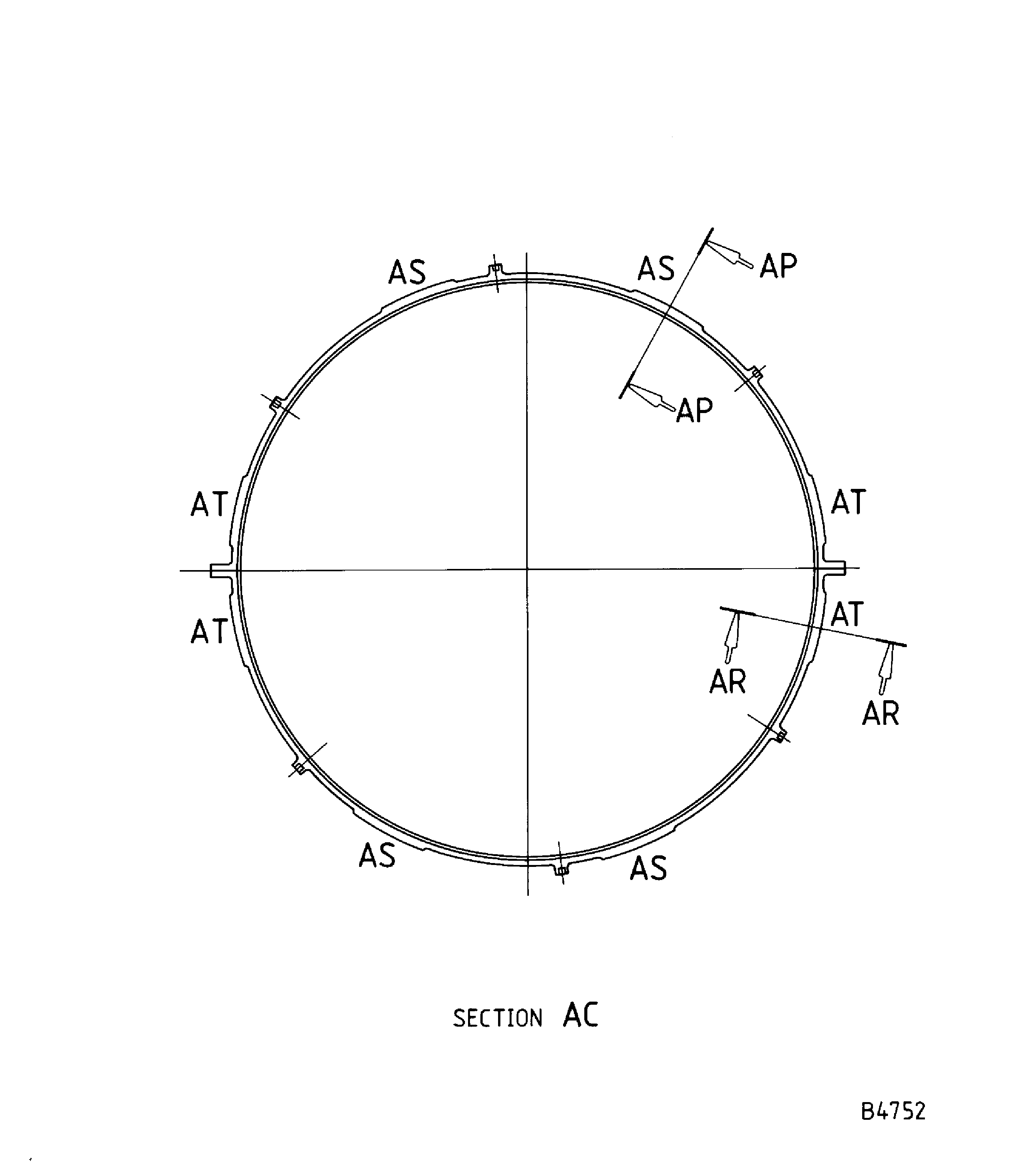

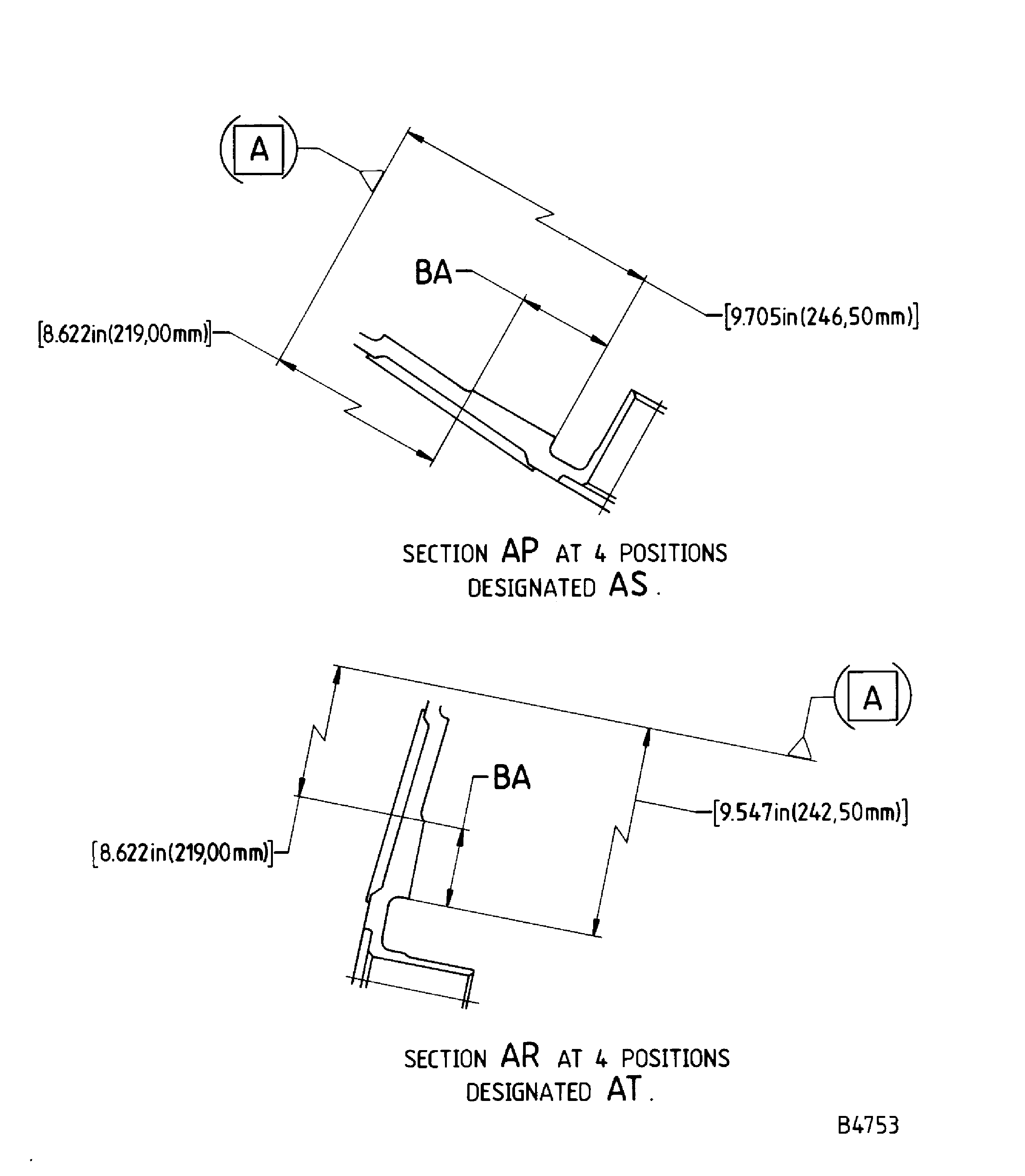

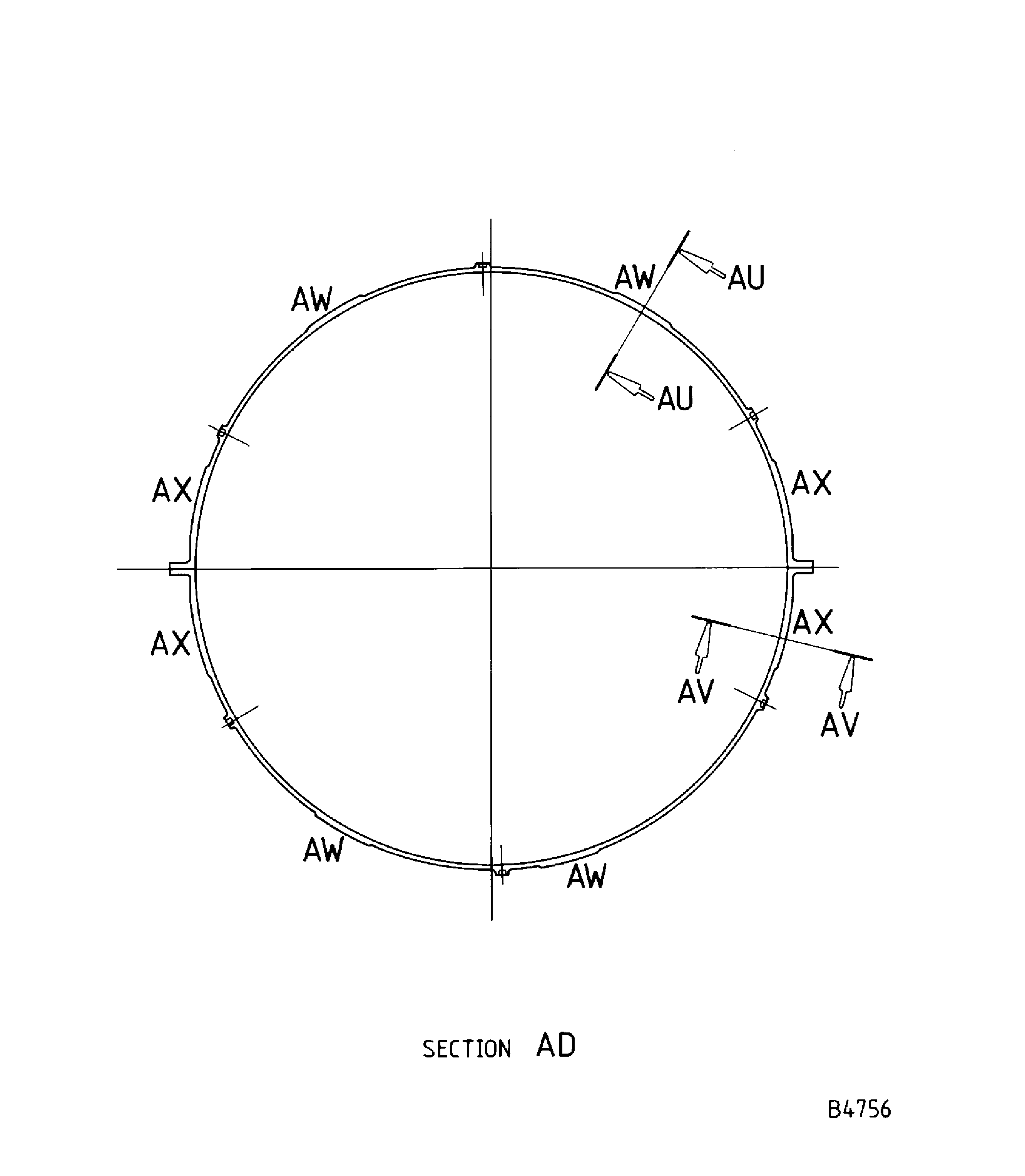

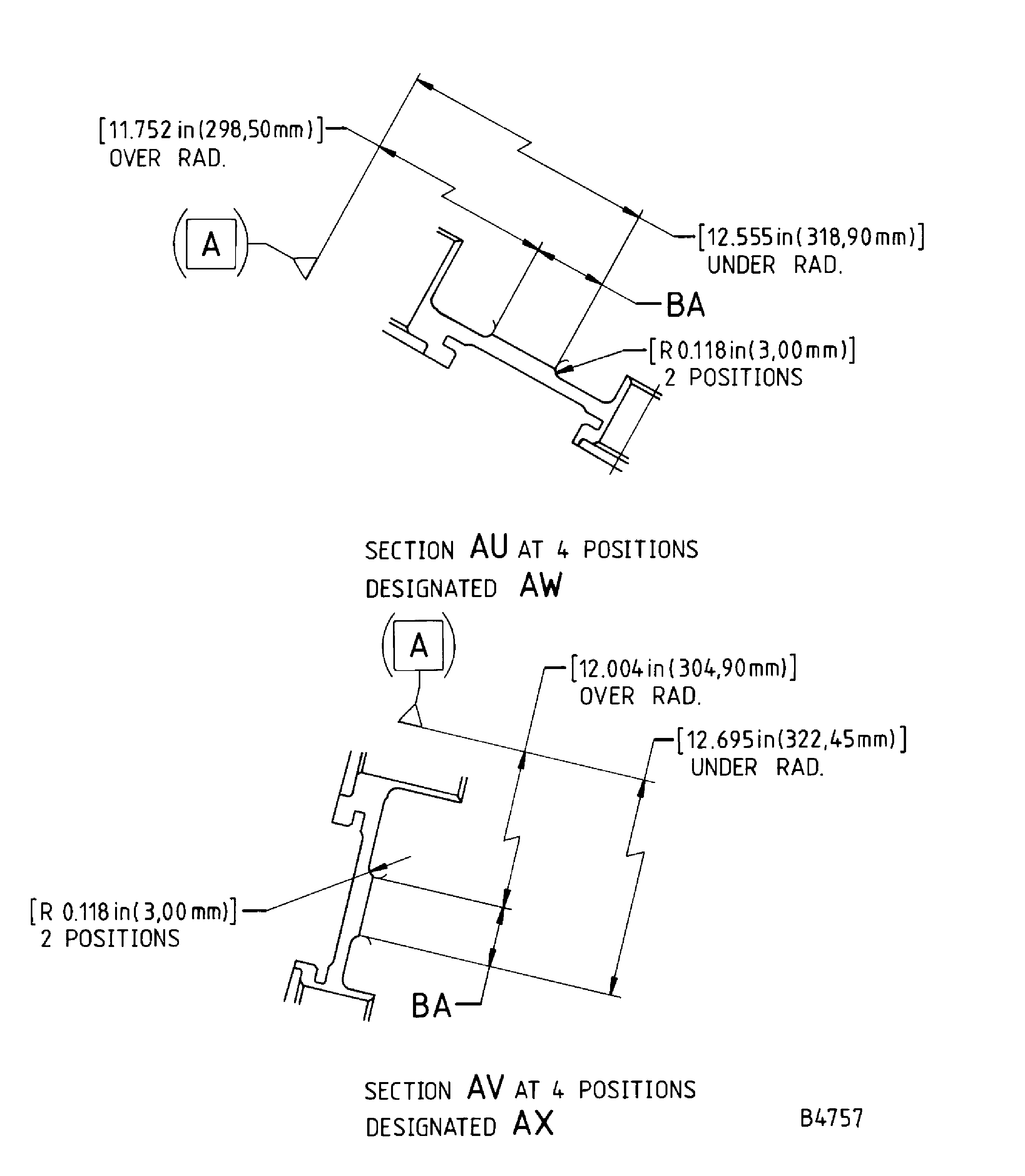

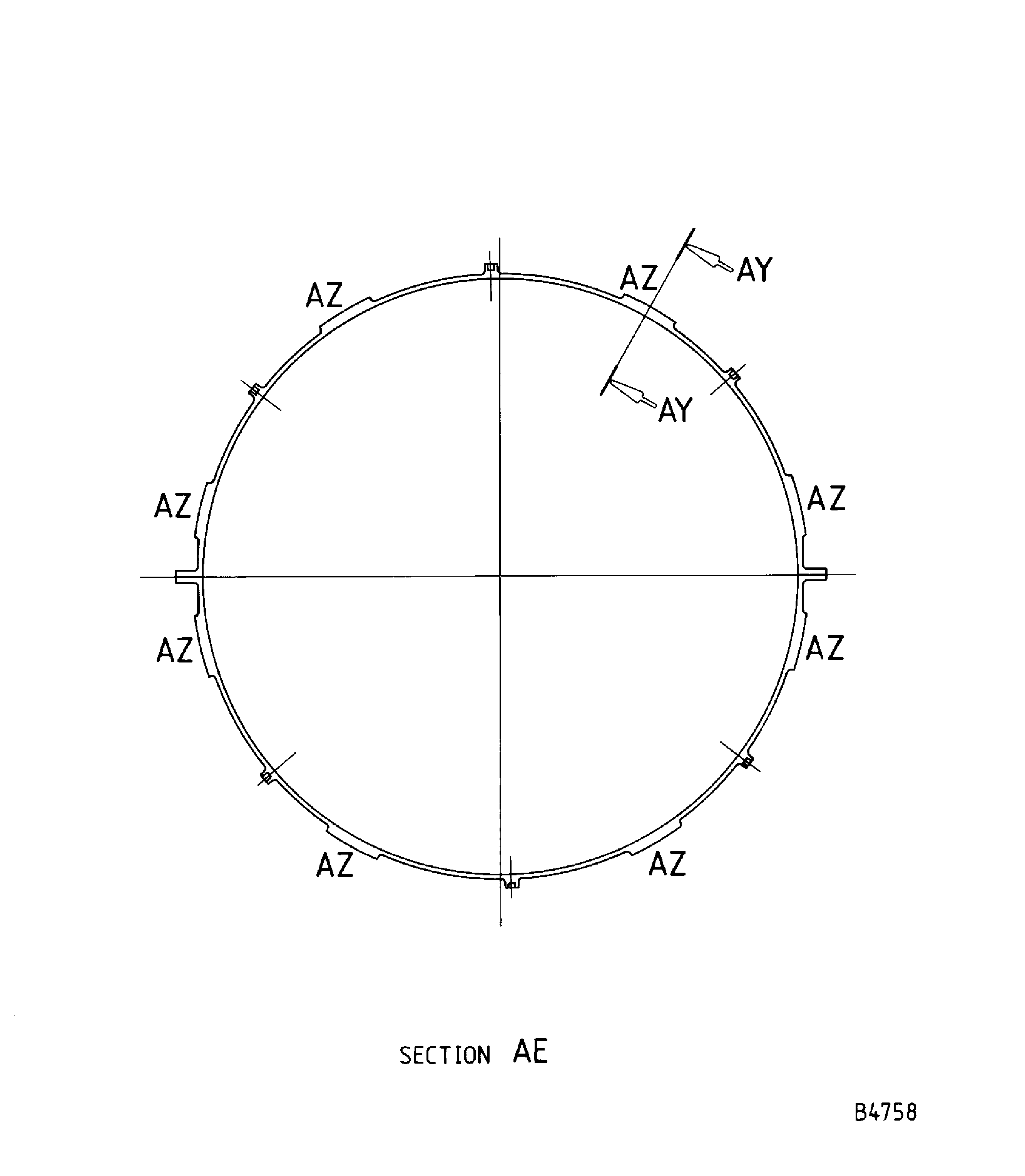

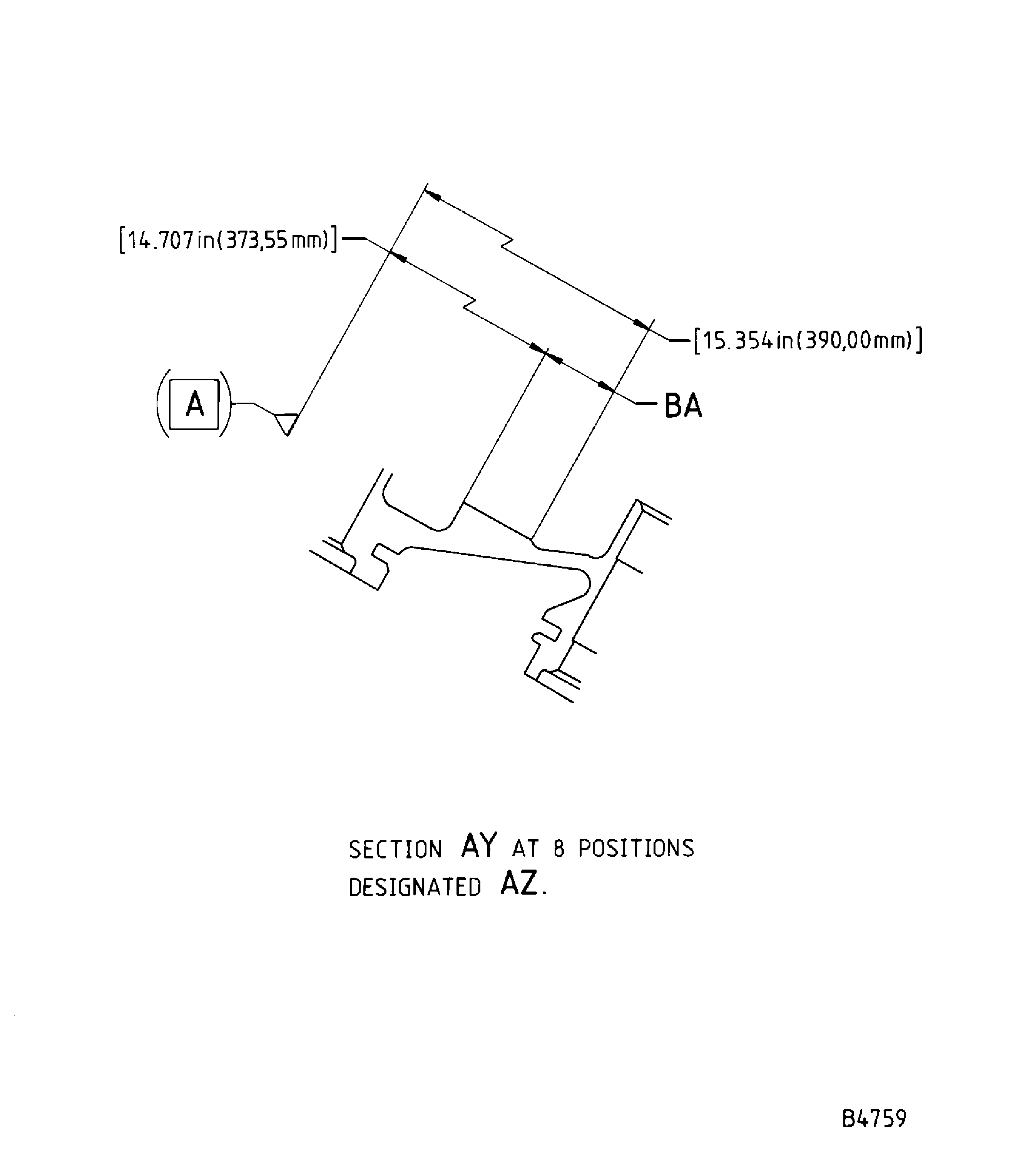

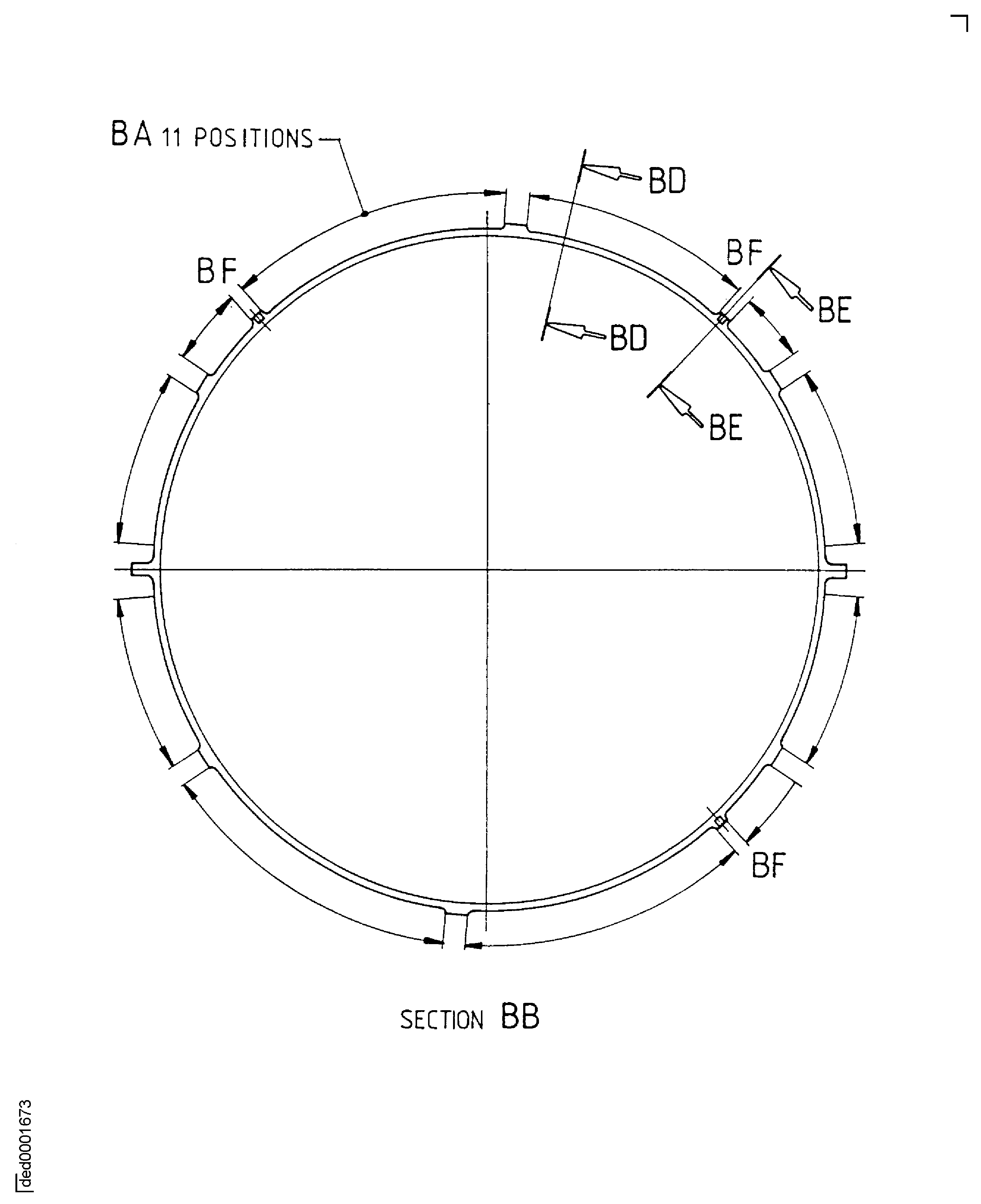

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

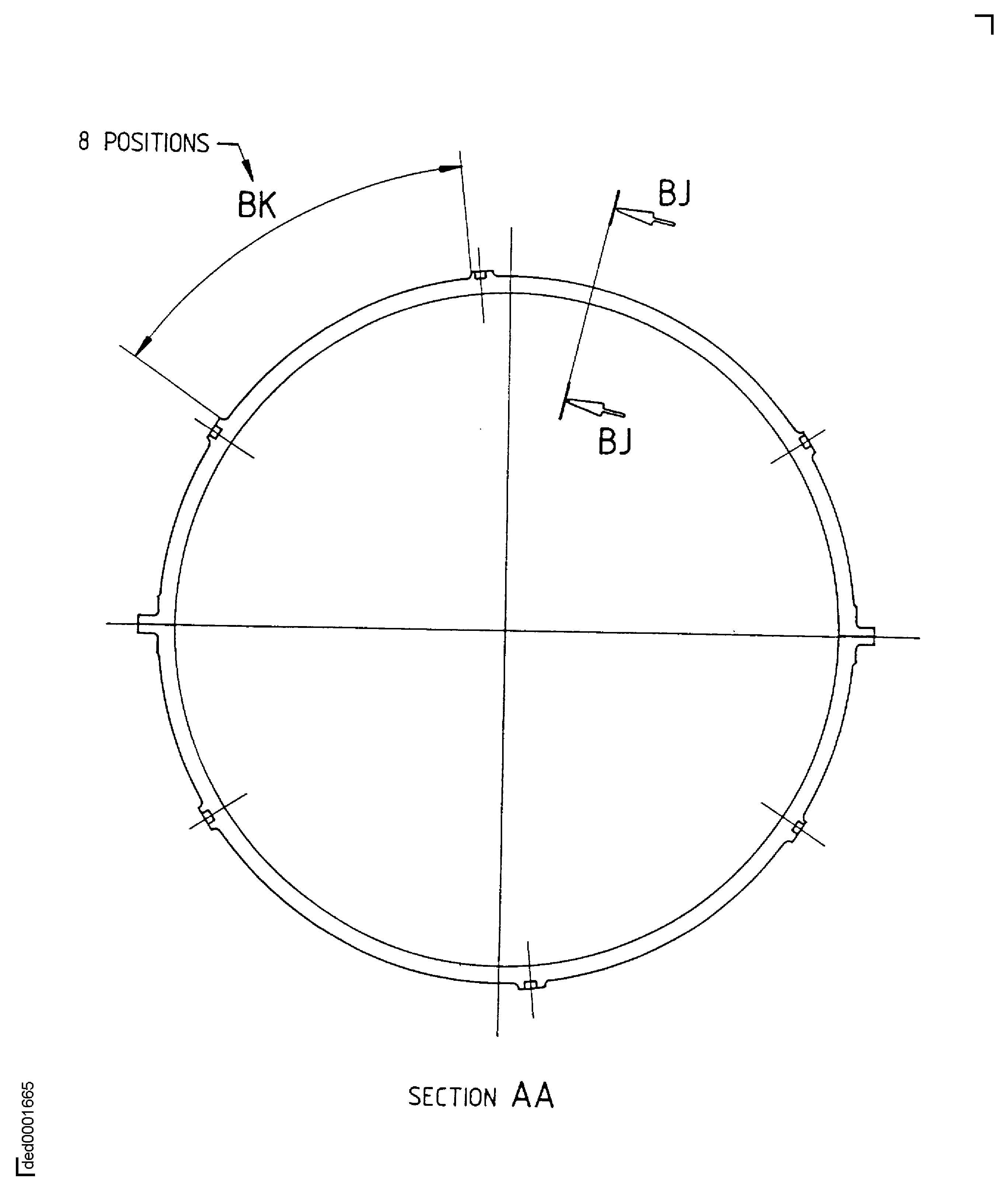

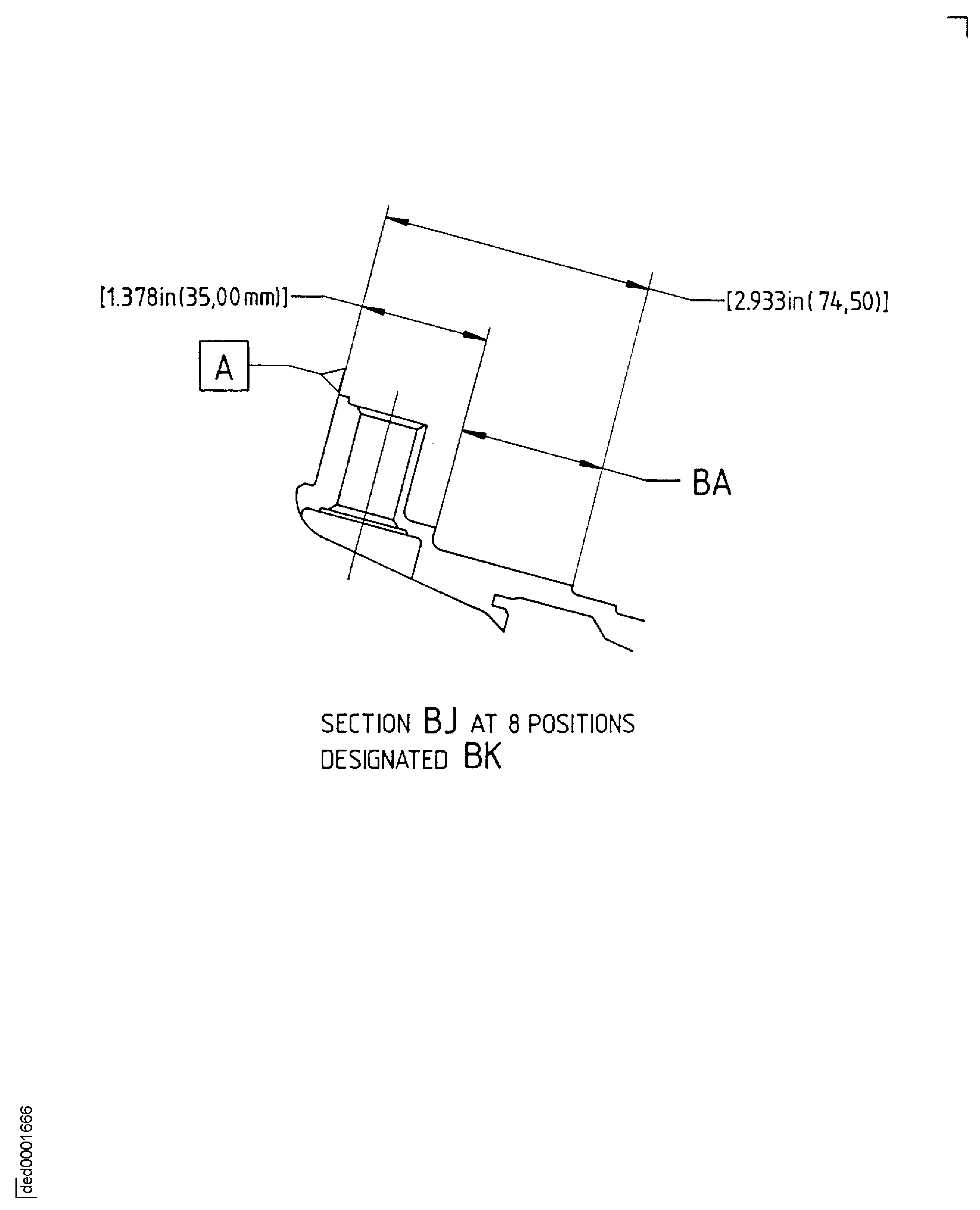

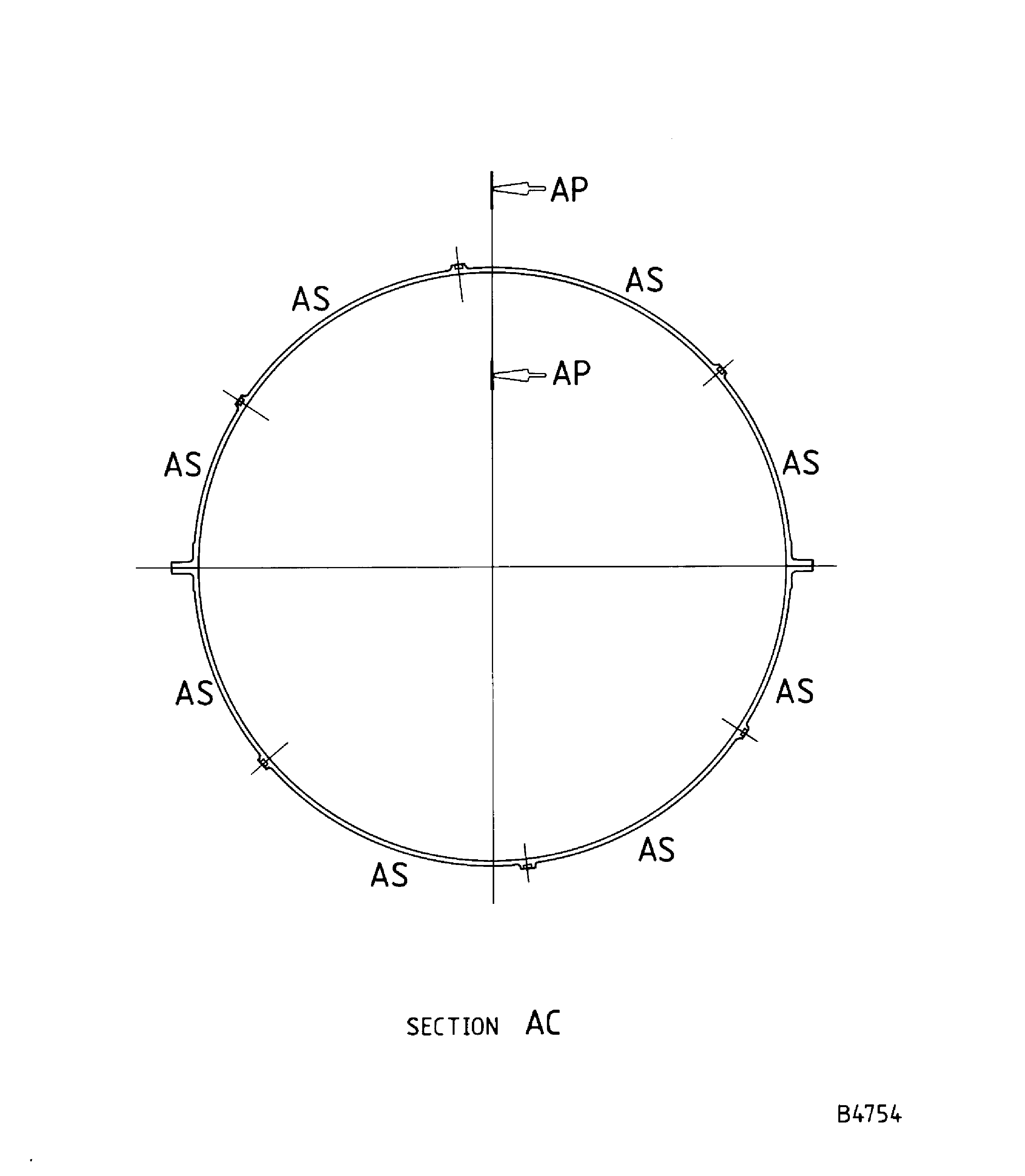

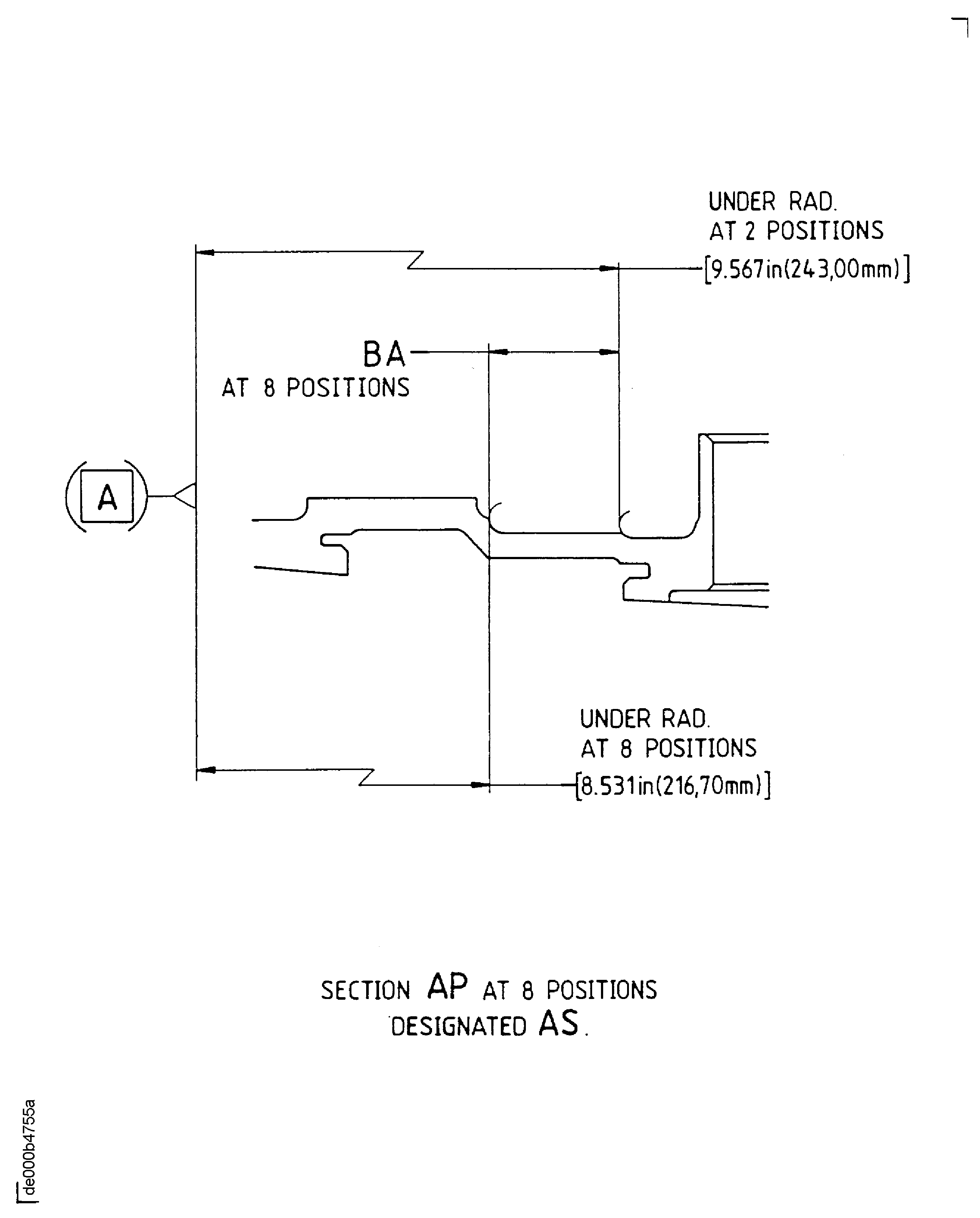

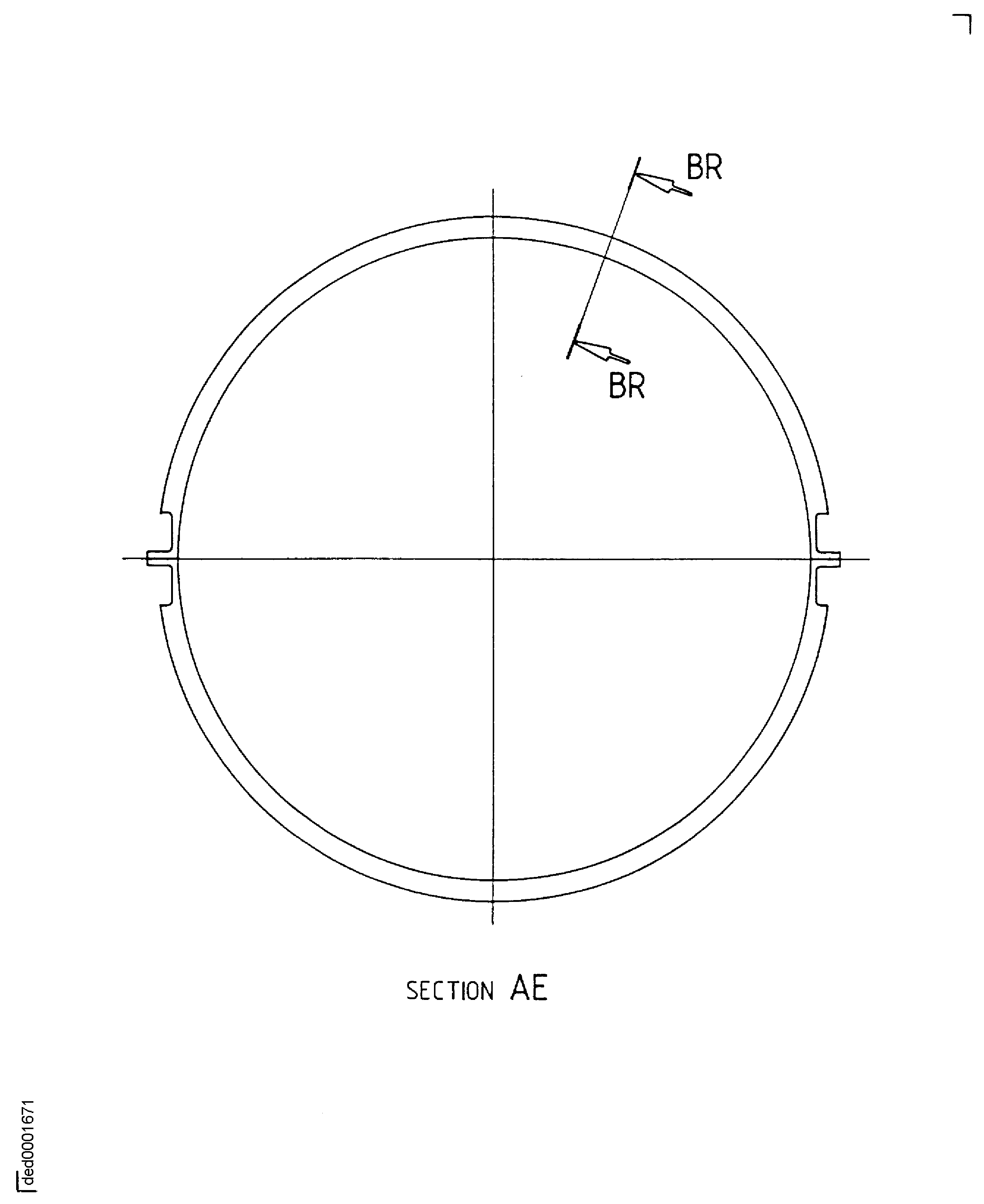

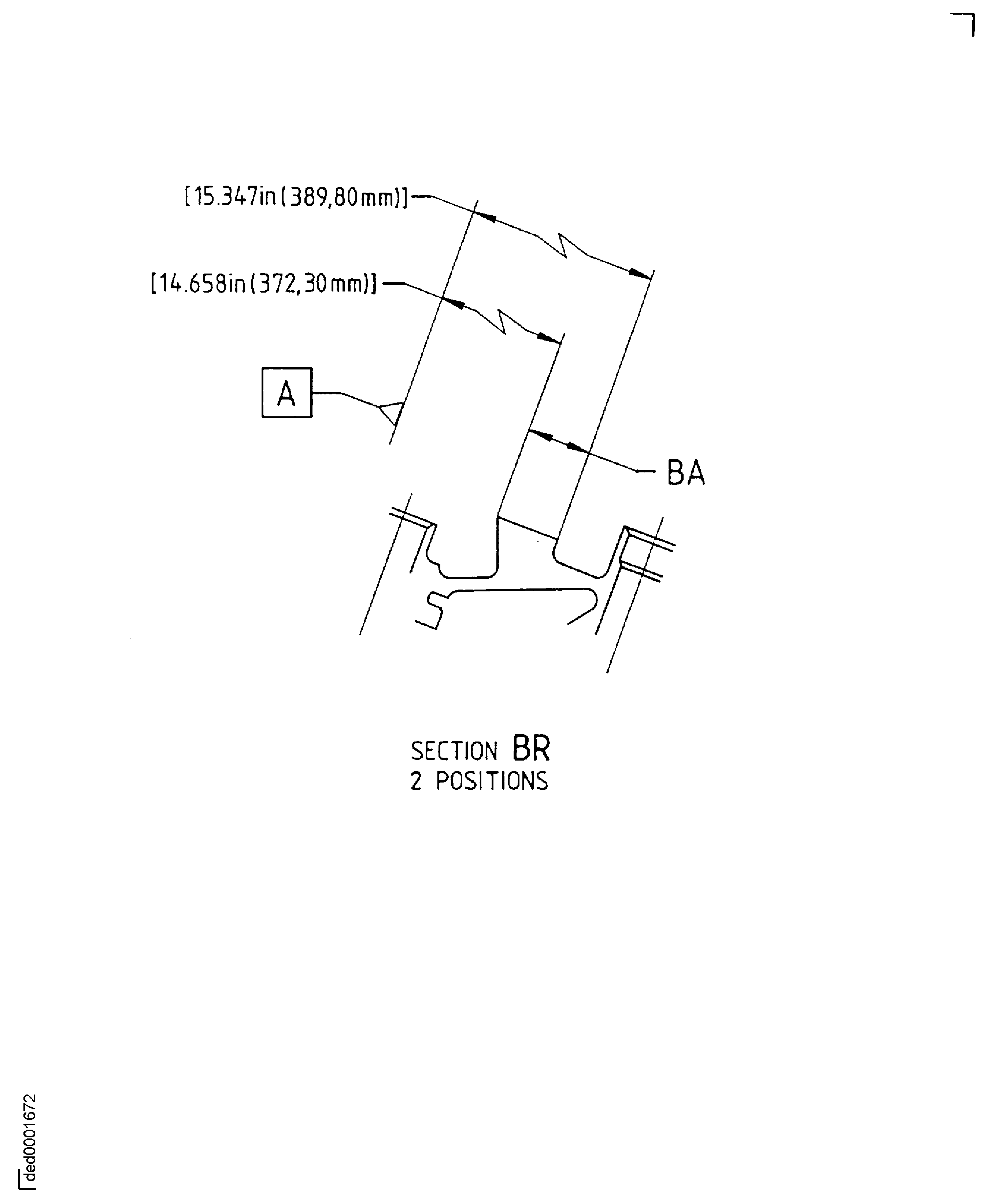

Figure: Repair details and dimensions - Assembly B

Repair details and dimensions - Assembly B

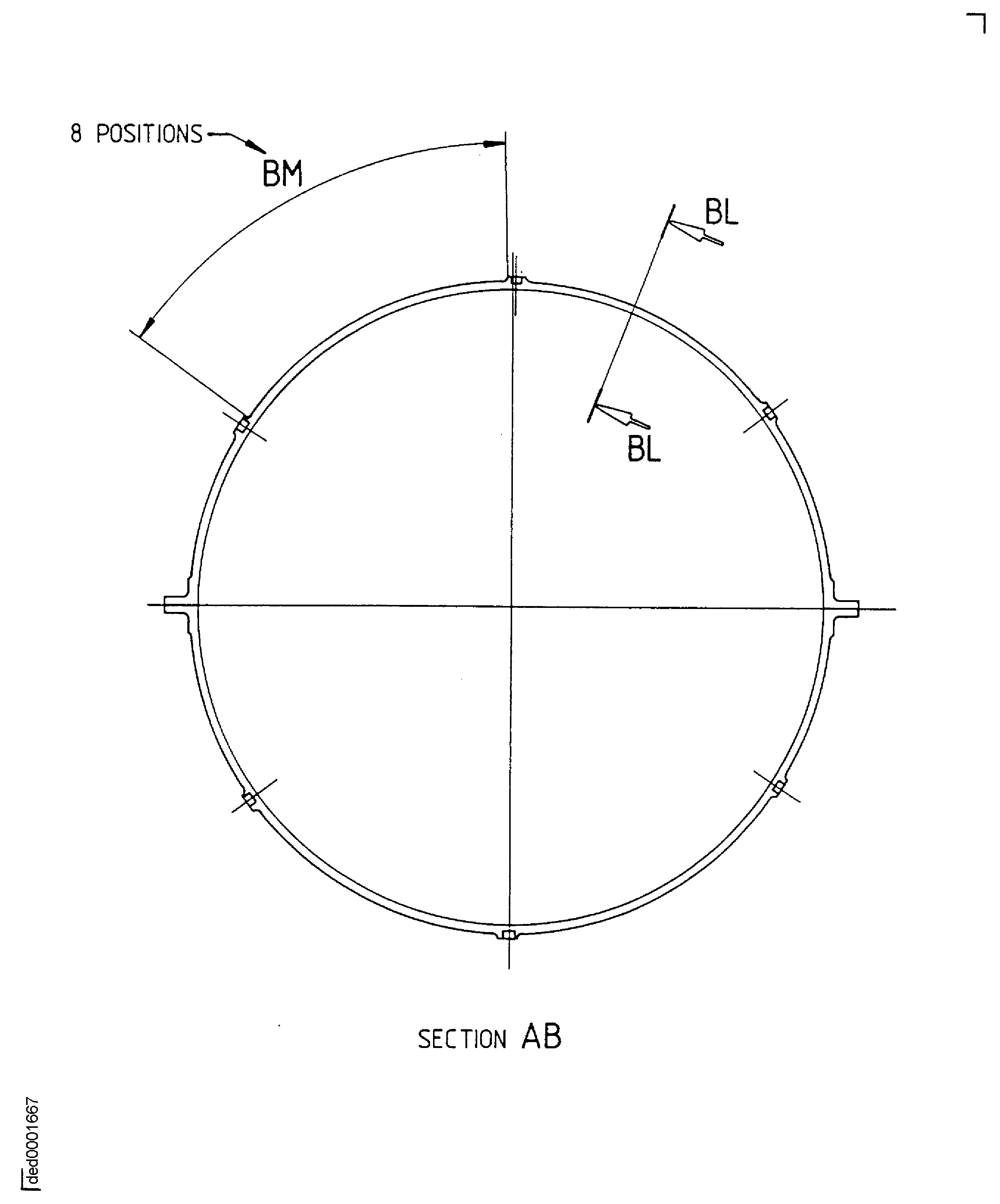

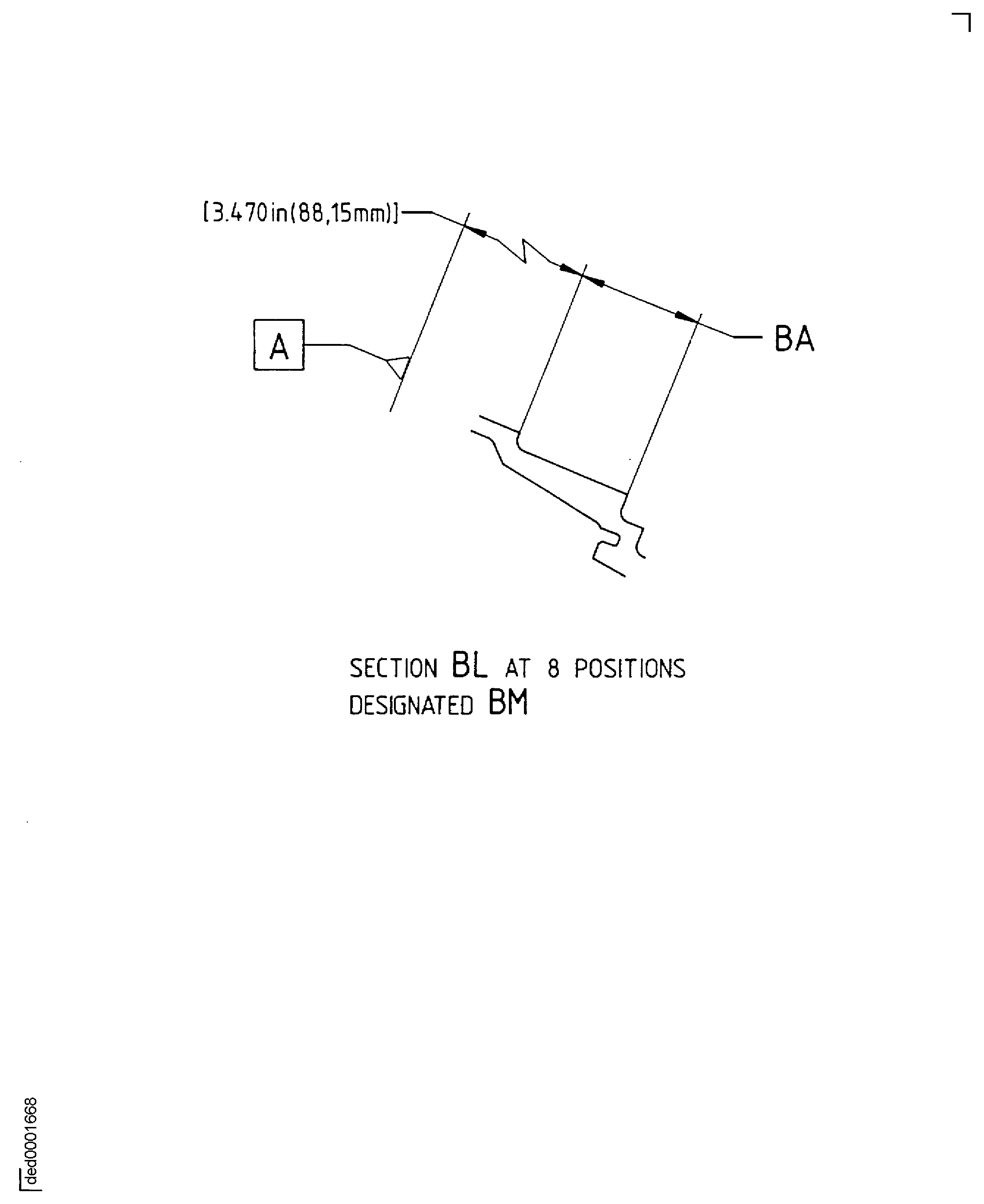

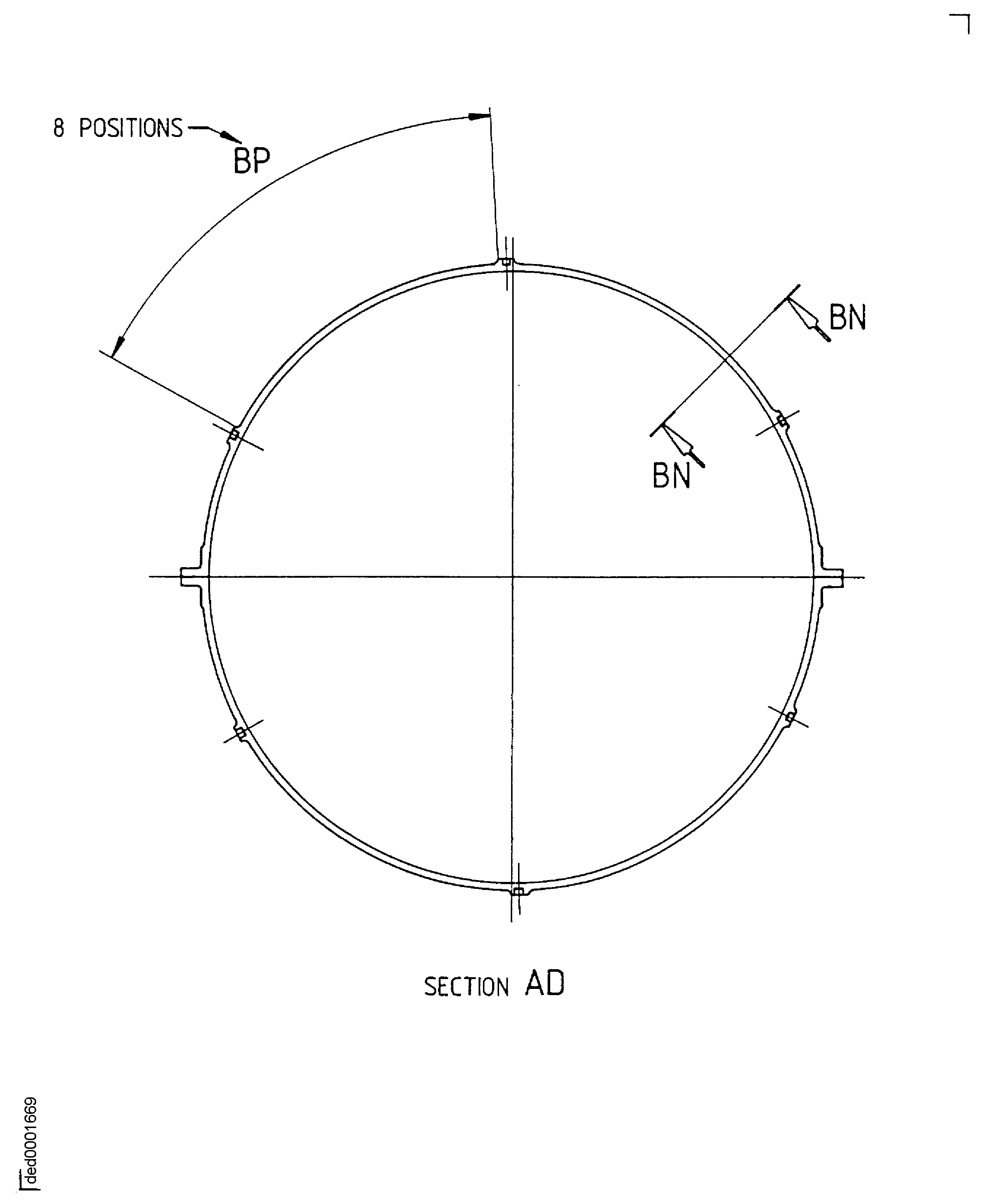

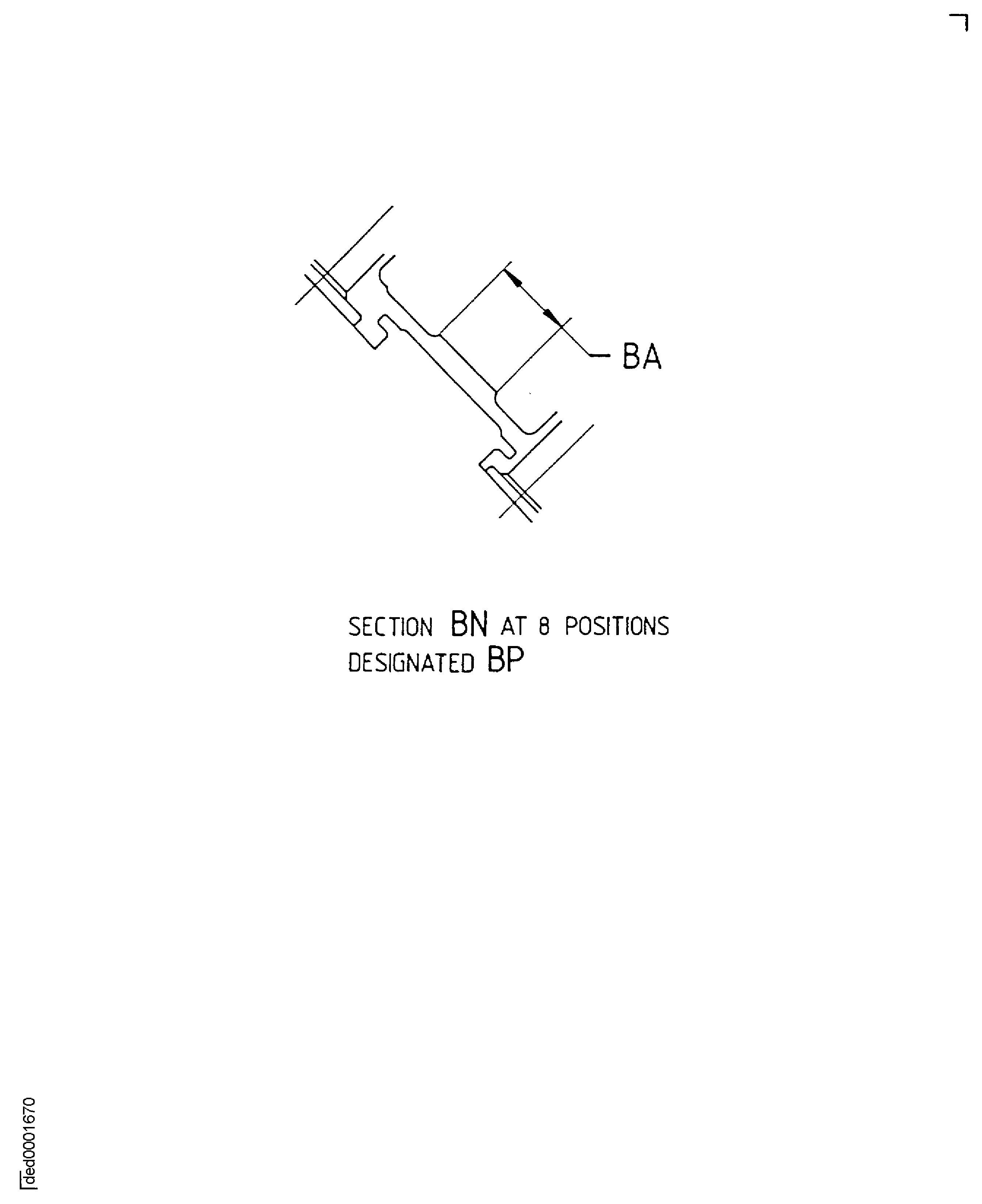

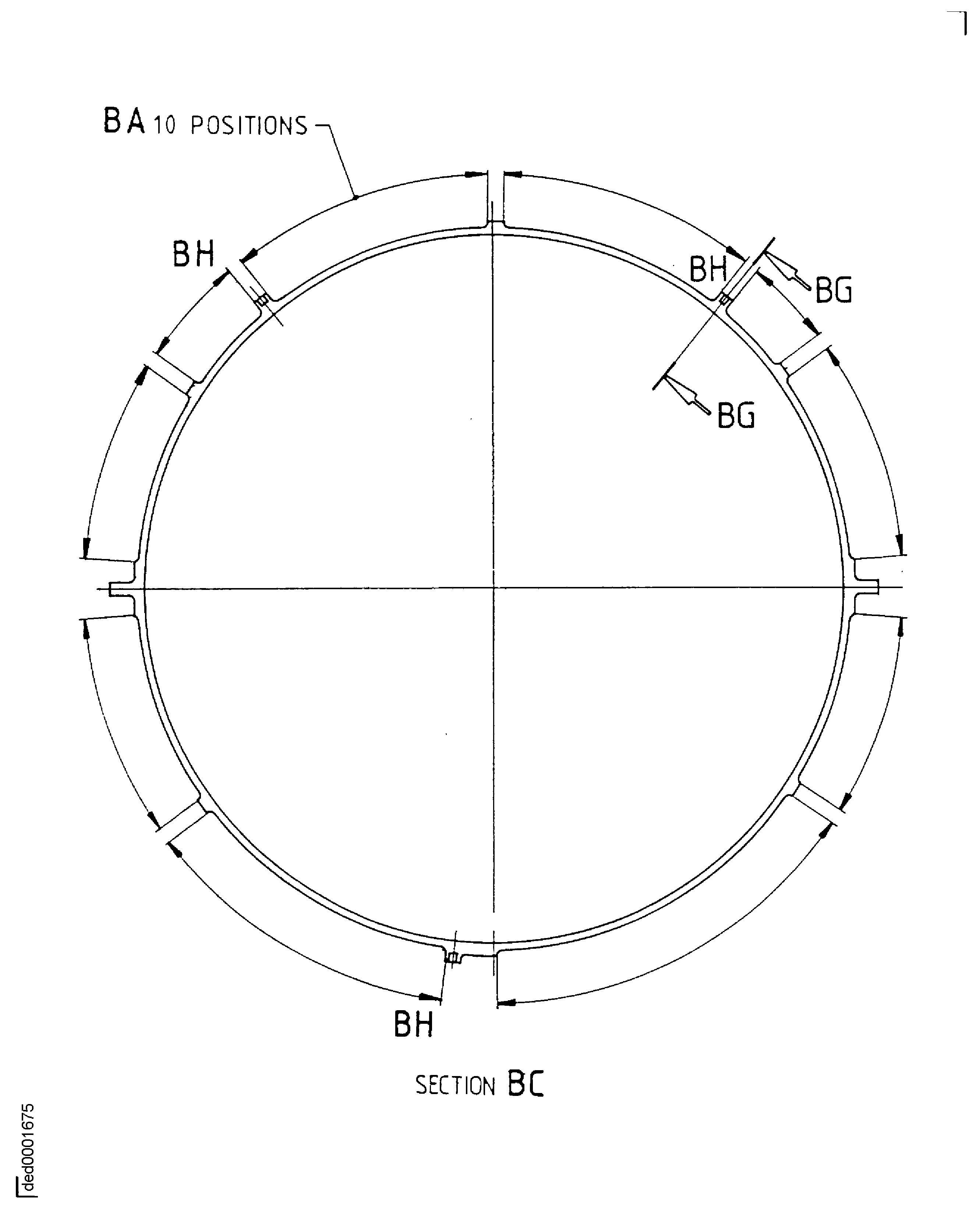

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

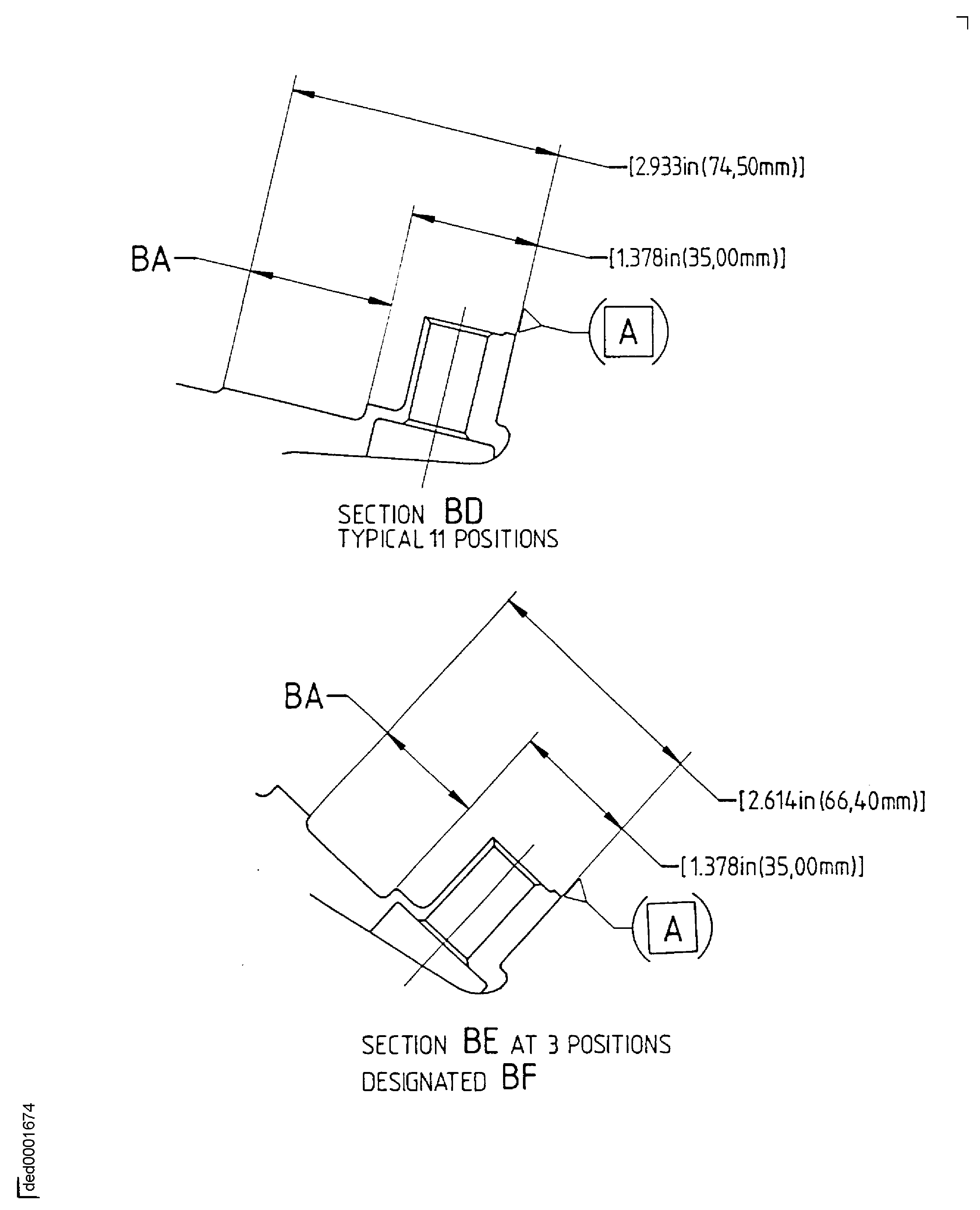

Figure: Repair details and dimensions - Assembly A and Assembly B

Repair details and dimensions - Assembly A and Assembly B

Figure: Repair details and dimensions - Assembly A and Assembly B

Repair details and dimensions - Assembly A and Assembly B

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

Figure: Repair details and dimensions - Assembly and Assembly B

Repair details and dimensions - Assembly and Assembly B

Figure: Repair details and dimensions - Assembly A and Assembly B

Repair details and dimensions - Assembly A and Assembly B

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

Figure: Repair details and dimensions - Assembly B and Assembly C

Repair details and dimensions - Assembly B and Assembly C

Figure: Repair details and dimensions - Assembly B and Assembly C

Repair details and dimensions - Assembly B and Assembly C

Figure: Repair details and dimensions - Assembly A and Assembly B

Repair details and dimensions - Assembly A and Assembly B

Figure: Repair details and dimensions - Assembly A and Assembly B

Repair details and dimensions - Assembly A and Assembly B

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C